In this post I have explained a few innovating and simple soft start circuit examples which may be implemented with heavy duty motors so that they are able to initiate with a soft start or a slow sluggish start instead of a sudden, bumpy start

Why Soft Start is Crucial for Heavy Motors

When heavy motor systems or high current motors are involved, initial switch ON current surge often becomes an issue. This surge tends to inflict huge arcing across the pump relay contacts causing corrosion and reduction in its life due to stress, and wear and tear.

The high current arcing not only causes relay contact issues, but also affects surrounding electronic circuits, causing them to hang or get disturbed due to large amount of RF interference generated during motor switch ON.

However safeguarding the costly motor relay becomes the main issue with such situations. Though there are many mechanical contactors available for controlling motor stress, these system are not efficient and are ineffective against the RF emissions.

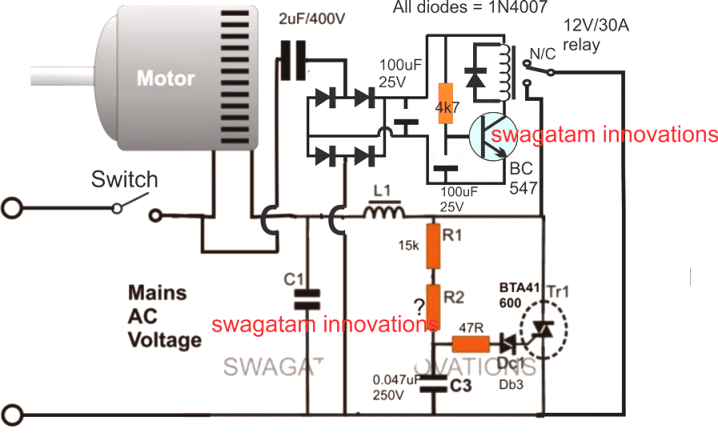

The simple electronic circuit presented below hopefully is able to eliminate all issues concerned with heavy motor switch ON surge generation and relay contact protection.

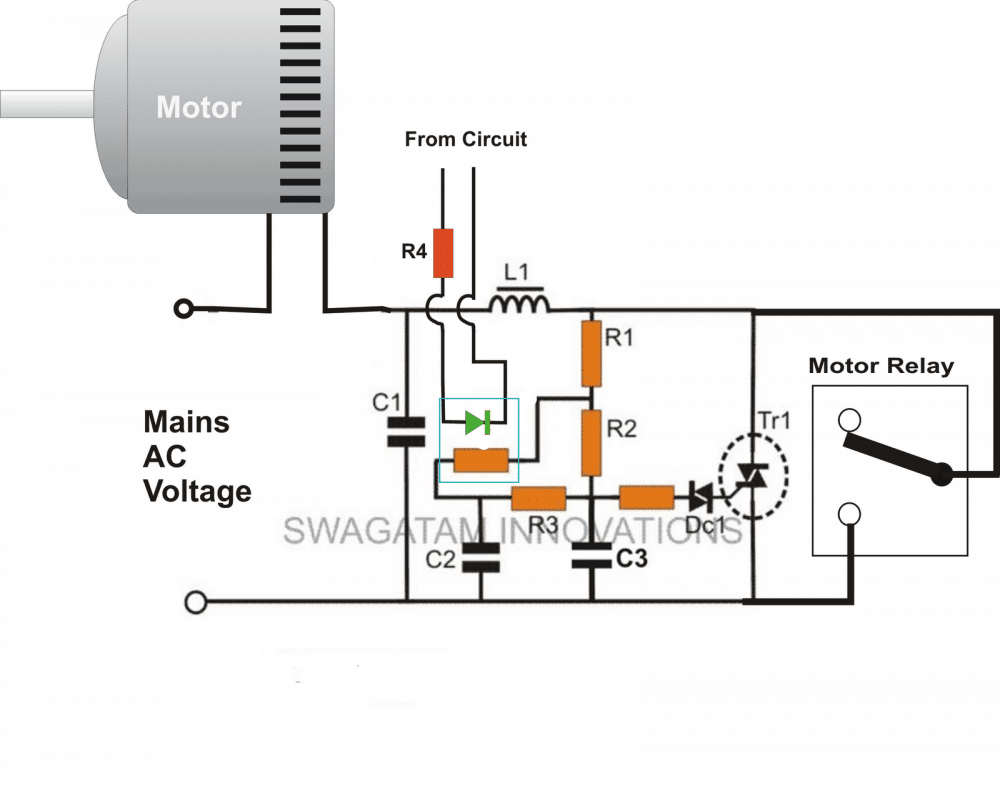

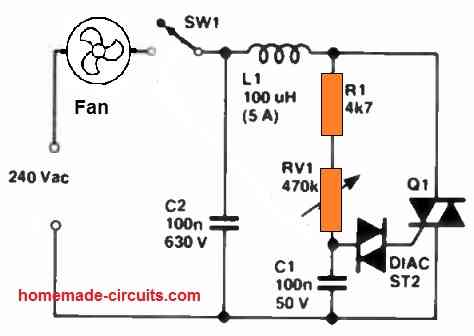

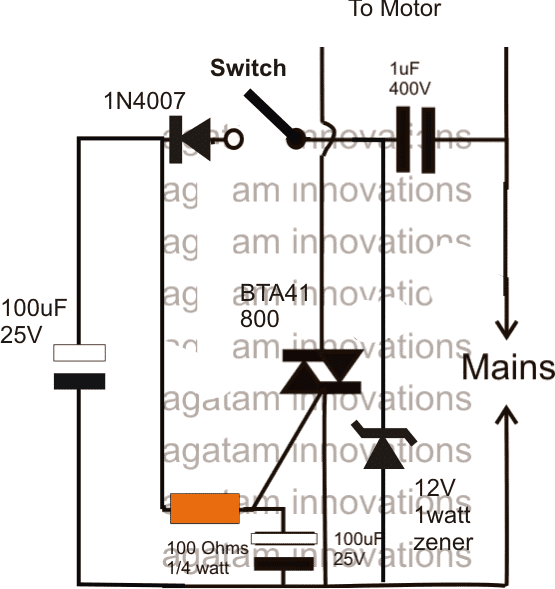

The figure shows a simple dimmer switch circuit incorporating an ordinary triac and diac configuration, which can be very effectively used for adding a soft start to any high current, heavy AC motor.

Designing a Soft Start using Triac Phase Chopping

Here the control pot has been replaced with a LED/LDR box. As we know that in normal dimmer switches, a variable resistance is used for controlling the fan speeds. Here the variable resistance is replaced with a LED/LDR arrangement. It means now the speed of the motor, or in other words, current to the motor can be controlled by controlling the intensity of the enclosed LED through an external trigger.

That's exactly what is done here. When the motor relay is switched ON, either by a switch or through an electronic control circuit such as a water level controller circuit, the LED of the attached dimmer switch is also switched ON simultaneously.

