This article explains a simple pure sine wave inverter circuit using Arduino, which could be upgraded to achieve any desired power output as per the user's preference.

Circuit Operation

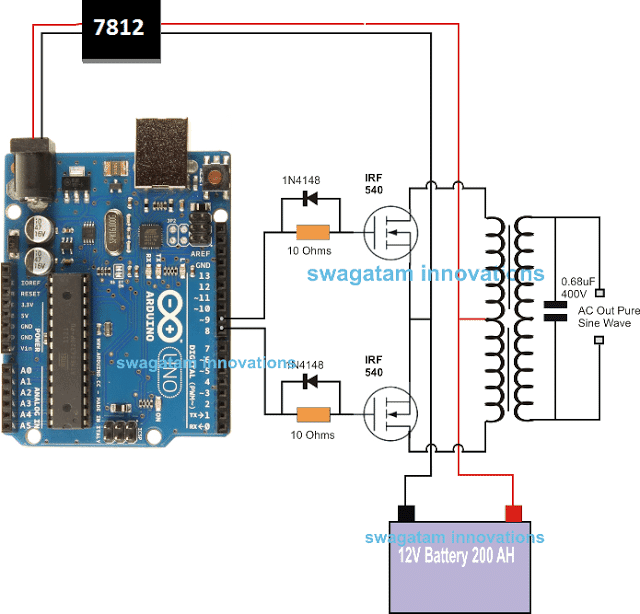

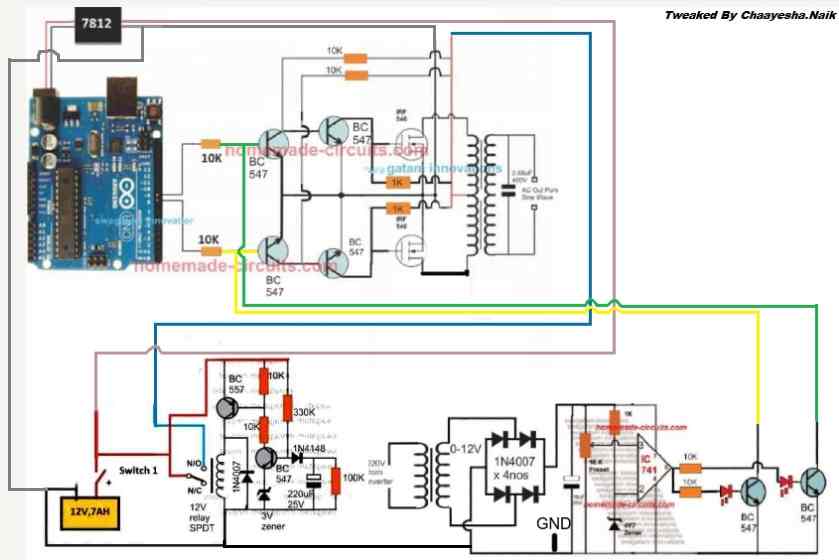

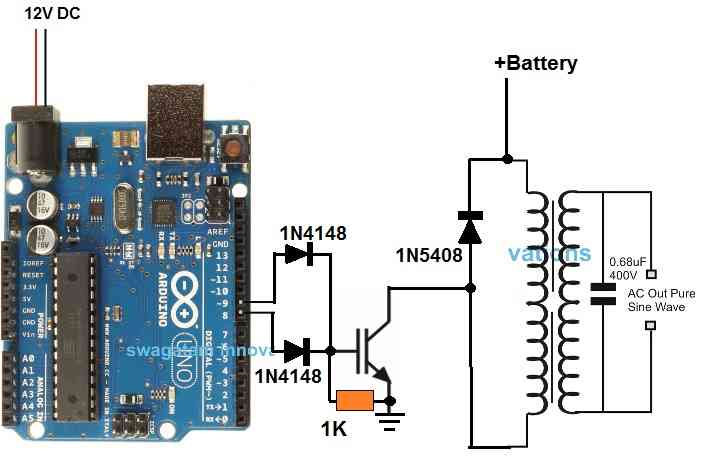

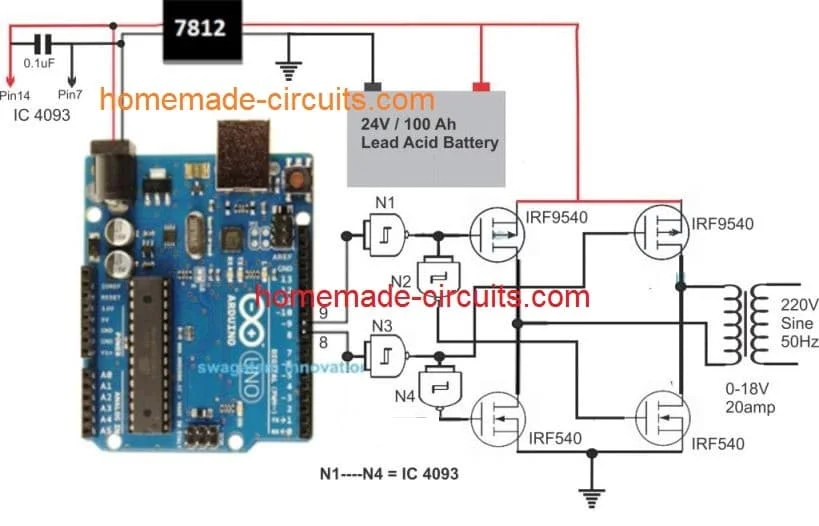

In the last article I have explained how to generate sine wave pulse width modulation or SPWM though Arduino, we are going to use the same Arduino board to make the proposed simple pure sine wave inverter circuit. The design is actually extremely straightforward, as shown in the following figure.

You just have to program the arduino board with the SPWM code as explained in the previous article, and hook it up with some of the external devices.

You may also want to read: H-Bridge Sine Wave Inverter Circuit

Pin#8 and pin#9 generate the SPWMs alternately and switch the relevant mosfets with the same SPWM pattern.

The mosfst in turn induce the transformer with high current SPWM waveform using the battery power, causing the secondary of the trafo to generate an identical waveform but at the mains AC level.

