In this post we learn through two examples how to build a simple110 V or 220 V AC light dimmer circuit for controlling light intensity with pot, using the principle of triac phase chopping.

A 220V dimmer switch circuit is basically a triac/diac based AC mains voltage regulator circuit which can be used for controlling the intensity of an incandescent bulb.

What are Triac Dimmers

We have already seen in many of my earlier articles how triacs are used in electronic circuits for switching AC loads.

Triacs are basically devices which are able to switch ON a particular connected load in response to an external DC trigger.

Though these may be incorporated for complete switch ON and complete switch OFF procedures of a load, the device is also popularly applied for regulating an AC, such that the output to the load may be reduced to any desired value.

For example triacs are very commonly used dimmer switch applications where the circuit is designed to make the device switch in such a manner that it conducts only for a particular section of the AC sine wave and remains cut OFF during the remaining parts of the sine wave.

This result is an corresponding output AC which has an average RMS value much lower than the actual input AC.

The connected load also responds to this lower value AC and is thus controlled to that particular consumption or resultant output.

This is what exactly happens inside electrical dimmer switches which are normally used for controlling

incandescent lights.

Warning: All the circuits explained below are connected directly with the mains AC, therefore is extremely dangerous to touch while powered ON and in uncovered condition.

Circuit Diagram of a Simple AC Light Dimmer

Working Video Clip:

Simple 220V, 120V AC Light Dimmer Switch Circuit

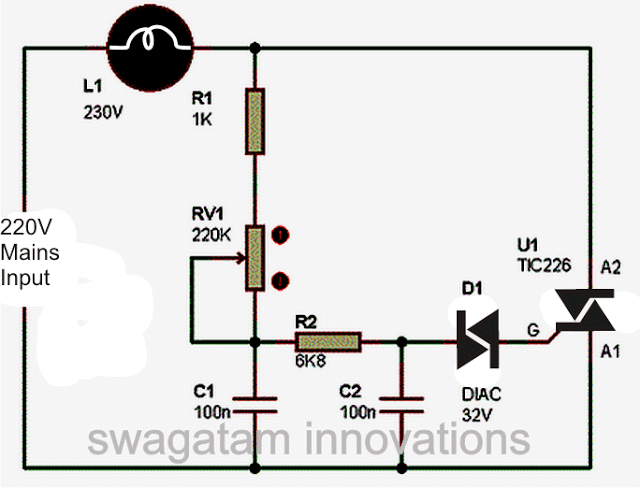

The circuit diagram shown above is an classic example of a AC light dimmer, where a triac has been utilized for controlling the intensity of light.

When AC mains is fed to the above circuit, as per the setting of the pot, C2 charges fully after a particular delay providing the necessary firing voltage to the diac.

The diac conducts and triggers the triac into conduction, however this also discharges the capacitor whose charge reduces below the diacs firing voltage.

Due to this the diac stops conducting and so does the triac.

This happens for each cycle of the mains AC sine wave signal, which cuts it into discrete sections, resulting in well tailored lower voltage output.

The setting of the pot sets the charge and the discharge timing of C2 which in turn decides for how long the triac remains in a conducting mode for the AC sine signals.

You might be interested to know why C1 is placed in the circuit, because the circuit would work even without it.

It's true, C1 is actually not required if the connected load is a resistive load like an incandescent lamp etc.

However if the load is an inductive type, the inclusion of C1 becomes very crucial.

Inductive loads have a bad habit of returning a part of the stored energy in the winding, back into the supply rails.

This situation can choke up C2 which then becomes unable to charge properly for initiating the next subsequent triggering.

C1 in this situation helps C2 to maintain is cycle by providing bursts of small voltages even after C2 has completely discharged, and thus maintains the correct switching rate of the triac.

Triac dimmer circuits have the property of generating a lot of RF disturbances in the air while operating and therefore an RC network becomes imperative with these dimmer switches for reducing the RF generations.

The above circuit is shown without the feature and therefore will generate a lot of RF which might disturb sophisticated electronic audio systems.

