In this post I have explained the fundamental tips and theories which may be useful for the newcomers while designing or dealing with basic inverter concepts. I have explained more.

What's an Inverter

It's a device which converts or inverts a low voltage, high DC potential into a low current high alternating voltage such as from a 12V automotive battery source to 220V AC output.

Basic Principle behind the above Conversion

The basic principle behind converting a low voltage DC to a high voltage AC is to use the stored high current inside a DC source (normally a battery) and step it up to a high voltage AC.

This is basically achieved by using an inductor, which is primarily a transformer having two sets of winding namely primary (input) and secondary (output).

The primary winding is meant for receiving the direct high current input while the secondary is for inverting this input into the corresponding high voltage low current alternating output.

What is Alternating Voltage or Current

By alternating voltage we mean a voltage which switches its polarity from positive to negative and vice versa many times a second depending upon the set frequency at the input of the transformer.

Generally this frequency is a 50Hz or 60 Hz depending upon the particular country's utility specs.

An artificially generated frequency is used at the above rates for feeding the output stages which may consist of power transistors or mosfets or GBTs integrated with the power transformer.

The power devices respond to the fed pulses and drive the connected transformer winding with the corresponding frequency at the given battery current and voltage.

The above action induces an equivalent high voltage across the transformer secondary winding which ultimately outputs the required 220V or 120V AC.

A Simple Manual Simulation

The following manual simulation shows the basic operating principle of a center tap transformer based push pull inverter circuit.

When the primary winding is switched alternately with a battery current, an equivalent amount of voltage and current is induced across the secondary winding through flyback mode, which illuminates the connected bulb.

In a circuit operated inverters the same operation is implemented but through power devices and an oscillator circuit which switches the winding at a much faster pace, usually at the rate of 50Hz or 60Hz.

Thus, in an inverter the same action due to fast switching would cause the load to appear always ON, although in reality the load would be switched ON/OFF at 50Hz or 60Hz rate.

How the Transformer Converts a given Input

As discussed above, the transformer usually will have two winding, one primary and the other secondary.

The two winding react in such a way that a when a switching current is applied at the primary winding would cause a proportionately relevant power to be transferred across the secondary winding through electromagnetic induction.

Therefore suppose, if the primary is rated at 12V and the secondary at 220V, an oscillating or pulsating 12V DC input to the primary side would induce and generate a 220V AC across the secondary terminals.

However, the input to the primary cannot be a direct current, meaning though the source may be a DC, it must be applied in a pulsed form or intermittently across the primary, or in the form of a frequency at the specified level, we have discussed this in the previous section.

This is required so that the inherent attributes of an inductor can be implemented, according to which an inductor restricts a fluctuating current and tries to balance it by throwing an equivalent current into the system during the absence of the input pulse, also known as flyback phenomenon.

Therefore when the DC is applied, the primary stores this current, and when the DC is disconnected from the winding, allows the winding to kick back the stored current across its terminals.

However since the terminals are disconnected, this back emf gets induced into the secondary winding, constituting the required AC across the secondary output terminals.

The above explanation thus shows that a pulser circuit or more simply put, an oscillator circuit becomes imperative while designing an inverter.

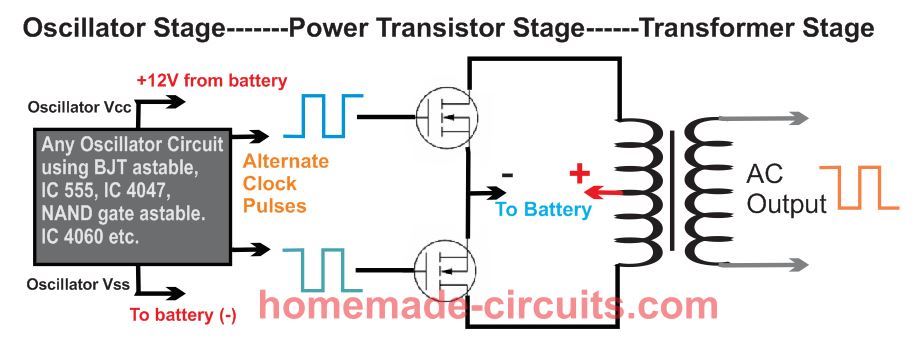

Fundamental Circuit Stages of an Inverter

To build a basic functional inverter with reasonably good performance, you will need the following basic elements:

- Transformer

- Power Devices, such as N-channel MOSFETs or NPN Biploar Power Transistors

- Lead Acid Battery

Block Diagram

Here's the block diagram which illustrates how to implement the above elements with a simple configuration (center tap push-pull).

How to Design an Oscillator Circuit for an Inverter

An oscillator circuit is the crucial circuit stage in any inverter, as this stage becomes responsible for switching the Dc into the primary winding of the transformer.

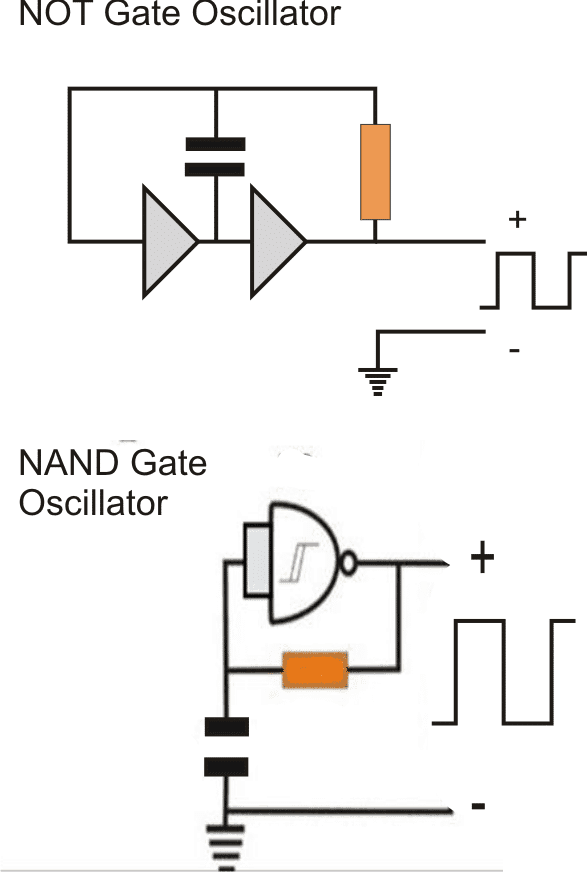

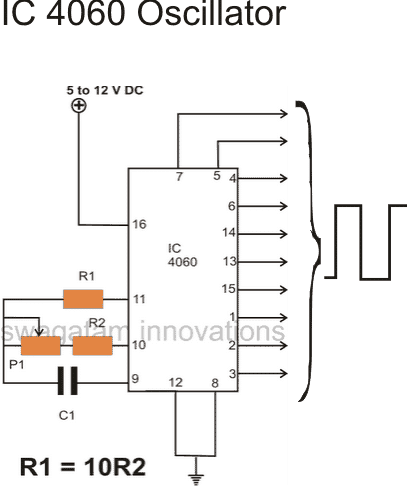

An oscillator stage is perhaps the simplest part in an inverter circuit. It's basically an astable multivibrator configuration which can be made through many different ways.

