In this post I have explained how an accurate 10 LED tachometer circuit can be built using ordinary parts like IC 555 and IC LM3915. The idea was requested by Mr. Munsif.

What is a Tachometer

A tachometer is a device which is used for measuring vehicle engine RPM. Thus, it is basically used for checking the performance of the engine and helps an auto mechanic to understand the condition of the engine so that it can be corrected or optimized as per the desired specs.

Generally a tachometer may be considered an expensive equipment as these are highly accurate and intended for obtaining correct RPM rates of the concerned engine under test.

The conventional units are therefore very sophisticated and generate highly accurate results while testing.

However it doesn't mean that a simpler version cannot be built at home. With electronics at its best today, making a tachometer circuit at home isn't at all difficult. What's more the results obtained from such circuits are fairly accurate and provides the required data for assessing the overall working condition of the system.

The Design

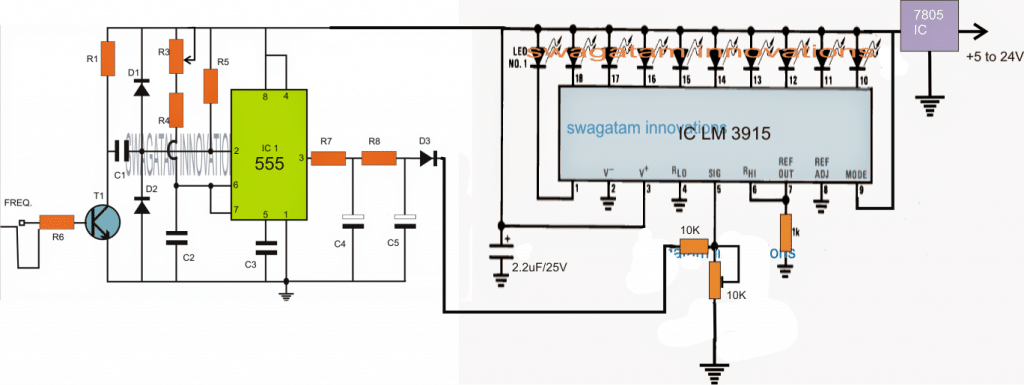

A simple 10 LED tachometer circuit can be seen in the above diagram.

The circuit basically consists of two mains stages. A monostable based tachometer using IC 555, and an LED driver stage using IC LM3915.

Referring to the figure below, the left side stage consists of a IC 555 monostable stage which triggers to the input frequencies from a given source such as an automobile engine, and causes its output to stay ON for a predetermined period as set by the R/C components at its pin6/2.

Circuit Diagram

This situation allows the user to set the response pattern of the output.

The output triggering of the IC 555 is further smoothened by an integrator stage using R7/R8 and C4/C5.

The integrated or smothened output is applied to a 10 step dot/bar LED driver LM3915 circuit stage.

The processed frequency to voltage conversion from the IC 555 tachometer circuit is appropriately displayed across the 10 LEDs associated with the LM3915 IC.

Since pin#9 of the IC is attached with the positive rail, the LED displays a bar mode pattern of the frequency level or the RPM level of the connected engine.

The 10 LED bar graph ascend or descend their illumination in response to the frequency levels from the automobile engine and allow the circuit to be used like an effective 10 LED tachometer.

Parts list for the IC 555 section

- R1 = 4K7

- R3 = CAN BE VARIABLE 100K POT

- R4 = 3K3,

- R5 = 10K,

- R6 = 470K,

- R7 = 1K,

- R8 = 10K,

- C1 = 1uF,

- C2 = 100n,

- C3 = 100n,

- C4 = 22uF/25V,

- C5 = 2.2uF/25V

- T1 = BC547

- IC1 = 555,

- D1, D2, D3 = 1N4148

Using only LM3915

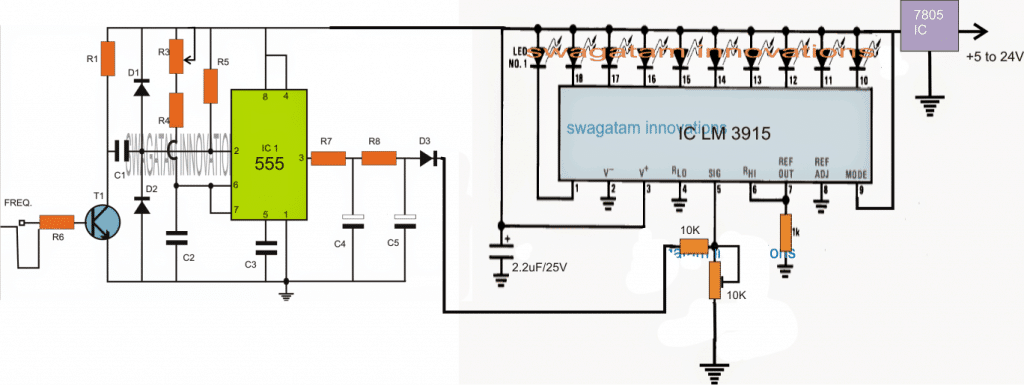

A closer inspection of the above circuit reveals that the IC 555 stage is actually not required and seems like an overkill for the purpose.

