In this post we'll try to investigate the making of HHO gas in automobiles for enhancing their mileage by approximately 50% or more, that means a reduction of petrol or diesel consumption by the same amount.

In the previous post I tried to put forth an innovative design of a high voltage low current generator which could be used for splitting water into HHO gas (by decomposing the H2O bond into two parts of hydrogen and one part of oxygen).

Using a high voltage for the electrolysis allows the breaking apart of the water molecules by brute force without the need of a higher magnitudes of current (amps), which in turn makes the procedure extremely efficient.

We can understand the above logic by analyzing the following example:

Higher Voltage is more Effective

Suppose we have a 12V battery capable of delivering a maximum current of 7.5 amps, if we use this battery power for the electrolysis we would probably be implementing it very inefficiently and the power required for the electrolysis would easily exceed by far than the power of the accumulated HHO gas in terms of megajoules.

However if the same 12V/7AH is boosted to say around 20,000 voltage with a current as low as 5mA would be able to yield better results (many people might not agree with this).

Moreover since this high voltage is pulsed using a PWM circuit, the sharp rise and fall of the pulses adds up to the efficiency level of the process.

Many critics argue and don't substantiate the use of a high voltage for yielding higher efficiency, however the following few examples provide us sufficient logical evidence regarding why a high voltage could be more effective than using high current for the electrolysis of water.

Passing a low voltage, high current potential through a very high resistance could be useless because the current would be restricted by the high resistance and produce little effect on the process. Since pure water can be notorious with its resistance value (pure water may have a resistance as high as 200k or even more), a high current at low voltage would be quite ineffective.

On the contrary a higher voltage would be strong enough to tear apart the water high resistance and be comparatively more effective, even though a lot lesser number of electrons would be passing through, but nevertheless we would see electrons crossing over with better efficiency.

Assessing with Practical Examples

Just try applying a 12V/100amp through a 200k resistor and check the current with an ammeter, according to Ohms law it would be around I = 12/200000 = 0.00006amps or 0.06 mA, in contrast if a 20,000 volt is used we would find it to be capable of delivering I = 20000/200000 = 0.1 amps or 100mA, that looks much impressive, although we wouldn't want 100mA to be used for electrolysis in order to avoid explosions or atomization of water, we can expect about 10mA to be quite sufficient for the process.

Another example that looks quite relevant to the subject is our body itself, we experience a lethal shock when we come across a high voltage AC with any part of our body, but in contrast if we touch a lower potential input such as a 12V AC we might not feel anything regardless of how high the source may be rated with amperage.

The above example provides an authoritative proof regarding the power of high voltage in terms of its riping ability through high resistance passages, the same may be true with lightning thunder bolts which are equipped with millions of volts and that's why are able to knock out the huge atmospheric barrier and reach the earth surface.

Having said this, in the proposed use of HHO gas in automobiles one must be careful regarding not supplying the high voltage with high current, otherwise that might lead to an explosion inside the water and result in atomization of water molecules which is definitely not an electrolysis.

Installing HHO Fuel Cell in Automobiles for Enhancing its fuel Efficiency

Here we'll talk about using the HHO fuel cell idea in a motorbike and learn the procedure of installing and integrating it with a motorcycle engine.

In one of our previous posts I have explained how HHO gas could be produced using a high voltage CDI coil circuit, we will use the same design for the proposed implementation and for enhancing a motorcycle's fuel efficiency.

Since your motor cycle would be already having a CDI ignition system this could make things much easier for us, since we could simply borrow it's function for the discussed purpose.

However we must be careful about a couple of things: the sharing of the high voltage pulse from the existing CDI should not hamper the actual ignition of the bike for which the CDI coil is originally installed.

Secondly, we don't want the vehicle's alternator to work extra hard for compensating the sharing of the CDI sparks with our HHO fuel cell.

Using Spark Suppressor

The above situations can be countered by employing a spark arrestor resistor or a spark suppressor device. This device is normally used in series with the high tension input from the CDI before it enters the spark plug.

As the name suggests the spark suppressor is used for suppressing excessive voltage from reaching the spark plug thus helping to cancel out the generation of unnecessary RF disturbance and noise.

This means that in normal conditions the spark plug would be wasting a good amount of energy by shorting the high voltage across it's spark gap which apparently looks pretty small compared to the enormous voltage it's been fed.

The use of a suppressor ensures that the excess voltage which would otherwise become wasted in the spark plug now gets restricted and is converted to heat, which is again a wasted energy unless it's diverted for some useful purpose.

The utilization of a spark suppressor resistor and by diverting the excess energy from the CDI coil to the HHO cell appears to be a smart move.

Circuit Diagram

WARNING: THE DESIGN EXPLAINED BELOW INVOLVES EXTREME HIGH VOLTAGES WHICH CAN BE LETHAL IF TOUCHED IN AN UNCOVERED CONDITION. EXTREME CAUTION IS ADVISED WHILE CHECKING OR HANDLING THIS EQUIPMENT. HHO GAS IS DANGEROUS, AND CAN LEAD TO EXPLOSIONS, AGAIN EXTREME CAUTION IS ADVISED WHILE GENERATING THIS GAS. THE AUTHOR CANNOT BE HELD RESPONSIBLE FOR ANY ACCIDENTS WHATSOEVER DUE TO NEGLIGENCE OF THE USER.