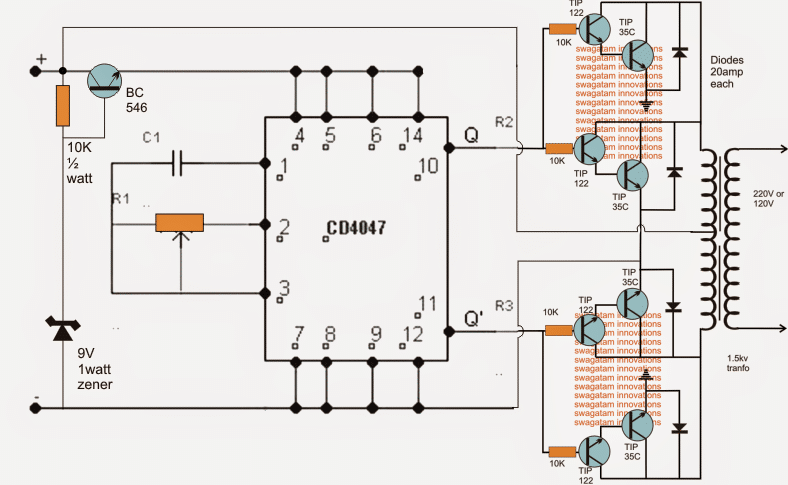

You can use NAND gates, NOR gates, devices with built-in oscillators such as IC 4060, IC LM567 or just utterly a 555 IC. Another option is the use of transistors and capacitors in standard astable mode.

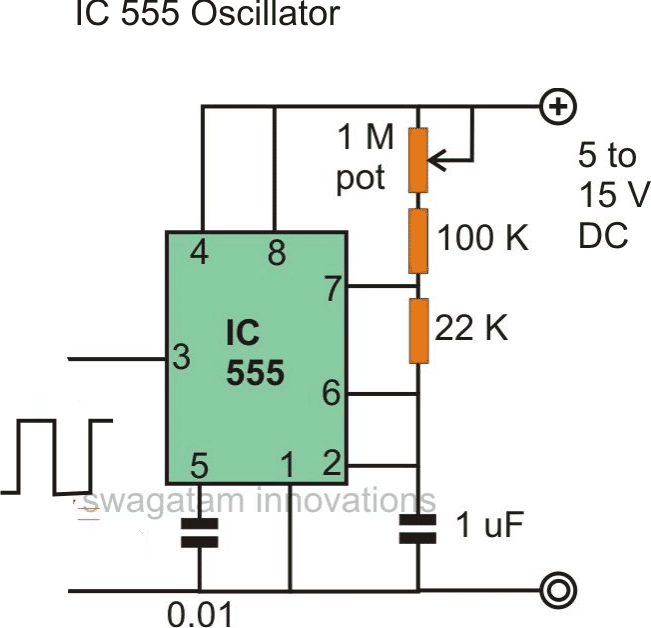

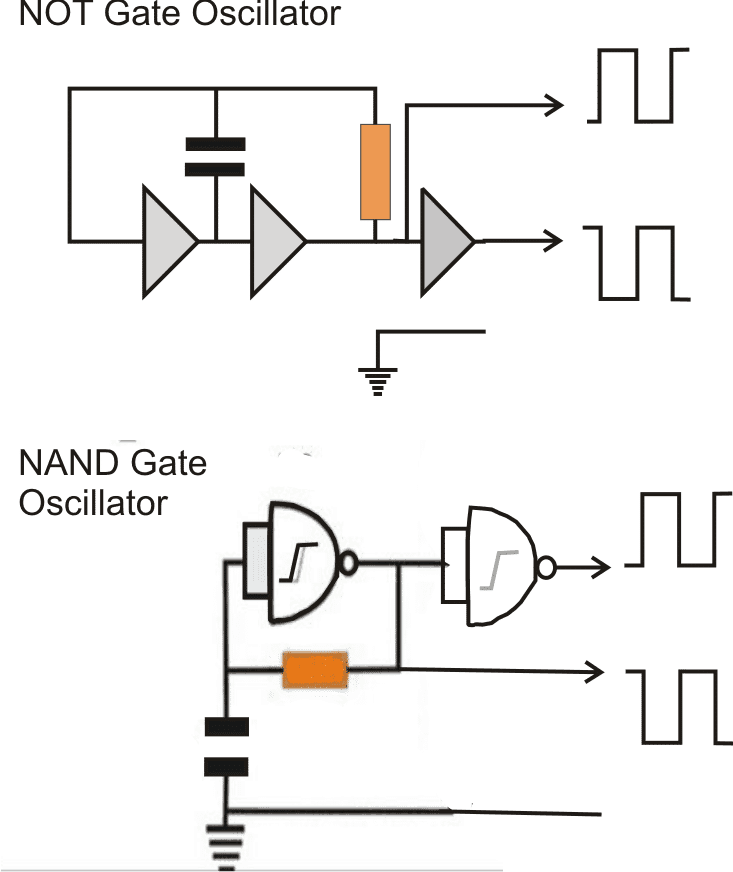

The following images show the different oscillator configurations which can be effectively employed for achieving the basic oscillations for any proposed inverter design.

In the following diagrams we see a few popular oscillator circuit designs, the outputs are square wave which are actually positive pulses, the high square blocks indicate positive potentials, the height of the square blocks indicate the voltage level, which is normally equal to the applied supply voltage to the IC, and the width of the square blocks indicate the time span for which this voltage stays alive.

The Role of an Oscillator in an Inverter Circuit

As discussed in the previous section, an oscillator stage is required for generating basic voltage pulses for feeding the subsequent power stages.

However the pulses from these stages can be too low with their current outputs, and therefore it cannot be fed directly to the transformer or to the power transistors in the output stage.

In order to push the oscillation current to the required levels, an intermediate driver stage is normally employed, which might consist of a couple of high gain medium power transistors or even something more complex.

However today with the advent of sophisticated mosfets, a driver stage may be completely eliminated.

This is because mosfets are voltage dependent devices and does not rely on current magnitudes for operating.

With the presence of a potential above 5V across their gate and source, most mosfets would saturate and conduct fully across their drain and source, even if the current is as low as 1mA

This makes conditions hugely suitable, and easy for applying them for inverter applications.

We can see that in the above oscillator circuits, the output is a single source, however in all inverter topologies we require an alternately or oppositely polarized pulsing outputs from two sources. This can be simply achieved by adding an inverter gate stage (for inverting the voltage) to the existing output from the oscillators, see the figures below.

Configuring Oscillator Stage to Design Small Inverter Circuits

Now let's try to understand the easy methods through which the the above explained with oscillator stages can be attached with a power stage for creating effective inverter designs quickly.

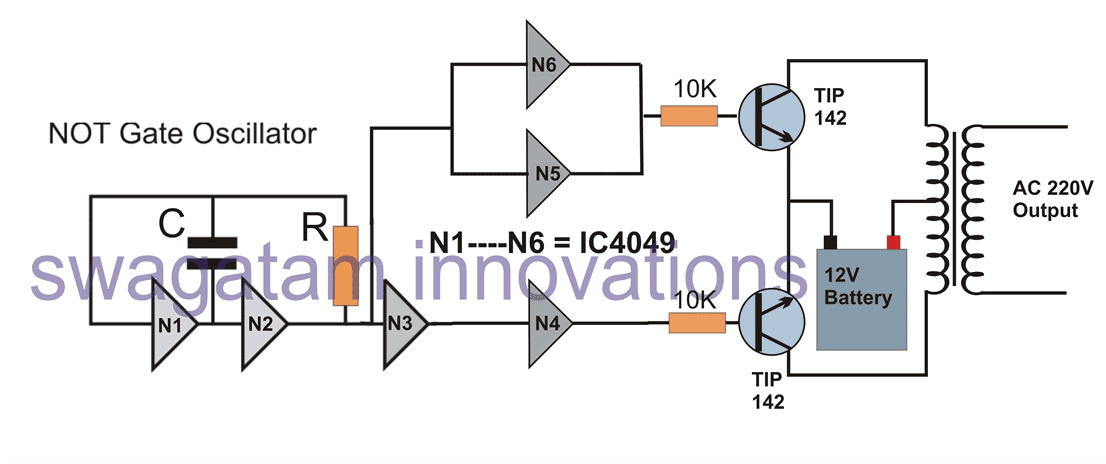

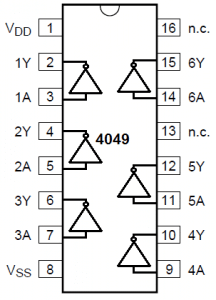

Designing an Inverter Circuit using NOT Gate Oscillator

The following figure shows how a small inverter can be configured using a NOT gate oscillator such as from the IC 4049.

