In this article I will elaborately discuss a simple to built yet awesome 1000 watt amplifier circuit, which could be easily upgraded to achieve upto 2000 watt output. It uses relatively fewer components and could be quickly set up for getting a massive 1000 watt power output on any 4 ohm, 1kva loudspeaker.

This circuit was sent through email by a dedicated enthusiast for publishing in this website

Introduction

The power amplifier discussed here is a 1000 watt Amplifier.

This amplifier works extremely well for pretty much any application that needs High power, high clarity, minimum distortion and outstanding sound.

Good examples of this could be Sub-woofer amp, FOH stage amplifier, 1 channel top notch surround sound amplifier etc.

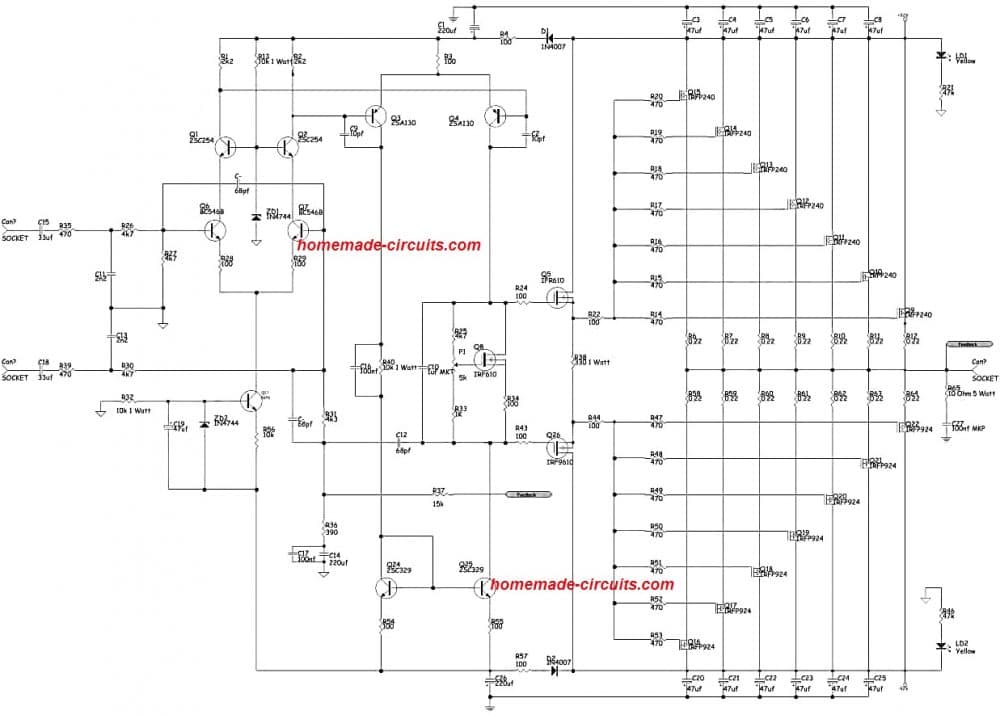

The amplifier features four key stages of amplification.

Let's begin by investigating each one stage with full detail.

The Error Amp

The first stage is actually an asymmetrical balance input error amplifier circuit.

This is a layout, that enables a single differential stage and also a balanced input supply.

An unbalanced source can be utilized in case either the inverting or non-inverting input is linked with the ground line of the signal.

Now let's discuss exactly how every single transistor within this stage operates collectively.

Q6, Q7, R28- R29, and help to build this important differential error amplifier.

This stage utilizes the transistor collectors with a cascode type of load. Q1, Q2, R13 and ZD1 constitute the cascode stage. This stage supplies a constant 14.4 volts to the collectors of Q1, 2.

R42, R66, Q23, ZD2 and C19 work as a constant current source, that resources 1.5 milliamps to the 1st differential stage.

Together these stages function as the first stage of the amplifier and essentially determine the way the entire amplifier is biased from start to end.

Voltage Amplifier Stage

This specific stage is designed for delivering the maximum possible voltage amplification required for the next stage, in order to switch the output stage with 100 % power.

R3, R54, R55, R40, Q3, Q4, Q24, Q25, C2, C9, C16 structure the 2nd differential voltage amplification stage. Q54 and Q55 work like a system which is called current-mirror load for the second differential stage.

This fundamentally pushes this stage to uniformly share the current acquired from R36, which can be around 8 milliamps.

The rest of the parts, particularly the capacitors work as local frequency compensator for this stage.

Bias/Buffer Stage

Q5, Q8, Q26, R24, R25, R33, R34, R22, R44, C10 does the job of Biasing and buffering, and hence the name bias and buffer stage.

The primary objective of this stage is to supply the MOSFET Gates with a constant and reimbursed supply voltage. And also to add a high impedance layer to the Voltage amp stage from the high Gate Source capacitance.

Without having this stage could certainly cause the frequency response and slew rate to become very bad.

However, the problem with this is the incorporation of an additional stage, a supplementary dominant pole across the amplifier's feedback loop.

The Output Stage

This stage switches the voltage produced in the VAS and supplies the full current necessary to operate 8 or 4-Ohm loudspeakers. 2-Ohm loudspeakers could be applied for some time, occasionally.

Actually I have checked this 1000 amplifier beyond 1600 watts RMS straight into 2 Ohms sub woofers. However I wouldn't encourage you to do this for any long term application.