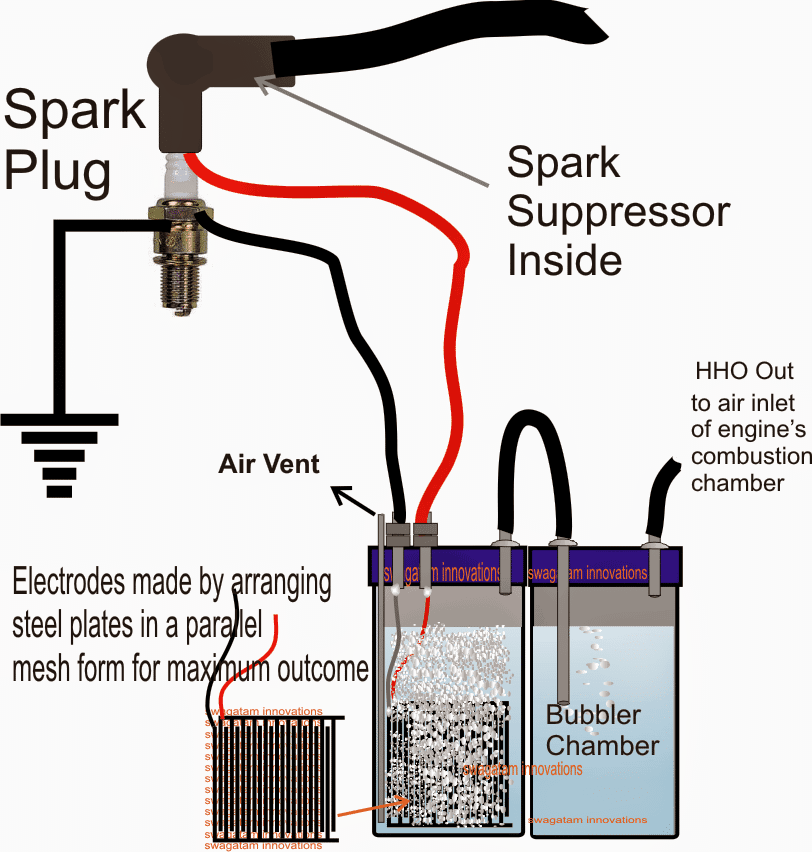

An easy to understand set up for generating "on demand HHO gas" can be witnessed in the above diagram.

The electrodes are made out of good quality stainless steel pates which are appropriately arranged in a mesh like formation through a face to face intersection but without touching each other.

Using Baking Soda to Increase Efficiency

A little baking soda is added in the water for speeding up the electrolysis process and assisting the electrons to flow with greater efficiency.

In the left container we can see an air vent pipe, this is introduced to allow air to pass inside the vessel as the water is electrolyzed into HHO gas. This air vent pipe prevents vacuum formation in the vessel while the electrolysis is in process.

Since the input high voltage is derived from the motorcycle's CDI coil or the spark plug, we can assume it to be in sync with the engines RPM and in accordance with the speed of the vehicle. Therefore the chance of inducing a disproportionate amount of HHO inside the combustion chamber is automatically controlled, making the procedures much safer and healthier for the vehicle's engine.

The HHO gas output from the bubbler chamber is directly integrated with the air intake passage of the motorcycle's combustion chamber.

Once the above set up is installed and initiated, an immediate improvement in the performance of the motorcycle's engine could be expected and a drastic reduction in the consumption of the primary fuel could be witnessed.

WARNING: THE PROPOSED CONSTRUCTION GUIDE OF HHO GAS IN MOTORCYCLE FOR IMPROVING ITS EFFICIENCY HAS NOT YET BEEN TESTED BY THE AUTHOR PRACTICALLY, EXTREME CAUTION AND CARE MUST BE EXERCISED WHILE TRYING THE EXPLAINED THEORY. THE AUTHOR CANNOT BE HELD RESPONSIBLE IN AN EVENT OF AN ACCIDENT OR A FAILURE OF THE PROJECT WHILE CARRYING OUT THE EXPERIMENT.

Hello, your original design for this topic is removed by you for security reasons, but topic is the same, question is in order to produce hho with HV in pure water, by dumping HV in KV but amps must be restricted in miliamps, exactly below 100ma?

Hi, thanks for your suggestions…Yes, the current will be low and much below 100mA for the above project…

I’m more interested in you original cdi circuit, and several other projects, one of them is Meyer brushed rewinded alternator… To keep it short, plan is to build-replace alternator stator windings with 4x CDI coils around rotor to simulate 4x phases with HV impulse.. For now

i know Meyer dereulated multi phases alternator work but not enough gas to start engine like him, he probably rewinded stator to 9 phases with thin vire to get HV, Cdi would be simpler to build and achieve same thing.

The basic CDI circuit can be found in the following links:

https://www.homemade-circuits.com/how-to-make-capacitive-discharge/

https://www.homemade-circuits.com/make-this-enhanced-capacitive-discharge/

I have not yet studied the Meyer alternator, so unable to provide my opinion on this.

I hope you succeed with this project.

Please do keep us updated with the results.

Additionally; I recommend you to examine the “Voltage Multiplier” circuits with only diodes and capacitors from 220Vac. It will be easier and more practical to obtain High voltage DC by adding it to the output.

Stay happy.

Şafak TAŞKIN from TURKEY.

Thank you for your interesting feedback. yes, that’s definitely worth trying.

I appreciate the idea.

Greetings. It was a project I did about 20-25 years ago. Regarding high voltage, I definitely agree with you, as is my experience. Best Regards.

Safak TASKIN from TURKEY.

Good morning sir, How are you doing today sir, sorry to disturb you again sir, Sir I construct hho cell using aluminium pipe with each having a distance of at least 1mm apart, is the distance apart OK?, another thing the amount of heat been dissipated is a lot sir

Hi Tunji,

what DC voltage are you using, and are you using any chemical in the water? If the DC is 3V and above and there is no chemical used, then 1 mm distance is fine.

If you are using a chemical like sulphuric acid, or similar then you can try wider distances also.

I’m using 220V Dc, converted directly from AC, I’m not using any electrolyte.

In that case you can keep 2 inches distance between the probes.

Please remember that using 220V can be fatal if not handled carefully and with necessary precautions.

You are doing it at your own risk.

OK, thank you so much sir, I really appreciate it.

You are welcome Tunji…

Hi sir, please I need your advice on this Dc generator, I need to know if I can use it for the experiment above, and what should be the distance apart for the Aluminum rod that I’m using

https://www.konga.com/product/switching-power-supply-ac-dc-power-supply-5v-40a-200w-6079466

Or Aliexpress

https://www.aliexpress.com/i/2251832698536301.html?gatewayAdapt=4itemAdapt

Or which power supply can you recommend, and also if 12v 1A transformer to Dc, can be made somehow efficient

Hi Tunji,

Yes, you can use those power supplies for generating HHO gas.

Alternatively you can simply use a 12V 1 amp AC to DC power supply for generating HHO gas.

For 5V DC, the distance between the electrodes inside water can be around 1 inch.

For 12V it could be anywhere between 2 inches and 1 inches.

The closer the better.

The cross section area of the electrodes also matters, bigger cross section will produce higher amounts of HHO.

Hi, I saw a video on YouTube, where someone is using Dc to Dc boost converter for Hho gas generator, with potassium hydroxide or sodium hydroxide in the water.

Sir with this type of implemention will the hho gas be efficient? If what modification can be done to increase it production?

Boost converter will work if it has high current otherwise it won’t be efficient.