Here basically N1/N2 forms the oscillator stage which create the required 50Hz or 60Hz clocks or oscillations required for the inverter operation. N3 is used for inverting these clocks because we need to apply oppositely polarized clocks for the power transformer stage.

However we can also see N4, N5 N6 gates, which are configured across the input line and output line of N3.

Actually N4, N5, N6 are simply included for accommodating the 3 extra gates available inside the IC 4049, otherwise only the first N1, N2, N3 could be alone used for the operations, without any issues.

The 3 extra gates act like buffers and also make sure that these gates are not left unconnected, which can otherwise create adverse effect on the IC in the long run.

The oppositely polarized clocks across the outputs of N4, and N5/N6 are applied to the bases of power BJT stage using TIP142 power BJTs, which are capable of handling a good 10 amp current. The transformer can be seen configured across the collectors of the BJTs.

You will find that no intermediate amplifier or driver stages are used in the above design because the TIP142 itself has an internal BJT Darlington stage for the required in-built amplification and therefore are able to comfortably amplify the low current clocks from the NOT gates into high current oscillations across the connected transformer winding.

More IC 4049 inverter designs can found below:

Homemade 2000 VA Power Inverter Circuit

Simplest Uninterrupted Power Supply (UPS) Circuit

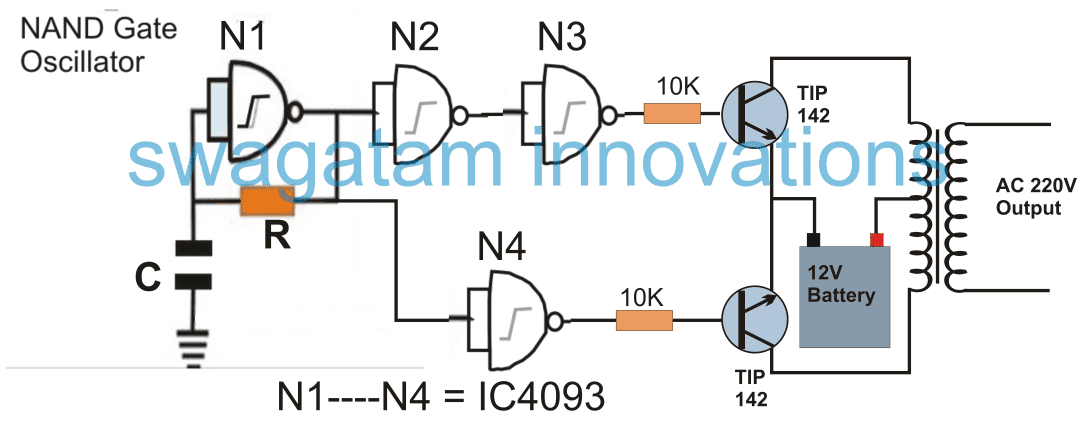

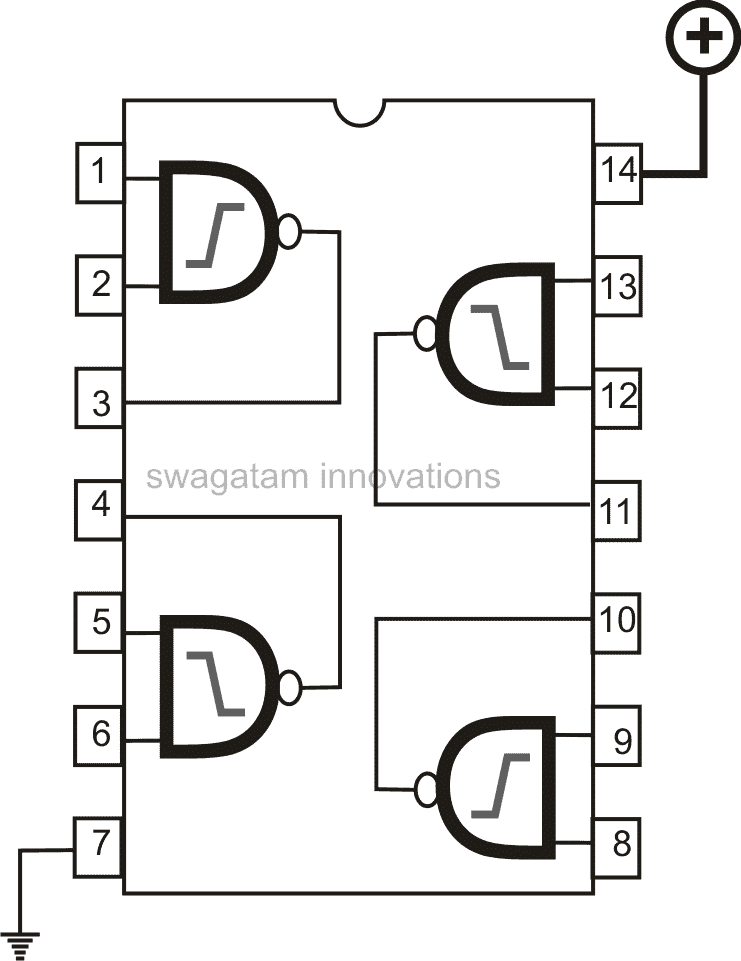

Designing an Inverter Circuit using Schmidt Trigger NAND gate Oscillator

The following figure shows how an oscillator circuit using IC 4093 can be integrated with a similar BJT power stage for creating a useful inverter design.

The figure demonstrates a small inverter design using IC 4093 Schmidt trigger NAND gates. Quite identically here too the N4 could have been avoided and the BJT bases could have been directly connected across the inputs and the outputs N3. But again, N4 is included to accommodate the one extra gate inside the IC 4093 and to ensure that its input pin not left unconnected.

More similar IC 4093 Inverter designs can be referred from the following links:

Best Modified Inverter Circuits

How to Make a Solar Inverter Circuit

How to Build a 400 Watt High Power Inverter Circuit with Built in Charger

How to Design an UPS Circuit – Tutorial

Pinout diagrams for the IC 4093 and IC 4049

NOTE: The Vcc, and Vss supply pins of the IC are not shown in the inverter diagrams, these must be appropriately connected with the 12V battery supply, for 12V inverters. For higher voltage inverters this supply must be appropriately stepped down to 12V for the IC supply pins.