The LED switches ON the triac and the connected motor.

Being a solid state device the dimmer switch acts a little faster than the relay and therefore the motor is first activated through the dimmer triac and just after a few milliseconds the triac gets bypassed by the concerned relay contacts.

The above process completely eliminates any sparking from the relay contact since the triac has already absorbed much of the current and the relay only has to softly takeover the already switched ON motor conduction.

Here the brightness of the opto-coupler LED is crucial, and must be set such that the triac is only 75% ON.

This adjustment will save the triac from initial heavy current transient and help the entire system to last for many many years.

The resistor R4 may be appropriately set for achieving an optimal glow over the LED.

Circuit Diagram

Parts List

R1 = 15K

R2 = 330K,

R3 = 10K,

Diac resistor = 100 Ohms,

R4 = to be adjusted as explained,

C1 = 0.1uF/400V

C2, C3 = 0.1uF/250V,

L1 = 10 amp/220V choke

Triac (Alternistor) = 10 Amp 400V,

Diac = as per the above triac.

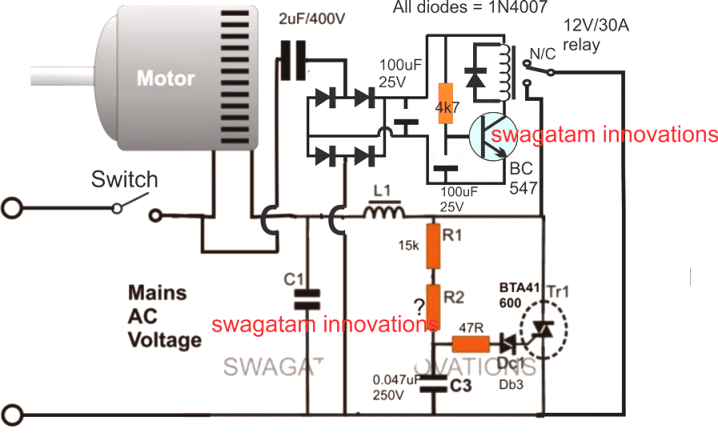

Upgrading Triac Soft Start with Relay

A little inspection reveals that the circuit actually does not require the opto coupler circuit at all. The circuit may be simply arranged in the following manner:

R2 should be selected such that the triac conducts only 75% of the power.

When power is switched ON, the triac provides a soft initial start to the motor until within the next split second when the relay also conducts enabling the motor the required full power. This completely safeguards the actuator contacts from the initial current surges and sparks,

Simplified Soft Start Design

As rightly suggested by Mr.Jim, an initial torque is imperative for initiating a motor optimally especially when it's loaded, if this initial torque is absent. the motor might stall with heavy loads under its belt and might start smoking within minutes.

The following circuit is designed for solving both the issues together, it inhibits the initial surge current to the ON/OFF switch and yet allows the motor to start with a "kick" so that it initiates without problems even when it's loaded.

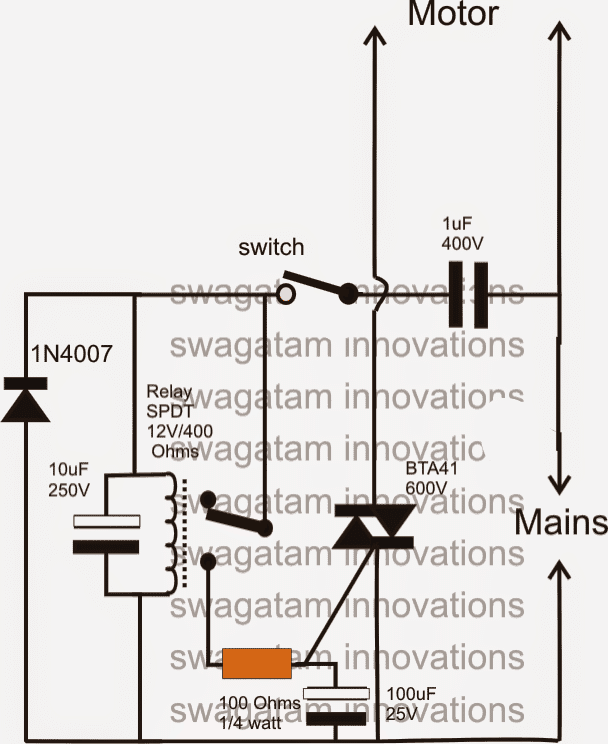

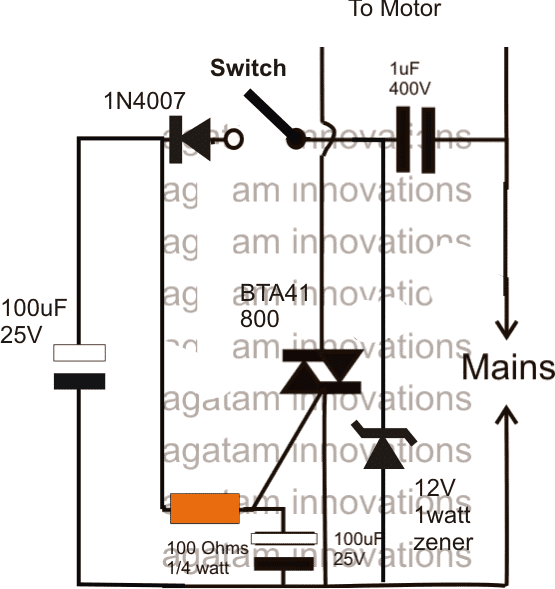

The above design can be even further simplified by removing the relay, as shown below:

An technicallu more sound PWM based motor soft start circuit can also be tried for getting a better control, a better torque and a reliable startup for the connected motor, even for 3 phase motors.

Soft Start Using Controlled Phase Chopping

Another way of implementing triacs through stepped phase chopping, for initiating slow soft start and slow end or slow stop circuit for heavy machine motors so that the motors are able to go through a gradually start stop actions instead of switching ON/OFF abruptly.

The idea is basically intended to ensure less wear and tear on the motor and additionally save electricity during the course of actions.

The idea was requested by Mr. Bernard Botte.

Dear mister Swagatam,

Sorry for my English , thanks anyway for any answer you will give Before the question. I use different apparatus to handle wood using universal AC motor originally made for a range between 230 to 240 volt 50hz (but I notice in certain part of my country 250V too) because I need a lot off different kind of machine and that was only for hobby.

I buy the cheapest machines I can find (I correct certain mechanical problems) for other machines. I use also a dimmer (home made based on the system used by vacuum cleaner and modified byNINA67 ) and It work great.

The motor run at +/- 18000 : 3 =6000 !!! Knowing the cheap cost of that machine I use it like a “good father” not intensively etcBut one day there was a fume

The machine smoke and i dismount the machine to isolate the motor to evict the fire . (the machine was under warranty but i need to make a lot off kilometers to make an exchange. And there, they don’t tell me it was a well known and reccurent problem … but … they know it! )

In fact when everything was cold . I look the axis who rotate he seems also shooting on the opposite side of the gear belt at every start Like there wasn’t a grower.