The proposed Arduino inverter circuit could be upgraded to any preferred higher wattage level, simply by upgrading the mosfets and the trafo rating accordingly, alternatively you can also convert this into a full bridge or an H-bridge sine wave inverter

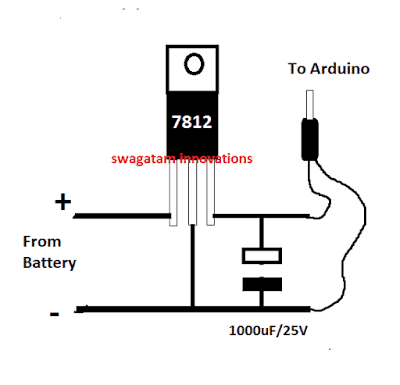

Powering the Arduino Board

In the diagram the Arduino board could be seen supplied from a 7812 IC circuit, this could be built by wiring a standard 7812 IC in the following manner. The IC will ensure that the input to the Arduino never exceeds the 12V mark, although this might not be absolutely critical, unless the battery is rated over 18V.

If you have any questions regarding the above SPWM inverter circuit using a programmed Arduino, please feel free to ask them through your valuable comments.

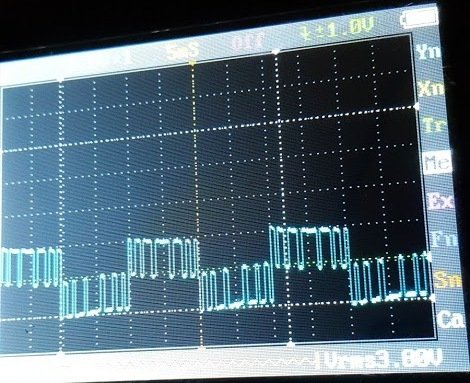

Waveform Images for Arduino SPWM

Image of SPWM waveform as obtained from the above Arduino inverter design (Tested and Submitted By Mr. Ainsworth Lynch)

UPDATE:

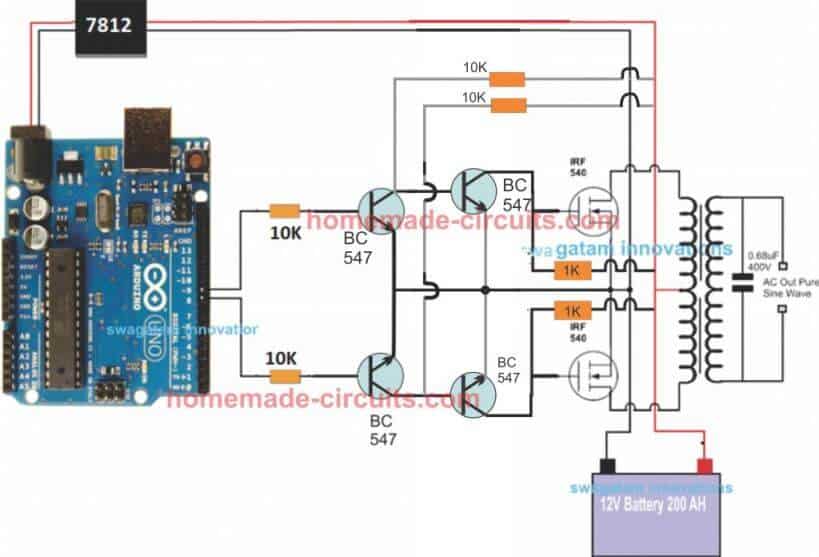

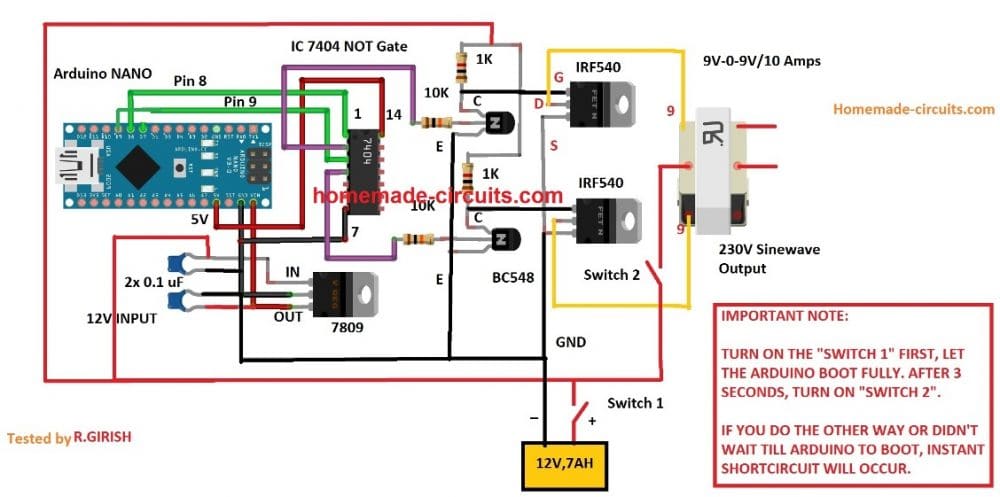

Using BJT Buffer Stage as Level Shifter

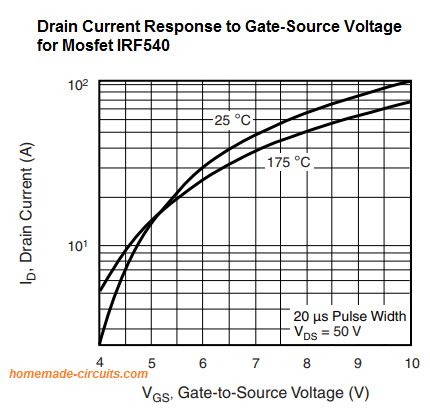

Since an Arduino board will produce a 5V output, it may not be an ideal value for driving mosfets directly.

Therefore an intermediate BJT level shifter stage may be required for raising the gate level to 12V so that the mosfets are able to operate correctly without causing unnecessary heating up of the devices,. The updated diagram (recommended) can be witnessed below:

Program Code for the above Arduino Sine Wave Inverter Circuit

// By Swagatam

void setup(){

pinMode(8, OUTPUT);

pinMode(9, OUTPUT);

}

void loop(){

digitalWrite(8, HIGH);

delayMicroseconds(500);

digitalWrite(8, LOW);

delayMicroseconds(500);

digitalWrite(8, HIGH);

delayMicroseconds(750);

digitalWrite(8, LOW);

delayMicroseconds(500);

digitalWrite(8, HIGH);

delayMicroseconds(1250);

digitalWrite(8, LOW);

delayMicroseconds(500);

digitalWrite(8, HIGH);

delayMicroseconds(2000);

digitalWrite(8, LOW);

delayMicroseconds(500);

digitalWrite(8, HIGH);

delayMicroseconds(1250);

digitalWrite(8, LOW);

delayMicroseconds(500);

digitalWrite(8, HIGH);

delayMicroseconds(750);

digitalWrite(8, LOW);

delayMicroseconds(500);

digitalWrite(8, HIGH);

delayMicroseconds(500);

digitalWrite(8, LOW);

//......