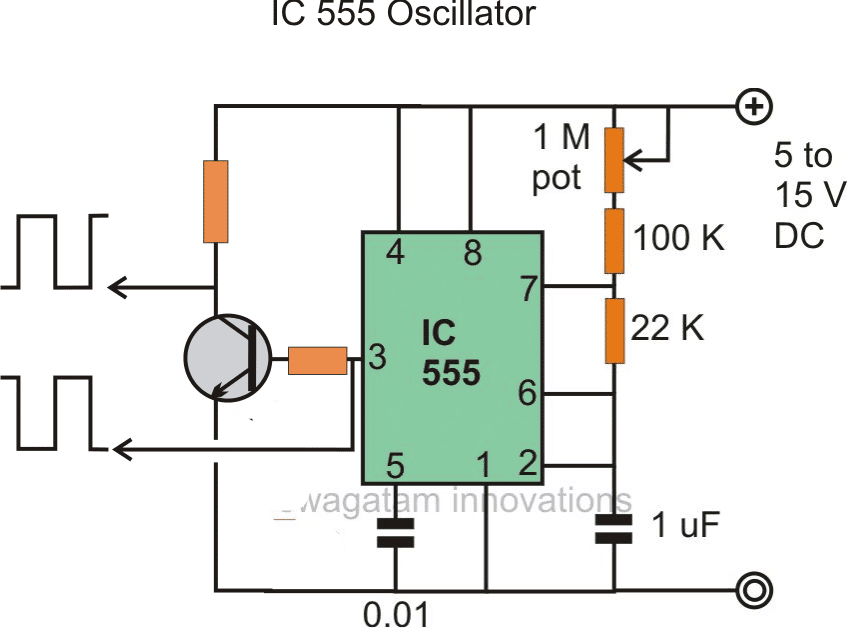

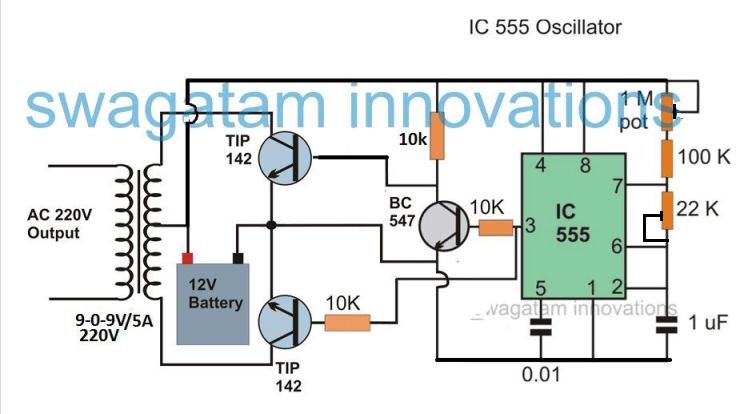

Designing a Mini Inverter Circuit using IC 555 Oscillator

From the above examples, it becomes quite evident that the most basic forms of inverters could be designed by simply coupling a BJT + transformer power stage with an oscillator stage.

Following the same principle an IC 555 oscillator can be also used for designing a small inverter as shown below:

The above circuit is self explanatory, and perhaps does not require any further explanation.

More such IC 555 inverter circuit can be found below:

Simple IC 555 Inverter Circuit

Understanding Inverter Topologies (How to Configure the Output Stage)

In the above sections I have explained about the oscillator stages, and also the fact that the pulsed voltage from the oscillator goes straight to the preceding power output stage.

There are primarily three ways through which an output stage of an inverter may be designed.

By Using a:

- Push Pull Stage (with Center Tap Transformer) as explained in the above examples

- Push Pull Half-Bridge Stage

- Push Pull Full-Bridge or H-Bridge Stage

The push pull stage using a center tap transformer is the most popular design because it involves simpler implementations and produces guaranteed results.

However it requires bulkier transformers and output is lower in efficiency.

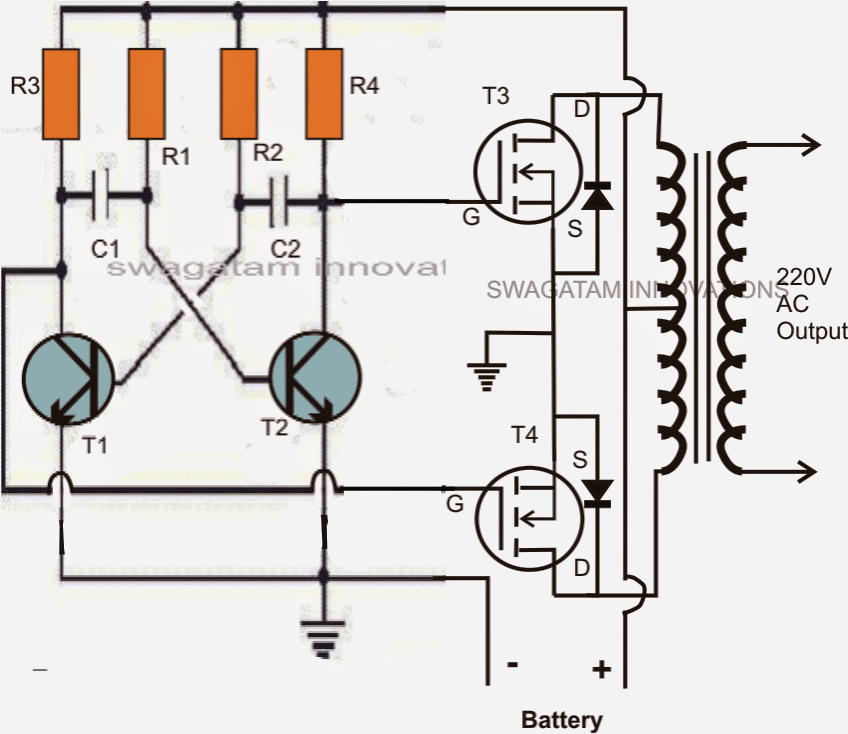

A couple of inverter designs can be seen below which employs a center tap transformer:

In this configuration, basically a center-tap transformer is used with its outer taps connected to the hot ends of the output devices (transistors or mosfets) while the center tap either goes to the negative of the battery or to the positive of the battery depending upon the type of devices used (N type or P type).

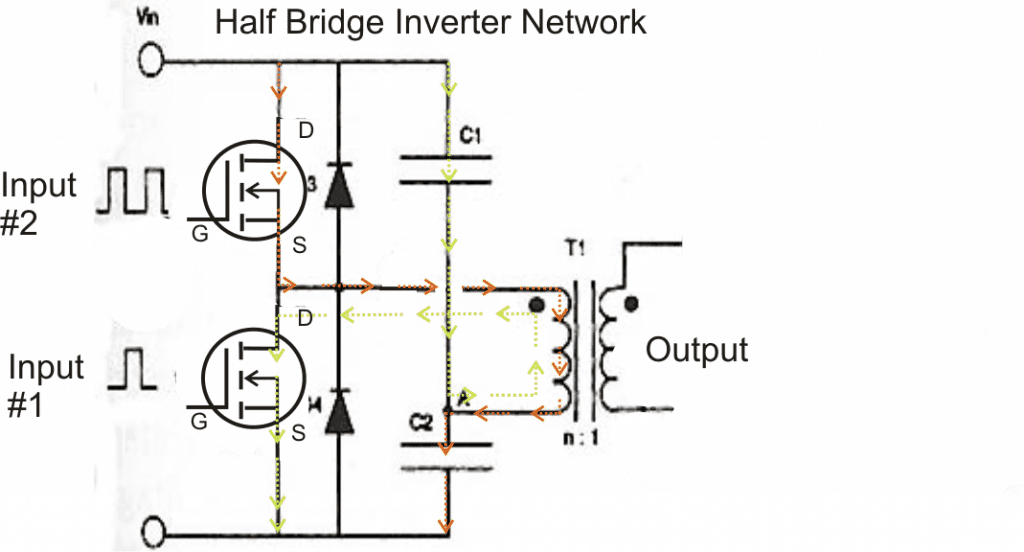

Half-Bridge Topology

A half bridge stage does not make use of a center tap transformer.

