This simple MOSFET controlled transformerless power supply circuit can be used for delivering a continuously variable 0 to 300V DC output and a current control from 100 mA to 1 Amp.

To protect against my high voltage research projects from going up in smoke permanently, I developed an easy circuit which is able to render a variable voltage supply of 0 to 330 Volt.

But please be cautioned, the circuit is not isolated from mains potential, and therefore can inflict a lethal shock.

The supply is short-circuit proof: the current is restricted to approximately 100mA.

WARNING: ALL THE ABOVE CIRCUITS CARRY LETHAL MAINS VOLTAGE AND THEREFORE ARE EXTREMELY DANGEROUS. IT CAN KILL ANYBODY, IF TOUCHED ANYWHERE ON THE CIRCUIT IN POWERED CONDITION. OBSERVE APPROPRIATE PRECAUTIONS TO AVOID ANY MISHAP.

Circuit Operation

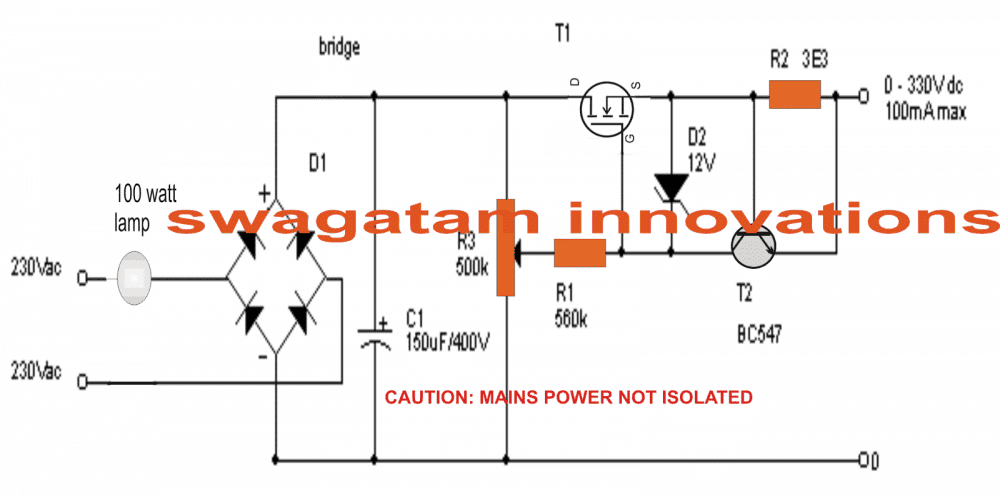

The design does not require a transformer, rather a 100 watt bulb is introduced at the input in order to provide ultimate safety in case of a short circuit or a component failure.

The mains voltage from after passing through the lamp is rectified with bridge D1 (1Amp / 500V) and C1.

T1 is configured as a source follower: the source of T1 complies with the voltage of the wiper of R3. D2 is insured to safeguard the gate of T1.

T2 and shunt resistor R2 establish the current limiter. Whenever the output current results in being excessive, T2 quickly discharges the gate of T1.

This stops the current from increasing any further. The value of R3 was basically identified experimentally; however it actually depends on the Hfe of T2 which means you may need to adjust the value of R2 appropriately.

Keep in mind T1 requires a large heatsink: in nastiest situation T1 would probably disperse 330V x 100mA = 33Watt!

You may try mosfets such as a BUZ 326 (400V/10.5Amp) or you may likewise use an IRF740 (400V/10Amp).

The output impedance of the power supply varies according to the beta of T1, therefore the bigger the MOSFET, the lesser the output impedance!

Circuit Diagram

UPDATE:

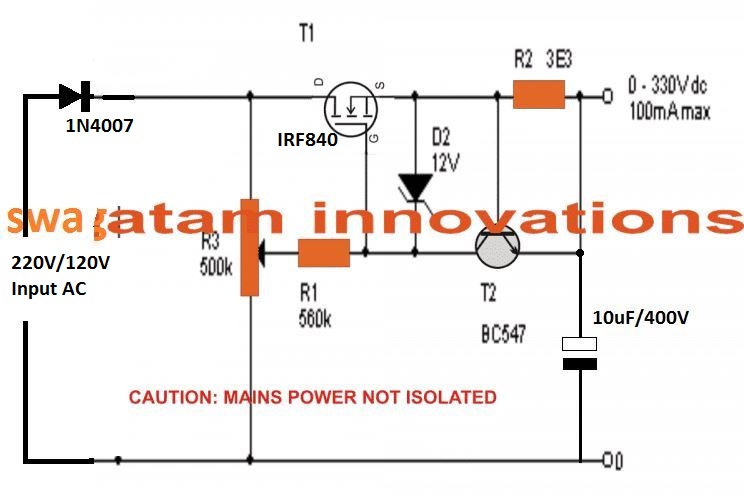

The above design could be much simplified as indicated in the following diagram. The bridge rectifier has been eliminated which drastically reduces the stress level on the MOSFET.

However, the ripple generated due to a half wave rectification may be significantly higher.

The output 10uF filter capacitor helps to reduce this to some extent. The value of this capacitor could be increased to higher levels for improving the DC quality.

The input series lamp can be added, although this may not be required due to the presence of the current control stage in the design. However, for better safety a fuse may be added in series with the input line.

The output load specification must not exceed 100 ma

Video Proof:

This power supply can be used to obtain a regulated power output, variable right from zero to 300 volts maximum. All the devices should be mounted on heatsinks.

Working Principle

The circuit regulates the output voltage using an IRF840 MOSFET (T1) as the main regulating element.

The 500k potentiometer (R3) controls the gate voltage of the IRF840 thus varying the output voltage.

The output current is controlled via the current-sensing resistor R2. When the voltage drop across R2 exceeds the base-emitter voltage of the BC547 transistor (T2 typically 0.6V to 0.7V) then T2 turns ON and reduces the gate voltage of T1 limiting the current.

D2 (12V Zener diode) ensures that the voltage of the IRF840 between its gate and source does not exceed 12V.

Key Parameters

- Vout: Adjustable output voltage (0–300V DC)

- Iout: Maximum output current (A)

- R2: Current sensing resistor (ohms)

- R3: Potentiometer for voltage control (ohms)

- Vin: Input voltage (rectified 220V AC ≈ 310V DC)

Formulas

- Output Voltage Control

The gate voltage of T1 is determined by the setting of the 500k potentiometer (R3). The output voltage is approximately proportional to the gate voltage of T1.

Vout ≈ Vgs(T1) - Vds(on)

- Where:

- Vgs(T1) = Gate-to-source voltage of T1

- Vds(on) = Drain-to-source voltage when T1 conducts (small value around few volts)

- Current Limiting (Iout)

The current limiting is handled by the sensing resistor R2. The voltage drop across R2 is compared with the base-emitter voltage of T2 (Vbe approximately 0.6V–0.7V). When the voltage drop across R2 exceeds Vbe, T2 turns ON and reduces the gate voltage of T1, thereby limiting the current.

Iout = Vbe / R2

- Where:

- Iout = Maximum output current (A)

- Vbe = Base-emitter voltage of T2 (typically 0.6V–0.7V)

- R2 = Current sensing resistor (ohms)

- Power Dissipation in R2

The sensing resistor R2 must dissipate power proportional to the output current:

P(R2) = Iout2 * R2

- Where:

- P(R2) = Power dissipated in R2 (W)

Choose a resistor with a power rating higher than P(R2) for safe operation.

- MOSFET Power Dissipation

The IRF840 MOSFET dissipates power due to the voltage drop across it and the output current:

P(T1) = (Vin - Vout) * Iout

- Where:

- P(T1) = Power dissipated in T1 (W)

- Vin = Input voltage (DC, ≈310V for rectified 220V AC)

- Vout = Output voltage (adjustable)

- Iout = Output current (A)

Ensure T1 has adequate heat sinking to handle the calculated power dissipation.

Example Calculations

Let us Assume:

Vin = 310V DC peak rectified from 220V AC.

Vout = 300V DC

Iout = 0.5A (desired maximum current)

Vbe = 0.6V

Step 1: Calculate R2 (Current Sensing Resistor)

R2 = Vbe / Iout = 0.6 / 0.5 = 1.2 ohms

Step 2: Power Dissipation in R2

P(R2) = Iout2 * R2 = 0.52 * 1.2 = 0.3W

Choose a resistor with at least a 0.5W rating for safety.

Step 3: Power Dissipation in T1 (IRF840)

At maximum output:

P(T1) = (Vin - Vout) * Iout

= (310 - 300) * 0.5

= 10 * 0.5 = 5W

At lower output voltages the power dissipation in T1 will increase so choose the heat sink to handle the worst-case scenario.

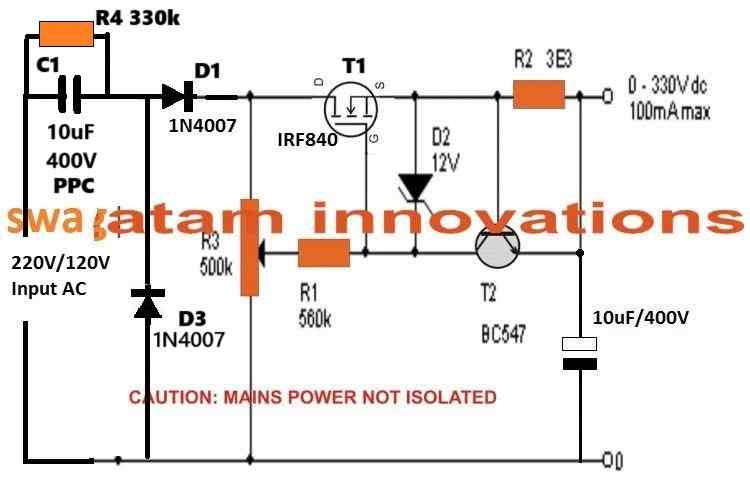

A Failproof 300V Variable Power Supply Design

To make the above 300V adjustable power supply completely safe and failproof, you can modify it by adding an input current limiting capacitor, as shown in the following diagram.