I show the motor in a company saling different kind of motor.

They make also refurbishing but they explain to me that it was an “exotic” motor but they set the same diagnostic .Start to fast So come my question: Could you please make a schematic to have a “soft start / soft ending ” for different universalmotors in fact if i use my dimmer system based on BTA 16 800 cw (better than the other mentioned above) it seems ok but i have only made 3 of them . I’ll want to integrate that in every big machine .

And use only the on/off switch.I want use thus a button to “switch on” and one to “switch off” or an on/off switch.

But also a potentiometer to select the minimum level (depending the power of each motors) when the motor start running and a potentiometer to select the timing (555) between the slow start and the full speed (maybe also shortcut the triac with a relay to have full speed an a green led if it is relevant (but it will be nice) for the switch off the timing maybe reduce. Why at the end because the extra current and problems binded.

Note : I have seen this application with “fpla” or dedicated processors but I am sure it can also be done with discrete components.Why i can not do that : because I never study the motors correctly but I know for example that it is not correct to start the motor with a zero crossing system because It give a maximum current and that make the same trouble (FIRE!) with the couple at start and max current …

I have seen this request in other forum touching other job mechanic wood etc … with no answer and people say also if it work with a potentiometer but when you change from a machine to another you can make mistakes etc…Regards Botte Bernard (Belgium)please don’t put my adress on the net Nb i like also in your presentation the datasheet because it’s no so easy to have it without paying

Bernard Botte

Designing the Stepped Phase Control Circuit

The requested idea of a soft start, soft stop motor switching circuit can be implemented using a simple triac based dimmer switch concept, as presented in the following diagrams:

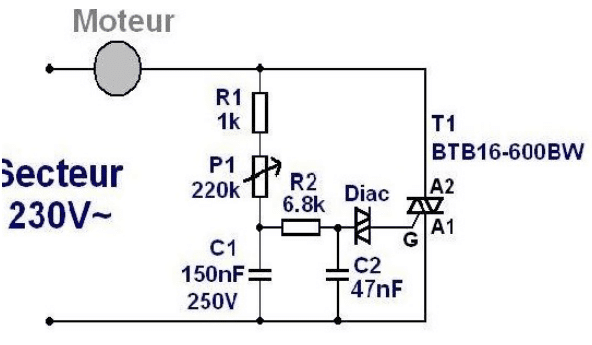

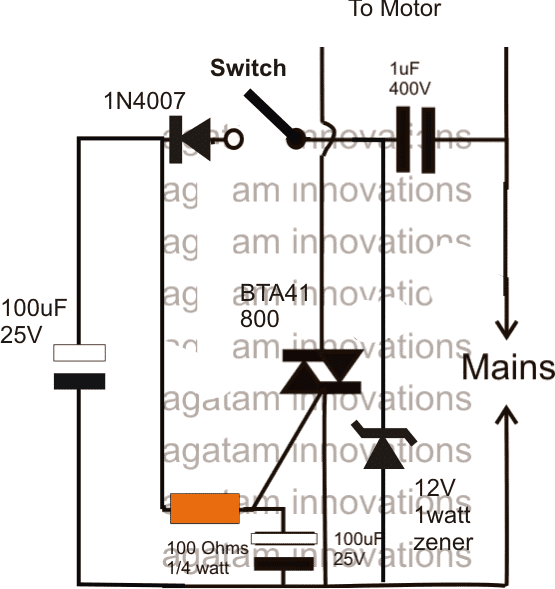

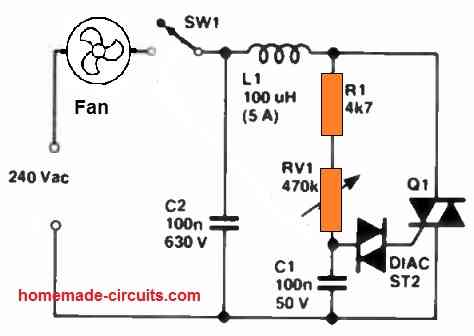

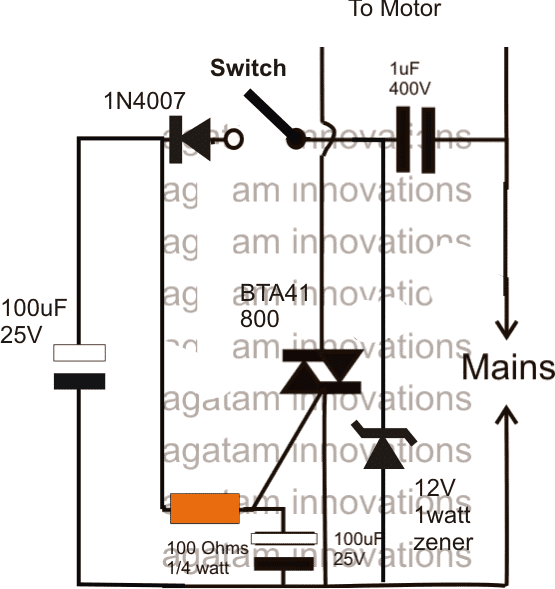

Referring to the above diagrams, the first diagram shows a standard light dimmer or a fan dimmer switch circuit using a heavy duty triac BTA41A/600.

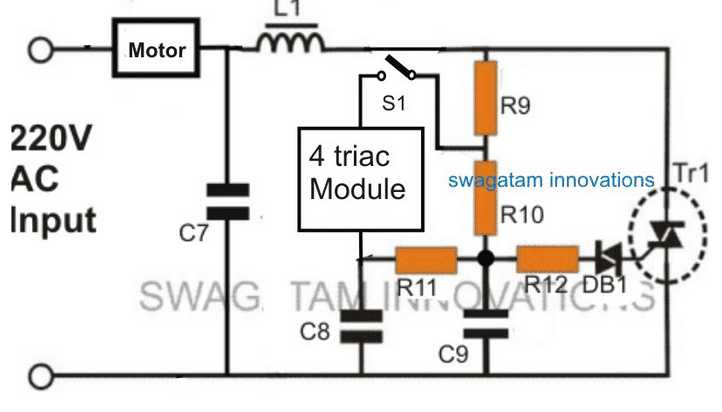

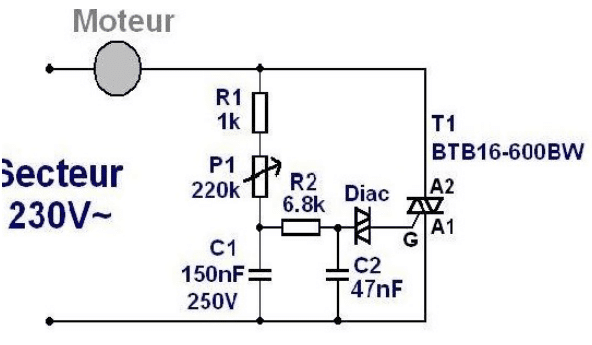

The section which indicates the “4 triac module” is normally occupied with a potentiometer for enabling a manual speed control adjustment, wherein a lower resistance adjustment generates higher speed on the fan motor and vice versa. In this soft start, soft stop design, this pot section is replaced with the indicated 4 triac module which can be elaborately visualized in the second diagram.