A half bridge configuration is better than a center tap push pull type of circuit in terms of compactness and efficiency, however it requires large value capacitors for implementing the above functions.

A full bridge or an H-bridge inverter is similar to a half bridge network since it also incorporates an ordinary two tap transformer and does not require a center tap transformer.

The only difference being the elimination of the capacitors and the inclusion of two more power devices.

Full-Bridge Topology

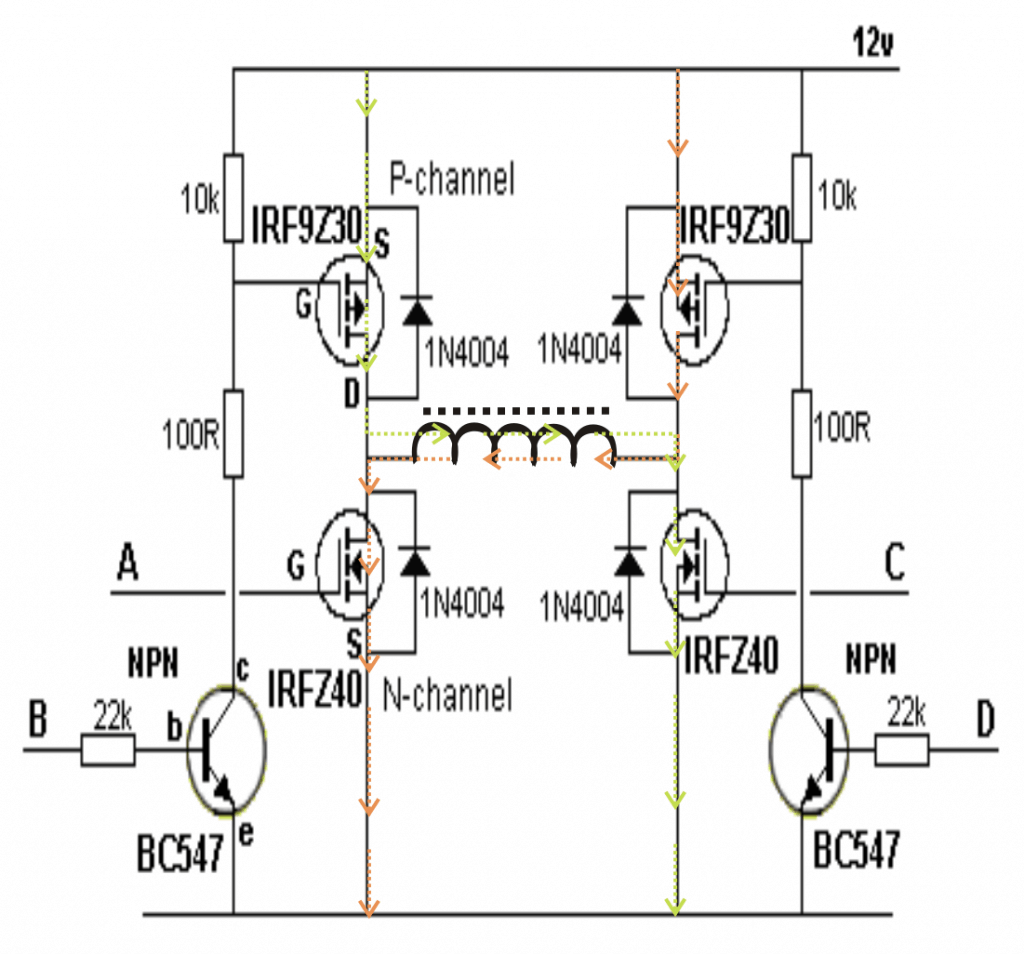

A full bridge inverter circuit consists of four transistors or mosfets arranged in a configuration resembling the letter "H".

All the four devices may be N channel type or with two N channel and two P channel depending upon the external driver oscillator stage that's being used.

Just like a half bridge, a full bridge also requires separate, isolated alternately oscillating outputs for triggering the devices.

The result is the same, the connected transformer primary is subjected to a reverse forward kind of switching of the battery current through it. This generates the required induced stepped up voltage across the output secondary winding of the transformer. Efficiency is highest with this design.

H-Bridge Transistor Logic Details

The following diagram shows a typical H-bridge configuration, the switching are made as under:

- A HIGH, D HIGH - forward push

- B HIGH, C HIGH - reverse pull

- A HIGH, B HIGH - dangerous (prohibited)

- C HIGH, D HIGH - dangerous (prohibited)

The above explanation provides the basic information regarding how to design an inverter, and may be incorporated only for designing a ordinary inverter circuits, typically the square wave types.

However there are many further concepts that may be associated with inverter designs like making a sine wave inverter, PWM based inverter, output controlled inverter, these are just additional stages which may be added in the above explained basic designs for implementing the said functions.

We will discuss them some other time or may be through your valuable comments.

Commendable article. Impressively designed and narrated

Thank you! Glad you found it useful.

There is an engineering-level series on inverter design optimization in the newsletter at how2power.com It has 23 parts and has been running for over a year, with inverter design articles in nearly every issue.

OK, thanks, nice to talk to you, by the way, i’m from Tanzania, nice to meet you, thanks for replying my question

You are welcome fadhili…

hi dude, is a JT also classified as inverter..??? i was really wonder about JT, i’ve build ones to drive a 15W LED lamp (normally it’s 220Vac supply)…

i was sukses driving this 15w led using a JT (using 12v dry cell as supply) but the Transistor (C5192) was very hot… have any idea to cool it down without using fan..???

Sorry, I have never heard of JT, so not sure what exactly it is and how it may be related to an inverter? You can keep the transistor cool by replacing the transistor with higher rated one and by attaching a large heatsink to it. You can try using a TIP122 transistor

really don’t know about JT, Joule-thief, a simple blocking oscillators.. just type “JT” in google search box and you ‘ll find the result

NO, searching JT in Google does not produce the result Joule-thief.

You could have simply mentioned Joule-thief instead of writing JT.

ooopppsss… OK dude, it’s my bad…. bact to the main question, is Joule-Thief classified as an inverter too.. and how to make the transistor cooler, instead having a bulky heatsink nor using fan, i’m install it in my motorcycle as a lighting, so the bulk heat-sink is the problem it self…

Joule Thief is not an inverter. It is a simple voltage booster or step-up converter circuit that can efficiently drive a load using a low-voltage power source, such as a single-cell battery. The primary purpose of the Joule Thief is to extract the remaining energy from a nearly depleted battery that would otherwise be considered unusable.

You can try a bigger transistor such as a TIP35, if it still heats up then there’s no other alternative but to use a heatsink.

thank’s dude, i was done attached a heatsink in my circuit at first, the transistor gone heated-up ’cause i decrease the bias resistor, when i use 1K the transistor stay cool (Vout = 97Vdc), but the light seem too dim… then i decrease the R to 330 ohm, the light seems brighter (Vout = 125Vdc) but the Tr goes to heat,..this is the problem,..

i was wonder how the ideal value for Rb and the ideal Np/Nf for the inductor,.. may with the ideal value for both the led still bright, but the transistor stay cool…

NB :

Np = Turn of Primary winding

Nf = Turn of Feedback winding

Rb = value of Bias Resistor

The transistor is getting hot because it is being driven with overload and over current. I have suggested you the transistor number in my previous comment, you can use that to keep the transistor cooler.