However, please remember that the circuit is safe and failproof only for the MOSFET, but it still carries a floating 300V AC, which can be lethal for any human if the circuit is touched in open and powered condition.

Using a Combination of BJT and Mosfets

Circuit Operation

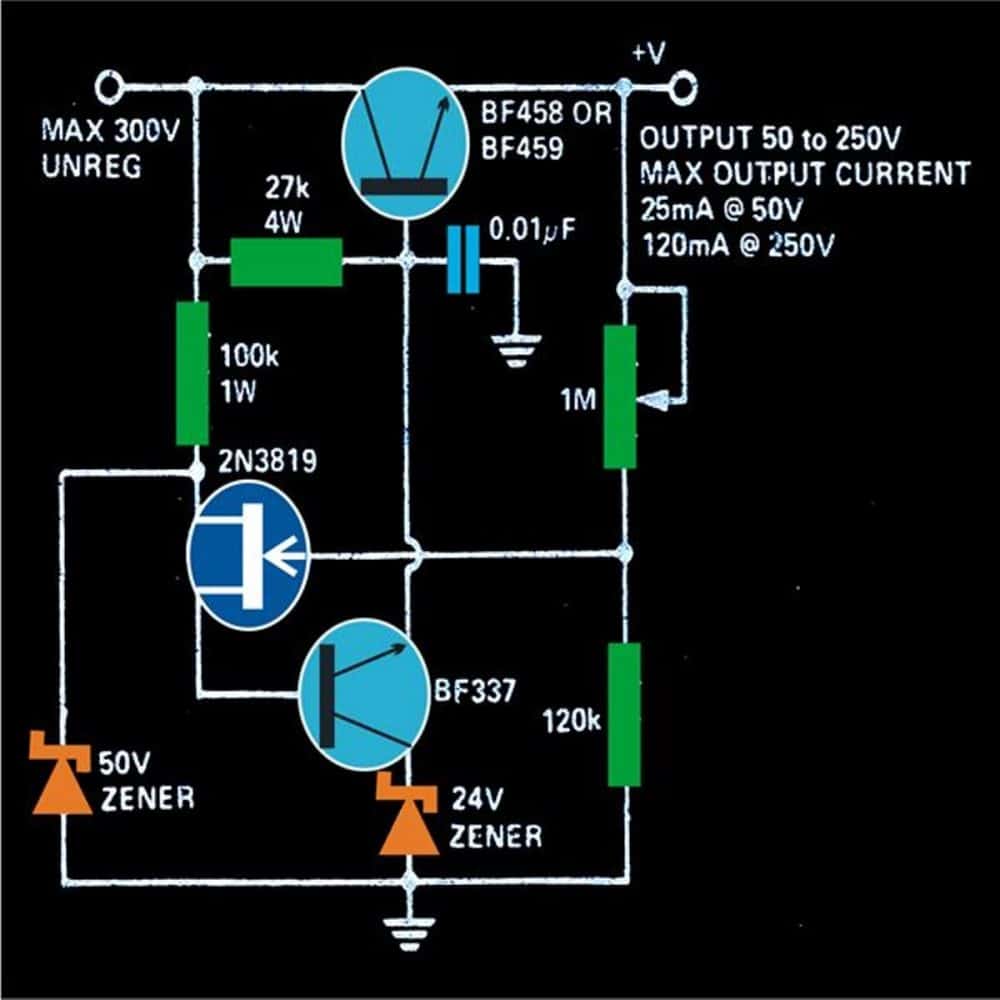

The next transformerless 0-300V variable power supply circuit diagram can be understood with the following points:

As can be seen in the figure, a high voltage transistor BF458 is used as the main load handling device.

Its base bias is controlled by another high voltage transistor BF337 whose emitter is clamped to a stable 24 volts.

An FET is used for selecting the base current of the transistor BF337 via a pot of 1M.

This setting adjusts the base current for the BF337 which in turn restricts the main transistor BF458s voltage and current flow to the output.

The input to the circuit may be derived directly from the mains AC after proper rectification and filtration using a bridge network and a 10u/400V capacitor.

The entire circuit is extremely dangerous to touch, due care should be maintained while making and testing this circuit.

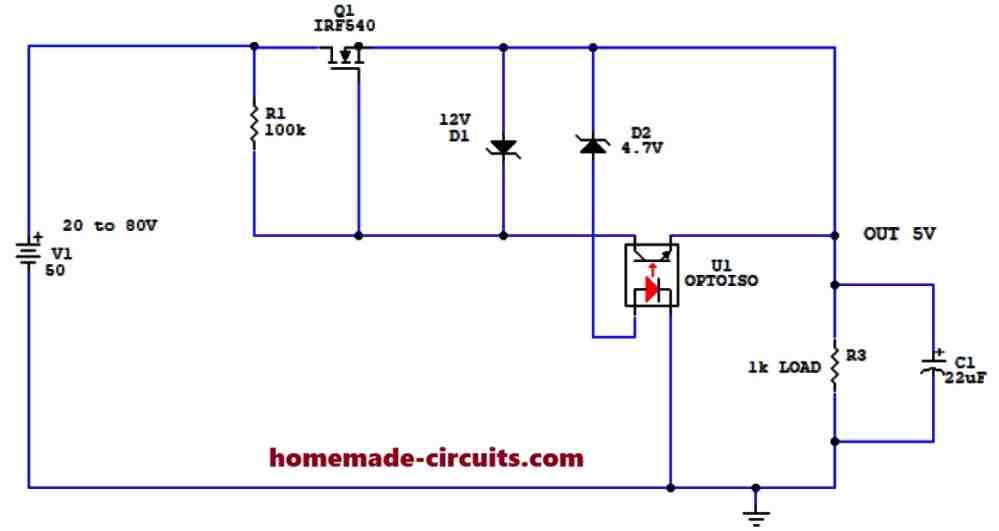

Converting 80V DC to 5V DC Stabilized Output

The above explained 300V MOSFET regulator circuit was successfully modified by Mr. Luigi to convert a varying input between 20V and 80V DC into a stabilized 5V DC output, using an opto-coupler feedback, as shown in the following figure. I am grateful to Mr. Luigi for contributing this design to this website.

Hi dear Swagatam;dizx))

I had sent my queston under the following article

https://www.homemade-circuits.com/prevent-amplifier-fuse-from-blowing-during-power-switch-on/#comments

and you have avised this page to share it.

As a result; I test my TV 220AC 160W with the 100W serial bulb and the bulb blinks but not regular for instant it blinks 5 times long period then 3 times short period however if change the bulb with a 15W then this time I see the regular blinks it blinks constantly in every second. And finally I use 14 uF capacitor as the serial then I see about 20 V in the serial capacitor but power card main capacitor has the initial voltage about 400V. So I need your comment for the situation

Thank you Suat,

You must check the voltage across the load, so if the main capacitor is the load and is showing 400V, then it is fine, but how is the TV behaving? Is it working?

GLAD TO ANNOUNCE THAT I HAVE BUILT THE CIRCUIT AND IT WORKED OUT VERY WELL. AT FIRST I WAS THINKING THE BC547 WILL FLASH BECAUSE I LOOKED AND DID NOT SEE ANY BIASING RESISTOR ATTACHED TO ITS BASE AND THE EMITTER IS NOT CONNECTED TO THE GROUND. I TESTED IT WITH 1OK, 1/2W AS LOAD AND WAS ABLE TO GET UP TO GET UP TO 20mA AT ABOUT 160V BEFORE IT STARTED SMOKING. I ALSO TESTED WITH 10 OHM, 5W RESISTOR AND WAS ABLE TO GET UP TO 160mA. ALTHOUGH THE OUPUT VOLTAGE WAS NEGLIGIBLE DUE TO THE FACT THAT 10 OHM RESISTOR WAS TO SMALL A VALUE AND THUS PREVENTING THE FILTERING CAPACITOR FROM BEING CHARGED. I LATER DID THE TRANSFORMER BASED FASHION AND IT ALSO WORKED FINE. ENGR. SWAGATAM, I AM VERY GRATEFUL FOR THIS YOUR AMAZING PLATFORM.

Thank you Mosses, I am glad it worked successfully for you…

Thanks for the nice work. Sir have you tested the circuit on full load or anything close to 90mA. I fear that bc547 might get too hot. I intend to make make this circuit to handle 200mA but I plan to use bc337. Is that ok or should I use 2n2222a instead.

Hello Moses, The load current is handled by the MOSFET, not by the BC547 transistor, so the BC547 is safe, and will not burn at any given output current. You can use any 50V 100mA NPN BJT in place of the BC547.

Ok thank you very much

You are welcome Moses.

Hi Swagatam,thank you for this circuit. Please, is it possible to use variable transformer (input 220VAC, output 0-300VAC) to control output DC voltage by controling AC output using this circuit? I need a variable power supply 0-350VDC also variable current supply 0-5A DC. This circuit is only for voltage DC output I understand but I need also a current regulated if there is any idea. Thank you!

Hi Bursach,

Yes, you can use the above circuit in conjunction with a variable AC output from the transformer. You can adjust the current by changing the values of R2 resistor…

Thank you!