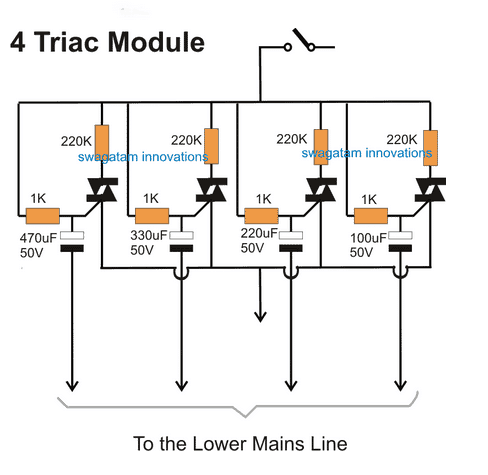

Here we see 4 triacs arranged in parallel having 4 individual 220K resistors at their upper MT1 arm, and 4 individual capacitors at their gates with different values, and with a sort of sequential order of high to low. When S1 is switched ON, the triac having the lowest value capacitor switches ON first, enabling a relatively slow speed start on the motor due to switching of the relevant 220K resistor at its MT1.

Within a few millseconds the next subsequent triac conducts which has the next smaller value, and adds its own 220K resistor in parallel with the earlier 220K resistor, allowing the motor to gain some more speed. Identically, the third and the fourth triacs also sequentially switch ON within the next few milliseconds, thereby adding two more 220K parallel resistors in the range, which finally allows the motor to reach its maximum speed.

The above sequential speed increase on the motor allows the motor to achieve the intended slow start switch ON, as desired by the user.

Quite similarly when the switch S1 is turned OFF, the relevant capacitors switch OFF in the same order but in a descending manner, which inhibits the motor from a sudden stop, instead it causes a step wise slow stop or slow end on its speed.

Feedback from Mr. Bernard:

Dear mister Swag, First of all, thanks for your fast answer. Because you tell me you have a timing problem I have changed my operating system to linux mint 18,1 ‘Serena’ so i haved to re-install all the program I need and test it (setup it!) So apparently everithings seems working OK ! About the first schematic I notice you don’t give any value to the upper side schematics so I pick it up from « How to Make a Simplest Triac Dimmer Switch Circuit »

Parts List for the above enhanced fan dimmer circuit(C1) C7 = 0.1u/400V

(C2, C3) C8,C9 = 0.022/250V,

(R1) R9 = 15K,

(R2) R10 = 330K,

(R3) R11 = 33K,

(R4) R12 = 100 Ohms,VR1 = 220K, or 470K linear => Replaced by genial 4 triacs module

Diac = DB3,

Triac = BT136 => BTA41 600

L1 = 40uH

About the second schematic so simple solution i never have dreamed !!! to be tested asap Genial! we say in French.

I doesn’t know that you can use polarized condensators for such AC applications! And also that 50 volt was sufficient! I you have a moment to explain why -

Anyway maybe i’ll try it this weekend if i have all the component. I prefer use new capacitors my stock never change since 1993!

In fact i was trying different ways using for example opto triac (MOC) but i also need to pick the freq of the AC network, also another based on your schematic Kiln Temperature Controller Circuit but with up down counter 4516b and 555 etc,etc so complicated

Many thanks

Regards

B.botte

My Response:

Thanks dear Bernard,

The image which you had inserted in the conversation did not get attached properly and therefore it was not showing, but I have corrected it now and have posted it back in the article.

I have rated the caps at 50V because R9 is supposed to be a 33K or a 68K resistor which will drop the current significantly and not allow the capacitors to burn, this is my understanding.

I have used polarized capacitors because the gate of a triac works with a DC drive, but yes you are right, in order to make it DC for the capacitors we need to add a 1N4007 in series with the gate 1K resistors.

Now with regards to this design, if suppose the idea does not operate very smoothly or fails to produce the expected results, we could modify the existing gate drive for the 4 triacs into optocoupler based drivers, and perform the same sequential delayed switching but through an external DC circuit.So this circuit ultimately has the potentials to deliver the intended results, either this way or that way.Regards Swag

YES I HAVE ALREADY ASSEMBLED THE 2 CIRCUITS AND THEY WORK

https://www.homemade-circuits.com/how-to-make-simplest-triac-flasher/

https://www.homemade-circuits.com/simple-ceiling-fan-regulator-circuit/

but with the SAME PROBLEMS = VARIATION of VOLTAGE at the OUTPUT

according to the VARIATION of the VOLTAGE of the MAINS at the INPUT

IT DOES NOT STABILIZE at 35v

this

" rel="ugc">

is the same as this one with minimal changes

" rel="ugc">

and I CANNOT USE POTENTIOMETER

SEVERAL PEOPLE WITHOUT SCHOOLING USE THE MACHINE

LOW INCOME COMMUNITIES = RECYCLING CENTER

so REMEMBERING the VARIATION of the ELECTRICITY GRID

110v varies between 107v to 127v

220v varies between 212v to 232v

how to ADD a ZENER or SOMETHING SIMILAR " rel="ugc">

" rel="ugc">

to FIX at 35v at the OUTPUT in these 2 CIRCUITS " rel="ugc">

No, these two diagrams are not the same…they are completely different.

" rel="ugc">

" rel="ugc">

In an AC dimmer circuit, if the input voltage changes then the output AC will also change it cannot be controlled with a zener diode.

If the 35V is DC then it can be stabilized to a fixed 35V…

in the PREVIOUS QUESTIONS

I am always making a REFERENCE of 35v OUTPUT also in ALTERNATING CURRENT

that is, a SIMPLE DIMMER with STABILIZED OUTPUT

in BRAZIL TRANSFORMERS are things from the MOVIE JURASIC PARK

If you want a AC dimmer circuit, you can try one of the designs from the following articles:

https://www.homemade-circuits.com/how-to-make-simplest-triac-flasher/

https://www.homemade-circuits.com/simple-ceiling-fan-regulator-circuit/

very bad google translation

or you didn’t understand my question

" rel="ugc">

this is nothing more than a DIMMER

with ZENNER to keep it at 12v

1-how to ADD a 110/220v SWITCH in this same circuit and which components to add/change???

2-if you CHANGE the ZENER to 35v will the OUTPUT also be FIXED at 35v???