OK, thanks man, nice to talk to you, by the way, i’m from indonesian, nice to meet you, thanks for replying my question,

No problem Dwi, Glad to talk to you. Let me know if you have more questions.

What is the best material that can be used for the outer casing of the invertor

Aluminum.

A group of us, in a third world country Nigeria, got together, bought components and had a technician put it together to give a 3.5kva inverter that functions perfectly.

We now wish to incorporate a remote monitoring and control system to be able to remotely switch on and off as well as monitor data from the system so as to ensure optimal operation at all times.

Neither we the owners, nor our technician knows how to go about it.

Kindly assist.

Hello, that might require too many complex circuits and networks, moreover the range will not be more than 50 meters.

How do I repair an inverter with output short-circuited?

If the output was shorted then probably the mosfets are blown….you will have to check the mosfets

How do i repair an inverter which will not power on but the fuse and power button are good

You must check whether the output wires are broken or not or whether the inverter is switching ON or not using the battery power.

Hi, thanks for coming up with this site, it has helped me alot in some projects.

Please I am trying to build 1kva inverter, can you guild me please?

Thanks

Hi, 1 kva inverter will require a 36V or 48V battery….you can refer to the following design, and try building it:

1500 watt PWM Sinewave Inverter Circuit

Hello sir, am a hobbyist and also a student in this descipline sir, I wanted to build an inverter using an old 2000watts stabilizer transformer core, I have been watching some YouTube videos on how to obtain the required parameters needed like TPV, SWG and Number of MOSFET to use supposed I want to build a 1kva inverter.

Please sir how do get all that from the transformer core size or Bobbin core area? Looking forward to your response sir thank you

Hello Aliyu, you will need a center tap transformer such as 12-0-12V or 9-0-9V, for a 12V powered inverter. You will have to check the existing transformer whether such a winding is available or not. If it is available then you can use it for making an inverter.

Pls sir, what kind of oscillator stage is used with either full or half bridge

Square wave and sine wave oscillators are used for making all types inverters.

Thanks for a wonderful explanation here

Thanks, glad you liked it!

I once drove an inductive load with an inverter. Turning off the load broke the inverter. However, I cannot find where the circuit failed. Where would you expect an inverter to fail under an inductive load?

Mostly it could be the power devices (MOSFETs, IGBTs) that might have burned, so you can isolate the power devices from the main circuit and check if they are OK or blown.

Good day sir, please I have this smiley su-kam 1.4KVa inverter showing high voltage output @ 280v. Even on load the voltage is still 280v. It’s burned about 3 incandescent bulbs already, I tried varying the two potentiometer on the PCB, no change was noticed, I even went ahead to change the PT but all still the same. What is the possible cause and solution to it sir. Thanks.

Hi Shankar, it seems the feedback control system is not working correctly, or malfunctioning. You will have to identify how the feedback system is configured from the AC output to one of the the IC input pins, and then troubleshoot why this feedback is not working for the output voltage correction

Hello please am new to electronics and i want to build, a pure sine wave inverter, any help from anybody here please.

thank you

Thank you sir for your impact.

Please sir I need 1000watt inverter circuit

Eben, you can try the following one

500 Watt Inverter Circuit with Battery Charger:

Use two MOSFETs in parallel on each channel

Battery must be 500 Ah minimum

I really appreciate your effort sir for the kin knowledge.

I build an inverter using SG3524 in the oscillator stage and 8 IRF3205 With a 12-0-12 transformer that is a 24v transformer after building the circuit it was giving me an output voltage of 175v but when I connect a load of 60watt the voltage begins to countdown. Am using a 12v battery of should I connect two 12v in series to power the circuit.

Please provide the wattage of the transformer and Ah value of the battery?

1000watt transformer with an input voltage of 220v and output of 24v then the battery is just 72Ah.

The power rating are quite substantial so 60 watt load shouldn’t have caused any drop. The transformer primary voltage should be slightly less than the battery voltage, so make sure this is also followed.

Sir what of if I connect two 12v battery in series to get 24v will the circuit work fine.

Whether it is a single 24V or two 12 in series, the effect will be the same.

What can I do to remedy the voltage drop

Your inverter has problems, so you must troubleshoot them, that’s the only remedy…

your transformer, battery, are oK…verify the MOSFeTs and the frequency of the oscillator

I must commend you for your efforts may God continue to bless you, sir I have question

In modified or sine wave inverter the transformer voltage is always equal to voltage at gate of the MOSFET i.e if the inverter is 12v the transformer voltage is 7v and for 24v it’s 14v my question is this how do this voltage charge a battery because to charge a 12v battery we need at least 14v and this inverter use the same transformer for both inverting and charging, how will this 7v at the transformer be increased to 14v and charge a battery

Thanks and best regards

The same transformer cannot be used for charging the battery. You will have to employ a separate transformer or a separate winding in the main transformer

Hello sir

How can I make a circuit for my 12v 0 12v 150ah inverter transformer

Hello Sir. I appreciate you for your wonderful and immense technical know how you been giving to the world. May God reward you for not with holding your knowledge.

Please sir, I want to ask a question and I wish there is a way to attach a file for clarity sake.

Nevertheless, why is the terminals (+ -) of a Battery UPS (Blue Gate 2kva) connected to the heatsink of the Mosfets instead of the terminals of the Mosfets?

Again can you help reproduce the schematic diagram of the above mentioned.

Thank you Emmy, +/- both connected with the heatsink sounds strange. The tab of a MOSFET is normally kept isolated from any connections. it can be difficult to judge the situation in your UPS unless we know the specifications of the MOSFET used.

Hello sir,

Your work always inspire me and allows me to think out of the way.

Sir I need your help, as I am designing DC-AC inverter, but the the DC voltage is 3 – 4.2 vDC as I am using li-ion 3.7 v battery to get 60vAC at the output. Also I am using solar panel for battery to charge.

I do referred the about circuit and tried, but I am not able to get the required output.

Please refer the modification from the about circuit that I should consider while designing circuit.

Thank you.

Thanks SSM, to make a 3.7 /60 V inverter, you will first need a 3-0-3V/60 transformer, do you have that??

I tried finding online, but was not able to found one. Is there any other way you can suggest me that will help me in designing the inverter.

thank you for the reply.

You may also try the following article:

https://www.homemade-circuits.com/7-simple-inverter-circuits/

No sir I was not able to find the 3-0-3v/60 transformer.

So what else are the options that I can use.

Is it possible to design the inverter without transformer?

Thank you for the help.

For transformerless inverter you will need a 84 v DC supply which will be then converted to 60 V AC through a full bridge inverter circuit

Hi Swagatam,

1)On your Mini Inverter using IC 555 Circuit. There is a resistor from Pin 4 & 8 on the IC going to BC547 collector and then to Pin 3 on the IC. Please give me the value of the resistor.

2) Also, I think that Pin 4 & 8 must be connected to +12V.

3) I would prefer to use TIP3055 instead of TIP142. Is this possible?

Your assistance will be much appreciated.

Regards

Jan

Hi Jan, I have joined the pin4/8 with the positive and have updated a new diagram for your reference.

You can use TIP3055 but you will have to connect another BJT with it to create a Darlington pair. The other BJT can be a 2N2222 transistor

Thank you Swagatam.

