In this post I have explained the circuit for a simple, universal capacitive discharge ignition circuit or a CDI circuit using a standard ignition coil and a solid state SCR based circuit.

How Ignition System in Vehicles Work

The ignition process in any vehicle becomes the heart of the entire system as without this stage the vehicle just won’t start.

To initiate the process, earlier we used to have the circuit breaker unit for the required actions.

Nowadays the contact-breaker is replaced with a more efficient and long lasting electronic ignition system, called the capacitor discharge ignition system.

Basic Working Principle

The basic working of a CDI unit is executed through the following steps:

- Two voltage inputs are fed to the electronic CDI system, one is high voltage from the alternator in the range of 100 V to 200 V AC, other is a low pulse voltage from a pickup coil in the range of 10 V to 12 V AC.

- The high voltage is rectified and the resultant DC charges a high voltage capacitor.

- The short low voltage pulse drives an SCR which discharges or dumps the capacitor's stored voltage into the primary of an ignition transformer or coil.

- The ignition transformer steps up this voltage to many kilo-volts and feeds the voltage to the spark-plug for creating the sparks, which finally ignites the combustion engine.

Circuit Description

Now let’s learn the CDI circuit operations in detail with the following points:

Basically as the name suggest, ignition system in vehicles refers to the process in which the fuel mixture is ignited for initiating the engine and the drive mechanisms. This ignition is done through an electrical process by generating high voltage electrical arcs.

The above electrical arc is created through extreme high voltage passage across two potentially opposite conductors through the enclosed air gap.

As we all know that for generating high voltages we require some kind of stepping up process, generally done through transformers.

As the source voltage available in two wheeler vehicles is from an alternator, may not be powerful enough for the functions.

Therefore the voltage needs to be stepped up many thousand folds in order to reach the desired arcing level.

The ignition coil, which is very popular and we all have seen them in our vehicles is especially designed for the above stepping up of the input source voltage.

However the voltage from the alternator cannot be directly fed to the ignition coil because the source may be low in current, therefore we employ a CDI unit or a capacitive discharge unit for collecting and releasing the alternator power in succession in order to make the output compact and high with current.

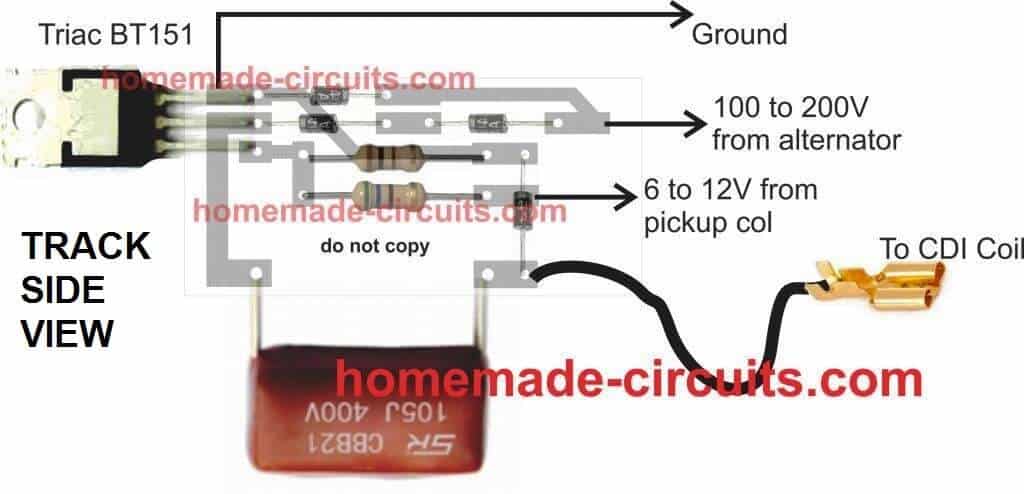

PCB Design

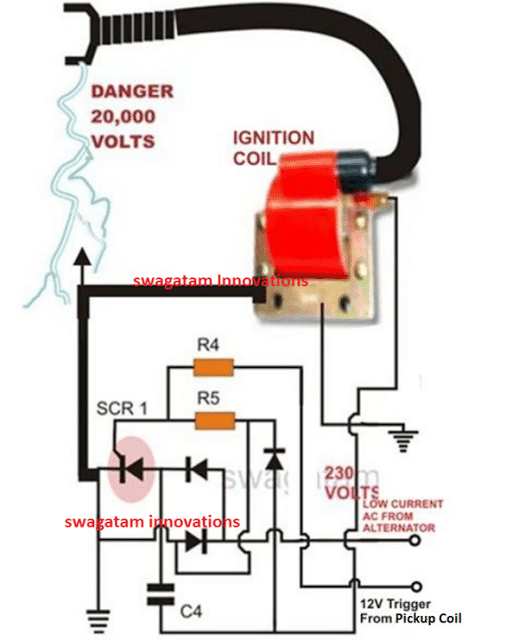

CDI Circuit using an SCR, a few Resistors and Diodes

Referring to the above capacitor discharge ignition circuit diagram, we see a simple configuration consisting of a few diodes, resistors, a SCR and a single high voltage capacitor.

The input to the CDI unit is derived from two sources of the alternator. One source is a low voltage around 12 volts while the other input is taken from the relatively high voltage tap of the alternator, generating around a 100 volts.

The 100 volts input is suitably rectified by the diodes and converted to 100 volts DC.

This voltage is stored inside the high voltage capacitor instantaneously. The low 12 voltage signal is applied to the triggering stage and used for triggering the SCR.

The SCR responds to the half wave rectified voltage and switches the capacitors ON and OFF alternately.

Now since the SCR is integrated to the ignition primary coil, the released energy from the capacitor is forcibly dumped in the primary winding of the coil.

The action generates a magnetic induction inside the coil and the input from the CDI which is high in current and voltage is further enhanced to extremely high levels at the secondary winding of the coil.