You can try something like this:

https://www.homemade-circuits.com/how-to-generate-pure-oxygen-and/

Wow, thank you so much sir for that quick reply, though I still have one more question sir, can I 3v to 6v ==> 10kv to 20kv power module, will it work?, is it effective? Or just a waste power? And which is preferable Sodium hydroxide or Potassium hydroxide as a solvent in water?

Thank you Tunji, If you are using a catalyst then you just need 3v for efficient generation of hho, rest everything is waste of power.

A drop of sulphuric acid is actually the best catalyst for fast electrolysis of water, however out of those two, sodium hydroxide is the preferable one.

OK thank you so much sir

Sorry, to disturb you again sir, I wanted to use multiple 3.7v lithium batteries, how should I connect them in series or in parallel for efficient Hho generation, thank you sir.

You can connect them in parallel.

Thank you so much sir

You are welcome Tunji…

So spark plug is for gating?

Couldn’t you do the same with just a coil pack? Some go from 20000v to up to 50000v. I know I am making a full inclosed system with that.

Hello, I understand everything here except one small detail, how do you physically connect the power and ground wires to the spark plug/resistor cap? Thanks.

Spark plug body will be already connected with the vehicle body, no need to connect it physically. The power comes from the ignition coil to the spark plug.

Thank you for your sharing your knowledge. I’m interesting with your HHO driver but I’m just a beginner. So please can you help me with my 13 plat dry cell hho generator. How I can install it in my car? How I can make PWM to adjuste amps for hho. Thank you for your cooperation and help.

Hi, I appreciate your interest, however if you are a beginner then this circuit may not be recommended for you. The above HHO cell experiment is recommended only for the experts or must be done under the supervision of a qualified and expert automotive/electronic engineer.

First thank you for your reply. Please Don’t worry I have done a lot of things. And I’m willing to learn every day new things, no body born with full of knowledge we all born to learn. So please help me I know you could help me. Thank you again.

OK, in that case you can go ahead with this project. However you would still need the help of a qualified automotive engineer to learn how to implement it in an automobile. I won’t be able to help with the automotive implementation. I can only help you with the building of the circuit and the PWM

I’m glad to here this from you. Please send me everything you could so I can start to build the PWM or try the car’s spark plug. I have bought some PWM speed controller but it’s getting hotter not even reach to 15A. So please what can I do?

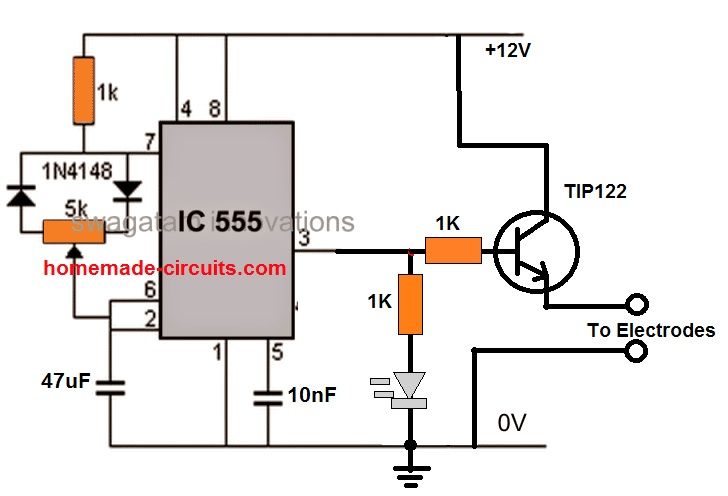

No problem! You can build the following HHO PWM controller circuit and use it to build your HHO generator circuit. Make sure that the electrodes never touch each other inside water, otherwise the transistor will burn instantly. Also, you can try adding a few drops of H2SO4 or sulfuric acid in the water to speed up the HHO generation process.

" rel="ugc">

Hi, the link to the previous post is not working, please direct me to the CDI coil circuit for HHO. Thanks

Hi, unfortunately, I had to delete the post because making HHO at home can be very dangerous and strictly not recommended.

For the CDI coil circuit you can refer to the following post:

https://www.homemade-circuits.com/make-this-enhanced-capacitive-discharge/

Dear Swagatam, thank you very much for sharing with the world your knowledge, much appreciated!

I would like to implement this setup with an OHV driven electrical generator, where the spark cable at the coil is not detachable. Can you or some fellow readers here suggest how to create the suggested parallel derivation, so I can have the spark and HHO cell both poeered by/from this single cable?

Thank you very much in advance!

Thank you Alex, for your valuable feedback. I appreciate it.

You can extract the high voltage from the high tension wire clip of the ignition coil which is fixed at the neck of the spark plug. That is probably the only place from where you can extract the high voltage.

I am building a 49 plate dry cell set up for my 6.0l truck engine. I was wondering if I could use my existing air conditioner circuit wiring to power the unit or would additional breakers and or transformers be needed. The plan is to unplug at the ac condenser and wire in with new disconnect plugs utilizing the existing ac circuitry.

Hi, Sorry I have no idea about the air conditioner circuit, so it can be difficult for me to comment on this.

Resistor is Royal 1693, 10KJM5w ceramic ?

You can buy any 10K 5 watt resistor, the one which you showed me earlier will work nicely. However this resistor is not a confirmed value….if this does not work then you may have to buy some other lower value until the bubbling through the electrolytic is just prefect

Sorry for stupid questions. Talking like 5k 3 w as next level resistor? Would fine tunng work with little electrolyte NaOH if weak? Just need to understand if the same influence electrolyte jas driven by amp as V. The more electrolytes the more gas but that draws amp and heat.

You can use H2SO4 for enhancing the effect but I won’t recommend that since the supply input is too high, and adding any chemical may cause explosion in the electrolyte. Do not use any external chemicals.

You must excuse me looking at the options, I am in South Africa. Some things are lmited and then some places want your arm and leg order. Buying online here is a nightmare by its srlf. Our postal services and public transport have come to a standstill for corruption and bankruptcy. Petrol/gas cost is another Govtax and public abuse. Getting things done here affordable is a challenge with distances.

OK I understand, no problem.