I have one query on transformer less power supply.

Actually I’m going to design one power supply which will be transformer less.

I tried for many topologies. That was not sufficient to provide me 5V, 500mA from bridge rectifier output 330V. Capacitor and Resistor dropper having issue with current it can deliver max. 120mA.

If anyone have suggestion on any particular circuit, please suggest me. with schematic also mentioned output current.

You can try the last circuit with an opto coupler.

Make sure to replace the MOSFET with IRF840, and feed the 220V input AC through a 10uF/400V capacitor and a bridge rectifier (using 1N5408 diodes)

me again! Mr Swagatham! can you give me a formula to rotate the coil to have an output 220 V AC 110 V AC with step-down transformer

Fastra, you do not any formula or circuit if you are using a step-down transformer, you just need to connect the 220V side of the transformer to the 220V AC input and then get 110V AC from the other side of the transformer.

bonjour swagatam ! J’ai une imprimante laser jet 110v AC mais dans mon pays nous utilisons du 220v ac, pouvez-vous m’aider avec un schéma 220v ac convertir 110v ac, car le prix du transformateur abaisseur est très cher dans notre pays ! Merci pour votre aide, que Dieu vous bénisse, votre travail et votre famille !

Thank you Fastra, i can understand your problem, however there’s no easy circuit to convert a 220V AC to 110V AC, unless a transformer is involved.

An SMPS can be used, but that will be far more expensive than an ordinary iron core transformer version….and an SMPS will also require a huge lot of calculations.

merci beaucoup pour votre aide et information

Hello Swagatam! Is this schematic 0 to 300v adjustable suitable for me, for the printer 110v AC 300w hp lasert jet

Hello Fastra,

Sorry, no, the above design is not suitable for your application, because the above power supply is suitable only for DC loads.

I tried this circuit to reduce the voltage of a 48V photovoltaic system, max input voltage 75V. I needed a stable 5V voltage to power a pic MCU which reads the panel voltage and sends via isolated serial.

It works well, I used an optocoupler to stabilize the voltage. If you are interested, I can send you the diagram which is very simple.

Thank you Luigi, for trying this circuit for your specific application, yes I would be certainly interested to see the schematic.

Please send it to my following email ID:

homemadecircuits

@ gmail.com

I have had to put two of these in series. There is a parallel resistor load a voltage divider and circuitry at the first -150 VDC node then another 0D3 and more circuitry to feed at -300 VDC. The 0D3 can NOT handle more than 40mA continuous load after it starts. It’s not supposed to anyway, but a lot cheating went on. With voltage divider off -645 VDC they run at 323 VDC +/- 6%. I also tied in the other -323 into the second regulator. I tossed in some 1N4007s too just to keep them to themselves. And yes those too look like they are in backwards because of the positive ground and the negative voltage supply. Hopefully those two -150 volt outputs will equal a stable -300. I also put the Zener diodes up close to the MOSFETs to keep them at more constant temperature. The Zeners were drifting with temperature changes.

That sounds good! I hope you have used separate bridge rectifiers at the input sides, for the two -150V modules. This is important to ensure both the modules are completely isolated from one another.

I found out I actually need to run two of these in series from a voltage divider upstream that outputs 2 x -323 VDC but it can vary from between -303 and -343 VDC with the mains voltage. Will the two -150 VDC outputs sum to make a -300 VDC output in the second regulator or do I set the first one for -150 and the second one for -300 VDC out? I also want to put some diodes in between the two units to keep everything separate with no DC feeding back from the second regulator to the first or is that a waste of parts? I tried some DIY SMPS regulators. WAY TOO NOISY! I had pretty clean DC coming into the SMPS regulators but with the SMPS regulators switching it put lots of high frequency noise into everything, especially with the two of them! They sync’ed up together and it was awful.

I think it’s better to set the first one for -150 VDC and the second one for -300 VDC out. You can put diodes across the outputs of the two units to keep everything separate and avoid DC feedbacks.

There’s zener diode in the above circuit which can become a source of noise, so i think a 100uF/25V capacitor could be connected parallel to this zener diode to filter out the noise.

Additionally you can also put a high value capacitor across the outputs of each regulator circuit for further noise suppression.

On further inspection I need two of these set for -150 VDC, and the negative voltage IN comes off a 25K/25K voltage divider from a filtered -645 volt supply node so that gives me -323 volts that could vary between -302 and -343 volts, as per the unit’s specs and the mains voltage. If I tie across ONE -150 VDC output I should get -150 volts regulated and if I tie in across BOTH (two) -150 VDC outputs I should get -300 volts regulated, correct? I need regulated -150 and regulated -300 regulated voltages. I have some other PSUs & some bread boards. If I strap the Lambda and the Japanese PSU together with diodes for safety that should give me a good -350 VDC @ 300 or so mA. I have tube power transformers around too! One would ALMOST work for the damaged transformer in my Nobatron 600B, but it’s 16 mm too tall to fit. : -(

Yes, that’s correct, you can connect the outputs of the two -150V supplies in series to get two -150V individually, and also one -300V DC output.

If I wanted to make this into a NEGATIVE 300 volt regulator would using a P channel MOSFET and a PNP BJT work? It’s just a pass tube bias supply, with reference sense & send regulation circuitry and it SHOULD only draw 40mA-60 mA. I’d think the Zener diode may have to be reversed too. I’d like those 0D3 tubes to go away.

Yes, you can convert the above shown design into a -300V regulated DC supply generator by using P-channel MOSFET and PNP BJT.

The P-channel mosfet can be also replaced with an equivalent PNP BJT.

The bridge rectifier polarity will also need to be changed for this application.

Yes, the zener orientation will also need to be reversed.

I started looking for P channel MOSFETS and PNP BJTs and THANK YOU THANK YOU so very much for confirming that theory! I shall have to make TWO that run at 150 volts each! I am coming off of a wacky isolated center tapped winding on a “main transformer” that is more or less wired up backwards with a 5R4 rectifier tube with the center tap being positive, relative with all of the filter caps being wired in reverse polarity. The two 0D3 tubes draw 100 mA EACH to start and these stupid designers HOPED they would start before they overheated an undersized $400+ 1170 VCT transformer. It’s just for voltage regulation (6BQ6 sweep tube pentode), reference/regulation voltage for the pass tube bias (5651 & a 6SL7), the feedback, and two regulated bias 0- -150 VDC voltage bias supply. There are two other windings in the transformer: A 240 VAC with no center tap @ ~ 75 mA for the 7 pass tube screen grids, and the 5R4 rectifier’s 5 volt 2 amp filament supply. Switching the unit off and on quickly would have all 7 5881 pass tubes running preheated with NO bias until the 0D3s restart. That jumps the screen current way up and that often fries that 240 VAC transformer winding and often cooks a selenium rectifier too. I already have -725 that is stepped down to -475 VDC post filter caps & some dropping resistors. There is my negative DC voltage supply for this regulator. Eliminating those two 0D3 VR tubes eliminates that 200mA starting current surge load. I may even replace the 5R4 with some 1N5408 diodes & shunt caps in a tube socket. The pass tube plates run off of a 970-0-970 or 1940 VCT transformer, and that filters through a gigantic choke & 3 450 VDC 82uF caps run in series with an old 50 watt 5K x 3 ohm Ward Leonard “voltage divider”. Reading about Ward Leonard (the man and the company) was very educational. I am adding an ON DELAY that activates and keeps the pass tubes OFF for 10 minutes if there is a short duration power outage or if some idiot toggles the unit off and on in quick succession. I can fit these regulator in tube sockets and just plug them into the 0D3 sockets and not worry about those 0D3s not lighting up in time. THANKS AGAIN! I am just an old stupid disabled electrician! I did PLC, relay logic, motor controls, instrumentation,4-20 mA, fire alarm, smart buildings, POI, etc. THANKS AGAIN! I loved working with the Indian electrical engineers. The white American engineers tended to be really lazy and very sloppy. I worked with some very good Pakistanis & an exceptional Englishman too, that were excellent engineers. The American EEs would keep adding stuff and forget to increase the load calculations. That’s just lazy and sloppy, and I have to do all of the calculations out in the field and send the plans back in. .

Thank you so much for the detailed explanation, it is indeed great to hear about tubes in this era of microchips.

Do let us know how the 300V controller circuit using transistors works for your application.

And feel free to ask or share any further questions or doubts you may have.

I have an old tube regulated PSU that uses two 0D3 VR tubes, which will regulate around 475 volts DC to 300 VDC with a constant load of around 35mA. Will this be stable @ 300 volts? Worst case it can surge to 60 mA or so.

The above circuit is extremely stable with its set output voltage.

Dear Swagatham, This is something that I been working on for a couple of days blowing a hell lot of Mosfets and Pots.

I have a couple of issues , that I hope you can help with.

1) Can I use the first circuit without the last current limitting section after the zenner diode with a 90 v dc input to get full current from the transformer ? (5 Amps) ( I can use really heavy heatsink for the mosfet).

1) When I connect only source to the positive of the 90 volt supply. I get voltage at the drain and gate too. Is that normal ? (Drain and gate not connected at all to anything). Since full 90 v is seen at the gate ,it develops a 10 to 80 ohm resistance between source and gate almost like a permanent short. it won’t work later.

2) A s source follower, can we get 0-90 v control since the gate voltage is clipped at the zenner diode voltage (12v or below the 20 v Vgs).

3) is the output current limited by the wattage of zenner diode ?

pls comment when you get time. thanks in advance.