The generated voltage at the secondary of the coil may rise up to the level of many tens of thousands of volts. This output is appropriately arranged across two closely held metal conductors inside the spark plug.

The voltage being very high in potential starts arcing across the points of the spark plug, generating the required ignition sparks for the ignition process.

Parts List for the CIRCUIT DIAGRAM

R4 = 56 Ohms,

R5 = 100 Ohms,

C4 = 1uF/250V

SCR = BT151 recommended.

All Diodes = 1N4007

Coil = Standard two-wheeler ignition Coil

The following video clip shows the basic working process of the above explained CDI circuit. The set up was tested on table, and therefore the trigger voltage is acquired from a 12V 50Hz AC. Since the trigger is from a 50Hz source, the sparks can be seen arcing at the rate 50Hz.

Have Questions? Please Leave a Comment. I have answered over 50,000. Kindly ensure the comments are related to the above topic.

like to make a circuit CDI discharge system.

discharge will be at 2000VDC , 12 jule power , 2-3 discharges per sec.

Input voltage 220 V /120 V AC,

please comment

Sure, you can try the above CDI circuit, the sparking frequency will depend on the triggering frequency at the “pickup coil” input terminal of the circuit…

kondensaattori sytyksen lisääminen esim boch käjettömäänn sytys järjestelmään? Palkoko maksaa.MSD A6 on kallis voiko vastaavan tehdä halvemmalla.

greetings Swagatam

I made this once but it didn’t work, I think I made a mistake somewhere,I wanted to know if this circuit is CDI, DC or AC?

thanks for sharing

Hi John, did you supply the 100V to 200V high AC voltage and the 12V pulsed voltage to the inputs of the CDI circuit as shown in the diagram?

Both of these voltage simply needs to be pulsed, it doesn’t matter whether they are AC or DC, they should be intermittent and not continuous, that’s all…please let me know.

Hi Swagatam thanks for reply,

When I made it again I saw that it worked very well, I must have been wrong before, it was really great, thanks

Can you share CDI racing or DC circuit?

And instead of bt 151 thyristor, can I use z44 MOSFET or 2n 3055 transistor?

That’s great John, glad it is working now!

For a DC CDI you can refer to the following article:

https://www.homemade-circuits.com/make-this-enhanced-capacitive-discharge/

No, I don’t think the SCR can be replaced with a transistor, SCR looks more suitable for this specific application.

helow sir i wish to have a 4pin cdi diagram..can riv to high rpm hopefully

Hi Mark, can you please provide the specifications of the 4 pins, I will try to help!

Hi, have you tried using this circuit with a square wave DC pulse as the trigger? I am using a similar design, although slightly simpler, only a current limiting resistor to the gate pin instead of a divider and slightly higher capacitance on the capacitor, but basic idea still remains. However I ran into a weird issue of it not revving past 1500 rpm.

Hi, It doesn’t matter whether the triggering pulse is a square wave or a sine wave, the SCR will trigger once the gate voltage crosses the 0.7V mark.

You can try the above design and check if it makes any difference.

Cool I just blew out my cdi on moped and I have no income but I got ability and some junk parts I can salvage all I needed was your information to build replacement cdi and get going again. And I noticed your section HHO which I believe has to do with hydrogen if I’m correct I want to make all my power come from hydrogen and the greatest fuel in world only thing I’ve been stifled by is coming up with easy free supply for electrolyte. But your just the help inspiration I needed book marked¡¿¡

Sure, I can help. If you have CDI related questions you can ask them here. For the HHO related questions you can feel free to comment under the following article:

https://www.homemade-circuits.com/how-to-use-hho-fuel-cell-in-automobiles/

Ya know I looked at that circuit and thought it looks to me like it could take reverse 20 volt except cap and I was right but the regulator was bad and I believe it was in need replaced b4 cool ty for simple circuit

can i use MOSFET irfz44n insted scr by151

No, MOSFET cannot be used in place of SCR.

Sir, Is there a way to modify or add a timing adjustment to the cdi circuit. auto or manual??? thanks Nick

Hi Nick, sorry, in this basic CDI circuit design, timing adjustment cannot be added.

thank you so much for your circuits and your help. Nick Carper

Sir, question about how to wire the cdi,, wire that goes to the alternator.. my magneto, has 3 wires coming from engine alternator coil, 18 total coils ,with. six,6 coils per wire 2011 suzuki savage 650 motorcycle. they run to a rectifier . How do I connect the single wire coming from cdi to the 3 wire magneto??? hope i made this clear.. thanks for any assistance. Nick in Missouri.

Hi Nick,

As far as I know, you will need to check the voltages from the respective alternator wires with respect to the body ground of your motorcycle. You may have to use an AC voltmeter to check this.

The wire that produces anything above 100V AC can be connected to the CDI 230 V input.

The 12V trigger input from the CDI must be connected with the pickup coil output of your motorcycle.

I think a good qualified motor mechanic or electrician will be able to guide you better regarding the relevant connections.

Thanks for a swift reply. Great job. I Understand, I think I can figure it out. 5 plus. Nick

Glad I could help!

Dear all

can you peaple give me a DC CDI Circuit for 200cc motor bike it will be very helpful

Thank you all for informations.

Hello Padmaharsha,

you can build the CDI circuit explained in the above article, it is perfectly suitable for you bike…

Hi Swagatam,

Thank you for your very useful explanation of the CDI circuit. I have a 1978 Johnson two cylinder two stroke outboard and I think there is a fault with the CDI unit. I have taken the unit apart and exposed the circuit board (which unfortunately caused some damage to components removing the protective resin).

I am trying to find out what the components might have been to recreate the circuit with replacement components and wondered if you might be able to help as your circuit looks smaller but similar. If you would be willing to take a look could I send you a photo of my circuit board to see what you think? Thank you in advance for all the useful information

Thank you Tim,

The above explained CDI design is tested on across thousands of two wheelers and auto rickshaws in India, in fact I have manufactured 1000s of these units and sold them in the local market without issues.