Thanks on that feed back, just considering your diagram for clarity in your suggestions, the fuse will be going on the red wire from the HHO generator unit to the spark plug wire. There will also be the resistor 10k-5w. The fuse will then be between the resistor and HHO unit.? Will there be a problem using a ceramic 10k- 5w resistor (you suggested the wound type) I only found ceramic at our suppliers. The secondary fuse on the coil would be where? Wire to plug or power feed to the coil? To get back to previous suggestion on switch from battery power source to coil source

In the previous discussion on the automatic relay switch from battery to coil. Those box switches are used in cars but determine 12V. Would that work to switch from battery to coil plug wire (always refer as coil being the source)in some Amp variation or do we we look at something different, considering volts. Rally appreciate you insight to the solution.( are there a basic component already outhere like car relay switch or does need a new combination of components.

See https://duckduckgo.com/?q=Relay%20switch%20used%20in%20car&ko=-1&iax=images&ia=images

You are correct regarding the position of the fuse, however if a 10K resistor is being used a fuse may become meaningless, because the 10K will be enough to handle the short circuit and prevent burning of the wires. A ceramic resistor may also work, just check whether the resistor is heating up or not….if it heats up then ceramic will not work.

Any 5 pin 12V car relay will work which are shown in the image sent by you.

Considering there is a 16amp fuse used with a battery unit, safety amp. Is similar safe guard required with coil solution?

You can put one fuse for the coil and the electrolysis circuit, it is never a bad idea.

Through many discussion you have mentioned so many surpressors and resistors?/Another point as very stupid question after google search to confirm and be sure. “The resistance can be a 10K 5 watt wire, wound resistor.” This is a thick 10k5w cable wound to coil?

Or specific 10k5w resistor you buy thats cable wound (I believe is correct)

Ok, got the wire wound resistor

" rel="ugc">

Not to assume but you suggested this in regards to the whole chat considering my HHO design also plates 3 mm apart?

OK will do….but plate distance will need to be adjusted with practical experimentation only…

Yes that’s correct.

Thanks for your responce. Just to make sure we are on the same page, please bare with me. The red wire,(before spark plug, no other place can attach to coil) you refer to your image? Then there is a suppressor in series between the HHo system connected. THE PPC(105/400v PPC) is a suppressor additional or the suppressor referred to(should be sufficient for bike or car you also referred to the 3 mm carbon rod in a chat sounded to be for bike). The suppressor if only one used can be increased. 105 can < to higher. For example, what would be the next one up? I am pure novis at this and would hate to waste your time and really appreciate it. Thanks

The simple idea to suppress the high voltage/current into the electrolysis unit would be to connect series resistor with the red wire that goes into the water. The resistance can be a 10K 5 watt wire wound resistor. !05 capacitor or any other capacitor cannot be used as a suppressor due to their low voltage rating. The 105 capacitor is supposed to be inside the CDI unit which generates the capacitive discharge into the ignition coil.

Thanks again for your patients. All info with comments got confusing at first. The 105 refered to the PPC (105/400v) suppressor, not the capacitor, sorry you have much more info in your head. Having reread your explanation without comments brought a bit of clarity. In my mind came up last concern of this as a fully working model. Power draw from the coil is a great concept but concern drawing from the coil rather than from the battery came to mind. Coil active to HHO generator with bike ONLY when the bike is running but how does it start with fuel and gas in the carburettor. BatTERY starts Hho before ignition so we have generated H gas to carborator(which would now also be preset for a saving balance) to keep balance of H and feul to start bike. Coil will have no H to carborabtor on the start. As I believe the carb get set for balance of feul and H mixture. So conclusion needs to bridge this delema. Will solution be to have a switch from baterry power to coil when you start bike? Do you envisage this delema or did I miss something.

Thanks, I appreciate your question, however I am not an expert with automobile engine mechanism, so I cannot suggest regarding how the HHO is supposed to react or work with the engine of the bike….this will need to be confirmed from an qualified automobile engineer.

Having researched around HHO, I explained you the concept and realise your skill and lack. The solution is electrically connected to swith from one to another to bridge a point from when H gas is required that AC or DC needs supply to ignition of its use for the continium of the coil keeping H gas generation. This is purely an electrical sulution posisibly by switch. So your electical opinion on this as an exercise or other solution than a swith. Is there complications with a sqith and possibly what would such a diagram work for this excise considering the explanation of working. Appreciating you input!

Sorry, I cannot understand your English translation.

Haha, sorry yes missed spell!

The solution is electrical. To bridge the problem. So at the point where the system can switch over from generating H gas required from required AC from the battery to needing H gas supply from coil. This could be achieved by using a switch in circuitry. Manual is easy. What about an automatic switch over. So when coil power kicks in HHO CELL swith overdrawing power from the coil. Could this be a challenge for you? Think it is a great solution. A Diagram of the components of this could be great!

Appreciating your input on concerns and the real impact on the different components. Amp draw enough gas for the battery to start the bike then riding replenish battery when HHO UNIT running from the coil.

Hope it’s clearer. Thank you so much for your patience and response

OK no problem, however, The HHO gas is only supposed to be an additional support for the existing fuel of the vehicle, the HHO alone cannot be used to power the engine.

So initially the engine will be started with petrol or diesel, and once the ignition coil is started then HHO can be released into the combustion chamber as an extra support to the petrol or diesel and for enhanced engine combustion with little petrol or diesel.

You correct! My concern is that carburettor adjustment with a good H gas flow settings may influence the bike difficult to start. Diverse bikes would then. have a working opportunity when you set a lean system. As the carburettor settings change with totally different settings to reduce fuel with more air H mix. This only way to maximise saving otherwise you waste fuel in combustion that H accommodation wast ob both feul elements.

There are many voices out there in the solution while combined wisdom gives a better solution for us all. Your suggestion from the HHO cell system is the best contribution to improve them while working in my opinion for bikes. The biggest problem is battery drain and then to improve the overall HHO combination percentage will theoretically be possible for larger CC and possibly full H IN SMALL.CC. If we can keep heat in the HHO cell low enough it will be a great solution with that switch which the suppressor would be included on a little board.

Considering taking it a strep further PWM (control amps keeping heat control)can be added for control but With that coil supply with a suppressor? Will it work on that coil supply considering amps or volts? What amp PWM would work considering amps without going too high or low? Your insight into electronics is of great value working in these diverse knowledge fields. Thanks for your responses, really appreciate it. I am sure many others coming to this page.

Thank you for your detailed explanation, I appreciate it! Unfortunately PWM may not be possible because here we are dealing with 20000 volts, only a resistor will be acceptable in this situation to control the excess current to the electrodes.