Dear Suresh,

Here are the answers to your questions:

1) Yes you can use the first without current limit, however the second diagram is more efficient so i would suggest you the second diagram. Please check the modified version of the second diagram in the following figure:

https://www.homemade-circuits.com/wp-content/uploads/2023/12/300V-MOSFET-power-supply.jpg

The source is not supposed to be connected to a supply because the source is the output not the input. The supply input must be connected to the drain.

2) From a MOSFET source follower you wwill get from 0 to 85V, since 5V might get dropped by the MOSFET. 12V zener diode between gate and source will not impact the source voltage, it will impact if the zener diode is connected across the gate and the ground line.

3) The output is limited to the MOSFET current handling capacity, not the zener wattage.

Hallo!

Thanks for information about transformerless power supplies!

Is it reasonable to use your “0-300V Adjustable MOSFET Transformerless Power Supply Circuit” for high power applications?

For example I am interested in using this kind of power supply with up to 5KW regulated load with current of 13A and more.

So, is your power supply a good idea for abovementioned example?

I think that there will be a lot of power needed to be dissipated with super-extra large heat-sinks which could be as big or bigger than a transformer.

Am I right?

Sorry I am just a beginner in this field

Best wishes from Latvia

Rahims.

Hello,

You are right, this MOSFET power supply is not suitable for high power applications, since it will dissipate huge amounts of power and will require enormously big heatsink.

Thank you very much!!

Hello Swagatam, I have been building the first circuit, but I am in a dilemma. I can’t get a 12v zener, or any zener. But I have a TL431A. How can I wire it so as to get 12v at the MOSFET’s gate? Also, I want to use an IRF510 transistor, later to use an IRF540. How do I include current control to vary the current as well? Thanks in advance

Hello Ikechukwu,

You will need a zener diode here, a TL431 cannot be used. You can use use zener diode between 9V and 15V. For a 220V AC input the MOSFET drain/source voltage must be rated at 400V, therefore IRF510 or IRF540 cannot be used here.

Hello again swagatam. I finally have a working circuit using a 6r125p mosfet, 500k potentiometer and sa5.0a unidirectional tvs diode across gate/source. I figured out I was mistaking fast switching diodes with zener diodes leading to most of my issues.

In a source follower configuration and using a potentiometer to control the gate. It only gets around 3-4v. Which doesn’t fully open the fet. Is there a way to increase the gate to source voltage? Or would it be better to switch to a logic level mosfet? With the sa5.0a I was expecting 9.2v since that’s the clamping voltage of the tvs diode.

Hello Alastair,

Sorry, I can’t figure out the issue you are facing with your circuit. In the video you can see that I have already tested the circuit and it worked fine for me.

I am not sure why a TVS diode would be required across the gate/source of the mosfet. According to me it should be a 12V or a 15V zener diode. The job of the zener diode is to make sure the gate source voltage does not exceed the zener value.

Okay well that makes much more sense why the failures seemed so random. I knew there was a maximum gate voltage but I just figured the response was quick enough to not have to worry about it.

So basically the gate resistor is to save the potentiometer from overpowering itself in this case? And I could base the size of my gate resistor on the size of my potentiometer? Is there any benefit to decreasing the size of the gate resistor?

Also when changing the configuration to parallel do I need multiple Zener diodes?

And are there any other things I could do to safeguard the mosfets while running them in a parallel configuration?

The gate resistor is for protecting the zener diode.

The potentiometer value is for protecting the potentiometer itself from high voltage and for preventing unnecessary heat dissipation.

These resistors are irrelevant to the mosfet if the supply is a constant DC.

If the gate signal is in the form of frequency then gate resistor required to be as small as possible.

In parallel mode the whole setup works like a single large mosfet, so a single common resistor and a single zener diode should work OK.

No other precautions are required for the mosfet except that its specifications which must higher than the input supply voltage and the load current.

Hello again and thank you for all of your help. I have a couple Toshiba 2sc5200 transistors available. Would this work as a replacement for bc547?

If so will the current limiting resistor still be calculated the same way?

If you were to add multiple transistors in parallel would this increase the power handling capability of the circuit even further? While still allowing you to control the available amperage?

And if you changed/added a pot to the base of the transistor, would this allow for an adjustable current as well?

I just realized the transistor only discharges the gate and doesn’t actually provide any power. Would a 2n222 be a sufficient replacement?

Would the current limiting resistor still be calculated the same way?

And would adding a pot after R2 or replacing R2 with a big enough pot allow for an adjustable current regulation?

The mentioned transistor will not work in place of BC547, since their specifications is completely different.

You can try 2N2222 instead.

Current limiting will still work even if the BC547 is replaced with an equivalent.

Increasing the number of mosfets will increase the current handling capacity of the circuit proportionately. The BC547 would still control the current normally.

Adding a pot at the base of the BC547 may be possible, but the control will not be accurate. It can done as explained in the following post:

https://www.homemade-circuits.com/simple-current-sensor-circuit-modules/

Thanks again for all of your help.

I’m still having issues getting my head wrapped around the use of mosfets. Specifically the source follower diagram is using an npn in a high side configuration vs the suggested npn configuration using low side.

Everything I’ve read said that an npn should be used in a low side configuration connecting the ground to the load. Because you need a higher voltage at the gate than your supply. And in a low side configuration you don’t.

Another question regarding the zener diode. And the configuration of the mosfet. The transformer im using also has a 0-10v supply. Could I use a common ground and supply the mosfet with 0-10v at the gate with a pull down resistor on the source to switch a 0-100v load?

And as I was writing my last question I realized… does a load needs to be connected for any of this to work correctly? ????????♂️

Since the reference voltage is from gate to source, and the source is unloaded with no reference to ground… Pretty sure I just had an epiphany while talking to myself.

The only thing I don’t understand is the placement of the mosfet in relation to the load. Since you could just place the load before the mosfet in the circuit.(drain) And use the mosfet to connect it to ground (source)

Am I starting to get it yet? ????

The high side, low side and bootstrapping issue arises when the drain/source of two mosfets are connected in series.

But in our example there is only one mosfet, which is configured as a source follower.

Source follower configuration makes sure that the source voltage follows the gate voltage, so the gate voltage can be varied effectively to vary the source voltage (load). That is the main benefit of using a source follower in a variable power supply like the above.

You can use a 10V at gate and 100V at drain with common ground but then how will vary the voltage to the load with this configuration?

In a source follower a small load is required to enable the circuit to work correctly. This load can be in the form of a 1 K 5 watt resistor.

A load at the drain will not allow it to be adjustable. The load can be adjustable only when it is connected to the source of the device.

Okay starting to make sense of things now. So thats why pnp transistors have their source in different position. That definitely helped solve quite a bit of my confusion.

I asked about the separate voltage because I remember seeing others use this method with an arduino or a separate power supply for high voltage applications. I’ve also seen extremely basic examples using an irf540, 100k pot, and 10k gate resistor. And that’s it. This was also for a 0-100v regulator.

Ideally I’d like the simplify the circuit until I get a better understanding of it. I’m slowly getting there…

Is it possible to replace the Zener diode with a resistor from source to ground? Or add a 1uf ceramic capacitor after the gate resistor as a buffer? Then calculate for RC network? It’s not perfect and definitely not foolproof protection but it should work no?

Actually I was wrong, the 10V on gate and 100V on drain cannot be use and will not work. Because with 10V on gate the source will generate less than 10V regardless of the 100V on drain.

So the load will get a voltage less than 10 V and thus cannot be operated.

This is how a source follower is supposed to work. It follows the gate voltage and generates a source voltage which is always lower than the gate voltage.

Zener diode cannot be replaced with a resistor, The zener diode makes sure that the gate/source voltage never exceeds the 12V mark and this safeguards the mosfet from burning.

I think I’ve figured out most of my issues. Here’s the post I referenced. And I had to go searching through the data sheet to figure it out. I’m using 2 13n50c mosfets.

The body diode allows positive biased voltage to flow from source to drain. And I was not able to turn off or adjust the mosfet, similar to how you just explained. So instead of positive voltage from gate to source. I ended up with an extremely voltage from gate to source. And the mosfet latched to power on mode.

After I turned the circuit off I was able to get them to turn back off using a pull down resistor.

Since you have a Zener diode across gate/source it allows the gate voltage to follow the source.

With a common ground I can do something similar like I was thinking originally. With a 0-10v gate, source connected to negative and drain connected to the load.

This allows for the positive voltage to flow from gate to source. Since the motor is supplied with a different power source.

I’m going to end up changing this shortly. But would a resistor or regular diode across gate/source fix the issue?

I was thinking with a regular diode anode on gate and cathode on source. That you might be able to get around this issue by directing the gate voltage toward the source instead of the drain

Hey, I’m working on a 100v adjustable power supply based on the 0-300v circuit and I’m having some issues.

I’m powering the circuit with full bridge rectified ac from a 72v transformer. And have 2 – 330uf smoothing caps before the fet.

Originally I was using too small of a potentiometer. Currently I’m using a 500k pot with 2 – 0.5w 1M resistors in parallel for the gate resistor.

This confused me quite a bit since most of the data sheets and circuits I found had a really small gate resistor? I’ve blown up enough pots now to know that’s not the case. But I still don’t understand why.

Currently I don’t have any current limiting in place and no zener diode.

After struggling for so long trying to build a power supply with multiple mosfets in parallel I finally gave in and went back to basics. Everything was working until I broke a pin off of the fet ????????♂️ feeling confident that I finally *did* have a working model I tried to go back to a parallel circuit. And blew another 2 mosfets. But at least the potentiometer was okay this time ! Considering it’s my last one…

What am I doing wrong with this parallel circuit? And is there anything I can do to help protect my precious fets from the mysterious deaths I’ve been bringing upon them ????