Thanks again

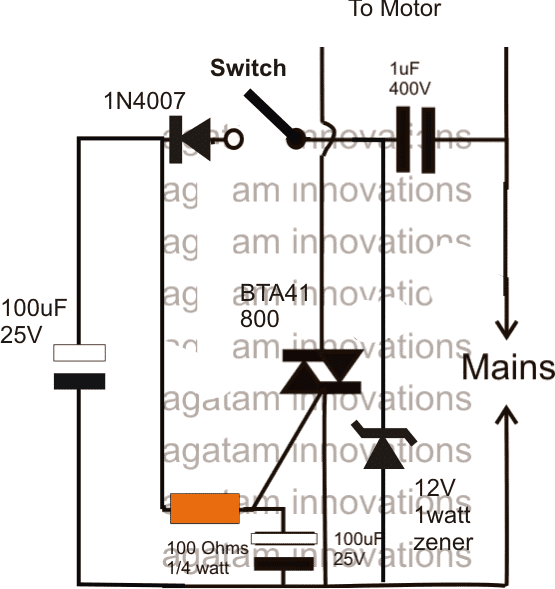

It is not a dimmer circuit, it is soft-start Triac switch with delay circuit.

The circuit will work for both 120V and 220V inputs so need of any switch.

The zener diode has nothing to do with the output voltage, it is just for stabilizing and rectifying the triac gate voltage.

Hi Mr. Swagatam

my English is very bad

(text written in Google Translate)

Here in BRAZIL the ELECTRICITY GRID is a BIG GARBAGE

110v varies between 107v to 127v

220v varies between 212v to 232v

I use a MACHINE that has a WIRE RESISTANCE

(shower type) 35v 300w

with the VARIATION of the GRID this RESISTANCE BURN OUT of nowhere

in this SIMPLE CIRCUIT

" rel="ugc">

is it possible to ADD a 110/220v SWITCH

or make this GRID CHANGE AUTOMATIC???

and the ZENER can LIMIT=FIX the VOLTAGE OUTPUT at up to 35v

even with the VARIATION of the ELECTRICITY GRID

if you can SHOW the COMPLETE CIRCUIT in an IMAGE I would appreciate it

my electronics are basic / just circuit assembly

and component replacement

Thank you for your attention

LUIS BUENO

99% RECYCLED-Brazil

Hi Luis,

A 35V load will certainly burn if it is used with a supply of 110V or 220V, so you must operate it with a regulated supply of 35V only.

If you use a 35V supply then no changeover or surge control circuit would be required.

However to convert a 110V or 220V to 35V 300W you would require a large transformer.

Let me know if you can procure this transformer…

In the Option 2, can I add an MCU switching option at the 47Ohm resistor with an optocoupler like PC817. Then, the Switch to the motor will close for all time. By allow current at the resistor (47Ohm), the BTA41 will be triggered.

I am thinking of this to make a compact SoftStarter for the single phase submersible pump so it can be controlled via ESP32. Also, I dont see RC snubber in the option.

Please advise with thanks!

An MCU might not work since it cannot control the triac with a 75% or 50% power output.

Only a triac dimmer setup as shown in the diagram can be used to implement the above.

You can add an RC snubber to the triac, or use a triac which has an in-built snubber circuit.

Hi Swagatam,

I have made a dimmer Using BTA41 with H11AA as the ZCD using the option 2 controlled by an ESP8266 promin D1. I also have a dedicated Soft starter (a Chinese brand) at hand using SSR. What I am wondering is: the Chinese one have functions to delay the starting up in xx seconds (means at the end of that time range, the voltage will ramp up to the full voltage from the beginning set level . i.e 50% of main voltage). So far as I understood, using triac mean cut off power provided to the pump at some segment from zero cross point and increase the duty cycle along the progress of the defined time. Does it mean the Chinese soft starter will do the same?

The reason I am asking is whether it would be okay for using the dimmer approach (typically the same as option 2) to control the soft starting up of the submersible pump using Esp32/8266? I knew that dimmer can not be used with regular AC fans but for light deeming only.

Best regards

Hi Dang,

I guess you are referring to the Design#1 from the above article, which incorporates a PWM approach through an opto-coupler?

Yes, your assumptions are correct regarding the soft-start using a controlled duty cycle. The Chinese circuit could also be doing the same.

If you are using Design#2 then the opto coupler is not required and it cannot be interfaced with an MCU.

The first circuit can be interfaced with a PWM MCU or any ramping PWM source.

An AC dimmer is specifically intended to be used with regular AC fans, provided they are capacitor-start type and not BLDC.

I’ve just joined your site today.

I’m keen to build the circuit with four triacs. I’ve purchased the components required to build this circuit.

I’m just unclear on some details. In the second diagram it shows four arrows pointing down and says “To the lower mains line.” There’s a shorter arrow pointing down in the middle of the four longer arrows. Where is this supposed to connect to?

Also, does the switch to start this circuit need to be a 10 amp?

And in the first diagram it shows a circle around Tr1. Does this signify anything?

Thanks.

Hi, sure, you can try it, but please be aware that the design is based on my assumptions only, so i am not confident whether it will work or not.

The short arrow will go to the junction of R11, C8.

The longer arrows will go to the bottom common line which connects with C8, C9.

The switch can be a 1 amp switch, that’s enough.

The circle indicates that the triac Tr1 might need a heatsink, depending on the load power spec.

Ten months since I placed my first comment. It’s taken me this long to get around to finishing building this circuit, based on your schematic above.

I fired it up today, and nothing at all happens. I’ve connected the circuit to a small motor out of a fan heater. The motor works fine without the circuit. I’ll go through all of my connections to look for faults.

I read above the following:

“I have used polarized capacitors because the gate of a triac works with a DC drive, but yes you are right, in order to make it DC for the capacitors we need to add a 1N4007 in series with the gate 1K resistors.”

I didn’t follow this part as they weren’t included within the circuit diagram. Do I need to re-do the whole triac module with four 1N4007 diodes?

Many thanks!

Initially, can you please remove the 4 triac module entirely and replace it with a pot as shown below, and check whether moving the pot varies the motor speed or not?

" rel="ugc">

That’s not the circuit I built. It’s this one, and the four triac module.

Yes, the pot in the above circuit is replaced with the 4 triac module, so temporarily please remove the 4 triac module and replace it with a pot to check if the circuit works in the basic mode or not?

My bad. Upon doing some more continuity testing on my circuit board, I found that cap C7 was not connected to the motor and L1. Really silly of me to not notice that, but it’s all about learning.

There was another track I had found earlier also not connected.

After this latest “debug” the motor finally runs, but it runs without the switch going from between R9 and R10 being activated. I guess I’ll have to do some more checking of all my soldering joins. 🙂

OK, no problem!

R10 must be a high value resistor of around 330k or 470k. Did you use this?

Hi Swagatam, I’m still working my way through trouble-shooting the circuit I built. I haven’t tried using a potentiometer yet. I’ve copied the image of the first circuit and annotated the component values onto the image, to confirm I have used the correct ones. I’m confused about one of the components used. In the original image it says the Diac = DB1. However in the parts list is says DB3. Which is the correct one please?