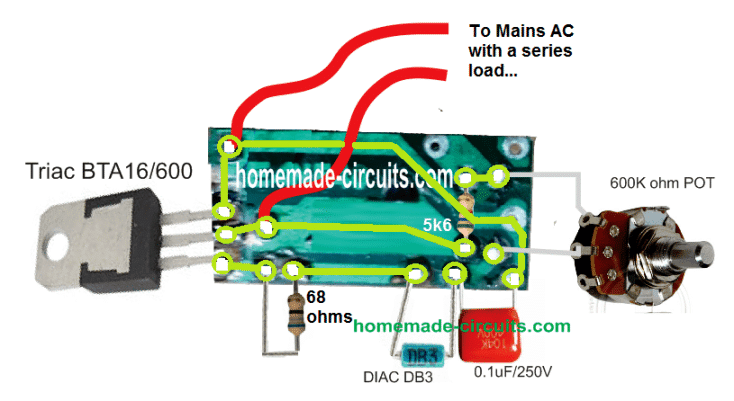

PCB Layout and Connection

Track Layout Details

Improved Design

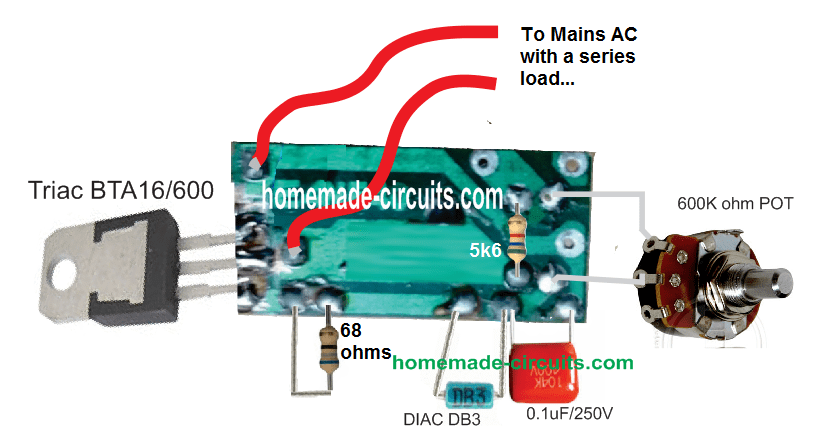

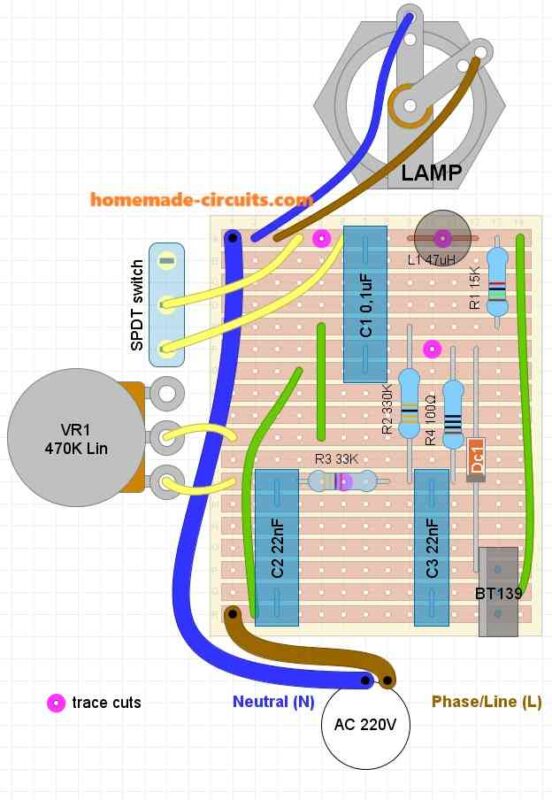

The AC light dimmer circuit illustrated below incorporate the necessary precautions for subsiding the above issue.