digitalWrite(9, HIGH);

delayMicroseconds(500);

digitalWrite(9, LOW);

delayMicroseconds(500);

digitalWrite(9, HIGH);

delayMicroseconds(750);

digitalWrite(9, LOW);

delayMicroseconds(500);

digitalWrite(9, HIGH);

delayMicroseconds(1250);

digitalWrite(9, LOW);

delayMicroseconds(500);

digitalWrite(9, HIGH);

delayMicroseconds(2000);

digitalWrite(9, LOW);

delayMicroseconds(500);

digitalWrite(9, HIGH);

delayMicroseconds(1250);

digitalWrite(9, LOW);

delayMicroseconds(500);

digitalWrite(9, HIGH);

delayMicroseconds(750);

digitalWrite(9, LOW);

delayMicroseconds(500);

digitalWrite(9, HIGH);

delayMicroseconds(500);

digitalWrite(9, LOW);

}

//-------------------------------------//Video Clip

Parts List

All resistors are 1/4 watt, 5% CFR

- 10K = 4

- 1K = 2

- BC547 = 4nos

- Mosfets IRF540 = 2nos

- Arduino UNO = 1

- Transformer = 9-0-9V/220V/120V current as per requirement.

- Battery = 12V, Ah value as per requirement

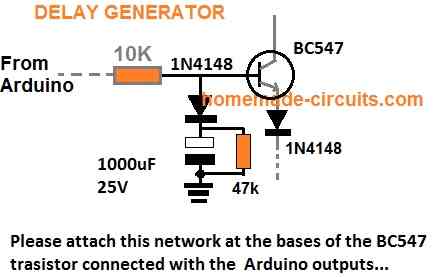

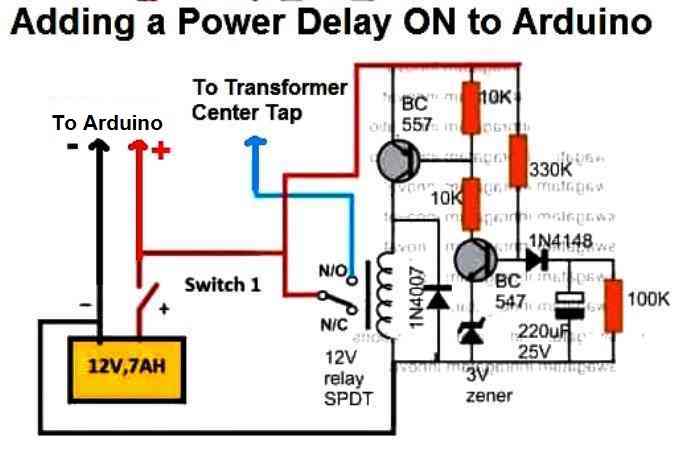

Delay Effect

To ensure that the mosfet stages initiate with a delay during the Arduino booting or start up, you may modify left side BC547 transistors into delay ON stages, as shown below. This will safeguard the mosfets and prevent them from burning during power switch ON Arduino booting.

