In this post I have explained a few interesting methods of constructing anti-corrosion probes for water level sensor and controller circuits by using alternating supply across the probes.

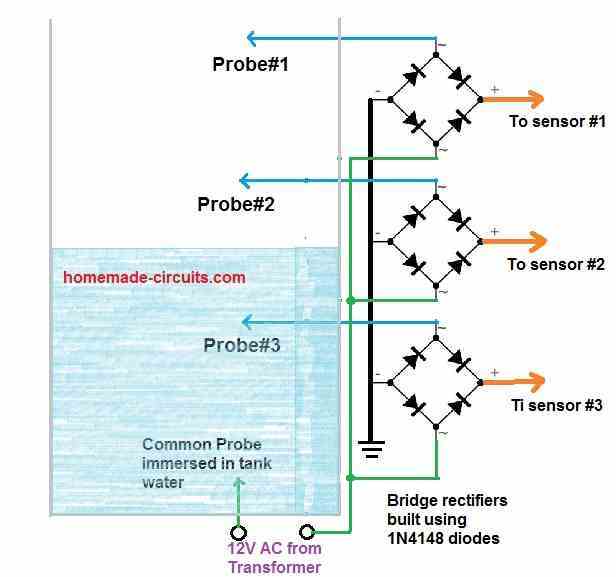

Using Bridge Rectifiers (New Update)

This simple anti-corrosion probe idea using bridge rectifiers happened to strike me recently and I decided to post it here for you all.

The complete circuit diagram is shown below.

The idea is actually very simple but very effective and cheap. A bridge rectifier circuit using 1N4148 diodes can be seen associated with each of the sensing probes.

One of the AC inputs of the bridge rectifiers are used as anti-corrosion probes for sensing the water level inside the tank, while the other AC input connections are made common for applying the 12V AC.

The other 12V AC terminal is used as the common terminal immersed inside the tank water.

The alternating current from this common wire passes through the water and hit the probe#1, probe#2 and probe#3 sequentially as the water climbs up in the tank.

This causes the AC voltage to pass through the respective bridge rectifiers and convert into DC across the relevant bridge rectifier outputs.

These DC outputs are then sensed by the attached electronic water level sensor circuit for switching ON or OFF the relevant relays or transistors.

Since an AC is used across the input probes, the probes remain perfectly immune to corrosion and thus the circuit works as an ideal anti-corrosion water level sensor circuit.

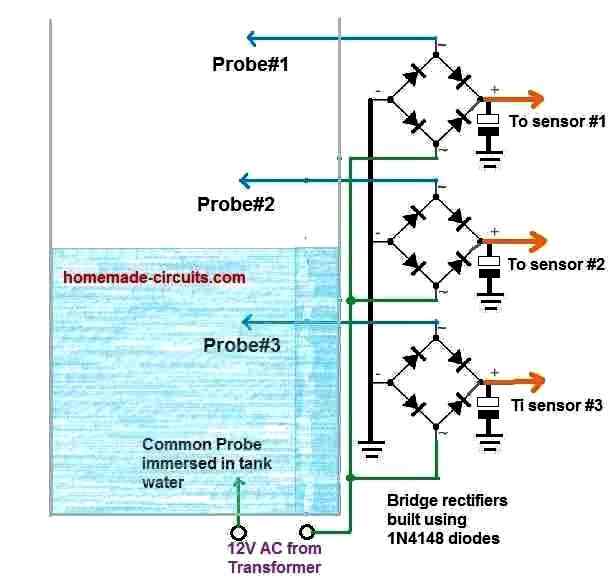

NOTE: PLEASE REMEMBER TO PUT FILTER CAPACITORS ACROSS THE BRIDGE OUTPUTS AND GROUND, TO FILTER THE AC TO PURE DC, AS SHOWN BELOW:

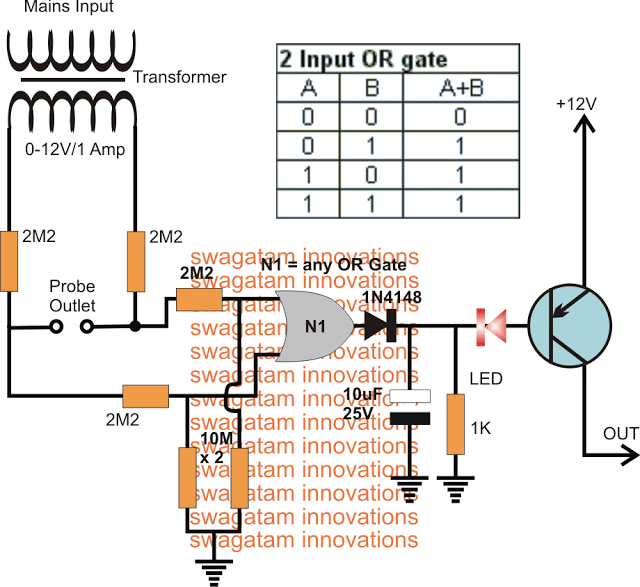

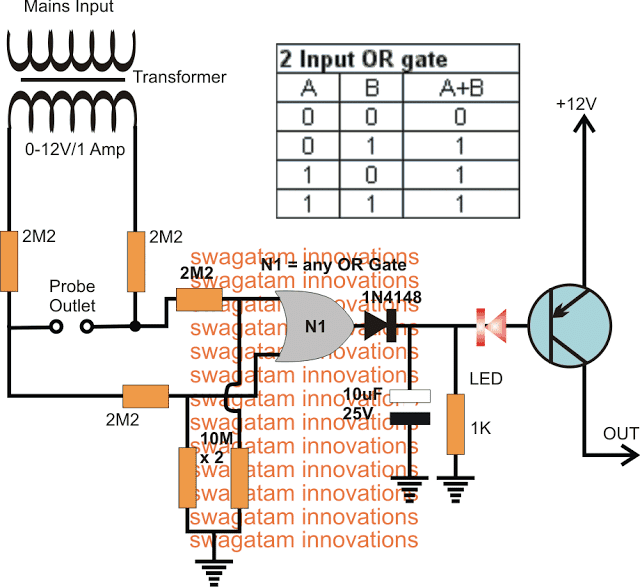

Using OR Gates

How it Works

So I have explained the above concept used for designing this anti-corrosion probe circuit for water level sensors and controllers.

Corrosion in water level sensor probes take place due to DC supply which is normally used for triggering the probes through water. This is aggravated by the process of minor electrolysis across the probe terminals which in the long term usage results in formation of layers of chemicals an minerals, gradually inhibiting efficient working of the probes and affecting the water sensing ability of the circuit.

To remedy this an AC supply is recommended so that the process of electrolysis is unable to develop across the probes due to the constant flipping of the supply polarity across the probes through the alternating nature of the supply.

In the design presented above, the AC supply is derived from a 12V transformer, via a couple of high value resistors for dropping the current across the probes.

The supply is carried forward to the inputs of an "OR" gate which specifically deals with this AC and produces the relevant output depending on whether water is present across the probes or not.

In the absence of water the applied AC generates alternately changing potentials across the two input pins of the OR gate. As per the truth table of the OR gate, a 0 and 1 or 1 and 0 on its inputs correspondingly creates an output of logic 1. This implies that while the alternate switching is applied over the two inputs of the OR gate, causes its output to consistently be at a logic 1.

Now if water happens to bridge the probe points, it instantly causes a relative short across the points causing the AC to disappear at the inputs of the OR gate.

In this situation both the inputs of the OR gate is held at logic 0, which causes its output to revert from logic 1 to a logic 0.

The above action switches ON the PNP transistor enabling the output to trigger the intended load such as a relay or an LED.

More number of gates could be employed with parallel probes points at different depths of the water tank in order to sense the various levels of the water if required, for building a multi water level anti-corrosion sensor probe circuit

The OR gate IC could be a IC 4071 or any other similar.

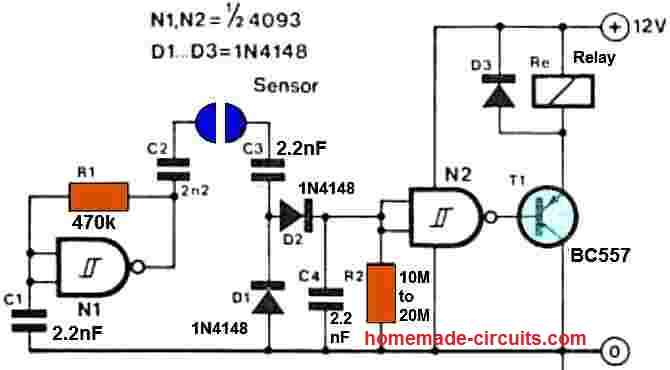

Another Design using IC 4093 NAND Gates

The impact of electrolytic corrosion between the liquid and the metallic sensors is an unpleasant disadvantage of several liquid level sensors. Metal electrodes are susceptible to corrosion, which results in a loss of efficiency (lower conductivity), necessitating their replacement at regular intervals.

