The post presents an industrial water level controller with drain timer circuit. The idea was requested by Mr. Lanfrank.

Technical Specifications

I saw your blog and was impressed by your knowledge and the service you render to all electronics enthusiasts.

I am a hobbyist and mechanical engineer by profession based in Thane.

I need help for a situation that I have for a small mixer project.

Please help me in designing a below circuit.

I have described the process below

(I have limited electronic knowledge and tried to put some input within braces in the process description below. Please ignore the comments if you feel there is better way/ economical way of doing the same as you go about the circuit design.)

Process description:

Power “On” switch

Activate solenoid water inlet valve to “open”

Fill a tank with water upto a certain level –( maybe a magnetic switch will help here)

Cutoff the water supply to tank after a certain level is achieved.(maybe solenoid inlet valve could be used here based on the on-off condition of the magnetic switch to stop further water filling up.)

Start 230 V ac motor/pump , (maybe after 10 sec delay) and let it run for “t” mins.(variable time “t” adjustment from 2 to 15mins).

After the selected the motor has run for selected time “t” , a drain solenoid should open up to drain for time “t1”( t1 corresponds to the time taken to drain water).

Pump in new water in the tank and repeat step 2 , 3 , 4, 5, 6

Pump in new water in the tank and repeat step 2 , 3 , 4. 5, 6

Pump in new water in the tank and repeat step 2 , 3 , 4, 5, 6.

Stop.

The above needs a count down timer as display in 7 segment display format.

Display decrements from total time T to 0 (signifying end of total process and having reached step 9).

Looking forward for your reply, please contact me or leave me your mobile so that I could contact you to discuss it further, regarding cost etc.

Here is the process description edited and revised.

Process description:

Power “On” switch

Activate solenoid water inlet valve to allow water in the tank.

Fill a tank with water upto a certain level –( maybe a magnetic switch will help here).

Cutoff the water supply to tank after a certain level is achieved.(maybe solenoid inlet valve could be used here based on the on-off condition of the magnetic switch to stop further water filling up.)

Start 230 V ac motor/pump , (after 2min delay) and let it run for “t” mins.(variable time “t” adjustment from 2 to 15mins).

After the selected the motor has run for selected time “t” , a drain solenoid should open up to drain for time “t1”( t1 corresponds to the time taken to drain water).

repeat step 2 , 3 , 4, 5, 6 - three times.

Stop.

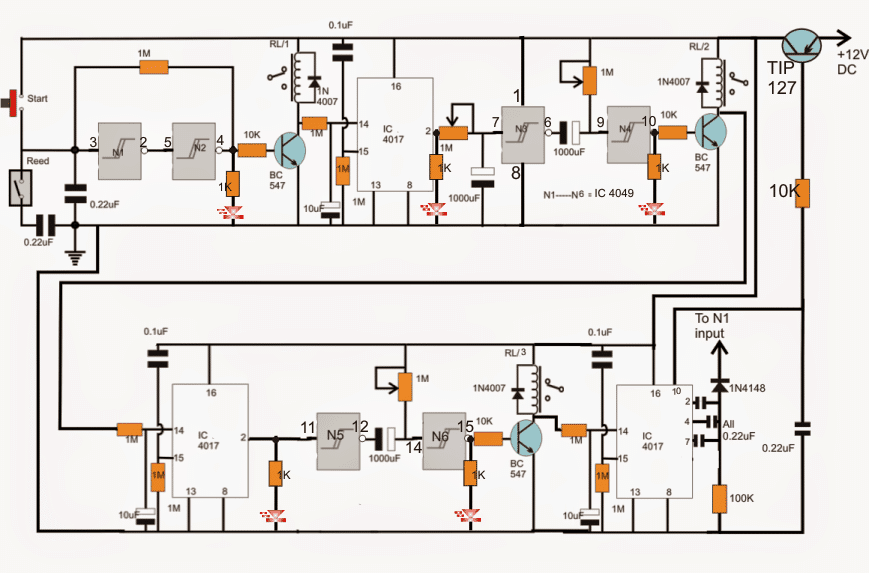

The Design

Referring to proposed tank fill/drain sequence controller circuit diagram, when power is first applied at the emitter of the PNP 2N2907, its base capacitor momentarily allows it to conduct until pin10 of the bottom-right 4017 latches the base of the transistor into a permanent conduction mode.

The circuit now gets latched and powered.