FOR INCREASING THE DELAY YOU CAN INCREASE THE 10K VALUE TO 100K

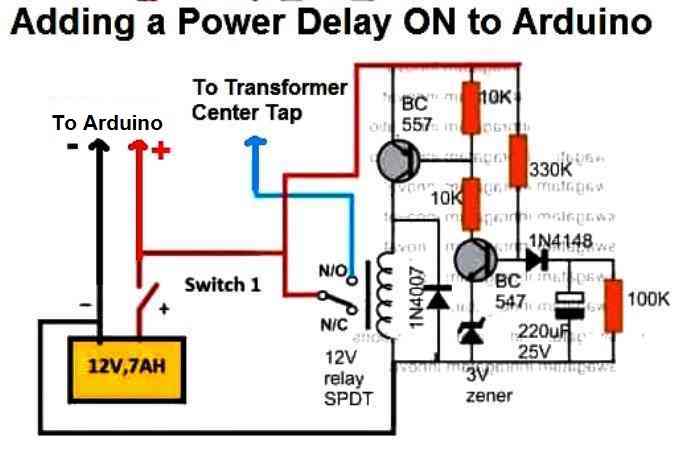

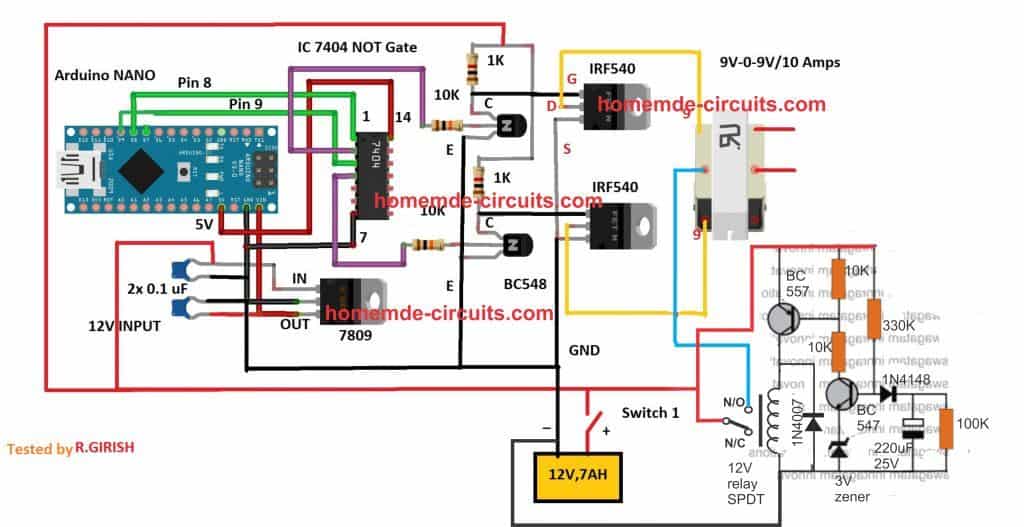

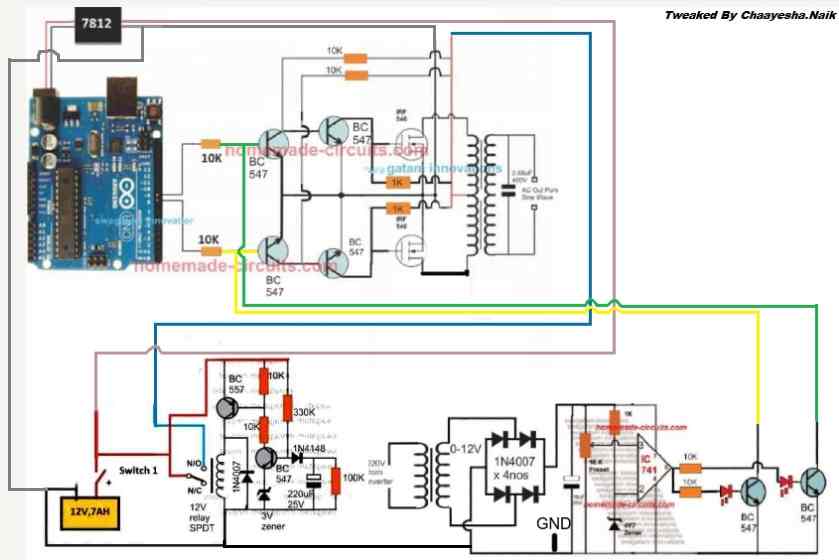

A More Reliable Delay ON Timer

If you are not comfortable with the response of the above passive delay ON timer circuit, you can employ the following configuration using BJTs and a relay. This design is extremely reliable and will effectively protect your Arduino and the inverter from burning due to a malfunctioning delay effect.

Just add this to the above inverter configuration.

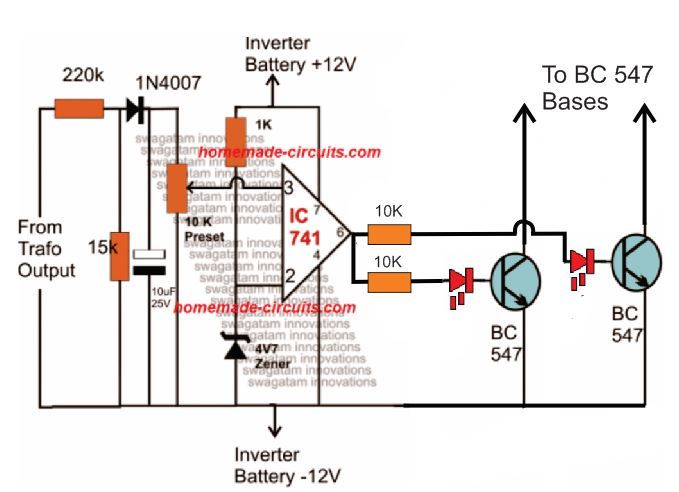

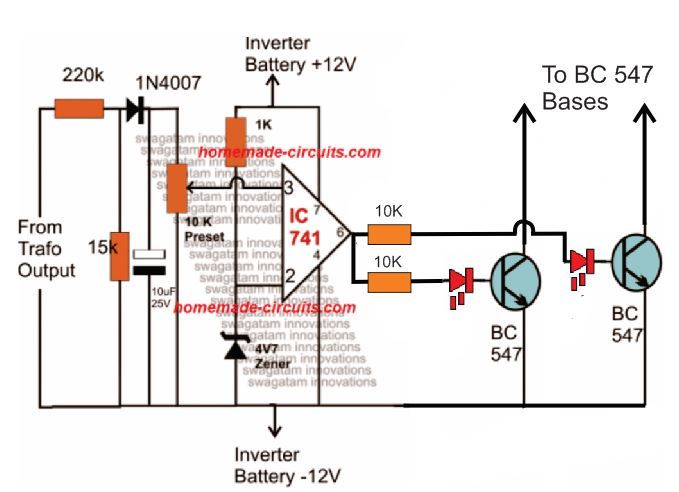

Adding an Automatic Voltage Regulator

Just like any other inverter the output from this design can rise to unsafe limits when the battery is fully charged.