Much appreciated

Regards

Jan

You are welcome Jan!

Good day sir, please I want to know how to determine the numbers of drivers to be used for any inverter circuit. thanks

Hello Dewise, I did not understand your question correctly…

Hi..!!

Sir i need inverter(dc to ac) designing and its circuit diagram.

HELLO SIR I NEED A GUIDE ON HOW TO BUILD AN INVERTER CIRCUIT WITH REMOTE CONTROL

Hello Ebuka, you can use remote controlled rely to control the battery supply of any inverter. The remote circuit is given below:

https://www.homemade-circuits.com/simple-100-meter-rf-module-remote/

Hello sir, thanks for your good work in impact knowledge to many ,specially me in particular. I am a student of Electronic Engineering currently work on a project to design a DC-DC inverter , DC-AC inverter for solar energy Grid connected system,Please, i need your input and technical diagram will be valued.

Thank you Tony, I have many DC-AC, and DC-DC inverter circuits and a few GTI concepts which you can find through the search box above. Once you find a suitable one then I can guide you further with it.

please, i want the equation which using for design inverter

I am interested in electronics and I don’t have any prior knowledge of it. I want your tutelage and guidance.

I am 50 years and want to revolutionize the power system in my country, Nigeria with solar inverter.

Hope you will be of good assistance.

Thank you.

I wish you all the best, let me know if you have specific questions, I’ll try to help!

Thank you so much sir for your great work but i want to build pure sine wave inverter please add other necessary stage in this tutorial

Thanks…

No problem Andu, you can refer to the following page

https://www.homemade-circuits.com/?s=pure+sinewave

Thanks for always being there, Sir

Yesterday, I tested my inverter with a 12V 100AH battery, and immediately I pressed the switch, the wire heated up and even gave small sparks. I don’t understand the cause sir, please help.

Hi Eniola, which inverter design have you used, please show me the schematic? There’s certainly some problem with the oscillator or the power devices in your inverter,

connect a 12V 5 amp bulb in series with the battery positive, and troubleshoot the fault until the bulb stops illuminating with full power. Full illumination will indicate some serious problem or short circuit in your circuit.

Hi Swagatam Sir

I’ve been able to build the inverter following the circuit diagram you sent me.

But it is giving an output voltage of 54 volts, what can be the problem?? Can this be due to my transformer because I used a small 2A transformer to test it.

Hi Eniola, Is it without any load? In that case the transformer is the culprit, if it’s with load then the load may be more than 12 x 2 = 24 watts, because a 12V 2 amp trafo will produce less than 24 watts so anything higher than 20 watts will drop the output voltage drastically.

Hi Swagatam, Sir

What will be the output of the inverter if I use

(a) 8 IRF540N MOSFETS

(b) 6 IRFP250 MOSFETS

and which one will you prefer for a high power output?

Hi Eniola, mosfets are only switches, the maximum handling power of the mosfet depends on its drain/source current rating (Id), add the Id rating off all parallel mosfets, that will be the maximum handling power of the msofets. The actual power comes from the battery

Hi, dear Swagatam Sir

I need your help on battery charger design.

Is it necessary I use a voltage regulator such as LM7812 in the design of a 12V charger?

Can you send me the best battery charger circuit for a 12V, 150AH battery? What’s the best ampere rating for such a charger?

Hi Eniola, for a 150Ah battery the charging voltage will need to be 14V and the current around 15 to 20 amps. 7812 will not be required here.

you can try the following link:

https://www.homemade-circuits.com/opamp-low-high-battery-charger/

Hi, Swagatam Sir.

1. What is the right resistors and capacitors to be used with CD4047 and IRFP250N?

2. Can you give a detailed explanation (or link) to how to determine the right capacitors to be used in a circuit?

Hi Eniola,

4047 requires just a single resistor and capacitor. The resistor can be a 1/4 watt and capacitor can be an ordinary ceramic disc type. The values will depend on the required frequency output which can be solved either with trial and error or through the specified formula.

Capacitors are fundamentally charge storing and time delay determining components. So depending on the application this time interval can be calculated with formulas, and the charge/discharge function can be determined based on the capacitor’s uF value. Capacitors are also used for blocking DC and allowing AC

Some information can be read here:

https://www.homemade-circuits.com/understanding-capacitors-made-easy/

Good day.

Can you please send me two or three circuit diagrams for 1000watts inverter circuits.

Also, can I change MOSFETS for higher output?

Eniola, you can use any simple inverter circuit and convert it into a 1000 watt inverter simply by upgrading its transistors and tramsformer. Here’s the details

https://www.homemade-circuits.com/upgrading-low-power-inverter-to-high/

Hi Sir. You are really doing a great job.

Please, a friend’s inverter is faulty. The inverter got burnt, it’s still working but it’s smelling and vibrating. What’s the possible problems and solutions sir. Thanks

Thanks Eniola, If it’s working yet smelling and vibrating then most probably it’s the transformer that’s short circuited and getting burnt. Try changing the transformer and check the response!

Hi, about the Half-Bridge, kindly i need to know what type of capacitors? and how much value should be?

Hi, you can use any capacitor above 1000uF…

by doing normal soldering procedures

its working awesome sir.. just completed the circuitry..thanx alot.. hope someday i may be able to follow your footmarks.. i am damn passionate for electrical & electronics both..

so each n every words from you i read every article.. the way u explain to some NOOBs!!! thumbs up..!

keep up the good work sir.. coz some1 here idolizes u..!

good day sir!

That's great Paritosh,congrats to you. definitely you will be able to reach your goals very soon, just keep working hard, and feel free to comment and ask your queries here whenever you are stuck….

sir i am tired of mosfets blowing away.. got a centretapped trafo. from old frontech ups.

cd4047 with 2 irfz44 cant bear the load.. so shall i connect same mosfets in parallel or should i try anything else.. lyk irf540 or switching to 2n3055 circuit explained by you with 4049..

efficiency wise…!

Paritosh, you can try TIP142 BJT instead, and see how it performs.

2N3055 can also be tried but for that the IC 555's BC547 will need to be replaced with 2N2222, and its collector resistor with a 100 ohm 5 watt resistor

thanx for your guidance sir.. its an honor for me..!

gonna build the above & 2nd last circuit & inform u as soon it works,,!!!

have a nice day.

you are welcome Paritosh.

please guide me sir.. as irs2453 isn't availible here in local shops.. either 555 4049 etc any oscillator that can be a gud replacement.. 555 4049 4017 4047.. these are mostly availible in any rural areas..

desperatly waiting for your response.. ccoz u r the only 1 whoz schematics i n many others blindly trust..even on those which u not even tried yourslf..

btw i'd bought 12 mosfets.. only 5 are alive.. thanx for that post.. atleast it wont be diwali on my room next tym i try anything..;-)

you can try the second last mosfet circuit in conjunction with the 555 oscillator circuit from the above article.

for C1 and C2 initially try 100uF/25V Non-polar Caps

…sorry non-polar is not required, you can use the regular polarized caps for C1/C2

thanx alot sir for your quick response.. m trying to make an h bridge driver.. wont it gonna work with 555ic..??

i mean the oscillation.. then pin 3 to h bridge.. one straight n one through bc 547.????

waiting for your reply to begin my task..!!