All of the fets I’ve killed have been well within their working voltage range, and mounted to the same heat sink. I’ve tried both high and low side circuits but I don’t think any of the parallel circuits I’ve tried to build have worked.

Hi, thanks for the question, I will try to solve your problem.

A small resistor at the mosfet gate is relevant only when the gate signal is a pulsating frequency. If the gate voltage is a constant DC then the value of the gate resistor does not matter. Moreover the potentiometer value has to be high in order to safeguard the pot from high voltage.

Another thing is that MOSFET gates cannot tolerate voltage above 20 or 30V across their gate/source terminals. Therefore a zener diode is a must across their gate/source pins of the FET if the supply is higher than 20 V.

You have not used the current limiting feature, that is fine, but make sure to put the 12V zener diode otherwise your MOSFETs will keep blowing off.

Hello Swag, well done Sir, please can I convert 60V from 5battries of 60ah each to 12v to power 12v appliances. Thanks

Hi Tinu,

Unfortunately the circuit which I have can handle a maximum of 55 V only…60 V is just a bit higher for this device:

https://www.homemade-circuits.com/0-to-50-v-adjustable-switching-power-supply-circuit-using-ic-lm2576/

Good day sir! To get 200mA output current out of the circuit instead of 100mA I intend using 2N2222A in place of BC547. My question is do I need to adjust the value of 3.3ohms resistor.

Hello Moses, the current is not relevant to BC547 rating, so you can use BC547 for 200 mA also.

For 200 mA current the 3.3 ohm can be replaced with a

R = 0.6 / 0.2 = 3 ohm.

I am interested in your post and I want to try it for experimentation as a smd led light driver, in your opinion which diagram is better than the two diagrams above, the first or the second, then in the first diagram there is a 100 watt lamp, can the lamp be replaced with a resistor as a safety (how much resistor value should I use) so that the circuit is safe, in the first diagram what do you think if the output is also installed a 10 uf 400 volt capacitor as in the second diagram. thank you for your attention

The lamp cannot be replaced with a resistor, otherwise the resistor will become too hot and burn. However, the bulb could be replaced with a high voltage PPC capacitor. A 1uF/400V will produce 50 mA at the output and so on. Yes in the first diagram also a 10uF/400V or higher value capacitor could be used at the output. In that case the capacitor after the bridge could be removed.

I have changed the first diagram and I installed a 105 j 400 volt capacitor and I parallel it with a 470 Kohm resistor, then I removed the 150 uf 400 volt capacitor and at the output I installed 10 uf 400 volt, I will practice it on the pcb hopefully the experiment is successful, thank you friends. Unfortunately I can’t send you a diagram change, buddy

It’s fine you can go ahead.

However be extremely careful with the circuit. It is not isolated from mains AC and therefore can inflict a lethal electrical shock if touched in an uncovered and switched ON condition.

Hi,

I would like to use a transformer both works 220v or 110v to power my heater 150w also I would be needing 12VDC to 3.3v via a regulator to power esp modules, Kindly could you let me know which transformer diagram is recommended to use. Thank you

Hi, what is the voltage and current specifications of the heater?

For the 12V to 3.3V conversion you can use an LM317 adjustable voltage regulator circuit.

Hello Mr. Swagatam

Actually, I am making an IoT prototype in which power would be required.

For esp chip, at the same time for heater blanket. there would be 2 rods of 75watt each for the blanket Volts 110v 1.25amp also I would be needing 12v for modules.

Hello Mark,

If your input is 220V and the heater is 110V then you will require a 220V to 110V 3 amp transformer for powering the heaters. For getting the 12V you can simply use a 0-12V/220V/1 amp transformer.

Нагреватели последовательно. Будет как 1 .12 v любой маломощный трансформатор. Конструкция меньше будет.

Hello Swagatam

I am a hobbyist of electronics and I was taught by qualified experts

I am now working on an available project that lights the lights at night and turns them off at daybreak, and they are several designs, including using transistors and others with integrators. Of course, these circuits need to supply power from 9 volts to 12 volts, but the important thing is that these circuits control the relays, and these relays need a relatively large current that exceeds 1 Ampere

What is your advice to use suitable feeding circuits to carry the relay

I salute you for your great efforts and move forward

Knowing that I am very interested in feeding from the general current directly to reduce the size of the device and reduce the material cost as well. Several feeding circuits have been tested from the main current 220 volts AC, but the current is so small that the relay cannot work and move the internal contacts to connect the lighting

Greetings again

May God bless you in all your endeavors and projects

Thank you محمد فؤاد الخليلي,

I appreciate your interest in electronics. It is strange that your relays require 1 amp. Even a large relay rated at 30 amp will not require more than 100mA current for its coil activation.

Anyway, for a 1 amp current I will never recommend a transformerless power supply, which is explained on the above article.

For any load above 200 mA I will recommend an SMPS circuit, therefore for your application also I would recommend you to use an SMPS circuit.

thank you so much

Please give me the simplest design

For SMPS so that I can easily implement it with a small final size and relatively little material cost

Thank u

I would rather suggest you to buy a readymade SMPS instead of making one, because making a SMPS can be quite complex and will require advanced knowledge in the field of electronics. However if you are interested to build it you can try one of the circuits from the following article:

https://www.homemade-circuits.com/how-to-make-simple-12-v-1-amp-switch/

Hello,

my name is Max.

I am currently building a simple tube tester (EL34/KT88) and need a constant 250VDC anode voltage that does not collapse at 200mA.

Where can I find a corresponding circuit diagram based on IRF840?

Can you help me??

LG

Max

Hi, instead of using a mosfet power supply I would recommend using two small transformers connected back to back o get the intended low current 220V output, as shown below:

ok sir! thank you!

hi sir! i’m one of your blog reader and follower from Ethiopia. in this article, all what you designed were helpful. but i want you to make slight modification on one of the ckts you built above so that i can use it for generator automatic voltage regulator(AVR). that means the output of this power supply will be fed to the rotor winding of the generator across carbon brush and if possible please include the generator main winding output voltage sensor so that the power supply can increase or decrease its output accordingly to meet the set point.

Thank you Habtamu, since I do not have an expertise in the field of generators, doing this modification can be difficult for me.

Dear Swagatam,

My question is about MOSFET power. In my case DC input voltage is 350V, output voltage is 310V, load current is 50mA. So, the voltage Vgs = 350 – 310 = 40V. Power dissipation on MOSFET should be P=40Vx0.05A=2W, but MOSFET (2SK2647, Fuji) is very hot. Please let me know the reason of this issue, probably I made some mistake in my calculation?

Thank you.

Hi Yurly, Vgs = 40V is too high, it should not be more than 20 V according to me. And I could not understand the formula through which you calculated the Vgs.

Vgs is not equal to input V – output V.

Hi!

So sorry, I made a mistake – I meant Vds, the voltage between drain and source is 40 volts (350-310).

In that case the mosfet should not have become hot, maybe the mosfets are not original? Can’t actually judge without testing them practically.

Hi, thank you for your opinion, will try completely different mosfet ASAP.

Sure, no problem!

Which circuit should i use to power up a 100 watt led . Thanks

what is the voltage and current specs of the LED? I recommend using a SMPS with a current control circuit, instead of the above transformerless design.

Its’ a flood light. 1500ma is the circuit current. Idk many circuits about smps with constant current. Can you suggest one. Thanks.

OK, but you did not specify the voltage? Is it 100/1.5 = 66V? Give me the correct V and I specs I’ll try to figure out the SMPS option

Dear Sir,

I want to use this circuit to drive 300 3.3V @20mA LED what modifications do I need to do pls help.

Kevin, you can make 4 strings of LEDs having 75 series LED on each string along with a 3.3k limiting resistor. You can then connect these 4 strings in parallel, with the above power supply. I am assuming your supply input to be 220V

I built this is it works but… When I increase the AC supply voltage from Zero the DC output starts to increase when I reach ~200VAC even with the Pot on Zero. At 240VAC input I am getting 60VDC output… The DC output can be increased by the pot is right up to full voltage but only comes down to ~40-60VDC. All other aspects seem Ok. Any ideas?

The output voltage depends on the voltage developed at the gate of the MOSFET through the pot. If the voltage across the pot increases, the gate voltage will also increase which will result in the output also increasing, so naturally if the input voltage increases the output will also increase proportionately. For getting a fixed output you may have to replace the pit with a zener diode of the desired value.

Hi, Thanks

My problem in adjusting the pot down to zero I still have ~60VDC output? The gate voltage does go to zero with the POT. I am using the IRF740. If I disconnect the pot connection to the gate (open R1) I still get the VDC output. I find that if my AC supply is less than 200VAC it works all the way down to zero, but above 200VAC I get an increasing VDC out without increasing the POT from off zero (0 Volts on the gate).

Hi, that sounds very strange, because the circuit is configured as a source follower, which means that the source voltage will follow the gate voltage. If gate voltage is zero the source will also show a zero voltage under all circumstances. You can try shorting the gate to the 0V line and check the output, if it still produces a voltage then I might suspect the MOSFET to be malfunctioning.

Hello,

it is saying the output is 0-300vdc 100mA max, if i need 3A max, which parts need to be changed ?

thanks a lot,

Cheers,

Lanny

Hello, you can get 3 amp by adding more number of MOSFETs in parallel and by calculating the R2 accordingly. However 3 amp would generate a lot of heat on the Mosfet at lower output voltage levels.