So you can replicate the above circuit and use it for your motor bike.

It could be actually very difficult for me to check the image of your CDI and suggest th component values or create a circuit diagram.

I have a Husqvarna 285CD chainsaw. It is in very good condition but the CDI ignition has failed. It is now impossible to obtain a new stator plate with all the coils etc. there are only two coils, one for charging the capacitor and the other to supply the HV for the spark. There is no extra coil or sensor to trigger the SCR/thiristor. I wish to find out how the triggering is done and a circuit to match. Both coils I have appear to be ok. The rectification and triggering are encased in a solid block of resin. I would like to remove the resin block and construct a replacement. Any help , circuit diagram, ideas, etc. would be very much appreciated. Johnl

Sorry, I have no idea regarding how the above CDI circuit can be implemented in your application without a pickup coil trigger voltage for the SCR.

I have a cdi for 2001 650cc savage motorcycle. It will supply a single spark and than quit, till I cycle ignition off and than back on for a single spark repeating each attempt to start. Coil. Plug, igniter and wiring have all been replaced. Any hint or answers would be appreciated. Thanks, new cdis from Suzuki are 700. Dollars . Thanks Nick carper.

The CDI will require a continuous source of pulses from the pickup col to keep the ignition sparks alive and kicking. Is your pickup coil providing the required pulses for this?

thanks for your answers to my inquiry. Yes I have a trigger coil that is working … Suzuki 2011 savage 650 single cylinder.

Hello. I made a CDI according to your scheme but I do not know why my R4 burns. Please help???

The pulse voltage to R4 gate resistor is supposed to come from the pickup coil which has very low current. What is your source for the 12V signal?

If it is from a power supply, decrease the voltage to 5 V or increase the R4 value to any value between 100 ohms and 1K

I use for yamaha YZ 125 1993. Tomorrow I will measure the voltage on the

pickup coil

OK, no problem!! Also you can feel free to increase the resistor value upto 470 ohms.

Hello Sir. I have the same problem. My 12v source is from pulse generator with 20.9 ohms 14.75mH coil. It burns when I reach 4000RPM.

Hello Andrew, the above CDI circuit has been extensively tested and used on Indian motorcycles and auto-rickshaws without any issues. So the CDI components and diagram is absolutely correct.

It can be difficult for me to troubleshoot your issue without checking it practically.

Dear Mr Swagatam.

I am not an expert in electronics. Need your advice please,

I own a small (Mosa msg chopper) 2 stroke engine welder and I’m having problems getting back the spark.

The thing is that this engine has an AC type of ignition which I’m not used to work on.

I say AC cdi because the engine does not have a battery or any sign of a direct current/wire going to the cdi unit. Please correct me if I’m wrong.

I daily work on mopeds of which most cdi ignition systems are built with charge capacitor or exciter coils and pick up/trigger coils located as two different coils on their own spot under/beside the flywheels.

This Mosa engine has only 2 coils under the flywheel/magnets:

1.The exciter coil or charge capacitor coil which function is to keep the engine sparking/running.

(I came to the understanding that the exciter coil and trigger/pickup coil are

fabricated as 2 functions in one coil)

2.The electromagnet coil which function is for WELDING ONLY. (not important for

spark)

The cdi unit has 4 terminals indicating the wire colors and their functions.

charge capacitor coil (green)pulse/ trigger (red)main coil (blue)ground (black)

The exciter coil or charge capacitor coil has two terminals going to the cdi unit. A red wire and a green wire.

The red wire is for pickup/pulse and the green wire is for the charge capacitor or exciter as shown above.

This is my first experience with this type of ignition of which I experience no pulse/trigger coil internally/externally visible.

The main coil which goes to the spark plug is OK.

I tested it on my moped and gives a nice blue spark.

My goal is to rewind the exciter coil but the engine manual only specifies the resistance for the electromagnet coil (2.9ohms) which is for welding function and not for spark.

There is no info on the exciter coil and it’s resistance.

I dissembled the wire from the exciter coil and opened up the cdi unit which I pretty much damaged some parts of but I was planning to buy a new cdi unit THAT FITS THIS TYPE OF CDI anyway.

The exciter coil is not available in stores so I will need to rewind it.

Please your advice on rewinding the exciter coil and it’s resistance.

If you would like to see some photos of the parts and/or the engine then I can send them to you via email or whatsapp.

mosa.com.au/inventory/manuals/MSG%20CHOPPER.pdf shows the engine manual.

Regards,

Dan

Hi Dan,

Sorry, I have no idea regarding the rewinding process of the exciter coil, because I have never come across practically with these types of systems. I hope someone else in this forum might be able to provide some help.

Dear Swagatam, Im thinking of using this circuit as the electrocution supply for the mosquito killer circuit you did in another link. How can I limit it to only 3500V and 9mA current? Thank you.

Hi Kitt,

In the PCB schematic you can see one terminal labelled as 100 to 200V AC from alternator. You can experiment with this AC voltage and reduce it to 24V AC in order to step down the output voltage from the CDI coil to the desired limits. Just as the AC voltage the current can be also reduced at this terminal.

Thank you vmuch. I assume when you put 200 volts AC, you wil get 20000 volts CDI output. so if its 100 VAC, goes down to 10k volts, and 24VAC goes to 2400 VAC. First there is a way to measure the Voltage using any voltmeter, etc? Or does the CDI have specs printed to show how much is the multiplier to the output? 2ndly, since we decrease the voltage to say 2400-3500V, what space distance would you think the mesh screen should have between each other? Thanks again 🙂

Your assumptions are correct, however I cannot confirm the exact output voltage that you may get using a 200V or a 24V, from the CDI coil.

One way of determining it is to connect 5nos of 1M resistors in series across the CDI output and measure and verify the voltage across these resistors using resistive divider formula.