for making an efficient H-bridge a driver IC is recommended, you can try other methods but you will face lots of troubles and blown parts with those methods….you can try the second last design from the above article, it's not as efficient as an H-bridge but might just do the job

i have an ups.. damaged board. tried to repair. but all in vain. its a 300w ups. its trafo is working good. during repair i bought 4 of its irfz44n.. so the thing is.. could you please guide me building a circuit for that.. it got a H kinda circuit n trafo isnt centre-tapped.. i tried making a circuit using tip127 n tip122 also with bc547 n mje3055… everything failed. i also have a 4047ic… its my humble request to please design a circuit using bc547, cd4047.. so that it may atleast provide 250w ac.. 300w trafo means has a capacity of atleast 20amps/12vdc. i am already having 3 of 12v 7.5AH batt…!!

please help as soon as possible..

thanx for all the circuits..

a 4047 IC inverter will require a center tap transformer, for a two wire transformer you will require an H-bridge driver circuit as explained in the following article:

https://www.homemade-circuits.com/2014/01/simplest-full-bridge-inverter-circuit.html

the "load" needs to be replaced with the transformer primary winding

let's give me the knowledge I I want to be 400 VDC 220VAC you are using diagram [email protected]

Hi Swagatam can you help me with something why is it that even though I have a dc circuit if I put it to measure ac it shows a voltage measurement

A DC content will always have some superimposed AC content which is also called ripple, therefore if measured in the AC range this will become apparent.

Hi sir i wanted to make a simple inverter, i saw a video on YouTube "Make an inverter : DIY Experiments [#2] power AC devices with battery ".circuit diagram is at end of video, there he use 12-0-12v(dc) to 220/230v(ac)transformer.but I'm not getting how much amps transformer he used ??

Is it ok if i use 12-0-12v to 220v&2amps transformer?if not suggest me a better one sir

Hi sir i wanted to make a simple inverter, i saw a video on YouTube "Make an inverter : DIY Experiments [#2] power AC devices with battery ".circuit diagram is at end of video, there he use 12-0-12v(dc) to 220/230v(ac)transformer.but I'm not getting how much amps transformer he used ??

Is it ok if i use 12-0-12v to 220v&2amps transformer?if not suggest me a better one sir

It will depend on how much load (watts) you intend to operate with the transformer output…just divide this requirement with 12V and you'll get the amp value….suppose you are planning to use 300 watt load with the trafo, then dividing this with 12V gives, 300/12 = 25 amps so you'll neeed a 12-0-12V/25amp/220V trafo for operating 300 watt load with a 14V/150AH battery

with 12V/2amps…the output power won't be more than 2 x 12 = 24 watts.

you can modify it and repost it that would be nice, probably getting it to use a 12v transformer would be nice because this circuit works well.

thanks, I may do it in my free time…

thanks it worked perfectly, I dont know how that worked but it did

Hii sir ,

What is value of resistance in 5th circuit

you can use 10k for both the resistors.

The lowest settings of the pot is 282hz and wen I adjust the pot it will go all the way to little above 1khz, it doesnt go as low as 50hz

remove the 500k preset from the shown position and connect it in series with the 10k resistor, now you'll be able to achieve lower values..

adjust the IC 555 frequency pot to acquire the desired frequency at the output of the inverter

?dl=0" rel="nofollow ugc"> ?dl=0

?dl=0

I have seen you made similar inverters to this, I tried this one, it works duty cycle is 50% and voltage would be ok if I used the correct transformer but the frequency is 282hz do you know how I coud get it to 50hz?

which one are you referring to? please provide me with the link?

Hi dear Swagatam, I intend to build a 1000 watt UPS with a different concept (inverter with high voltage input dc). I will use a battery bank of 18 to 20 sealed batteries in series each 12 volts/ 7 Ah to give a 220+ volts storage as input to a transformerless inverter. Can you suggest a simplest possible circuit for this concept which should include a battery charger + protection and auto switching by mains failure. Later I will include a solar power input too.

Hi Taiye,

I'll to post the design soon in my blog for your reference, please keep in touch.

with 5v out, gate driver won't be required.

what if I have a 12V out

Thanks a lot buddy 😀

MCUs don't have 12V out, but 12v would be also suitable for driving msfets directly.

Can etch and use this circuit with a load of 200W.

Thanks a lot

would I need a gate driver if i am generating the PWM from a micro controller?

Can u plz name some alternatives to the mosfets IRF9Z30 and IRFZ40 coz they arent available in my area

you can try IRF9540 and IRF540

Hi again, I hope you will soon be able to suggest a suitable circuit for my project requested in my last mail of March 17. …. Aquarius

Aquarius, please refer to this post:

https://www.homemade-circuits.com/2014/03/1000-watt-ups-circuit.html

My heartiest thanks for the circuit. i will build this one soon and let you know the result. Aquarius.

you are welcome!

Hi dear Swagatam, I am ur fan & have built many projects for my personal use with success & had a lot of pleasure. God bless you. Now I intend to build a 1000 watt UPS with a different concept (inverter with high voltage input dc). I will use a battery bank of 18 to 20 sealed batteries in series each 12 volts/ 7 Ah to give a 220+ volts storage as input to a transformerless inverter. Can you suggest a simplest possible circuit for this concept which should include a battery charger + protection and auto switching by mains failure. Later I will include a solar power input too.

Thank You Aquarius!

I'll try to post it soon and let you know, most probably I would publish it within a couple of days.

Hello Swagatam,

i need to convert 12v dc to 120v ac with at least 5 amp load capacity.

i need a suggestion what could use for my purpose.

could u suggest me ???

thank you

Hello Rudra,

you can try the circuit design shown in the following link:

https://www.homemade-circuits.com/2012/09/mini-50-watt-mosfet-inverter-circuit.html

sir i also want to know all information about inverter

Hello swagatam, will this circuit(link below) give me a modified sinewave?

4.bp.blogspot.com/-Uepf26wgJO0/TpQGZ-0QbHI/AAAAAAAABA4/lb51Ejk9SAs/s1600/12+to+220V+modified+sinewave+inverter.jpg

Hello ifeanyi,

yes it will work and give you a modified sine wave,.

Hi question = cncmesin but an investor to 220AC 220AC single phase of variable frequency from 50 to 400Hz you could make the sine wave generator integrated or L298 TB6560? and place suitable for 220V mosfet

thank you very much

Yes it's possible, thanks for the good suggestion!

hi,i need 1000w circuit diagram of ups

what is the use of bc547 or any transistor in this circuit

for making frequency.

hello sir

do you have 3 ph inverter design, in 1 ph 220v 0ut 3 ph 220V 400Hz, with simple design

thks

reply

I am sorry cnc, presently I do not have this design.

Hi

I m trying to make 12 v to 230vac

2000w

Please send, simple circuit,

Transformer details

12V/200 watt inverter will require a 166 amp transformer, and a 1000 Ah battery, is it possible to get them?

Hi Swagatam

I am trying to make 12 v to 230vac

2000w and 3000w

Please send, simple circuit,

Transformer details

Hi Nimai, if you use 12V to make 3000 W inverter then the current for the transformer will be 3000/12 = 250 Ampere….such a transformer looks unpractical, and unfeasible, therefore you must use a 48V battery, instead of 12V battery

You can try the following basic model first and then go on upgrading it with more mosfets for getting more power:

https://www.homemade-circuits.com/2012/09/mini-50-watt-mosfet-inverter-circuit.html

T1/T2 must be replaced with BC546 for 50V supply.

Good day,

Please make the basic design first and then we can gradually try upgrading it for more power.

No, the above circuits are not suitable for 48V, you can try the following design with 48V:

https://www.homemade-circuits.com/2012/09/mini-50-watt-mosfet-inverter-circuit.html

use BC546 for T1 and T2.