R2 = 0.6 / 3 = 0.2 ohms, 2 watts

hi good work . please i want to know if there is any way i can make this circuit a bigger amps like say 3 amps to run by dc motor? i made it but the transistor bc547 kept blowing. i will appreciate your quick response. thank you

Thank you, 3 amps is not recommended, since the MOSFET can get immensely hot. Instead you can use the last circuit from the following article:

https://www.homemade-circuits.com/treadmill-motor-speed-controller-circuit/

Good day,I built the power supply with your scheme,but it does not work.I adjust 150 vdc out with 250vdc inp and I can adjust the vout but it does not stabilize the Vout,also as soon as I put a load with 18kOhm resistor the Vout goes to zero.Your scheme is with irf740,a 470 kOhm trimmer a 12 volt zener and a 470kOhm resistor

What do you recommend?

Thanks

Greetings

Hello, When I checked it practically and found the circuit to be working perfectly….it is source follower mosfet circuit, the output will be almost same as the gate voltage of the MOSFET…..if the gate voltage fluctuates then the output will also fluctuate…

Hello Swagatam!

I am working on designing a multi-input (couple of AC values like 240VAC, 120VAC, 24VAC) -> 24VDC output supply for my load (120ohm, 200mA). Both space and price are important for me, that’s why I don’t want to use a transformer or a 3-4$ capacitor. What would you recommend?

Thank you in advance & appreciate the work you do here!

Hello Suka, capacitive power supply is the cheapest option, there’s no other option cheaper than capacitors, although you won’t get isolation from AC mains.

Hi Swag

I need 0-300v dc variable voltage but constant 100mA power source using transformer and potentiometer. Can it be done by modifying the above circuit diagram??

Hi Chinmaya, yes it is possible to use the above concept. You can remove everything that’s connected on the AC side of the bridge rectifier, and replace it with your transformer secondary wires.

Hi

can I use this circuit for 600 volt DC input and have a 0 to 600 volt regulator ?

You can use by upgrading the MOSFET accordingly

Hello good time

Thanks for your good suggestions

But I need a 12 to 15 volt regulator circuit with a current of 25 amps. Can you help?

If possible, please email me the circuit.

Thanks a lot

Hello Ahmad, 25 amps cannot be achieved using capacitive power supply, SMPS is the only feasible way to achieve this!

Hello,

I’m interested in 220Vac to 220Vac voltage regulator using z network source

topology. I’m looking for a design using mosfet or Igbt using a PWM controller

chip. Output is say good for 3kva. Please publish a detailed circuit and complete specs if you have one.

Thanks a lot.

Hello, sorry I don’t have the mentioned design at the moment with me…if it is feasible I will surely investigate the concept and try to post the requested circuit soon…

Is the 100 mA a limiting factor? I would need .8 amps @150 DC

thanks for your clear ecplanations

Thank you, no it is not. Current can be increased by upgrading the T1 and R2 values

.

Dear sir,

Having gone through some of your projects they are outstanding.i need your assistance.i need to design a variable power supply of 0v -240vdc with a current of about 50-60amps,I have a source supply of about 240vdc.but I need to vary it so I can use it can suit my purpose otherwise it will spoil what I want to use it for.and also how do i incorporate it to charge a substation battery 110vdc.with 120vdc at full and 110vdc at low voltage i.e switching and working automatically.note I have an igbt module ch400ha-24h . how do i incorporate it for the variable power supply or in to the entire system.i await your generous assistance

Regards

Oladimeji

Thank you Oladimeji, sorry I do not have the mentioned power supply design, I guess a variac is the only suitable option for such massive specs.

Hi swag how to make 300ampere and 0-150 volt dc adjustable modul/circuits? Thx

Hi Dani, for 300 amp current it would better to go for a variac with a bridge rectifier at the output

Hi thanks for ur reply swag, btw do u have the schematic diagram for those variac with a bridge rectifier?

Hi Dani, both the items will need to be purchased readymade. The bridge rectifier should be rated at 500 amps as shown below example:

How to deaign a 3000 watt, 300v and 10 amps dc power supply

Hi Swag,

thank you for the circuits offered to people!

I am dealing with a High Voltage Power Supply at say 10-300 (and 30-600 second version), current 10-500mA that will not be pure linear as it has too much losses.

Tried a SCR controled rectifier to keep the voltage difference to about 10 volts from rectification capacitor to the output and while this work good to about 230 volts, the pulses of SCR closing makes noise and strong current pulses. Also current is not controlled, just limited to the max set.

Any ideas to a more SMPS circuit?

Thanks Ioannis,

In the following circuit, if you change the secondary winding to 100 turns, then may be the output could be converted to 600 V, this can be experimented to the required specs.

https://www.homemade-circuits.com/110v-14v-5v-smps-circuit/

Thank you very much for the tip. Much appreciated.

The MOSFET is supposed to be attached with a large heatsink

Very nice you did there dude, is this diagram can drawn 10w led x 10, I think it’s equal to 100w?

thank you, yes you can use 10nos 10 watt leds in series, making sure that the pot adjustment is correctly matched with LEDs total fwd voltage

Hello Swag,

I saw a circuit like yours(0-300vdc) which control the voltage of the motor up to 180vdc by pwm. Could it be possible?

I mean since mosfets control voltage between drian and sourse by gate, can control the voltage by limiting voltage of gate by pwm. is such a configuration possible?

Thanks

Hello Mah, the 0-300V circuit is not a PWM circuit, it is a simple MOSFET source follower circuit.

PWM is also possible whch I have already discussed in one of my other posts

Hello sir i want to make the transformerless power supply having output of 14volts and 8amp fir my dc load can you help me for this?

Regards

M Anas

Hi Anas, I do not have this SMPS design, better to buy a ready made one according to me…

Hi Master,

I made this circuit and run the dc motor successfully without any annoying noise (like i had with the paid 4kw SCR dimmer).

But there is excessive MOSFET heat that i need your kind help.

After 1min of running motor without any load the MOSFET heatsink got very very hot.

Can i replace it with BTA41-600 or IRFP460 to get rid of getting hot? Or something like use couple of IRF840 with large heatsink?

Thank you

Hi Mah, the MOSFET may be getting hot since you are operating a 180 DC V motor from a 310V DC, due to the wide input/output differential. That is exactly why a PWM is recommended for such applications.

Sorry, triac cannot be used with DC loads. You can use fan cooling for the mosfet.

Thanks Swag,

I prefer PWM too due to the torque. But i dont know why the pwm circuit does not work while all parts were tested and connections checked 1000 times.

Thank again

No problem Mah, but torque can be achieved only through a a feedback, otherwise no circuit can provide toque at low speeds.

The PWM design will work only if you test and confirm the stages separately.

Sir i’m working on this circuit but in my area IRF740 is not available, so instead of this can i use IRF640 or IRF840?? can I just put the 100w bulb in the input or in the output i have to put some load or just check with the multimeter?

Hi Amit, you can try IRF840, it is fine to use this MOSFET, IRF640 will not work. For testing purpose you can add a 10 watt bulb. Output load is not required for confirming the voltage control response of the circuit. Alternatively you can remove the input bulb and add it across the output terminals as shown in the video.

Is it possible to make a 220v to 150v transformer and use a bridge rectifier to get 180vdc?

Kindly advice

That would be an ideal approach. Using transformer will solve the issue very efficiently.

Hello Swag,

How can we get fixed180VDc from the circuit?

Is this possible to tune the pot for 180V in output then replace the pot with an equall resistor?

Thank you in advanced

Mah

Hello Mah, yes that’s possible, you can also do it through a preset variable resistor, once the adjustment is done you can glue it permanently.

hi dear friend….

could you help me?

I need a variable power supply of 0-120v, 3amps for a hand made proyect..

Could you give me some schematic to make or some idea how to made that power adjusted supply?

thank you so much.

Martin from Argentina.

Martin, the only proper solution is to use a variac, there is no other easy solution for this…

ok, thanks for your fast response..

What about your other design…? with TL783..? Can it deliver 3 amps with additionals power transistors..?

Can you help me to change schematic circuit to get more current with same IC..?

The TL783 will become hot as the input output differential increases, this will waste a lot of power. you can try this but the mosfet will become hot

https://www.homemade-circuits.com/wp-content/uploads/2019/11/TL783-High-voltage-Adjustable-Regulator.jpg

Ok, thank you for your answer.

Even adding that IRF740 transistor, how much more can I demand from the output current to the diagram you sent me?

Finally, there is the possibility that in the diagram that you have sent me, to be able to control the output current according to what I want, I mean, have control of the desired current in the output?

Thank you

The current range can be as required by you, provided the MOSFET remains cool. For current limit you can add a BJT network around the MOSFET source exactly as indicated in the above article

did you receive my last question?

Yes, and I have answered it!

Plz give me the circuit diagram of AC 0-300v/.500ma transformerless variable power supply .

use a light dimmer circuit:

https://www.homemade-circuits.com/how-to-make-simplest-triac-flasher/

sir, the circuit which is shown in image is different then what is shown in video. As one capacitor, one transistor, one zener and two resistance is used but in video 3 zener one resistance is used. please help me i want this variable power supply from 0-150 v for gel electrophoresis purpose.

Pawan, in the video 4nos of 3V zeners are used in series to make a 12V zener. And the current control stage is not used…the basic voltage control set up is the same as shown in the diagram.

Good day,

I really need to lower the mains voltage (230Vac) to 100V but i don’t want to use this power supply as it is now because it’s current is limited to 100mA and i need about 40A. If i put more transistors in parallel and of higher current ratings and remove R2 and T2 i’am sure the current will go higher, right sir?