The distance between the mesh wiers could be around 3 to 5 mm.

I think I have a related article posted in this blog which you can see in the following link:

https://www.homemade-circuits.com/mosquito-killer-circuit/

Thank you again. Got it with the mesh. Regarding the 5nos 1M ohm resistors..so I will have to measure using voltmeter in 1 resistor. So the “20k volts” would be divided through the 5 resistors effectively giving 4000volts each. Can we measure using ordinary voltmeter? Another question is if I intend to use 24VAC up to 110VAC, will the specifications or values of the components in your circuit be changed? and what are they incase I use 110VAC and/or 24VAC? Thank you again 🙂

I don’t think the total voltage can be determined by measuring the voltage across 1 resistor. It looks much more complex than that. So the resistor method might not work. If you have a voltmeter which can measure upto 5000V then you can simply use the meter to measure the output directly. Remember the output will be pulsed, so the meter will show only the average value of the pulsed DC. For example if the input 12V trigger pulse has 50% duty cycle then the voltmeter will show 50% of the actual output voltage from the CDI coil.

The circuit will not need any changes for input AC voltages ranging between 12V and 200V AC.

Ok great! Very clear and well said. Ok. I will make the 110VAC (60hz) as my trigger pulse. anyway, the mosquitoes still will get electrocuted around 10000VAC. Im doing this to replace the High Voltage transformer that I use (very costly due to shipping 🙂 and if damaged, u have to replace cause its hard to rewind. Thanks again Swagatam! More power to you and on what you do! 🙂 Namaste!

Thank you Kitt.,

The trigger pulse should be 12V DC pulse and the AC input can be a 110V AC.

Yes, certainly 10000V should be more than enough to electrocute the mosquitoes

Sorry, forgot to ask. Do I have to put the 680 ohms resistor in between R4 and Trigger as shown in your video? what is its purpose? Thanks.

You can add that resistor for an increased safety for the SCR…the value can any value between 470 ohms and 1K.

Ok Thank you Swagatam! 🙂

You are welcome Kitt.

I do not understand…4 diodes in the picture but 3 in the schematic.

Which one is correct?

Shunt kickback voltage? Diode from cap output to ground.

The PCB layout picture and the schematic diagram, both have 4 diodes.

Need a cdi design for 650 cc s40 suzuki motorcycle. 2001 single cylinder. Thanks Nick

I think you can try the same CDI circuit explained above. It should work.

Thanks Nick

Hi, in your cdi circuit, why do you put a diode who is shorting

the negative part of the AC wave from the alternator ?

Hi, it is not my design, it is the original design taken from rickshaw CDI.

Because as stated, it is half wave rectified DC. So it is only rectifying half of the waveform. The voltage is high enough that half wave pulsed DC is sufficient to charge the cap. and we only need a small DC pulse from the trigger coil to fire the SCR. So long as the trigger provides the I(gt) that the gate on the SCR needs (typically only like 0.5-50mA), it will latch the SCR and discharge to the primary of the ignition coil.

Hi Swagatam

I have a 1960 vintage CDI that resembles similar DIY products usually marketed by Tandy or Jaycar for the hobby market, except this one has been commercially produced and after 60 years has failed.

Enquiries suggest that it is the capacitor and that the early capacitors failed because they ‘dried out’, is this still a problem.

Geoff P

Hi Geoff,

60 years is a long time, and we can’t expect more from an electronic device.

CDI circuits don’t use an electrolytic capacitor for the capacitive discharge, rather a PPC a metallized PPC is used which do not have electrolyte inside. So “drying out” of the capacitor may not be possible. Nevertheless, wearing out of the capacitor may be possible due to overuse. Another part that can go faulty is the SCR which is subjected to a huge amount of stress during the charge/discharge switching process

Hi Swagatam

I am from Philippines and I have an interest about this topic can I use your diagram as a reference in our research paper to support my argument that there’s an AC CDI in the ignition system of the motorcycle. I ensures that this will be use only for educational purposes.

Please advise.

Best regards John Lloyd

Hi John,

No problems at all. You can feel free to use the concept in your papers.

Hi Swagatam

First Let me say I love your site and have bookmarked it.

I have been looking for a long time for a simple CDI set up to go between the set of points, and the existing ignition coils on my positive earth classic motorbike.

Can any of these circuits be redesigned to take positive earth/ frame wiring.Obviously all the Diodeswill need to be turned arround but I’m not confident about the other components,

Please advise.

Best regards Desmond Tutu

Thanks Desmond, glad you liked and bookmarked this site!

I don’t think changing the diode polarity will make the design compatible with a positive earth vehicle. It looks more complex than that, because we have an SCR whose polarity will also matter. Actually I am unable to find an appropriate solution at the moment. If I happen to find anything useful will surely let you know.

can you please show and explain a circuit diagram for a scooter cdi that has the ability for advancing the ignition sparking for when the engine speeds up

Sorry, I do not have a CDI circuit with an ignition advancing feature

@Marcelo

Sorry, but no such luck.

.

D5 shunts inductive kickback from the ignition coil to ground.

.

D3 ensures that the left side of the 1.5uF cap will never go more than the voltage drop of D3, around 0.7V negative.

.

D4 a zener diode, sets how negative the gate of T2 can go, when the pickup coil goes negative.

.

Poorly designed circuit, or a case of the “money guys” wanting the engineers to cheapen a better design.

.

Hope it helps, but I can’t see any date on the posts (???), or a direct way to reply to a particular post.

.

/Søren

Hi Swagatam!

In the circuit of the link below, does diode D3 and D4 have a function to partially recharge the capacitor? I ask this because the primary of the coil generates oscillations after the spark is generated, can it be reused?

Hi Marcelo, sorry I can’t figure out the function of the diodes…

Hi Swagatam

I’m just looking at your CDI design. I’m about to construct it but I have a couple of questions I hope you can answer?