All the 0.1uF capacitors connected with the pin14 of the 4017 make sure the IC gets reset and in a standby position with their relevant outputs held at a "0" logic. This ensures that all the relays stay in a deactivated position at power switch ON.

Also, the input capacitor of N1 resets N1/N2 into a negative latch so that the output of N2 commences with a logic zero keeping the relay shut off.

Now when the "start" button is pushed, N1 negative latch is reverted to a positive latch creating a positive at the output of N2 which in turn activates RL1, switching ON the motor solenoid inlet valve that may be connected across its N/O contacts and mains.

The inlet valve keeps water running in the tank until it reaches the specified threshold, triggering the reed relay into a closed position. This action yet again grounds the N1 input via the series capacitor reverting the N1/N2 latch to its original negative state. The inlet valve here gets shut off.

Shutting off the above relay transistor causes a positive pulse to emerge at pin14 of the attached IC 4017, which responds by shifting its output high logic from its pin3 to pin2, pin2 now becomes high which begins charging the input capacitor of N3 via the 1M setting until after the predetermined delay the capacitor becomes fully charged causing a high logic at the input of N3.

N3 responds by making its output low which in turn forces the input of N4 to become low and its output high....toggling ON the connected relay driver stage.

This initiates the water pump and keeps it switched ON until the input capacitor of N4 charges fully, reverting N4 output to zero and shutting off the motor. This delay is determined by the 1M pot at the input of N4.

The switching OFF of the above relay transistor causes the next IC 4017 to push its logic high to its pin2 which quite identically initiates the N5/N6 timing sequence switching ON RL3 and its associated drain solenoid but only until the N6 capacitor gets fully charged wherein the relay shuts off after a delay set by the N6 1M pot

The above switching just like in previous stages influences the last IC 4017 which transfers a logic high at its pin2 inducing a momentary high logic at the input of N1, yet again reverting its latch to a positive mode, simulating the pressing of the start switch....the process begins yet again, and repeats for 3 times until a high logic is forwarded to pin10 of the bottom right 4017.

This high logic blocks the PNP 2N2907 conduction breaking the power supply to the circuit via the PNP, instantly switching OFF the whole circuit into a stand still.

The power now needs to be switched OFF and switched ON again in order to restore the circuit in a standby position.

RL1 = Activates water solenoid

RL2 = Starts 220V water pump (2 min ON delay is adjusted by N3 pot, "t" minutes ON is determined by N4 pot)

RL3 = Opens drain solenoid (t1 is set by adjusting N6 pot)

Feedback from Mr. Lanfrank

Hi Swagatam ,

Thanks, I guess I would try it out myself and experimenting given I have no option now and you are busy too.

Ok a few queries before I go and buy the components to construct my first circuit.

1.For the last 4017 part of the circuit, does it feed back into dot node of N1?

2.For the Relay marked RL1/RL2/RL3, what would be the part number/specification? Solid state or mechanical?(I would need a long lasting one).Please recommend.

3.There are three 1 M pots, can you specify type of pot I need to buy as I ask the shop guy?

4.For the 12V dc power source, is there any way to get 12v from the normal 240 v ac without means of transformer(maybe thru alternate circuit).

What would you recommend transformer or circuit for getting 12 v dc to feed transistor at right top corner as transformer might be costly or heavy.

5.What are 74HC14?

6.For the capacitors, which type of capacitors would you recommend to be long lasting?

7.For the 0.1 muF shown with 4017 ICs , is the circuit closed going from pin 16 to the capacitor? As it extends to the left beyond capacitor.

8.For Capacitor shown is there a negative /positive side to be taken care of like where I can make out that the darker plate is negative side.

9.Using breadboard would be a good start to test out, if I would need to lay this circuit out on a proper pcb board, which one would recommend?

10.Which software do you use for drawing this circuit diagram, looks like a good software utility.

Lastly, I guess lamington road is the best place right?

Any recommended best shop/place to buy?Thanks for taking out time to respond as always. Can't thank you enough!!

Regards,Lanfrank

Solving the Queries

1.Yes, but it need not be exactly on the dot, could be anywhere within the lines.

2. A mechanical type will do. The coil voltage needs to be equal to the supply voltage, while the current rating of the contacts must be as per the load (solenoid, motor) specs.

3.Any good quality will do,specify it as: 1M “linear” potentiometer.

4.You can buy a standard 12V, 1amp AC/DC SMPS adapter from the market, making it yourself may not be required.