Yes that’s right, but the output will not be an AC, it will be DC

Good day sir,

I tried this schematic and as i said i used two paralleled FDL100N50F mosfets and a 5W 12V zenner. This is the problem: when i connect a 2000W load such as a resistor to it, the voltage immediately rises to 187V and won’t let me adjust it from the potentiometer. What can i do to be able to adjust the voltage?

Thank you,

Good day Razvan, as you can see in the video, it works smoothly for a resistive load, so it should work for your application also, unless something is incorrect in your design.

I would recommend testing it with a 220V bulb using a single MOSFET, to check if there’s anything wrong in the configuration

Sir please suggest me a circuit for 0-50v 0-1amp regulated variable power supply

Hi Arun, you can try this circuit:

https://www.homemade-circuits.com/0-60v-lm317-variable-power-supply/

Good day sir, Can I use these curcuit to supply plate voltage of 250vdc at 150mA? If I parallel two output regulator will it be able to supply plate voltage for my vacuum tube project? Thanks

Hi Cornelio, Yes surely you can do it, but the MOSFET will not need any change. You can either do it by modifying the R2 value, or by replacing the lamp with a 3uF/400V capacitor. Then you can remove T2 and R2 entirely

Hi Sir,

SMPS circuit is design with high frequency transformer and KA5M0***R fet for spindle motor drives but the problem is there so much power dissipation across FET so what step should be taken to resolve that problem.

best regards

H Sam, a power device will start getting too hot if the load exceeds its optimal ratings. Make sure to use an FET whose current and voltage ratings are twice that of the load or the motor rating

Dear

I HAVE A UNIVERSAL MOTOR VACUUM CLEANER MOTOR 2000 WAT I WANT TO OPERATE IT ON DC VOLTAGE IS THIS CIRCUIT ABLE TO OPERATE IT

PLEASE ADVICE ME

Hello, if the motor is a DC motor then it will work with this circuit, but if it’s an AC motor then it won’t.

Hello Eng. Swagatam,

Find below the manner I calculated the wattage:

Given:

Number of Batteries in a pack: 16 pieces of Battery

Ampere of each Battery: 1300mAh

Voltage of each Battery: 1.2 volts

Then:

Voltage of battery pack (total voltage used by the cordless saw): 19.2v=16 pieces of Battery x 1.2 volts (Voltage of each Battery)

Amperage of the tool (total):20.800 = Ampere of each Battery: 1300mAh x 16 (Number of Batteries in a pack)

Wattage of the tool (total): 399.36 = total voltage: 19.2v x 20.800amps (Amperage of the tool (total))

My Summary:

Voltage: 19.2

Amperage: 20.800amps

Wattage: 399.36watts

Eng. as a matter of fact I am amateur in electronics. I started it as a hobby so please I stand to be corrected on the above presentation.

In case it is correct, kindly modify the suggested circuit to output at least 400watts/20v power. If there are any mistakes please tutor me on it.

Now concerning the winding of the transformer, is it possible to recommend already made one for me to purchase. Getting the items required for the transformer to DIY is posing a challenge. Many thanks. Danny

Thanks Danny,

When supply sources are joined in series, their voltages will add up, but current specs won’t.

So in your case the total voltage will be 19.2V but the current will be only 1300mAh.

You cannot draw more than 1.3 amps (max) from this series battery set up for your saw machine.

And therefore a 1 amp current would be more than enough to charge this battery series, without issues.

…yes you can easily buy one from any online store, or more simply you can do it with a transformer based design, as shown in this article:

https://www.homemade-circuits.com/how-to-make-current-controlled-12-volt/

Dear Mr. Swagatam,

I need a trnsformerless power supply with dual ouput. The first output is to drive leds (50-250/300V, 5-20mA), and the second output is for supply the controller circuit (microcontroller/arduino) (5V stable, 7805).

Please give me the schematic circuit or link that meets to its need.

Thanks

Hi Izul,

you can try this

https://www.homemade-circuits.com/wp-content/uploads/2019/10/two-output-transformerless-power-supply-circuit.jpg

remember it is not isolated from mains and can be fatal to touch when powered.

Thank you Sir.

What about following link / circuit, is it able to be implemented for my needs ?

https://www.homemade-circuits.com/wp-content/uploads/2015/02/surge2Bfree2Btransformerless2Bpower2Bsupply.png

It will also work, just replace the TIP with IRF730

Alright sir.

Thank you very much.

No problem!

Hi Eng. Swagatam,

Thanks for the numerous circuits and electronic designs you have freely placed at the public domain for our viewing and experimenting with.

I need a 19v to 19.2v transformerless DC power supply to operate a cordless circular saw whose battery packs are very dead. I hope you can help with a circuit design. Many thanks

Thanks Danny, could you please tell me the current requirement for the load, in amps.

Glad to receive a fast response from you.

Unfortunately the cordless saw does not carry any of the requested information on neither the device itself nor the accessories like the battery pack nor the charger set. I saw nothing too in the manual.

Here are links to the manuals: https://www.alltradetools.com/pdfs/new/archive/Kawasaki-19.2V-3-to-5-Hr-Battery_840638_eng.pdf

https://usermanual.wiki/Kawasaki/Kawasaki691191UsersManual219633.2052279797/view

However I want to open one of the two battery packs to see the voltage and amps of each battery as well the number of batteries in each pack. I welcome any advice from you sir. Many thanks. Danny

Surprisingly the linked articles also do not have any reference to the current requirement of the unit. However I assume it to be no less than 10 amps or even higher. Your battery specs might help us to get the required information.

Yes, I from what I saw in the battery pack embossed on each battery may be of help.

Kindly peruse these information:

Number of Batteries in a pack: 16 pieces of Battery

Ampere of each Battery: 1300mAh

Voltage of each Battery: 1.2 volts

Voltage of battery pack (total voltage used by the cordless saw): 19.2v

Eng. I hope these current information may churn out something good.

Many thanks for your time and patience. Danny

OK, it means a 1 amp smps would be enough, although i find it strange how a 20 watt supply can power a powerful saw unit?? You can try the second design from this article:

https://www.homemade-circuits.com/how-to-make-simple-12-v-1-amp-switch/

to get 19V you can modify the output winding to 20 turns, and change the zener diode to 20V zener.

Yes Eng. but my issue is not a charger problem. The power tool came with 2 battery packs but are all dead. They are very expensive to replace so I have decided to convert it from a cordless to a corded tool. That is I want to use an AC – DC power supply instead of a battery pack. So what I need is a circuit that can provide the 19.2v (20v) and the accompanying respective wattage which I guess is about 400w. Many thanks

Sorry Danny, I got lost, I mistakenly imagined that the batteries needed to be charged. I do not have a 20amp SMPS circuit , and even if I had I wouldn’t have recommended it due to its complexity. The easiest option is to get a 14V 20 amp iron core transformer, and rectify its output using 50 amp bridge rectifier and a 2200uF/50V filter capacitor. This would perfectly take care of your 400 watt saw and drive it smoothly without any issues, although the size of this trafo could be too large.

Many thanks Eng. Swagatam for your help and advice.

You are welcome Danny!

hello sir may i ask if u have a circuit to control the speed of a dc motor 180vdc input 1.5 hp. thanks

Hi Ralph, you can adapt the following concept and easily use it for your specific application

https://www.homemade-circuits.com/make-this-pwm-based-dc-motor-speed/

Thanks a lot for this circuit? Mr swagatam, i can apply this in my led strip wit 72 leds, each 3 led will light in 12 volts, in total series of led will consume of 208 volts. i ask one more question is this safe for my back light led tv as a subtitute in broaken inverter? thanks a lot for your reply, GOD bless!

Thank you Armand, I am sorry since this design is not mine I cannot suggest anything with confidence. Although others have built it successfully I still wouldn’t want to risk anything by suggesting on assumptions.

Hi Swag, I been looking at your work and find it amusing.

I need your help, I want to build a transformerless power supply will you be able to provide me with a circuit please.

Input: 220VAC. 50Hz

Output: 0-200VDC. 8A Max continues. 12A Peak.

Thanks and Regards

Kevin

Hi Kevin, I am sorry, I do not have this SMPS design with at this moment, I think a variac should be the recommended candidate for handling such massive input ranges

Can we modify it to have adjustable current too. Where do i need to put a current limit potentiometer. Using direct potentiometer isn’t suitable as i require 3 to 5 amps power.

you can modify the R2 section with a rotary selector switch and attach the desired number of resistors with it, and then you can select one of those for achieving the required current control limit

Hello sir ,

I need to make a circuit which switchover automatically between 11.1v 8800mah li ion battery and smps 12v 2amp circuit.At the load side I have used stepper motor ,TFT graphic lcd and wifi unit which is powered by smps supply. Is it possible to charge a battery with this smps supply and make switching to battery supply in the absense of smps supply.Charger circuit is also required.I am new to electronics please help me to find out charger circuit+auto switch circuit.

Hello Sham, you can try the second circuit from the following article

https://www.homemade-circuits.com/2013/04/automatic-micro-ups-circuit.html

please adjust the opamp preset through proper understanding and thinking, otherwise you will keep struggling with it.

The idea is simple.

pin#3 of the opamp is the battery voltage sensor.

when the voltage on this pin#3 goes higher than the pin#2, pin#6 switches to the supply level and vice versa, since pin#2 is fixed at 4.7V implies that as soon as pin#3 voltage becomes higher than 4.7V, pin#6 instantly becomes high, switching OFF the PNP transistor

sir can i ask a favor ? could you make for me a circuit intended for testing a led strip for led tv back lights? i made this circuit above i used a 1:1 ratio transformer it works well even in a single beads with out damaging it but my fear is the electric shock.

elmar, if you are using a 1:1 trafo then shock is already controlled to a great extent, make sure the current rating of the secondary is less the 10ma, and use a large filter capacitor after the bridge,

thank you very much sir for your kindness.

you are welcome!

hi sir swagatam is this circuit could be use in testing led strip?

or how to modify this circuit for the purpose of testing led back lights strip without shock

Hi Elmar, shock cannot be avoided in this design, it’s better to use an SMPS based power supply instead of this one if shock is a concern

Hi Sir ..Your circuit ideas are awesome.