Hi great idea! Been looking at solution to save battery 12v battery on bike, HHO draw 3.8 A. Wondering if bike alenator could replenish that on battery and not go flat? Opinion here?

Considering your solution of drawing from coil.

Placing suppressor in series to HHO system and you mentioned cathode and anode plate appart 2/inches. Considering my HHO system design with plates 3mm appart WITH ROD IN TUBE IDEA. ( a 2nd design, There is points of isolation between of 1mm at some points but plates +NN-NN+ all in water) Would the suppressor strenght help with this spacing. The voltage and jump. Would I use 2 in series, what’s your suggestion like the PPC 105 be sufficient? THEN TOTALLY AVOID 2 nd design, considering volt jump or spark? I really, appreciate your insights

Add info, bike is 250 skygo

Hi, thanks, glad you liked the concept!

I think the suppressor should be actually in series with the electrolysis supply (red wire) instead of the high tension supply. This will ensure two things, current consumption will be low which will save power, and this will also stop the arc from jumping across the electrodes. However, the electrode distance should be a mater of experimentation, and it should so adjusted that the spark can never jump across the electrodes, or alternatively the suppressor value could be increased for achieving the same. 105 value should not be changed or reduced otherwise that could affect the sparking in the spark plug

Hello from Cape Town, South Africa.

The idea of diverting current from the spark plug concerns me as I’d be wary of misfires resulting.

A possible solution may be to invest in a cheat HT coil from a scooter or similar. Wire it in parallel to the engines HT coil then do what you like with a isolated ht spark.

As my bike was stolen last Monday (goodbye test bed) have not tried this but don’t see why it wont work.

Hi, The idea here is to use the excess energy from the spark and use it for the electrolysis. There won’t be any misfires because the spark gap is very small and the voltage from the ignition coil is too high for the small gap, so even with a little reduced current the sparking won’t be affected.

Using an external ignition coil might not help the purpose since it would consume extra power from the alternator for the electrolysis.

Nice idea, i connected the wires to the spark plug but the engine wound not start, when i disconnected the wires the engine started,i did exacta as the diagram.

Thanks for the nice idea, thumps up from me!!!

Please connect a 1K 1 watt resistor in series with the HHO supply and check again, and make sure the HHO water probes are at least 3 inches apart in water, and do not put any external chemicals in water. If 1K doesn’t work, try higher values!

Several questions –

First, how long will the baking soda last?

Second, how would you keep the water from freezing in the winter?

Third, why would you run the air through the air intake instead of off the vacuum of the motor?

Fourth, ideally this would start off HHO but won’t it need to start off fossil fuels and then flip over?

Fifth – what is the ideal spacing between plates? Or is it better to try and locate woven stainless or perhaps stainless steel wool?

Lastly – Would running a cap in place of a battery work? I understand about caps and batteries, but it would make sense for space reasons to start the process off a cap before the vehicle starts.

I don’t using any catalyst in water, just simple tap water will do.

The concept might not work in countries with freezing temperatures. Or perhaps the rise in temperature due to electrolysis could convert the ice into water.

I did not properly understand your 4rth point.

The spacing can be around 2 inches apart.

If there’s no battery then it can be started with an alternator, but capacitor might not work…

I can clearly see that you’ve put in a lot of thought and work to this project. Did it work? ,Did the bike start and run okay? Did it run cleaner and leaner? Were you happy with the results?

Rgds, Bruce Pooley.

I have only explained an effective way of producing HHO in any automobile, I have not tested the outcome myself…

hello.

sorry not a technical person, what does the suppressor look like?

is it something I can easily purchase?

Please inquire this in any two wheeler automobile shop, they will probably be able to provide you the part quickly

🙂 I wish you knew where I live(we call a lot of things by different names here), believe it will be much easier to have a photo to show the person at the shop

can you please elaborate more on how to connect the *resister in series*

I’m confused by the terms resister and suppressor

You can use one suppressor in series with the spark plug wire, and another suppressor in series with the HHO generator wire, in this way the high voltage will be uniformly distributed across the two units.

thanks for the information.

I did background research on how to put the suppressor in series but I’m still quite lost.

a very simple pen drawing will help a lot!!!!

You can try this set up

thanks for the great information!!!!

bless!!!!!!!!!

what should I expect the water temperature to be?

thx for this information after i investigate some weeks i have a plan of hho cell using high voltage with no more than 0/5 amp but i am a little limited with tools and parts …my question is what if i have : 12v 3 amp power supply connected to pwm circuit and connected to the ignition coil and connected to the hho cell …before trying this i would know what the dangerous thing here that i should be intended to …i find a lot of circuits that require capacitors so when the ignition coil circuit is on opened the pressure from magnetic field should be securely absorbed ( what can be used instead of capacitors )

note: i am planning to build it not in the car/bike but as separately system so iam going to use all the possible 40kv +/- voltage (high frequency 100khz +/- )

Extreme high voltage is actually not required and in fact not recommend for water electrolysis. In fact even 220V DC is enough to break pure water into HHO, so I won’t recommend ignition coil if the system is not intended to be used in a vehicle.

In the above article I have suggested the use of ignition high voltage since it is freely available in the vehicle and some amount gets wasted through heat, this excess energy could be diverted to generate HHO.

Yes a capacitive discharge circuit is recommended with ignition coils, to safeguard the coil from excessive heating and burning, the schematic for the same can be found here.

https://www.homemade-circuits.com/how-to-make-capacitive-discharge/

lets say that i want to use it separately and i would like to use about 200 v lets say that its dc i think its not but how i can get this 200v and release the another 39800v … my plan can not use something else expect this coil

The excess voltage will be released as heat in the water, but since the current will be too low the heat will be negligible. To make sure that the current is low, use thin graphite rods as electrodes, which could be salvaged from any dead, tiny AAA sized dry cells, and also keep the distance at least 5 cms apart in water. Do not use any electrolyte in water.

I appreciate ur answers so much …thx for giving me some time and Nswered my questions ????

You are most welcome!

hello super your diagram, just a question before testing on my lawn mower in my garden and then on my motorcycle, the less black can it be taken on the mass of the chassis or a mass of the engine, thank you in advance.

Thanks, The ground is connected to engine and chassis by default in all vehicles.

Learn some electronics and then we can discuss…Water resistance is very high it will only allow a few mA or even less. I have presented a rough concept it may need to be tweaked further for perfection.

Ignition coil will produce pulsating DC NOT AC.