A way to solve this is to guarantee that the sensor electrodes have an AC voltage instead of a DC potential. The electrolytic reaction is greatly slowed by the continuous change of electrode polarity, resulting in a significant reduction in corrosion.

The level sensor's fundamental working is relatively basic. An oscillator is formed by the circuit that surrounds N1. C4 will be charged up through the AC coupling capacitors (C2 and C3) and the diodes as soon as the two sensors are submerged in water, and the output of N2 would be pulled low so that the relay will be activated after a brief period.

As an example, the relay could be used to activate a pump, which then regulates the liquid level. Once conductive link across the two sensors leads is removed, C4 discharges through R2, causing N2's output to become high and the relay to turn off.

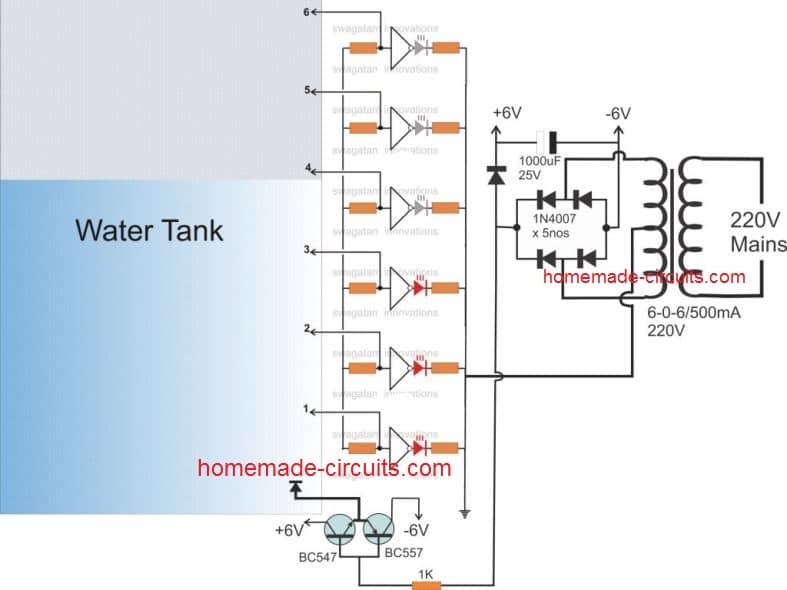

Simple Corrosion Free Water Level Sensor Circuit

The following figure a possible simpler method of creating a corrosion free water level sensing terminals.

NOTE: Please connect a 100K resistor between base/collector of BC557 transistor, otherwise it will not respond to the base 100 Hz switching

In the diagram we can see that the reference ground terminal at the bottom of the tank is supplied with an alternating +/- 6V instead of a normal DC. This forces the other terminals to conduct in a push-pull manner with the reference to this base terminal and this hopefully prevent corrosion from developing across the connected water level sensing terminals.

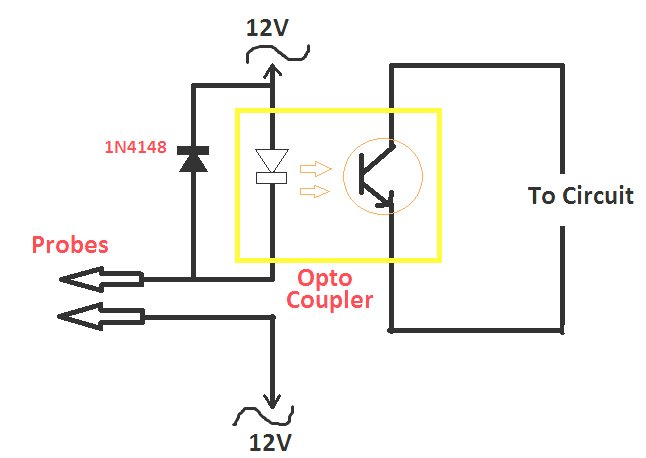

Using Opto Coupler

A perfect corrosion free water sensing probe can be built using an opto-coupler stage between the probe and the controller circuit as shown below:

As can be seen the probes are applied with a 12 V AC through the LED of an opto-coupler, and a reverse diode. One half AC cycles pass through the water and the probes by means of the opto LED, which triggers the controller circuit, while the other half AC cycle flows through the reverse diode.

The continuously reversing cycles of the AC ensures that no electrolysis of water is able to happen across the probes, which prevents any form of oxidation or corrosion development over the probes.