The main concept here is to convert the frequencies into an average DC whose level would be proportionate to the input frequency level. This implies that a simple diode, resistor, capacitor network would be enough to accomplish this action.

Also called an integrator, this small circuit network could be integrated with the LM3915 for ensuring that the voltage level stored in the capacitor is proportionately varied depending on the frequency levels.

Faster frequencies would allow the capacitor to charge and hold the DC proportionately better resulting in a higher average DC output and vice versa. This would in turn produce an equivalent level of LED illuminations on the LEDs attached with LM3915 output.

Here's the simplified version of the 10 LED tachometer using just a single IC M3915.

A Video Demo for the above Circuit can be witnessed below:

My Conclusion is not Correct

It's indeed very silly of me, since I completely missed the point that the above circuit was only interpreting the voltage generated by the motor, so it is not representing the frequency or the RPM, rather only the generated voltage levels.

Although this may be also proportionate to the RPM, it is technically NOT a tachometer circuit.

Therefore I confess that the first circuit shown using the IC 555 circuit the actual and true tachometer design.

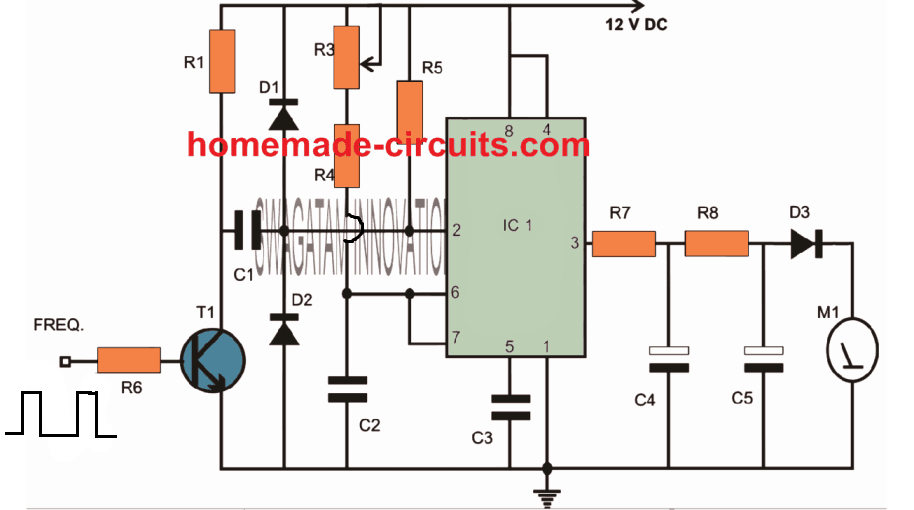

Simple Tachometer Circuit

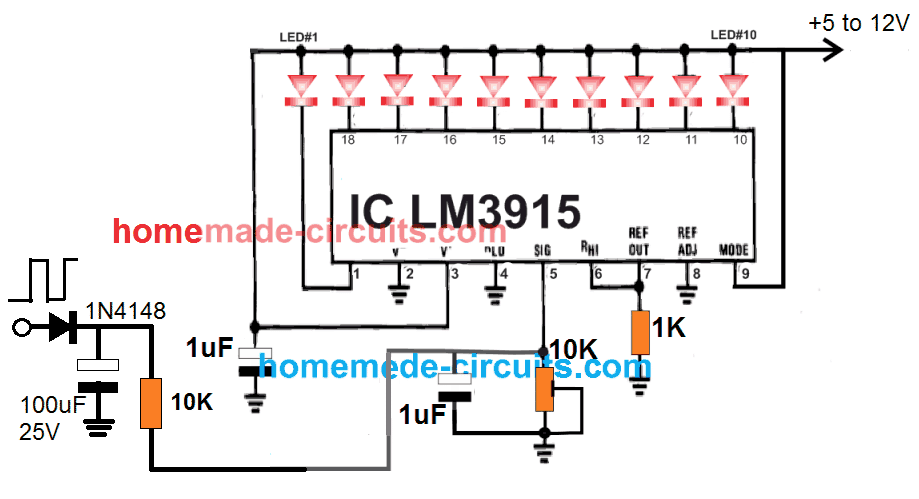

So far we studied a 10 LED version of a tachometer, however the idea could be much simplified using a moving coil meter as I have explained below. Here I have explained how to build a simple IC 555 based tachometer circuit which can be used for directly measuring any frequency over an analogue volt meter.