By your reply I clearly understand you know absolutely nothing about electronics. Absolutely all transformers in output has only AC. This AC can be pulsed but anyway it still remain an AC. If you do not know this basic of physics, at least check at wikipedia. If you want to get DC you must use a rectifier. Normal water resistance is not so big, only distilled has really high resistance.

BTW I have 25+ years experience in making, repairing electronics. Up to analog processors controlling current sources of 450V and 630A, with a lot of pulse transformers of course. I just was curious how deep you going for clickbait.

I’ll keep this reply as is, so that other readers can mock at your knowledge.

Agree the collapsing field cause dc spark.

Those red, black wires are to be replaced with Spark/ HT cable – regarding insulation else spark will jump to chassis, your legs in case of naked motorbike. The high voltage breaks down the thin air to reach the ground in least resistance path . If spark circuit is loaded, will result in poor spark and engine stalling. Later possibility of CDI failure too. Looking at at all these complications, it’s preferable to have separate circuit for HHO generation. Failing of CDI in the middle of a journey can be disgusting one.

The set up doesn’t need to be exactly as given in the diagram. You can have the distance more separated to avoid sparking, and the voltage can come through a suppressor resistor. The vehicle will never stall as long as sparks are continuous without breaks, doesn’t mater even if the sparks are not too strong.

Hi Swagatam,

It would appear you are trying to promote a perpetual motion machine. Your idea cannot possibly work, more energy will ALWAYS be required to split water into oxygen and hydrogen gas than you will generate by burning the hydrogen. And the combustion process will only be at best about 30% efficient. So the energy required to produce the hydrogen gas will be three times the combustion energy even if the electrolysis process was 100% efficient (which it won’t be). I suggest you familiarize yourself with the laws of thermodynamics before suggesting schemes like this which can NEVER work.

Hi Vic, may be you did not understand the concept fully. The electrolysis process uses the wasted energy from the spark plug. The energy supplied by the ignition coil to the spark plug is unnecessarily high. Since the spark gap is just a few mm apart, it can be arced with much lower amount energy, while the remaining energy can be bifurcated to the HHO cell for the HHO production.

I hope you got it now!

It is a very interesting idea from which it is only a step towards the water car. In the 70’s of the last century, this was even said to be that electrolytically decomposed water into an oxygen-hydrogen mixture is fed to the engine where it is burned, and of course water is generated as waste. There was no longer enough to bring this water back to the generator, where it would be re-decomposed into the oxygen-hydrogen mixture and the perpetuum cell phone is in the world.

It is true that this device is described here a little differently. It’s just like an additional combustion. Here’s just a question of how much power I use to distribute that water and how much power my engine will increase. If I forget all this, there are still a few technical problems.

First, try to discuss this water decomposition with an experienced chemist, who will surely explain that the oxygen-hydrogen mixture you create is extremely dangerous from the explosive point of view, otherwise they say that this mixture “barks” when burning.

Second: The voltage and current decomposition data for water decomposition are at least improperly formulated. Depending on the size of the electrodes and the distance from each other, if you operate the water at a voltage of about 12v, but if there is distilled water of about 10µs, you will achieve a current of several meters or just µ ampere, according to the electrode sizes and distances mentioned above . you can accelerate this process by adding liquor to distilled water, which will increase conductivity rapidly, but only water will decompose in the decomposition process, the lye will remain there. Therefore, it is sufficient to add distilled water and the process will continue.

This was the essence of the “oxygen-hydrogen” welder published in “Do It Yourself” in my youth until there was a few explosions of these devices. Fortunately, those developers were designed so that the amount of mixture produced was quite small, so the explosion was rather just a “freak” and did not cause destruction. I personally experienced such a bang with my developer.

So that my view is, put your hands away from such devices. Not to mention how badly it affects the engine in the combustion chamber, where the oil burns at elevated combustion temperatures, and only after a few 10000 when you find that the engine is “running out” due to imperfect lubrication.

You said, “…we wouldn’t want 100mA to be used for electrolysis in order to avoid explosions or atomization of water…” (This is at 20kv.)

From what you have said there must be a cross-over point of voltage vs current where it becomes dangerous. Is there a known formula, or electrolysis law that predicts where the danger level occurs? Thanks!

I have not yet investigated about the formula, however the easiest way is to start with the lowest possible current, may be at around 10mA, and then check the response by gradually increasing it until the most favorable combination is achieved.

According to your contributions I conclude that ohms law does not tell you anything. To achieve a certain current, you must have the appropriate voltage and resistance. You can change the resistance in this case by the flat plate and the conductivity of the water. The conductivity of the water can be varied by the addition of lye or other chemicals which will not decompose by electrolysis. So, you don’t need 20kv to get any currents there if you adjust the conductivity of the water. Further, water will still decompose into hydrogen and oxygen, whether you use a lower or higher voltage. Under certain conditions, this will only affect the amount of mixture produced.

It seems you missed it completely, it’s not the plate size but the distance between the opposite plates that matters for decreasing the resistance. However, higher voltage gives you the facility to initiate the electrolysis even with plates positioned far away. Rememeber we are dealing with pure water without any form of catalyst.

Nobody’s saying we have to use 20kv, I am suggesting the 20kv source because it’s already available with excess current across the spark plug which simply gets wasted during arcing, because originally the sparks can fly more than 5mm distance whereas the spark plug gap is just 1mm apart, we can channelize the excess current/voltage for the electrolysis purpose…I hope you got my point.

The spanning distance of the spark at atmospheric pressure or under cylinder pressure is very different.

In addition, it would be advisable, with suitable electrolyte conductivity, to include the generator in series with the high voltage circuit for the plugs. This would replace the necessary resistance to the HV attenuation, while not increasing the energy consumption for gas production.

Hi, Thanks for your good post. I have a question.

Q1: If I connect my hho cell with spark cable and body(-), will it effect my motorcycle CDI device?

Q2: What is the good sell design for this system? (+-+-+-+-) or (+nnn-nnn+).

coz heat is the main problem for hho cell. (+-+-+-+-) is more production but cell take too amp and heat. (+nnn-nnn+) is less production and low amp draw. I hv no idea about high voltage for production and heat. Thanks.