1/ In the first graphical design the cathode of the bt151 goes directly to ground but in the circuit diagram below that image the cathode goes to ground via an in4007 diode. I take it the first diagram in correct and the schematic is wrong? Please advice.

2/ If Ignition timing is to be advanced or retarded, Im guessing the only way to do that would be to set up the motorbike timing to be fully advanced then process a delay through an arduino or similar cpu to retard the ignition timing, dependent on the rpm?

Thanks and regards Steve

Hi Steve, the schematic and the PCB drawing are both exactly the same. In both the designs, the cathode of the SCR goes directly to the ground.

Advance retard can be done by special circuits with the help of the triggeres obtained from the pickup coil

Hi Swagatam, oops I didn’t spot the ground line. I was looking in the wrong place 🙂

Am I right in assuming D1 could be omitted as could R5?

R5 is operating as a part of a voltage divider bringing the voltage at the gate down to 7.69volts but the BT151 will handle the 12volts from the pickup without needing to drop the voltage. Is there a reason why you did that?

If D1 is blocking voltage to ground, couldn’t that be omitted too?

Thanks

Steve

No problem Steve!

I think nothing should be omitted in the circuit since the design is tested professionally in automobiles with perfect results, so I won’t recommend modifying anything in the design. Every part has some relative function and should not be omitted.

Hi Swagatam

I’m just trying to work out how to obtain the 12 volt signal from the pulser coil of a Yamaha DT200LC to input to your CDI unit. I believe from the bikes wiring diagram the pulser coil only has 2 wires so I’m uncertain how to obtain a 12v pulse from it.

I’m guessing it’s a Hall Effect sensor and the 12volts is generated by the pulser coils when the pulse magnet passes the sensor, the sensor not having any power supply and one side of the coil goes to ground? I’m guessing this based on the fact the bike will run without a battery fitted so presumably no power is being sent to the pulser coil.

Do you have any ideas that could help me sort out the issue?

Thanks

Steve

Hi Steve, yes the trigger input to the CDI can be through a Hall effect sensor and magnet assembly on the wheel, however, a Hall effect sensor cannot work withpout an external supply. You will need a 5V external supply from the alternator to feed the hall effect and then direct it to the CDI.

Linear Hall-Effect Sensor – Working and Application Circuit

Thanks Swagatam

Could the 5volt supply for the Hall effect sensor be taken from the 230volt low current AC from the alternator that is used to charge the CDI capacitor? I realise I will need to rectify and regulate the voltage.

I’m just trying to work out how to get the 12v signal from the Hall effect sensor to trigger the SCR 1.

If the bike normally runs without the need of a battery, the supply voltage for the Hall effect sensor must be coming from the alternator, but it comes via the CDI.

Any ideas?

Thanks

Hi Steve, yes you can extract any desired voltage from the alternator using the following capacitive power supply

Hi Swagatam

Thanks for all your help. Can the same voltage from the alternator to run both the capacitive power supply as well as supplying the voltage to the CDI capacitor C4?

Thanks again.

Steve

Hi Steve, yes the 5V will serve as the triggering voltage from the hall effect, and the 220V AC from the alternator can be used for the CDI

Hi, in your page there are many ideas for projects, great job congratulations, where can I find a circuit to test the CDI? do you have any diagram to make or what data do I want at the input in the green terminal and in the red terminal? white is a mass. Thanks.

Hi, thanks, please see the video, and replicate the set up exactly as shown in the video, you will be able to test the circuit in this way. See how two transformers are connected back to back to get a low current 220V for testing the CDI

Hi!

Great circuit. Would it be able to run a larger 3.3L 6 cyl tractor gasoline engine?

Thanks!

-RF

Hi, Thank you, yes it can be, the main capacitor will need to be increased to 2uF/400V or maybe 3uF/400V

Hello Schwagant

Build myself a hydrogen generator from Stangle Meyer without the use of chemicals, only with pure water. For this I need a pulse generator high current low pulse generator which is described by other providers with ultra-short pulse generator. I have a 12V 70 amp alternator in the car. Where can buy a ready-to-install pulse generator or a complete kit with instructions. Please help.

I’m from Germany (Bavaria)

Can’t translate English on the PC

Hi Andreas,

You can very easily build a 12V high current pulse generator using an IC 555 PWM circuit as shown in the following diagram:

Let me know if you have any further questions!

ist time on the internet !

i have a problem with a honda 1980 cg125 field bike im trying to fit a cdi to it.

no lights or no battery, just want it to run on a field

its an ac unit. can i use the black wire (1.5vAC) to trigger the cdi unit. the original pointswire

the are other wires on the plug 2v 4v 6v fron the genarator.ac

the cdi kit is a coil reg and cdi and a solanoid which i dont need,

ive tried to takeing the gen wire off the points and just used points earth to try and triggr the cdi ,no luck !

i do hope someone can help me with this problem ,thank you very much for reading this stephen.

The triggering signal must come from a pickup coil, or any arrangement that creates a single 5V or 12V pulse in response to each rotation of the wheel.

good morning Swagatam congratulations for the work presented – my engine has 2 pistons with 2-stroke operation but does not have a pickup coil trigger – it only has alternator ac current – it is a system used in all simple moped bikes – you can supply the model of the electrical diagram of the CDI? thanks for the help – Alvaro Tolda Lima

Thanks you Alvaro, you can definitely use the above design for your bike, it should work. However you will need a pickup coil triggering for the operations, so you may contact a qualified mechanic to get it installed in your bike too.