Hi Stu,

DB3 is the correct one, and is easily available.

Let me know if you any further doubts or questions.

HI Swagatammy ? is i have deep well pump 120 voltscan i install a soft starer and if wher can i found them

thanks

Hi Mario,

You can add one of the above soft start circuits to your 120V deep well motor, however you will have to first build the circuit and verify its functioning on a workbench, I am not sure whether this circuit is available ready-made or not.

Hi Swagatam;

I found a motor P/N: KM-36F1-500 allegedly it is for the water meter purpose and it has mini gear box. Some sellers introduce it as 3 V and others do 12 V. The coil resistance is about 5 or 6 ohm. How I can decide on proper voltage? Best Regards

Hi Suat,

You can start from 3V and slowly increase the voltage and check at what voltage the motor starts warming up. If the motor starts warming up at a certain voltage level that will indicate a high voltage for the motor. You can reduce the voltage by 1V from that level to ensure the correct voltage for the motor.

Hello, I want to thank you for this article. I do need clarification on my specific situation. I have a 240V 60Hz submersible water well pump that I run with a 4000 Watt engine generator. The inrush is too great for the generator but I can turn the pump switch on and off rapidly to keep the generator from choking off until the pump starts spinning enough for the generator to handle the load. Obviously the turn solution is a larger generator but I think a slow start circuit may replicate what I am doing manually with the on/off switch and save me some money. My question is because this pump uses 2 hot wires plus neutral, do I replicate the slow start circuit on both of the hot legs or do I just need the one circuit?

Thanks for any help you can provide.

Hello, yes you can use two relays, or a single DPDT relay. However, you can also try 3 relays, meaning a relay for the neutral wire also, to make things entirely safe.

Hi Swagatam,

On Simplified Soft Start diagram above, the current run through the triac is only a few second before passed back by relay, for motor less than 1 HP, can I replace triac by an SCR? If so, any circuit change?

Thank You.

H Awak, I think that is possible. You can use any 300V, 8 amp SCR for the purpose. Use of SCR will allow a better slow start for the motor, since only the half AC cycles will be passed to the load thereby causing slower start for the load.

Thank a lot Swagatam, I will love this curcuit that will solve my water pump problem.

My pleasure Awak.

Hello,

I have 3hp 220V single phase motor for table saw.. currently starting with 40uf cap. for soft start from Q&A below I understand scheme 2 is best. as I have very little knowledge in electronics.. could you help –

1. what resistance should be R2?

2. what trigger voltage of diac?

3. will starting capacitor still be needed?

Thank you for a great and inspiring website!

Jonatan

Hello,

the starting capacitor is supposed to be a part of the motor, it is not associated with the dimmer circuit.

R2 will need to be experimented to find which value generates around 60% of speed on the motor without the relay assembly.

Hi I’m trying to find a suitable cct to enable a starter motor (on a classic Norton motorcycle) to soft start. It runs at 12v and 50A DC quite successfully but the mechanical system wears due to the shock load and a soft start would enable the system to cope better.

Many thanks

Hi, You can try the second design from the above article:

https://www.homemade-circuits.com/pwm-motor-soft-start-circuit/

If you can build it correctly it will do the job for your as intended.

Hallo sir. I use a 2000 wat cut of machine, always trip without a soft start. My workshop using 2200 va 220 volt. A lot of soft start free tutorial is starting using external on of switch, so the switch on the machine must be modified. Can it be modified fot alot of tools so it just plug into the soft start. And switch using the machine without modified the on of swith on the machine, like the japanese made soft start i buy, it just plug the machine to soft star, an it run automatically when i switch the machine on. The last time i made the soft start is using the switch on the soft start not automatically by the machine, so the switch on the machine has to be tied in the on switch. I thinking of making the soft start that trigered by the current flow when i switch on the machine. Thx alot.

Hi Bayu, I do not have a current triggered soft-start circuit with me now, if I happen to find one, will let you know!

Hi Bayu, I do not have a current triggered soft-start circuit with me now, if I happen to find one, will let you know!

Did you manage to find one of these circuits ?

If so please send to me

hello sir

I am using the 2nd circuit, in that if I use BTA136, it works for some time then got damaged after some trials. Means MT1 & MT2 of ic got short when I check the ic separately.

And then I used BTA41 as in the figure, then R1 is getting hot. I used 470k Pot at R2.

I used 1000W Drill as load.

Hello Rutvik, it could be due to heavy back EMF from the drill machine, which might require stronger snubber network for the triac. I would rather recommend using a phase chopping control circuit for the drill machine instead of a PWM circuit. You can use a dimmer switch with BTA41 triac as shown in the following article:

https://www.homemade-circuits.com/how-to-make-simplest-triac-flasher/

Hello Sir, i am using BTA41 triac, the heating of R1 is solved but the triac turns on even without connecting R2 in circuit. When i connect just C2 without connecting R1 and R2 the triac is turning on.

Hello sir, the circuit with BTA41 is working perfectly. I mistakenly reverse the mt1 and mt2 connections

thank you so much for the help.

Just one more query I have that the soft start is working perfectly but when the load switches to relay it gets an instant change in speed. It didn’t change smoothly so is there anything to do to switch to full power smoothly.

Rutvik, the slow start is from 50% or 75% by the triac initially, and then 100% by the relay, there cannot be any intermediate stage in between this. Otherwise you may have to build the LED/LDR based circuit, where the LED will glow slowly and cause a slow speed increase of the motor automatically.

Hii

I am trying to make the 2nd upgraded circuit but when i turn on the supply 15k register are burn and realy is not triggering what should i do now

Hi, which resistor did you use for R2. R1 can never burn due to the presence of R2 in series, there could be something wrong in your connections.

The relay circuit is a simple capacitive power supply based design and it has to work. What is the coil resistance of the relay??

Coil resistance is 411ohm i am trying this circuit can you please tell me how to connect the relay i have 5 pin relay coil 1,2 and no3, nc 4,5comman please let me know how to connect them with the circuit and right now i am not able to

Get the full output

you can read this for more info on relays

https://www.homemade-circuits.com/how-a-relay-works-in-circuits-how-to-connect-it/

Hi there!

May I ask what is the best solution in the end? It’s a bit confusing for me. Thank you so much!

Hi, the second circuit is the best possible solution…

Wait a sec! 🙂 I thought you said that <> And afterwards you put more circuits. This is why it is becoming a bit confusing. I hope you understand.

So.. you are referring to this one when you say that it is the best?

" rel="ugc">

yes that’s the diagram I was referring to. Instead of the capacitive power suply using 2uF you can use an AC to DC adapter for better safety to the BC547 to the transistor

Thank you so much!! I will look into it.

In the second circuit “Upgrading Triac Soft Start with Relay”, what mHenry value should L1 be?

I have various inductors/chokes and toroidial coils on scrap boards. What would be the most suitable?