Hi, Glad you liked the concept.

yes it might affect the ignition process of the engine, therefore it is advisable to use a suppressor resistor for both the units, one for the HHO cell and the other for the spark plug separately.

sorry I do not have idea idea regarding the electrode configuration, you may have to investigate through some practical experimentation

Thanks your quick ans. CDI spark plug output AC/DC? coz if AC it may not work to make HHO. I am not sure. plz clear this. Thx…

It is in the form of pulsating DC, meaning a high voltage DC switched ON/OFF at a high frequency….

swag,

Thank you for your response. I looked at other schematic you advised. I don’t fully understand it. What is requirement of step up transformer in your hho circuit? Should it be pulsed at 50hz? Can the tip122 transistor be operated at this frequency?

Looking forward to hearing from you.

Hi Perry, the ignition coil primary is designed to work with 100V minimum and upto 300V, therefore it becomes necessary to step up the 12V DC to above 100V for operating the ignition coil optimally.

The frequency is not crucial but 50 Hz looks quite fine, and can be used

Why would the TIP122 have problems with 50Hz? sorry I could not understand this justification, kindly clarify.

Swag,

I built your hho high voltage schematic. I have noted some deficiencies in it. The pwm circuit only supplies 8hz at low end and 9hz at high end. Duty cycle is greater than 50%. My transformer operates best at 50hz. I think this a problem to getting unit to work. Do you have a modification of the pwm circuit?

I would appreciate any help.

thanks Perry,

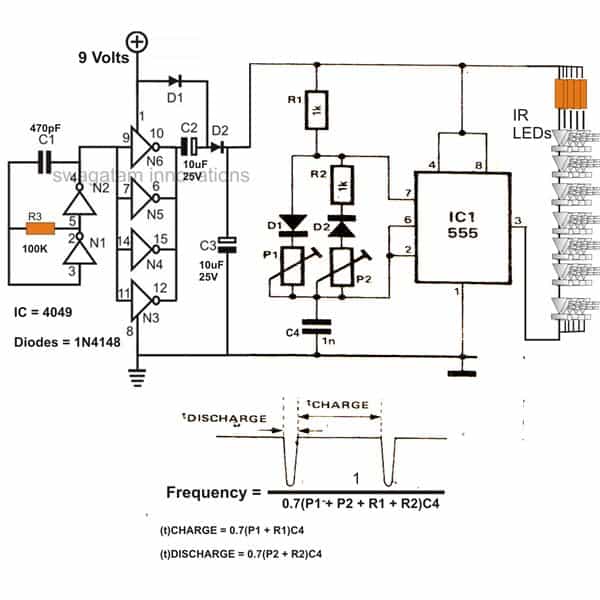

you can try the IC 555 PWM design which is employed in the following circuit

" rel="ugc">

please ignore the IC 4049 stage, and the attached LEDs.

Swag

What i want to know is the value of the cap in ufd mfd pfd.

Thanks

Perry, uF stands for microfarad, The 1uF, and 100uF are electrolytic, the 105 is PPC, or MKT, the 10nF is ceramic disc.

Thank you for which cap i need to use. Can you tell me. What the value is in micro or milli farads?

swagatam,

I will build your hho generator using cdi ignition coil. On your schematic, you call for a 105/250 capacitor. Is this a ufd or mfd size? Can a electrolytic cap be used? What do you recommend?

Perry, the 105/400V capacitor should be a non-polar type (PPC or Polypropylene Capacitor), it should be similar to the one indicated in the second last image from this article

https://www.homemade-circuits.com/types-of-capacitors-explained/

thank you for your reply. Base in the picture above there is a red wire connected to the positive wire of the ignition coil and theres is also a spark suppressor, the question is, where should I exacly connect the red wire, is it before the spark suppressor or after?

thank you

you are welcome!

connect it before the suppressor, that is towards the high tension cable.However I think the real problem could arise due to difference between the resistances of the air gap of the spark plug tip, and the water resistance.

spark plug's air gap may have a resistance of over 5 meg (2mm apart), while water only around 200k.

to create a balance between the two you might have to add a resistor with the HHO cell wire, or increase the distance between the electrodes to an extent where the sparking in the spark plug does not get affected, you may have to find this balance with some trial and error on your workbench table.

Hi sir,

Thank you for the quick reply.Actually I'm just using 2 wires for positive and negative and each end is submerged in the water, the two ends are far enough about 1.5-2 inches.

How do I add suppressor resistor, can you show me a diagram?

Is it right if I directly connect the positive wire to the tip of spark plug? this is what i did.

thank you

Jake, from where are these two wires coming? it is supposed to be from the high tension wire of the ignition coil and the ground.

you can try increasing the distance of the electrodes inside water to increase the water resistance…and remember do not use any form of chemical in the water, the water must be pure tap water, without any external agents.

for a suppressor resistor, you can go to any motorbike spare part shop and tell them to give you a spark plug noise suppressor resistor, it will be a small cylindrical shaped black carbon rod, about an inch long and 3mm in diameter, connect this in series with the HHO cell wire.

..no do not take the positive from the spark plug, take it from the high tension ignition coil cable…

hi sir,

i tried this method sir, actually it looks very simple but when it try it with my motorcycle it's not starting, it seems that the currents are all diverted to to hho cell. I tried to remove the ground of the hho cell then when the engine started I manually connect the wire to the body of the vehicle then engine stopped.did I do something wrong

.please help me

.thank you..

Hi Jake,

That should not happen, I think you must first check the HHO apparatus on table by connecting the supply from your bike's ignition col, and if possible remove the spark plug from the bike engine and check the response of the spark while the HHO is also connected. This will allow you to find the fault in the design.

If you find the spark getting affected you can reduce the diversion by adding a suppressor resistor in series with the HHO cell.

I have manufactured ignition coils and CDI systems, therefore I am sure that The current from the ignition coils strong enough to power both the devices comfortably.

good morning sir,

can i directly use the current from the spark plug or i need any circuitry before connecting it to spark plug…

yes you can extract some energy from the spark plug high tension cable into your HHO generator….but you will have to first experiment with it to ensure that the voltage does not cause explosions or any abnormal reaction inside the HHO container, if it does then you can reduce the current by adding a wire-woulnd resistor in series with the source.

hi sir,

i have completed making up with the hho dry cell.

After connecting it to the bike battery it draws a lot of current at the end i get the results of producing HHO..

but the battery is draining quit fast..

i saw many plans about pwm but getting confused…

i liked your plan about CDI.

Please help me in making my hho cell more efficient by drawing less current..

so that there is no load on battery.