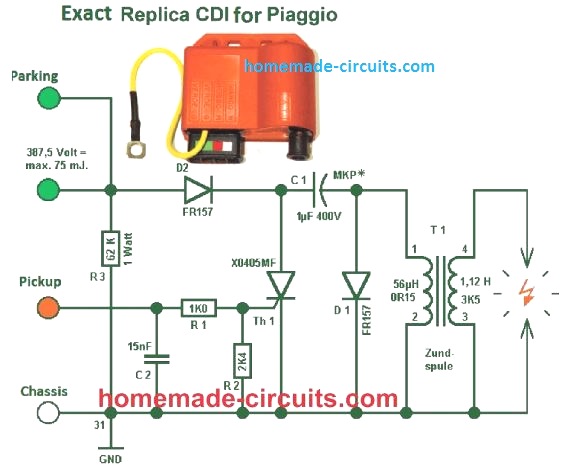

Hi dear Swagatam;

I’m from Brazil.

I have any problems with Vespa 200 CDI (Brazilian model use Ducati System).

The Indian replace are bad quality, and very expensives , because a hight tax in Brazil.

Do you have CDI diagram for this model ?

Look the Chinese and Indian CDI :

Hi Cleuzio, Reputed Indian brands are one of the best, may be you got a duplicate version. Yes, because of tax the good ones can be a lot more expensive in your country.

The CDI version explained in the above article is the universal design which can be used for all 2 standard wheelers

Thanks for the prompt reply! I guess I was not clear on my intended use? I need an astable operation that will provide the 3-4 pulses per second without an external trigger. In an attempt to conserve battery power, what would be the lowest freq that the charging oscillator can operate at to provide full charge at the 3-4 PPS? I do think I need another 555 to provide the astable trigger? Would a “divide By” circuit be a better option? to provide the wanted PPS

Yes that’s possible, the set up can be seen in the following article;

https://www.homemade-circuits.com/make-this-enhanced-capacitive-discharge/

I don’t think I understood the second part of your question, regarding the lowest frequency of a charging oscillator.

If you elaborate on the exact working principle of your circuit that may help me to understand it better.

Using the enhanced model How low of a freq cycle will the cap still be charger up enough to fire the coil? I am looking to fire a coil 3-4 times a second and will be run on batt power due to location. Will the 555 allow this or do I need to build a hybrid using a dual 555 (556) chip and run the oscillator at a higher freq and the second part of the 556 to run the spark freq?

The circuit given above is very much capable of firing 3 to 4 times per second, provided the pickp coil triggers the circuit at this rate.

There’s no need of any further enhancements.

Good evening, can I use a 250v 3uf capacitor instead of the 1uf one?

Hi, Cristian, You can use it!

Hi, could you elaborate transormers’ ground connection as they simulate coils?

The CDI is DC, and is operated with half AC cycle from the alternator…the ground is the body of the vehicle.

Sir i have made this cdi and i had connected it to my 2 stroke Yamaha rx 100

But it dint work can I know any troubleshooting for this problem I haven’t changed any parts but also it didn’t work

Prajwal, it will surely work, but you must test the results on work bench first before installation, so please check it as per the video set up. Basically you just have apply a low current 220V across the 200V terminals and a 12V pulse at the trigger input to verify the system.

Thanks for ur rply sir i did a another one and connected it and it was working.

OK, Glad it finally worked!

Can you please send me the schematic for a 2 stroke. i believe the Yamaha will work on my Kawasaki.

You can use the CDI which is described in the above article, it is a universal design for all 2/3 wheeler engines.

HI, have you ever built a cdi box for a Wisconsin s14d engine ? my Bolens 1477 tractor has this motor, new there $80.00 why the high price, well the cdi box is shot. Thanks

Hi, I haven’t built a CDI for a tractor engine!

HI, the simple CDI looks like a Yamaha PW 50 CDI box, could this CDI replace the CDI on the Wisconsin s14d engine ? Thanks

Hi, if the tractor ignition system works with a single spark plug then definitely this circuit can be used.

Thanks for sharing this post. Very informative and appreciate the detailed component list.

Few questions:

Q1) what exactly is the SCR doing? Is it like a ‘normally closed’ circuit between anode to cathode so that while capacitor is charging, anode is grounded through cathode – and then the trigger pulse into gate briefly breaks that ground sort of like when points open?

Q2) suppose i want to trigger the SCR with a micro controller (arduino). just send 5v pulse? how long of pulse? spark starts at beginning of gate pulse or end of gate pulse? figure it’s beginning, but perhaps my lack of understanding of SCR (Q1) requires spoon feeding.

Q3) at low revs, if i want to multiple spark, how long for cap to recharge before next pulse? since magneto pulses are sync’d on flywheel, would multiple spark only be possible with your ‘enhanced CDI circuit’ that is driven by IC555 and step up transformer?

Q4) not seeing component spec on step up transformer in enhanced circuit (Transformer 0-12V/220V/1amp).. do you have a PN or a link to cart it? *asterisk* on my need: current project is magneto bike with 6v battery and power bus for lights, but if you can kick me in right direction for that.

THANK YOU !

Thanks very much , Glad you liked the post!

1) SCR is normally open, and conducts when a trigger is applied at its gate. In the absence of a trigger the capacitor charges through the 200V input. When a trigger is applied the SCR dumps the charge across the ignition coil primary.

2) The timing of the pulse will need to be determined through an oscilloscope and with some trial and error The timing should be such that it allows optimal charging and discharging of the capacitor.

3) Again, this will need to be measured using an oscilloscope through practical tests.

4) The step transformer for the enhanced version could be any standard 12V /1 amp / 220V transformer. It can be procured from any reputed online store…it’s easily available.

what is the maximum voltage can produced by normal bike engine alternator.. like pulsar 150 (2007 model), if alternator is faulty what is the minimum voltage required to produce such arcs?

It is normally rated to produce 100 to 200V AC for the CDI coil. 75V to 100V AC is the minimum requirement for a good spark with at least 200mA current.

I have a problem with my Cdi motorcycle ..I want to modified the Cdi because my rpm around 7500 ..I want more ..normally which component I must be to change ? Please help me…

you can use this same design which is explained above, because if the RPM is 7500, your pick up coil will generate the triggering signals at this rate which will correspondingly trigger the coil at 7500 pulse rate.