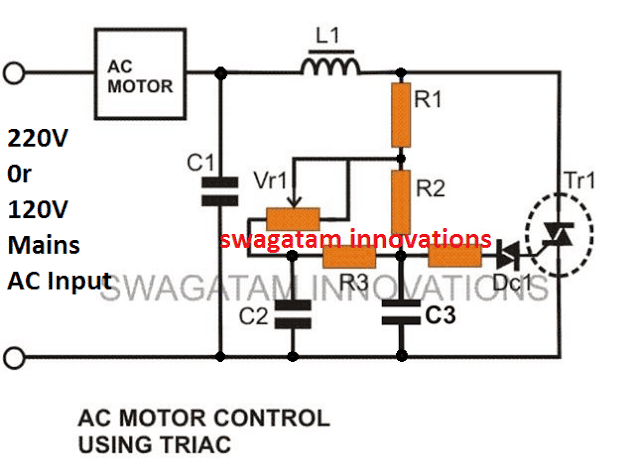

This enhanced design also makes it more favorable with high inductive loads such as motors, grinders etc.

This becomes possible due to the inclusion of C2, C3, R3 which allows the diac to be fired with consistent short burst of voltage instead of a abruptly switching pulses, which in turn allows the triac to be fired with smoother transitions, causing minimum transients and spikes.

Circuit Diagram of an Improved AC 220V Light Dimmer

Strip Board Connection Diagram

Parts List

- C1 = 0.1u/400V (optional)

- C2, C3 = 0.022/250V,

- R1 = 15K,

- R2 = 330K,

- R3 = 33K,

- R4 = 100 Ohms,

- VR1 = 220K, or 470K linear

- Diac = DB3,

- Triac = BT136

- L1 = 40uH (optional)

SCR AC Light Dimmer

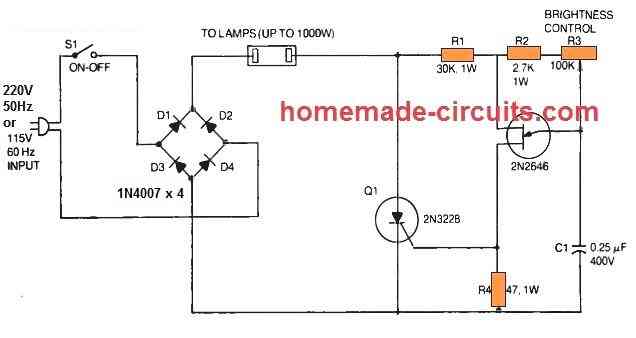

An adjustable RC-type phase-delay AC light dimmer circuit is shown below which consists of R2. R3, and C1.

The capacitor C1 fixes the time period where a 2N2646 unijunction transistor (Q2) produces a triggering gate trigger pulse to turn on the 2N3228 SCR (Q1).

By some manipulation of the light-duty control, R3 pot the user is able to change the SCR output across a large range.

In the phase-control circuit, resistor R2 works like a security unit that inhibits rheostat R1 from getting fixed at 100 % anode voltage of the UJT.

This specific rule is applied here to regulate the illumination level of the incandescent lamps, whether as a single lamp or many in parallel as high as to 1000 watts.

In this design, a full-wave bridge rectifier is built using 4nos of 1N4007 silicon power diodes (D1 to D4) that supply rectified power-line voltage for the SCR and the lamp.

Due to the full-wave output from the bridge, it becomes possible for the SCR to take care of both half-cycles of the AC line voltage.

The phase-shift system is sensitive to frequency and has been designed for 60 Hz mains input only.

Therefore the circuit is not going to work with fluorescent lamps and should not be plugged into these.

The 2N3228 SCR 5-amps. 200-volts. but higher-powered SCRs could be replaced for high current applications, and the UJT 2N2646 section of the schematic could be kept unchanged.

Besides SCR circuit is supposed to be used like an AC light dimmer, this circuit can be employed likewise as a heater or oven controller.

Have Questions? Please Comment below to Solve your Queries! Comments must be Related to the above Topic!!