Hi Akshay, the consumption by the HHO generator will depnd on the cross sectional area of the plates which are inserted into the liquid. …but still this can not be so large to discharge the battery quickly….you can check if there is any short circuit inside the container

Water is one of the most unknown materials we have in the Universe and newest research and industrial applications shows that water has a MEMORY and many other new effects if treated with RF frequencies where water can creep from one container to the other bilding a bride ( see the You Tube documentary). I read also all about Stanley Meyers invention and in my opinion, each material can have a resonance frequency. Widely used today is for example the Ultrasound SONIFICATION in many industrial processes (see Ultrasound cavitation in the Biodiesel process). It might even be possible to split up HHO with Ultrasound alone! I heard that Honda has a Motorcycle Prototype that runs on water only but it seems they locked the project in (if not, the whole world would drive with water now). I would test the HHO generator on a two cycle Motorcycle motor connecting the HHO outlet in the hose before the oscillating Valve unit. One could use a parallel CDI Unit only for the HHO generation- not "stealing" the pulses from the Spark plug. I have a Yamaha AG 100 and a Chinese 4 cycle 150 ccm Cross machine and might give it a try. In the AG 100 there is a steel cable bowden which regulates the two stroke oil supply to the Motor. This one might be used to drive a potentiometer which could vary the HHO production according to the Motor speed. But one could also use the voltage from the Spark plug coil exiter coming out from the generator plate of the Motor.Very good article from SWAGATAM- I like this site!

Thank you Rainer for sharing your valuable suggestions, I am sure the readers will be inspired and enlightened by it, and I am glad you liked my website…please do keep visiting.

Hello Swagatam,

Thank you very much for sharing your interesting design.

I would want to convert a 91 GSX-R 750 to your system. Should I connect the HHO generator to only one of the spark plugs?

The bike has 2 ignition coils and the setup should be like this:

kzrider.com/media/kunena/attachments/6412/coilwiringplugandprimarypick-ups.jpg

I would want to use a 7 plate design like this:

https://www.youtube.com/watch?v=mvV_cFOvXPQ

My plates would be 100 x 130 x 1 mm each.

Would one cell be enough or would you recommend 2 (1 per coil)?

How would I secure proper fitting of the cables to the spark plugs?

I plan to add a simple bubbler and rely on the metal net of the air filter (k&n) as a flame arrestor by leading the HHO to the outside of it.

I am aiming at at least 30% improvement on mileage – but more would be nice of course :o)

Any input from you would be very much appreciated.

Kind regards

Thorsten

Thank you Thorsten,

According to me therer's nothing too critical about the parameters which you have stated, you can go ahead with the mentioned plans and it should work.

power from a single spark plug would be enough for getting good results.

The input could be secured to the spark plug neck where the high tension cable from the CDI is clamped

however a practical test will only be able to confirm the actual results, which can further tweaked for improving the overall efficiency of the system.

Hello Mr Swagatam.

Do you think that i could use a xenon hid ballast i statof the cdi coil?

the CdI is already installed in the vehicle therefore it's referred for the use of its excess voltage for the HHO generation, I am not sure how you would be fitting the xenon ballast in the vehicle, may be it would also serve the purpose

Hello sir,I have installed a hho cell in my scooter bajaj chetak and it works …but the only problem is h2 is producing at very high rate .I want to control the production of h2 .is there any mechanism to control the production with throttle.

Hello Kiran,

the HHO gas is supposed to be integrated with the petrol pipe feeding the ignition chamber, so that it is allowed to enter the chamber only at the right time and when required, therefore I think it is already controlled by this intake pipe valve mechanism.

you can consult a qualified automobile technician for more info regarding this.

HI kiran kumar ! Could you please send a video on youtube , realy interested because I thought that it doesn't work. So happy that someone tried it and it works, I have read all Stanley Meyer's patents and effectively, he uses very high voltage on all his setup, running about 20k volts up to even 80l volts

High production is good. Every body want it. stop ur oil inject. than test again. it should run without oil. plz calculate ur hho production (LPM). and share your hho cell design. it could be help us.

Wouldn't the left side air vent need a check valve? Otherwise your O2 (hopefully O2 and not just mono oxygen) and H could exit via the vent and be lost rather than exit through the right-side bubbler.

the bottom end of the vent is immersed deep inside the water, whereas the HHO is generated at the top surface.

Sir i tried this experiment in my bike but it didn't work. While i connect the wires as mentioned in image even bike not starts. If i remove the black wire bike starts but spark coming inside the jar. Can u tell me what would be the problem. And one more doubt what happen if i connect it directly to the battery.

Naresh, you will need to check and verify the stages separately and then simulate the whole process on a work bench, and then install it in your bike….you'll need an expert automobile engine mechanic's assistance while carrying on the procedures…who should be thoroughly aware how motorcycle ignition works…you'll need to confirm each and every point with meter and troubleshoot if something's not working at a given point.

if you connect it to battery then also it would work but the outcome will not be free…here we are trying to utilize the excess spark energy which is wasted across the spark plug…and thus we are trying to achieve a Free HHO gas for enhancing the ignition.

Thanks lot for your immediate response sir.. 🙂

Hi sir

I have tried it but i didn't test it in my bike. HHO is generating in the experiment but as soon as the water color is changing like brownish. Is there any problem with the construction? And one more doubt how long the liquid work in a single fill. Eg. 100km or 200km? . Am using a 150 ml airlock plastic jar.

Hi Naresh,

If the current or the PWM is high then more quantity of HHO will be generated at a rapid rate, which will cause the water to turn murky quickly….so you can try reducing the PWM or the current from the input to prevent the water from getting brownish.

I am not sure for how long a given quantity of water may last, however again it might depend upon the rate of the HHO release

Mr. Swagatam,

I am interested to experiment with this HHO Fuel cell.

As a starter, can you give me a simple hint for the measurement od the S/S plates to be made facing each other face-to-face, just enough for experimenting? I understand the hazard involved, it is may call for the safety.

Thanks for this information..

Mr. Unknown,

it could be a matter of some experimentation, however approximately 10mm distance between the mesh plates would be just OK

Hi thank you for all the information. I have install a 2nd ignition on my motorcycle and the coil generate enought spark. I connect the high voltage wire to the + of my electrolyser and the ground (motorcycle body ) to the negatif but there is no gas generated. What can be the problem. The electrolyser work well when I connect it to a battery.

Thank you

Hi, I have tested the circuit using rectified 220V AC and it worked nicely, so it should work with the ignition spark voltage also. Instead of the motorcycle ground try using the battery negative as the ground terminal and check the response.