I assume L1 is supposed to limit the current similar to the choke in a fluorescent strip light?

L1 and C1 are not critical you can remove them entirely. They are normally included in fan dimmer applications to eliminate RF noise into the atmosphere, since phase chopping creates a lot of noise. These noises can have adverse effect on some sensitive equipment and also produce disturbing noise in AM radios (rarely used nowadays)

In the second circuit “Upgrading Triac Soft Start with Relay”, what mHenry value should L1 be?

I have a passive PFC choke from an old CRT TV PCB and various toroidial coils from old ATX PSUs.

What would be suitable? Does L1 act as a current limiter similar to the coil/choke in a fluorescent strip light?

hi there,

will the soft starter work for a 24V dc motor.

Hi, this will not work, but you an try this:

https://www.homemade-circuits.com/pwm-motor-soft-start-circuit/

It is good circuit for motor soft starting.can I get complete kit from any where online purchase.

Pv mM based much improved simplified circuit I wish to use along with 555 based automatic water level controller (efy circuit)with ON/OFF relay.Hope I can use your circuit.

Hi Ravindra, you an surely use any of the above concepts with your existing module…

Ravindra, sorry I do not have much idea regarding the availability of such kits online.

Hey Swatagam, what a great site for information. I am trying to find a circuit for a simple soft start on a single phase blower motor (120 VAC/10 amp) and am looking to limit the inrush current to 10 amps. The current inrush I'm measuring is 25 amps. I like the simplicity of the 4th circuit but am more interested in limiting the inrush current than protecting the switch. I also need something that can handle multiple on/off cycles so a NTC thermistor can't be used.

Much Appreciated!

Tim

Thanks Tim, I am glad you liked my site…yes if you are looking just to stop the inrush then an NTC would be quite good, and you can select the appropriate one as per the specifications. You can refer to this website for the chart from which you can select the one that may suit the best for your requirement

https://www.digikey.com/en/ptm/a/ametherm/choosing-ntc-thermistor-for-inrush-current-limiting-capacitive-applications

sorry, I thought you preferred NTC…..however NTCs can be used for multiple ON/OFF situations also, an NTC will not get damaged until its maximum current specification is not crossed

Unfortunately, the cooling time on the NTC won't work for this application and am looking for a circuit that will limit the inrush for multiple on/off cycles possibly within 10-20 seconds. So I was looking for an active circuit.

Tim

In that case you can try the first circuit in this article, this circuit appears to be the most feasible one among the other designs, the relay can be eliminated if required

The LED could be operated through a small capacitive power supply connected with the motor switch, and a relatively large value capacitor added across the LED for achieving a slowly increasing brightness….

Hi Swagatam, nice blog, keep on writing. Can you please explain working of 4th(last) circuit. I am bit confused.

Thanks Rahul, In the last circuit, the switch is prevented from taking the heavy load of the motor and is used to toggle the low current triac gate, this ensures a permanent life for the switch, and additionally the 100 ohm resistor along with the 100uF capacitor causers the triac to switch ON rather sluggishly which in turn enables the motor to achieve a kind of soft start…

I want to build your 4th circuit to drive 150W 230VAC waterpump.

BTA16-600 is fine, right?

Is heatsink necessary?

Should I change 100ohm resistor? because BTA16 gate trigger current is smaller than BTA41.

Sorry my english is bad.

Thanks so much..

yes 16 amp triac will do for a 150w motor…but heatsink will be required.

100 ohm can be replaced with a 470 ohm resistor.

I personally prefer the second design as it looks more effective for the proposed application.

Hi Mr. Mujamdar

Found your website while searching for a soft start for a table-saw, very interesting site, i read all the comments for that design unfortunately i'm totally confused about which of these circuits to use.( ref: https://www.homemade-circuits.com/2012/09/adding-soft-start-to-water-pump-motors.html).

My table-saw is 110v 13amps brush type motor, could you pls. help choosing the appropriate circuit.

Thanks

Roger

Thanks Roger, the PWM approach is the most sophisticated one and according to me this concept should be ideally employed for all motors for getting a perfect soft start

the second option from the above article is also a good one which you can try. the resistor in question will need to be optimized appropriately.

Thanks for the prompt reply, i'll try the PWM option.

Thanks again very much appreciated.

Roger

you are most welcome!!

You can try a PWM based soft start circuit to tackle this, if still it does not start then the inverter power might need to be upgraded.

https://www.homemade-circuits.com/2015/06/pwm-motor-soft-start-circuit.html

Hello,

Great work sir.

Will this work for a 115v 2hp 19.8A compressor motor? I am attempting to run off of a poorly made modified-wave 5kw/10kw power inverter that cannot handle the start-up surge.

Thanks -ray

Thanks, Ray,

yes you can try the above designs, however these will require some initial tweaking and optimizations to make it work correctly for an application.

hi sir, thanks for the blog, could u give something on disadvantages of soft starters

PWM soft start probably has no disadvantages…

Sir good day..sir can this ckt be applied to a three phase motor?..if not, do you have a ckt for a three phase motor

Rea, for a 3 phase motor, it would be more appropriate to incorporate a PWM based soft-start, which looks reliable as described in the following article:

https://www.homemade-circuits.com/2015/06/pwm-motor-soft-start-circuit.html

Hi everyone,

Can i have your e-mail? i want to discussion about my project. my project is water pump pressure controller. i have problem to create the circuit. tq

Hi Everyone,

I have a small 6v dc motor to drive a model carossel I would love to have a soft start or slow start, to make it look real, max amp draw would be no more than 1 to 2 amps, nominal draw would be around 500 to 800 milliamps, does any one have any ideas as to what I can use.

Regards Peter

Hi Peter,

you can try the following concept:

https://www.homemade-circuits.com/2015/06/pwm-motor-soft-start-circuit.html

hi i want a soft starter just for 1 hp starting capacitor with clutch based motor which circuit of soft starter should i use? can u plz tell me?

Hi Naveed, you can try the second circuit from the above article, I would be also publishing a PWM based soft start circuit soon, which you can refer to for your application once it gets published

Any switch that can only ON then OFF using any technique without switch OFF manual.

sorry, I could not understand your need….

I need a soft start for a 15 amp, 120 volt Table Saw. I think circuit 2 is what I need? what is the value of L1? I have plenty of coils and chokes but can only identify by inductance and size. My triac is rated for 40 amps.

L1 is not critical, it's introduced only for suppressing noise in radio receivers, however you can make it yourself by winding around 200 turns of 1mm magnet wire over an iron bolt

Swagatam sir

magnet wire mean enamelled copper wire Right ?

that’s correct!!

Hi there, first of all I need to congratulate your writing and your site, it is very good, so far it has helped me quite a lot, that said I would like to make this circuit for my place, but I have one issue.

I can't find this TRIAC anywhere, (there's not much supply/demand for electronic components where I live), I can find smaller TRIACS, but I don't know if they will be able to behave just like your circuit. Do you think I could replace this TRIAC with a more modest one?