5. It’s the IC number which contains (encloses) the shown N1----N6 gates (please check its datasheet to see the internal structure and compare it with the circuit’s N1-----N6 for getting a clearer understanding)Just remembered that these ICs strictly work with 5V supplies not with 12V…..so please

replace it with IC 4049 which are safe even on 12V supplies.

6.Under normal conditions, all capacitors can endure upto 50 years; still for extremely efficient performance you can use “metalized polyester” type, 50V rated (only for the non-polar ones which are symbolized two black parallel blocks)

7.Yes obviously it’s closed, there’s no break in the line, is there any?

8.Two dark plates indicate that these are non-polar types, meaning no +/-, can be put any way round

9. If you are well versed with bread boards, you may try it out on it, once verified, the design could be

assembled on a glass epoxy based PCB with green masking

10.I use CorelDraw for drawing the schematics.

Yes, Lamington Road is the most appropriate place to procure all the required components for the project

More Queries from Mr.Lanfrank

Hi Swagatam ,

Thanks for the updates.

Your patience is even more than your knowledge of the subject. I have a few doubts though it may sound a bit too simple to youJ (I have attached the same questions in word document in case you are unable to see the images that accompany the queries.)

1. I liked your trick with LED, any specs of LED that I should procure?

2. For IC 4049, are the numbers 3, 2 , 5 , 4…………7, 6, 9, 10……………11, 12 , 14 , 15 corresponding to the pin locations of the IC’s or are these just sequential numbering? (as I was looking to connect the right pin of the IC’s

3. I was researching for the REED you indicated thus and I suppose since the entire circuit works on 12 v dc, an AC REED might not work .

Can you guide me with the specs of the REED you mentioned in the circuit, so that I can accordingly buy the right one from the market as I guess you mean a DC Reed.

4. As I was researching for Relays RL1, RL2, RL3, I found that solid state relays are bit long lasting and cheaper(given that i need to buy three relays) what would be the specs of the relay? Should it be a DC relay or AC as it would be starting a 230v ac pump.

5. For your comment on “0.1uF capacitor directly across the +/- supply pins of all the involved ICs”, I guess for IC 4017, the 0.1muF has already been shown on the diagram. For IC 4049, do you mean connecting the pin 1 of all such IC’s to positive and pin 8 to negative (viz. 1 goes to positive and 8 goes to negative?)

Investigating the Circuit Isssue

Hi Lanfrank,

The LED can be any ordinary 5mm RED or Green LED.

Did you check the datasheet or the image of the IC4049, please check it online, you will find 6 triangle shaped elements inside the IC, each of these has an input and output terminated through relevant pinouts of the ICs.

I have indicated these triangles as squares, so basically both are one and the same, the shape is not important rather the inputs and output pin configuration is what we need to look at.

All these gates (triangles) are identical (duplicates) with their functions that means you can use any triangle (which are indicated as square blocks in my diagram) anywhere in the design....however to avoid complication you can simply follow the pin configuration that I have indicated in the diagram.

No, the 3, 2, 5...are not sequential numbers those are actual pin numbers of the IC 4049 as explained above.

For understanding the reed relay you may go through the following article:

https://www.homemade-circuits.com/2014/05/making-float-switch-for-corrosion-free.html

Solid state relays are much costlier compared to mechanical types, I would recommend a mechanical type as these would easily last for the next 50 years, if you are looking for something more reliable than this then it's your wish:)

Whether it's a solid state relay or a mechanical both will have a DC triggering section and a corresponding AC load bearing section.

In mechanical relays the coil is the DC triggering while the set of contacts are responsible for toggling the AC load, in response to the DC coil triggers.

For more info you can read the following post:

https://www.homemade-circuits.com/2012/01/how-to-understand-and-use-relay-in.html

The relay specs will depend on the load ampere specs, however the coil voltage for all the relays will be 12V.

The relay is the later part of the design first you will need to confirm the various operations of the circuit which can be done by replacing the relay coil points with a 1K resistor, once the operations are confirmed this resistor could be replaced back with the specific relay coils, as given in the diagram.

I don't see any 0.1uF cap across pin16 and ground of the 4017 ICs, you may be confusing it with pin15 0.1uF caps.

For the one IC 4049 it will be across its pin1 and pin8. The six squares (or triangles) are the gates from a single IC 4049.

Hope this helps:)

Have questions? Please Comment! Once posted, your comment will be sent to me for moderation (Rest Assured!). Your comments must be related to the above article...