To control this an automatic voltage regulator could be employed as shown below.

The BC547 collectors should be connected to the bases of the left side BC547 pair, which are connected to the Arduino via 10K resistors.

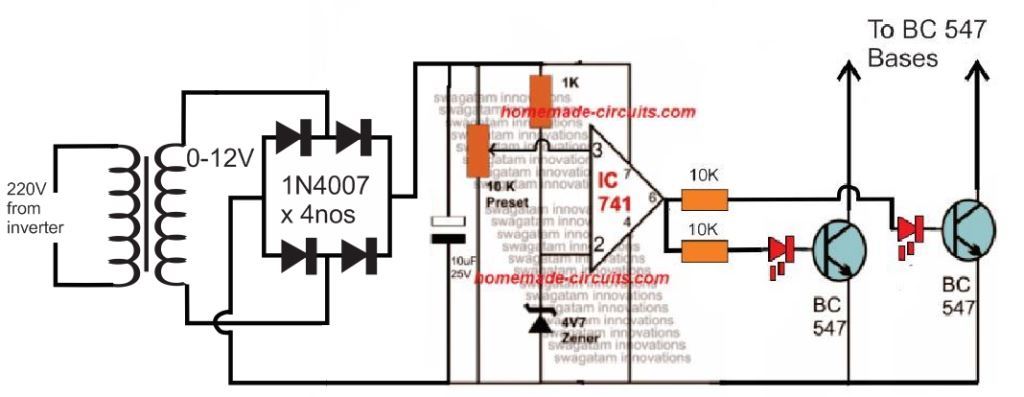

For an isolated version of voltage correction circuit we can modify the above circuit with a transformer, as shown below:

How to Setup

To set up the automatic voltage correction circuit, feed a stable 230V or 110V as per your inverter specs to the input side of the circuit.

Next, adjust the 10k preset carefully such that the red LEDs just light up. That's all, seal the preset and connect the circuit with the above Arduino board for implementing the intended automatic output voltage regulation.

The Complete Circuit Diagram

The complete diagram using the automatic voltage regulator and the delay ON timer would look like this:

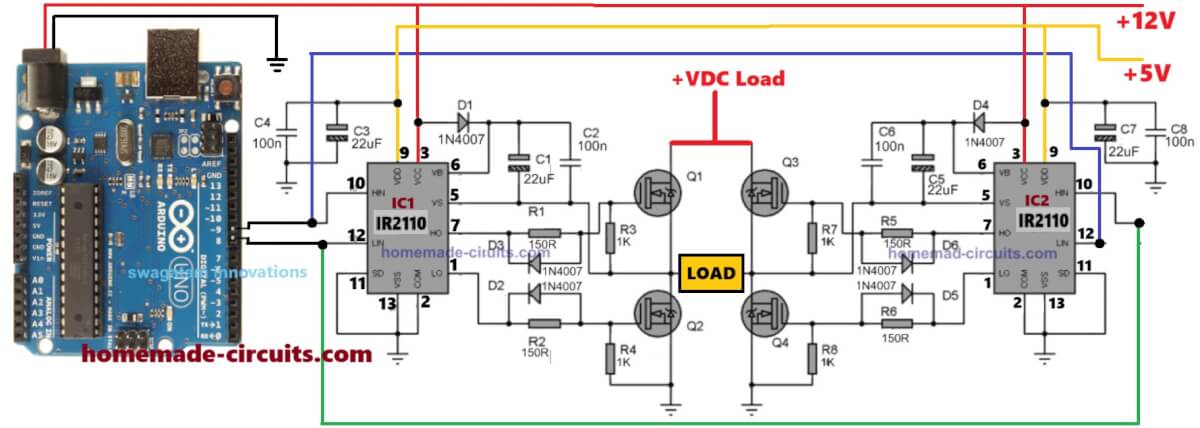

Using CMOS Buffer

Another design for the above Arduino sinewave inverter circuit can be seen below, the CMOS IC is used as an aided buffer for the BJT stage

Important:

In order to avoid an accidental switch ON prior to Arduino booting, a simple delay ON timer circuit may be included in the above design, as shown below:

sir is that IRFZ44N mosfet use kar sakte ??