The specifications of my motor are:

Power: 1 HP / 0.746 kW

Voltage: 127/220 V

Current: 16.9-8.1 A

Any help will be highly appreciated, cheers!!

Hi thanks! you could probably try using a 10amp triac which is comparatively smaller than the shown one. A 10amp triac would hopefully handle the initial kick of a 1HP motor, moreover the attached dimmer circuit would set the triac at around 25 to 50% less current so it would quite fine (the second circuit in the article)

hey!! thanks a lot for the response! I managed to find a BTA16-800B, hopefully it will do the trick, I will try the second circuit in the article with this triac, and the specificacions of the motor I posted above, hopefully it will be able to have that initial kick, start, and don't have that pick of current.

I'll post my results back, cheers!!!

Hmm..BTA16-800 looks quite OK to me since it's rated to handle at least 16amps continuously.

I sincerely hope you succeed in achieving the intended results, wish you the best!!

Hi,..

I'm using PSpice to simulate voltage at the gate of BTA.

I replace capacitor 100uF to 470uf, voltage increase from 0 to 5 Volt in 1 second. Is that mean Triac output will slowly increase from 1 to 220V in 1 Second?

I Dont know the working principle of the triac,.. Sorry, I'm Newbie in Power Electronics…

yes it would slow down the triac anode to cathode current but only for a very short duration, after that the triac would instantly fire to full conduction.

You can also refer to the following design which I posted recently, and it makes more sense:

https://www.homemade-circuits.com/2014/06/motor-soft-start-circuit-for.html

I do understand that no more fire in pressure switch (for my case using waterpump), because TRIAC taken that job,

But how this circuit reduce motor starting current?, As far as I can see this circuit look no delay at all…

try the second circuit, the last circuit is specifically intended for protecting the contactor or the switch, it may not help in providing a slow start

Hello, thank you for posting this circuit..

for last circuit, Is that suitable for 100 to 300 Watt motor waterpump?

Diode 4007 and Relay 12 V, what is that for in the circuit?

Thanks

Hi, thanks, yes it would be suitable since the triac is capable of handling well over 30 amps.

the relay is for switching the triac ON, so that the switch is relieved from any sort of initial surge current and thus makes sure the switch lasts forever.

the diode is for half-wave rectifying the relay supply voltage from the 1uF capacitor.

in this scheme:

3.bp.blogspot.com/-62VIG17IfmA/Ul5QSpoYZFI/AAAAAAAAFgQ/jhSjl1jMmtU/s1600/motor+soft+start+circuit.png

I traded a variety of values of capacitors but nothing all the same moving at full speed

and relay 12v very much to hear there are probably more than 12V

I can not believe that the Google can not find a scheme that works soft start

the motor will not take 1 second or 2 seconds to catch speed, if it does in that way it's coil could burn.

electronics is all about understanding and then building.

The 100 ohm resistor needs to be increased also along with the capacitor to influence a delay.

The relay has no connection with the delay it's the triac which causes the delay.

Figure 3 is a not good scheme for electric motor immediately at full speed

why?…..first of all it's designed for safeguarding the switch contacts not for soft start.

however the 100uF capacitor at the triac gate could effectively produce the required soft start also…

Hello again Swagatam,

I stumbled across your blog, again, when looking for a circuit allowing me to drive an air compressor (and maybe a small fridge) from an inverter rated for 300W, with a peak of 600W. The compressor itself draws 240W, but the truck's fuse allows for 300W, no more. Direct battery connection is impossible as it sits below the driver's floor. Inrush current is unspecified.

Do you know how much current would be drawn with your circuit when compressor is started?

Hello Pat,

A soft start feature could be initiated by suitably selecting R2 in the second circuit however all the circuits explained in the above article are basically for safeguarding the concerned switches and contacts from the heavy initial surges which is implemented by diverting or sharing the current through a triac,

Any inductive load will necessarily draw the specified amount of current and it's quite recommended, I think you can use a slow-blow fuse which would wait for a second and will not blow if the surge does not last beyond that initial phase.

or may be you can try an electronic fuse as explained here:

https://www.homemade-circuits.com/2012/04/how-to-make-automotive-electronic-fuse.html

Hello,

I'm not sure to properly understand what you mean by "specified amount of current". Of course I don't expect the compressor to draw anything less than the 240W written on it, just to eliminate very high inrush current to avoid burning the inverter. By adapting the last circuit to account for the necessary "kick" in motors than can't be unloaded, like in a fridge, by how much would the inrush current be reduced?

Pat, If the motor is loaded, it wouldn't be correct to force a soft start to it because that would cause a choking effect on the winding and the motor would not initiate properly but keep drawing heavy current, so it has to be allowed to suck-in the required full amount of high inrush current, just to enable it to produce that initial "kick" and restore into the normal stance as soon as the motor has gained enough RPM.

The last circuit in the above article would not stop the motor from drawing the initial high current, it just ensures that the toggle switch is kept aloof from the initial surge and the contacts never burn due to these inrush currents.

Is this a good scheme for soft start:

static.elitesecurity.org/uploads/3/2/3215883/APEX%20soft%20start.jpg

could be, but the last design in the above article is simpler

can you build ponticiometar to that scheme I sent you, and exactly where and how many ohm

there's no easy way to insert a pot in the design, it will need to be modified greatly for that.

so can you change the schema with a built-in potentiometer with labels, of course if it is not a problem for you and thank you

the existing design is already set at 50% less power. for a pot control feature the MOC LED will need to be controlled through PWM using a IC555.

If possible i'll post it in this blog soon.

hi..

how are you i want to make a project to indicate the PH of water plzz can u help me.

hi, if possible i'll surely try to add the design soon in my blog.

Hi Bro..

How can I connect this above circuit with This one? https://www.homemade-circuits.com/2012/01/how-to-build-gsm-based-cell-phone.html

i want to start a 3 phase induction motor using this circuit..

I am sorry Udit, all my circuits are for single phase applications, cannot be used for 3 phase.

Hi Nick,

Yes, replace the capacitor across the relay coil with a 100uF/50 Volt…..

Hi Nick,

Replace the capacitor across the relay coil with a 100uF/50V, this will surely rectify the issue.

The circuit is actually pretty simple: If the relay contacts close, the triac would get the gate current and activate any load that's connected with its shown leads. So there's no chance the motor won't run.

You can replace the motor with a light bulb and check the response, if still it doesn't work then surely the triac pinouts may be wrongly configured or due to some other connection fault.

Hi Nick,

I have answered your issue in the previous comment, the circuit needed some corrections and it's been updated in the new diagram, please check it out….your relay is OK.

The last circuit had issues with the diode and the switch positions, I have corrected them, it should work now.

Hi

I am having trouble getting this to work. I think that all of my wiring and components are good and the right way round, except that the impedance for the relay is 1550 ohms. What might I change to get it to work? Or any other suggestions

Thanks