I am designing a variable dual power supply circuit with high current output .. I have a 300 W transformer. I was initially thinking of making the circuit with LM317 and LM337.. but it is very difficult to get LM337 in our place. So I have designed the circuit with 7805 and 7905 Ics. By putting them in dual mode with the ground as common I got +5V 0 -5V dual power.. By connecting 2 pots between the Battery ground and the Ground pins of 7805 ( pin#2 ) and 7905 ( pin#1 ) I could tweek the output voltage from 5V to the full 15V range which was exactly my requirement.. The circuit is successfull in delivering the voltage range.. But the real problem happens next I am not able to take enough current from the output. I cant run high current loads with it. To compensate that I have used 2 to 4 no.s of TIP3055 Ics after 7805 regulator and there was improvement in the current. But not completely.. Now I need the help of you to design the current amplifier section at the output of the negative voltage regulator Ic ( 7905 ). I have several 2N3055 NPN transistors and MJE2955 PNP Transistors with me.. please help in this problem.. I have sent you an email comprising the designed circuit

Hi RT,

Your 2N3055 connections are correct and they should be able to deliver high current, but make sure to add a low value (may be a 22 ohm2 watt) resistor with the base of each transistor, otherwise they may get damaged if the load is bigger.

Please the 12v is it as a result of 12v zener diode please how come the 12v and why not use 330v which is the required output voltage

yes it is, but the main reason is that by grounding 12V level the mosfet will be completely shut off…

Please sir can u elaborate more on how to calculate the value of R2 because if i multiple the value of R2 being 3E3 by 100mA is not giving me the 330v. And in one of the comments i read u said for 300mA R2 will be 2ohms u get by dividing 0.6/0.3 i want to know the 0.6 please can u give me steps on how 2ohms is gotten

Thanks and best Regards

Faith, use the following formula for setting up the resistor

R2= 12/current Limit

for 100mA, this becomes

R2 = 12/100 = 0.12 ohms

correction:

R2 = 12/0.1 = 120 ohms

Thanks. I'll give it a go.

Hi

I'm looking to make a 430V 150ma supply for a tube amplifier. If I use a 350V transformer to supply the input voltage, increase the voltage on C1 to 600V and use a higher rated MOSFET, should the above layout work? What would you recommend as a suitable MOSFET? Any issues that you can see in an audio application?

Hi, yes according to me it should work….

Hi dear Swagatam

i need a transformless power supply for my leds which change 230 v ac to 0-35 v or more

but please simple and without transformer

regards,

Ali, you did not mention the current requirement….?

2-5 amps

but please simple

that's very high, you will have to opt for an SMPS version, capacitive type may not be recommended.

Thankss swagatam

Ok,below 1 amp i can choose?

Ali, you can try the following concept

https://www.homemade-circuits.com/2016/07/scr-shunt-for-protecting-capacitive-led.html

but make sure the SCR is rated above 2 amps

and change the zener diode with a 35V, 1 watt

Hi Mr. Majumdar,

Is this able to used for electron tube amplifier, without any hum?.

Thanks so much.

Hi Ronald, hum will depend on the filter capacitor value, if it is properly optimized then the hum can be controlled to the desired limits.

Please sir, what modifications can i make in the circuit above in order to get a regulated 12v, 300mA at the output? And i don't need the light bulb at the input.

Jideofor, I cannot suggest much regarding this circuit because it is not designed by me and it can be dangerous if anything goes wrong, especially because it is not isolated from the mains in any manner…

it's better to go for a capacitive power supply

if you have excluded the current limiting stage then initially try a resistive load with relatively high resistance such as a 40 watt bulb at the load side or a 25 watt soldering iron etc.

In this situation the input 100 watt bulb can be eliminated.

Hello, and thanks for the diagram. Have tested it and the setup continues to burn the irf740 as soon as I come over about 250DC primary. Has cooling, and tested with bulb at about ½ wattage. Have tried with less zener, but even 10v burns it. What could be the reason?

Hello, the circuit won't activate until a load is connected at the output, if it's burning without a load then something could be seriously wrong with connections or the device, make sure that the fet "source" is towards the load.

and remove C1 initially and check the response without it

also you can try connecting the zener across the gate and bridge (-) of the supply.

you can do it by altering the R2 value.

R2 = 0.6/.3 = 2 ohms, is a good value for getting 300mA

hi swagatam,

i need 500volt at 100mA power supply with input of transformer and also want lcd display for voltage indicating and current cntrl circuit at 100mA

please help me for this plzzz

Hi Atish, you will need two 1 amp transformers, one rated at 0-6/220V and the other 0-12/220V. Connect the 0-6, 0-12 with each, and connect the 0-12V side 220V to AC, you will get 500V at the 220V side of the other 0-6V transformer..you can use this 500V for supplying the bridge rectifier of the above circuit.

You can use any LCD ammeter, and connect it in series with the positive line to get the current display.

ok then so you haven't desinged any circuit like that +70 -70 & Gnd

sorry, I think I gave you the wrong link, here's the one I wanted you to see:

https://www.homemade-circuits.com/2014/07/0-to-50v-0-to10amp-variable-dual-power.html

but it will require a transformer.

I would need something to provide -70, +70 and ground

with this circuit i was wondering if I use the ground from the supply along with each output if that would work.

I don't think that would work

Can i get a circuit like this that can produce dual polarity voltages for various amplifiers from probably 0-100v at about 3 or more amps, the supply in my country is 110v

you can try the following circuit:

https://www.homemade-circuits.com/2013/06/0-300v-variable-voltage-current.html#uds-search-results

use TIP35/TIP36 instead of 2N3055/2955 in the diagram for getting a 0-100V range

…I do not have a trasformerless design at the moment…

Thanks sir let me try………but I have an diagram how can I send it to you in which e-mail id…

you can upload it to any free image hosting site online and provide the link to me here, i'll check it out

Hi sir I want to make a variable power supply for 1Amp load.

My purpose is to test relays and adjusting 555based, Opamp based circuit….

Please sir help me…

bhanu, you can use a LM317 circuit as shown in the first diagram here:

https://www.homemade-circuits.com/2011/12/how-to-build-simplest-variable-power.html

use 10k instead of 5k for the pot

input can be anything from 5V to 30V

Thanks Sir.Sir please suggest me a book where I can found the datasheet of different ICs

Arapan, the internet is the best source for learning the datasheets, you can try googling them online.

hi Swagatam 🙂

I want to ask.

1. if the input should be given 100watt bulb

2. if the circuit is safe to touch the output.

3. and for how many watts the resistor wear.

Hi Muhamad,

1) yes 100 watt is required for safeguarding the mosfet

2) No the circuit is extremely dangerous to touch

3)R2 is 2 watt rest all are 1/4 watt

Hello sir swagatam please tell me how make Stabiliser AC

hello joseph, you can try the following circuit:

https://www.homemade-circuits.com/2011/12/how-to-make-small-homemade-automatic.html

more example links can be found at the bottom of the article

thank you sir swagatam, i will try

Dear Sir please tell me how can I know about the functions of different IC's….

Dear Arpan,

check their datasheets.

sir plz give modification for high amp like 50amp at 60v thankx in advance.

Nitin, connect more mosfets in parallel with the existing one, and calculate R2 accordingly…

Hi!

Thanks for sharing. I'm actually designing a similar circuit but with SCRs to improve efficiency, did you think about doing one like that?

Kind regards,

Francisco

Hi, yes I have a SCR design using a zero crossing detector stage, but I am not very sure if it would be entirely safe.

The above design looks more convincing to me.

Thank you Mr. Majumder for publishing this ckt. However I require a perfect ckt. for charging my 2X1.5 V chargeable batteries i.e. a 3V charger directy from 220V AC main supply, those are generally supplied with chinese make re-chargeable torches (easily available in the local market). My two sets has been damaged & I am unable to use them.

You can use your cell phone charger for charging the 3V batteries by adding 4nos diodes in series with the positive line. The diodes can be 1N4007 type.

Hello sir please help me!!!

I have 220v to 400v 2A stepup transformer, actually according to various condition I want 0v DC to 400v DC using microcontroller’s PWM technique not by any potentiometer resistor, I am expert in programming only but not in power electronics. I need your help….my mobile no. is 8983378973.

Hello Mudassir,

what help do you exactly need in power electronics, please specify? With 400V PWM the peak will be always 400V which can be dangerous for many appliances.

Actually according to various conditions I need DC voltages like 25V DC, 50V DC, 75V DC, 100V DC……………375V DC and 400V DC. I know that , at various T-ON and T-OFF timings of the PWM we can generate various output voltages, but i dont have any MOSFET circuit to do so.

I request you please provide me a circuit diagram with suitable MOSFET rating so that i directly give output of PWM to the circuit to generate the voltages. As i have said that i already have stepup transformer (220v to 400v)

You can use the set up explained in the following article:

https://www.homemade-circuits.com/arduino-full-bridge-h-bridge-sinewave-inverter-circuit/

Repace the Arduino with your PWM input, and make sure to connect the MOSFet drain/source to the 400V DC supply.