Yes, you can use IRFZ44 MOSFETs in the suggested design.

how to make spwm from 4 mosfet in place of 2 like shown in 1st fig upto 80-100W power (please show circuit diagram or DM at my E-MAIL ID)

Do you mean a 3 phase sine wave inverter using H-bridge topology?

Yes, I am planning to write an article on this topic.

I will post it soon and let you know.

No I’m actually talking about 1 phase with H bridge and it’s really helpful if you reply it or make an article on it …. plsI appreciate it if you do

OK got it! I will post it, and let you know soon..

Hi Sir im designing same project, i would really appreciate your assistance. I can even pay you if i have to. Please send me an email for update

Hi Walker,

No need to pay, if you have any related questions please feel free to ask, I will try my best to help you succeed with this project…

I’m Designing a transformerless inverter capable of delivering 500W and output frequency of 60Hz. Beside adding DC boost converter what other changes are to made if i follow steps of your project. It’s a pure sine wave inverter like yours.

No changes would be required in the H-bridge, you can build it exactly as shown.

Meaning i will have to add DC boost code to your code and my calculated DC boost values i will obtain pure sine wave inverter delivering 500W and AC output of 60Hz?

For bosting the battery voltage to a higher level at 60Hz, you only need to add a transformer at the output of the H-bridge MOSFETs, meaning the “LOAD” points must be replaced with the primary of the transformer, and the secondary can be used with an AC load with boosted output.

They were specific not to use a transformer that is why i chose to use DC boost converter

Then you can use the boosted DC output supply across the H-bridge MOSFET drain/source, that’s all is needed.

Sir if I make this project then it’s necessary that I need to use bread board?

And also if I wanna increase power output then I can use transformer?

And also sir is that I can use specific separate battery for supply Arduino UNO ?

Anishka, Breadboard is not recommended for the H-bridge project, so you should try it only on a well designed PCB.

If you are using a 12V battery, then you can use a transformer as the “load” for converting 12v to 220v.

Separate battery is not required.

You can use a IC 7812 for getting the 12V supply, and IC 7805 for getting the 5V supply for the circuits from the main 12V battery.

I have created the diagram which you can see below, while in the meantime I will write the article description on this.

" rel="ugc">

For the code you can use the same code which was used in the above article…

thank you very much sir I appreciate it and it’s really helpful for me …

You are welcome Anishka,

For the complete article you can refer to the following post also:

https://www.homemade-circuits.com/arduino-h-bridge-sine-wave-inverter-circuit/

Witch is the maximum output power possible with IRF540 ? I need to obatain 100VA 110V @ 400 Hz for a vintage avionic radio equipment. Thanks.

100VA, 110V, 400Hz is easily achievable using IRF540 MOSFETs, provided the transformer and the battery are also appropriately rated.

Good day sir. can lm358 OpAmp be used for the feedback circuit?

Hi Hillary, yes any standard opamp can be used.

Hey I built this circuit today after some years now, I keep getting one Fet blown, not sure if its because I am using Irfz44n Fets, I did not build the delay on circuit, Instead switched pin 9 and 10 to input on boot up and added a delay then switch them to output when the arduino is fully booted after 2 seconds but I still have the same fet shorting on each leg, the software method is a standard practice, I I still get output from the inverter with one fet blown 30v.

Would irf740 work better thats the only other thing I have.

Hi, In my experiment I used IRF540 and did not have any such issues. But i don’t think the IRFZ44N can be the problem, unless the MOSFET has some internal defect. You can isolate the power supply input to the transformer center-tap and the Arduino, and then switch ON the Arduino first, and then after about 5 seconds switch ON the supply to the transformer and check the results.

irf740 may not be suitable because it is rated at 400V and your transformer may be rated at just 12-0-12V.

I added a software delay but when I read the article I realize the delay should just be for one Fet I delayed them both which is probably my issue.

also I used the modified spwm code that Mr Atton made im not sure if you tested that without issue also, if not I would just use your code.

Please initially check with a manual delay, by isolating the transformer center tap and the Arduino, and please use only the code supplied by me, because it is the tested one.

Hi swagatam. Trust you good?. I have designed the above circuit which is working perfectly fine. But my problem is the feedback circuit which I have designed just as it is but it is still not working. Please try and solve my problem for me. Thanks

Thank you Jonathan,

I hope you have built and implemented the following feedback circuit:

" rel="ugc">

I would suggest you to test this circuit stage separately using a variac.