However you can do one change, just place the diodes with BA159.

How i want modified my motorcycle from 8000rpm to 12000rpm

Hi,

.

4 pulses/second equals 240 pulses/minute no problem for a motor, or rather, probably not possible to keep a motor idling that low.

.

/Søren

Hello, I had opened my household generator as it is not starting. I think it might be the cdi. I want to know if this cdi will work or not ? If yes then i will be happy?. In your schematic diagram the pickup connection is single wire but on my generator engine the pickuphas two wire, how will i make the connection ? The pickup box is magnetic thing inside as metal gets attracted to it. Thank you.

Prosenjit, yes it should do the job for you! Out of the two wires one could be the negative or ground wire, please identify with a meter which wire is common with the ground line of the generator, once identified you can then connect it with the common ground line and use the other wire as the trigger input. If you are unable to identify use each wire randomly and check which one works.

Thanks for your reply. Now i understood the wiring. I will surely try that out. One more thing what is inside that pickup box, does it has any magnetic switch as it is magnectic. Thanks.

sure thanks! The pickup box normally has an iron cored coil which is triggered by a magnet fixed with the engine wheel, as the wheel rotates the magnet moves past the pick coil, and this induces a magnetic pulse in the coil, and this pulse output is used as the trigger for the CDI circuit.

Hello, I have a sea doo and the mpem (multi purpose electronic module) burnt a diode from a stator over charging it. I can not buy this board so i replaced the diode. The engine cranks and all works except I do not have spark. The board has a key security built in with no work around so I would like to build a cdi so I can bypass this unit. Its a 2 cylinder 2 stroke engine. Would any of the cdi schematics on this site work for me?

Thanks

Hi, you can surely use the CDI discussed in the above article, however it will work only if your system includes an integrated alternator and a pickup coil. Otherwise you may have to build one of the designs explained in the following post:

https://www.homemade-circuits.com/make-this-enhanced-capacitive-discharge/

Okay great. It has a pickup coil and a charging coil so this setup will work with 2 opposing firing spark plugs?

OK, in that case if the charging coil is able to generate around 100V to 200V this can be configured with the points marked 230V, and the pickup output can be connected with the points marked 12V…both with respect to the ground line.

Once hooked up and initiated, the High tension wire should start generating the required high voltage for the spark plug

This is all good news for me. Anyway I can send you a schematic showing what I have and what I want to replace with this cdi?

Sure! You can upload the image in any free image hosting site and provide the link, I’ll check it.

Here is the link to q screenshot of the ignition circuit.

https://drive.google.com/file/d/1IStxAoNOJdPuamQ17LDsBas1guowouHo/view?usp=drivesdk

Thanks for showing the wiring diagram, however I am not able to identify the pickup coil and the alternator inputs for the CDI, it seems the CDI coil is supposed to be all electronic, not sure.

So what I want is to cut out the electronic module (which includes the cdi) and just use the 2 coils (magneto in top right of the diagram) and built a cdi to power the ignition coil and get spark. I have looked all over and can not find a replacement module so this is a last option. Is it an option? Thanks again for all the help.

Using a multimeter identify the alternator output which produces 100 to 200V, and also the 12V from a pickup coil. Once these two are identified you can quickly integrate with the above shown CDI design for initiating the sparks

So my local store only has these options for the SCR

NTE5465 SCR

NTE5645 Triac

The direct converaion was NTE5466

Will either of those do?

The SCR specs are too low, it will blow instantly, the triac specs look OK, it can be tried, might work

NTE5466 looks much better, you can definitely try that

On the picture I sent you the link for it shows a YL and YL-BK leaving the magneto but does not show where they go. They go into a regulator rectifier and then those leads head back into the diagram. I used my meter and believe those yellow wires to be the AC but because they do not ground on the engine how would I integrate that into the CDI? Or do I need to use the circuit that uses a transformer and does not use the AC from the engine?

sorry it will be difficult for me to understand and trace your wiring diagram without a practical test, you may have to do it yourself.

If you can just find the pickup coil that would be enough, the CDI circuit could be run with a battery and integrated with your system quickly

Hello, friend. I need a cdi circuit for a kymco quannon 125, it burns to me original, I want to replace the burned parts, so I need a circuit of the capacitors, transistors, relays their strengths and specifications. Thanks in advance.

Hello friend, I am sorry at the moment I do not have any specific design for the mentioned model, so won’t be able to help in this regard.

Hi swagatam, i have yamaha outboard 4-strokes 9.9hp and my cdi is broken, can i replace old one using this method above? thanks in advance

HI OG, the discussed CDI is suitable for all general motorcycles, it may not work efficiently only in high speed racer motorcycles or other forms of enhanced bikes, you can give it a try, most probably it will work.

Hi !

Will this circuit works for Honda CR125 1996 2 Stroke (motocross) ?

Thank you !

Hi, according to me it should work….

hello.

Does it work on a 250cc motorcycle?

Thank you.

yes it will work

David

Would you please clarify if your motor-bicycle is for normal usage or for racing?

By the way, DAVID

You mentioned, you are new to electronics. So how are you going to handle it, even if you get some working circuit? Do you have soldering experience?

Oh Sorry Swagatam, I overlooked the new "LOAD MORE" bar.

Hi Abu-Hafss, most readers get confused due to the wrong placement of the "load more" button, If possible I'll try to shift it over the comment box soon, that will make it easier for the readers to know regarding the hidden comments.

WE will surely wait for the new article. Thanks for your interest and time!

Hi Sawagatam

I cannot see the following post (+ posts after this) in your blog despite of repeated reloading of the page:

Thank you Swagatam + Abu-Hafss

Thank you Guys for replying so quickly to my question!