Circuit Diagram

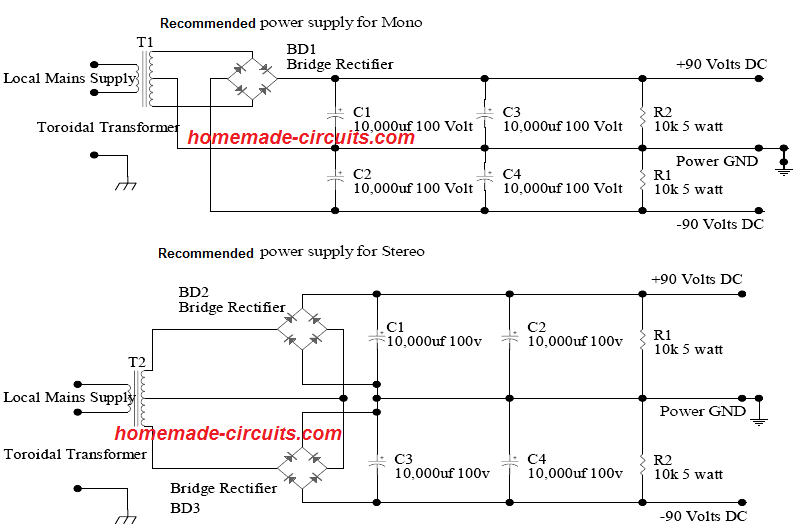

Power Supply Specifications

The power supply elements for this amplifier are as given in the following paragraphs. It is for a single Channel only.

1 x Transformer rated at 1000 watts. Primary windings are supposed to match your house AC supply. eg: for India and Europe the primary winding should be at 240VAC rating.

The secondary windings of the transformer should be rated as follows.

2 x 65 volts AC at full load.

1 x 400 Volt 35 Ampere, Bridge rectifier.

2 x 4.7K 5-Watt ceramic resistors

Lowest filter capacitor specifications can be 2 x 10,000uf 100 volt electrolytic.

Best value could be 40,000uf per supply rail.

Testing and Set Up

It is strongly recommended that you test the functionality of the amplifier right at the begining in order to ensure it really is performing correctly.

This can be accomplished by soldering a 10-Ohm ¼ watt resistor between the output of the amplifier and one end of the 330-Ohm 1W resistor used as R38

By doing this we link the feedback resistor R37 with the output of the buffer stage.

This basically bypasses the output stage and converts it into an extremely low powered amplifier, that can be freely analyzed without destroying the costly output stage.

Once this is done, next attach the +-90 volt supply to it and power it ON.

Make sure to have 4k7 Ohm 5-watt bleeder resistors soldered across the power supply filter capacitors.

At this point hoping nothing is smoking, using a multimeter on V range, measure the below shown voltage drops around the following resistors. In case they read close to the shown values within a range of +-10% then you could be positive the amplifier is ALRIGHT.

R1 = 1.6 V

R2 = 1.6 V

R3 = 1.0 V

R55 = 500mv

R56 = 500mv

Offset voltage at R37 might read a 0 volts, but also could be as high as 100mv.

Final Testing with Loudspeakers

Once you have completed the inspections, make sure to switch OFF power and take away the

10 Ohm resistor.

Thus we now have arrived at the stage where we should execute a maximum test out on the amplifier module.

There are still some inspections that must be carried out initially.

• The Drain pins upon all the output devices have to be inspected for socket to the heat sink.

• The power supply wiring may be examined regarding right polarity to the PCB.

• The Multi-turn pot P1 may be flipped back to 0 Ohms, to ensure that a reading of around 4.7k is achieved across the Gate and Drain pins of Q8 IRF610.

• While connecting the power supply, make sure to include 8 amp fuses placed on each of your power supply supply lines.

• Link up a multimeter on DC volt range to the output of the amplifier.

Alright given that you might be satisfied that this 1000 watt amplifier circuit is set up accurately, now connect power by using a VARIAC for those who have access to one, or else simply energize the amplifier through the given power supply

Checking out the voltmeter you can expect to see something around 1mv to 50mv offset (leakage) voltage.

If it is not seen then switch OFF the power supply and reexamine your work.

In case everything is alright switch off the system and with a fine screwdriver fine-tune P1 for the biasing of the output stage.

However initially attach the voltmeter around one of the output stage Source resistors with the help of Alligator clips.

Now once again switch ON power to the amplifier and gradually fine-tune P1 while examining the voltmeter, for a reading of 18mv.

After this, check across the remaining portion of the Source resistors and trace out the one, that has the largest value, and fine-tune P1 until 18mv is measured on the voltmeter.

Next, hook up a loudspeaker and music input to the amplifier and using a CRO for those who have one analyze whether the waveform is tidy and without any noise and distortion or not.

In case you do not have a CRO and Signal generator, hook up a pre-amp and loudspeaker and very carefully listen to the output quality. The output sound ought to be extremely clear and vibrant.

That's all, now enjoy! You have just assembled yourself and outstanding 1000 watt power amplifier which could be used for achieving a throbbing sound with a mind boggling power output...

Another Interesting Design

Here's another cool easy to build 1kva power amplifier circuit, which can be quickly built and implemented.

It is actually a 500 watt design but the power could be boosted to 1000 watts by suitably increasing the number mosfets or replacing the mosfets with higher rated variant.