Circuit Operation

The circuit diagram shows a simple configuration utilizing the IC 555. The IC is basically configured as a monstable multivibrator.

The pulse is derived from the spark plug and fed to the end of R6.

The transistor responds to the pulses and conduct in accordance with triggers.

The transistor activates the monostable with every rising pulse of the input.

The monostable stays ON for a particular moment each time its triggered and generates an average ON time at the output which is directly proportional to the average trigger rate.

The capacitor and the resistor at the output of the IC integrate the result so that it can be directly read over a 10V FSD voltmeter.

The pot R3 should be adjusted such that the output generates the exact interpretations of the fed RPM rates.

The above setting up must be done with the help of a good conventional tachometer unit.

Parts List

R1 = 4K7

R2 = 47E

R3 = CAN BE VARIABLE 100K POT

R4 = 3K3,

R5 = 10K,

R6 = 470K,

R7 = 1K,

R8 = 10K,

R9 = 100K,

C1 = 1uF/25V,

C2 = 100nF,

C3 = 100n,

C4 = 33uF/25V,

T1 = BC547

IC1 = 555,

M1 = 10V FSD meter,

D1, D2 = 1N4148

Video Demo shows the testing of the above circuit

Simple Moving Coil Meter Tachometer Circuit

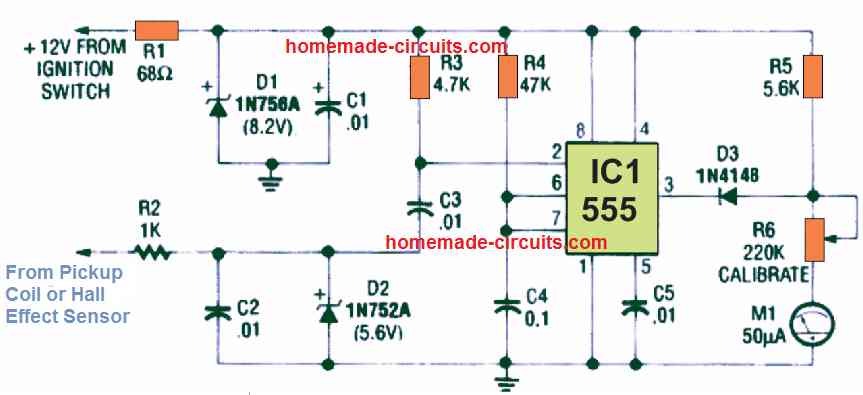

The figure below displays how a simple analog ,tachometer or revolutions per minute (rpm) meter can be built for motor vehicles. The circuit is driven by a regulated 8.2 volts acquired through the vehicle's 12 V battery and the ignition switch. The supply is stabilized using resistor R1, Zener diode D1, capacitor C1.

The 555 is activated with a signal from the vehicle's pickup coil processed by the circuit stage comprising of resistor R2, capacitor C2, and Zener diode D2.

The 50 uA moving coil meter M1, which is rigged as the the rpm indicator here, is triggered through pin 3 of the 555 via diode D3. The meter gets the driving current by means of a series-connected resistor R5 and potentiometer R6 through the power supply the moment the 555's output is high.

However, the current is decreased almost to zero by means of diode D1 as soon as the 555's output becomes low. The meter is actually a current indicating system, although it is hooked up like a voltage measuring meter with appropriate multiplying resistors.

FET Tachometer

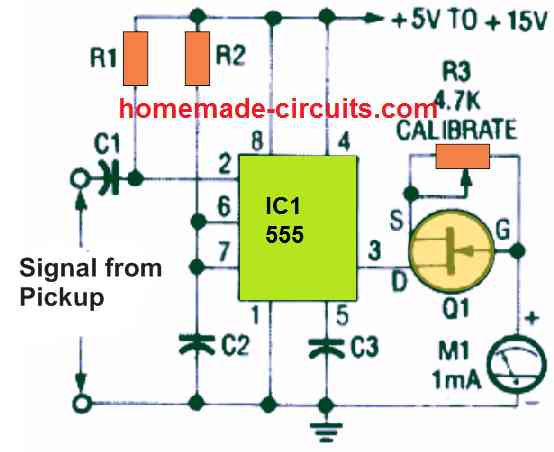

The next diagram below exhibits a different analog tachometer meter which involves neither a multiplier resistor nor a stabilized power supply. In this design, the IC 555 output pin 3 is attached to the meter via JFET transistor Q1.

The FET is wired like a constant-current generator by means of potentiometer R3, it delivers a fixed-amplitude pulse to the meter irrespective of the fluctuations in the supply source.