Abu-Hafss- Are you asking for a picture of the magneto itself or a picture of the coil and how it is wrapped under the protective sheathing? here is a link to one like mine i found on ebay. i.ebayimg.com/images/g/NaMAAOSwR29ZE5We/s-l1600.jpg the magnet looks like this

@DAVID — Yes I wanted to see the coils inside the magneto cover. Anyway, I understood your required CDI is 2-wired self-triggered type used on motor-bicycles. That is slightly different from the one discussed in this article.

I shall post an article for that CDI but it might take a week or so, as I am bit engaged these days. I hope you can wait for a few days.

Hello

+Swagatam Majumdar,

I was curious if this application can be used in a single spark small 66cc 2 stroke motorized bicycle? I have no battery and engine is "push started" by release of clutch which spins the "magneto" which i assume acts as an alternator would but on a smaller scale. I have not measured the output of the magneto to the CDI that comes with this kit but I wish to get the best performance possible. I have a faulty CDI that does not produce enough to get spark from plug that is necessary. It is a solid state CDI. do you think that I could open it up somehow and upgrade the components and or repair this thing so it would work?

I apologizes all this circuitry stuff is pretty new to me.

thank you for your dedication and your willingness to share your vast knowledge! You are very inspirational in my desire to further understand circuitry and the whole bit!

Reguards, David

Thank you David for posting your question and trusting my knowledge. If you are new to electronics then definitely you would find it almost impossible to troubleshoot or repair any faulty electronic unit…moreover since it's a solid state version would have more sophisticated parts than what is presented in the above article.

The CDI explained in this article looks an ideal choice for your requirement, and in fact can be used for generating sparks on any vehicle that may be equipped to generate a minimum 60V AC, and has a pickup coil.

The 60V is used for activating the ignition coil which ultimately generates the high voltage for the sparks. The pick coil responds to the wheel rotation and triggers the CDI to generate the high voltage pulses at the same rate as the wheel rotation.

Even if the pick coil is absent, the high alternator output can be suitably dropped and used as the triggering source for the CDI coil.

So basically if your bike possesses the above then you could easily exploit the above design in your favor.

Hi David

The above circuit should work with your 66cc bike without any problem. However to ensure correct operation, it is advisable that you send us a photo of inside of your magneto.

Thank you Swagatam + Abu-Hafss

Thank you Guys for replying so quickly to my question!

Abu-Hafss- Are you asking for a picture of the magneto itself or a picture of the coil and how it is wrapped under the protective sheathing? here is a link to one like mine i found on ebay. i.ebayimg.com/images/g/NaMAAOSwR29ZE5We/s-l1600.jpg the magnet looks like this

if you need a picture of the coil of the magneto let me know and i will cut off the sheathing on an extra one i have and send you a link.

thanks again for your assistance!

one more Q: can all of the components that are required for this build be purchased at radio shack? Or is there a better place to acquire these types of special parts that you guys go to for items such as these?

I am having trouble locating the R4 = 56ohms is this a resistor? which is better to use a ceramic or ?? i found a 60Ohms resistor will this work?

http://www.allelectronics.com/category/530300/resistors/power-resistors/1.html

Thanks David, the ebay image is not opening for me.

the 56 ohm is a 1/2 watt resistor….however the value is not so critical, you can use any nearby value, such as 68 ohm, or even 100 ohm will do.

it can be as shown below:

projectpoint.in/thumb.php?f=image/data/CFR_1W_56E.jpg&w=400

60 ohms will work but try to get a CFR type as referred in my above comment, a wirewound type would also work but it's not necessary

Hi Swagatam,

I really enjoyed this article though I felt a bit lost in certain parts because even though I like electricity and electronics all I know I've learned "the hard way" ':). But my question is how do certain cdi's defer from other brands? Like I would like to apply this on your article to my yamaha dt125r but my bike is a bit of a transformer because it no longer has many stock parts. Like for example here in my country is very hard or very expensive to get original or oem parts, so I managed to make the bike rub without a cdi but I feel it is not as precise as it should, and the trial and error cost me a few more parts. In case you are interested what I did was i took out the pin on the crankshaft that allows the flywheel to be in the correct position so I could advance it or retard it, and so I plug the source coil wire directly to the ignition coil and placed the piston at TDC and made a small mark on the crankshaft to know when it is in TDC and also on the flywheel for reference, then I tried to kickstart the bike (it is a 125cc 2stroke) and if it didnt work i moved it bit by bit to find where i would get a kind of good spark but sometimes I got a recoil from it and made the engine run backwards, when it was a bit off of TDC it was not a problem because it would just run back instead of forward x) But if it was too close to TDC the recoil would crank the kickstart so hard it would break a few things, but it was fun though. So back to my question I would love to find a way to make my own CDI for my bike what specs would I need of the bike itself so I could build one?

Thanks in advance and best regards,

Thanks Robert,

I too enjoyed your adventures with your motorcycle and it clearly proves your innovative nature and skills. Since automobile is not my main field of work, I tend to forget quickly anything that I try to grasp in this field. Therefore I could not understand much the mechanical modifications you did in your bike.

However I am pretty sure that if your bike could work without a CDI then definitely it would do much better if the above explained CDI circuit was installed in your bike. Because the above design is an universal design and can be used for all regular bikes which are presently running on the roads throughout the world.

No doubt about it, and you can easily do it by assembling the little number parts indicated in the diagram, and simply hook them up with your bike's electrical.

I am sure you will be able to build the circuit and implement it successfully…. if you have any difficulty with the testing of the circuit, do feel free to post it here, I'll try to solve it out for you…

Hi Robert

Answering your question, the shape of the CDI unit is not important. Basically, there are two types of CDI unit i.e. AC-CDI and CD-CDI. Two different CDI units, different in shape/size for two different bikes can have same circuitry.

As you mentioned, if your bike has a source coil with high voltage output (about 180VAC) then the above circuit would definitely do the job provided the connections are correct.