In this circuit, can you please test how much voltage do you get across the 10uF capacitor.

Remember, this DC voltage across the 10uF is the direct interpretation of the AC 220V that comes from the inverter output. When the inverter output voltage rises, this DCV also rises. As soon as this corresponding DC voltage at pin#3 of the 741 IC goes above the pin#2 zener vooltage, the output pin#6 of the IC turns high causing the BC547 to conduct and ground the MOSFET gates, shutting down the inverter.

So please verify the above stage separately and let me know.

Hi Swagatam,

As you know, sinewave PWM (SPWM) could be generated at different high frequencies (though much higher than 50 Hz). Since I don’t have Arduino board (though I design the hardware and firmware of my controllers using AVR MCUs, as ATmega8 and ATmega32) I wonder if you measured the PWM frequency which is generated by the offered Arduino firmware above. Thank you.

For instance, let us assume that the SPWM frequency is around 16 KHz. Naturally, it needs to be filtered to generate the 50Hz pure sinewave output at the transformer secondary. I read many articles on how to build a pure sinewave inverter, but none of them shows how the SPWM filtration is done. The only device which is supposed to do it in their circuits is the inverter power transformer since there is no explicit filter. But to let the transformer act as a filter, its mutual coupling coefficient (K) shouldn’t be made close 1 (as in mains stabilizers for example). The more K is made lower than 1, the higher the leakage inductance between the MOSFETs and the load is. And this leakage inductance does the filtering (shunted also by the iron losses at the high frequencies). But the more (K) is made lower than 1, the lower the transformer efficiency is. In practice, separating the coils of the primary and secondary, instead of winding them on the same coil, lowers (K). The optimum distance between the two coils is usually determined by trial and error. But if by adding a small capacitor (<1uF) at the transformer output (not loaded), the output voltage is acceptable (its high frequency ripple is hardly noticeable), the transformer is ok.

Thank you Kerim, for the valuable information.

Each 50 Hz half cycle is chopped into 7 pillars, or 7 pieces, so each 20 millisecond cycle accompanies 14 PWM peaks.

I know this may look a little higher to handle for an iron core transformer, but in my experiment it worked perfectly well, without any buzzing or heating up of the transformer.

Yes, adding a high voltage capacitor at the output side of the transformer helps to smoothen the SPWM cycles into pure a sinewave like frequency.

If I understood you well, the PWM of the Arduino program (above) is 700 Hz only. At this relatively low frequency, I expect the ripple of the sinewave output is not small. So, I wonder how it looks on your scope screen in your experiment. Please let me know if the output ripple could be made small even at this very low PWM frequency and without an external LC filter. Thank you.

But, even with such a high ripple, the generated output is much better than of a square wave or quasi-sinewave.

For instance, among your many published articles about the pure sinewave inverters, which one its PWM frequency is highest?

Thank you Kerim, for calculating the frequency.

According to my knowledge the only way to reduce the ripple is either by using a capacitor at the transformer output or by increasing the pwm frequency and using a ferrite core transformer.

In the above Arduino concept I used a 3uf capacitor at the output which produced a relatively good sinewave, however if this capacitor value is increased that might further help to improve the sine waveform quality and reduce the ripples proportionately, although that would also incur some power wastage. The above sinewave inverter project uses the maximum frequency for the pwm among all the published articles.

I asked about the SPWM frequency because lately I wrote a code for ATmega8 to generate the SPWM at 15.625 KHz (8000 KHz / 512). (For instance, since about 40 years ago, I used to write my CPU/MCU codes in assembly language only). This code can be used for a push-pull inverter which I designed its hardware too. Its push-pull transformer could be driven by two sets of N-MOSFET which, in turn, are driven by discrete circuits using BJT; NPN & PNP for fast turn on-off with dead time.

By simulating the code and its hardware, the results were as expected. I set K=0.99 in the transformer model. I hope soon I will have the time to test it in real.

In case we will find a way to let you receive files from me, I don’t mind sharing my design here (code and circuit).

MCUs existed 40 years ago? I did not know that. Thanks for sharing the info.

Sure, please feel free to share the codes anyway you like, through email or directly through comments using online free upload sites.

I appreciate your kind efforts.

Sorry for not being clearer. You are right, 40 years ago, MCUs didn’t exist, only CPUs did (as Z80).

I had to say on my precious post:

“In the last 40 years, I used to write first my CPU codes (for Z80), then my MCU codes (for C51 and AVR families).in assembly language only”.

OK, got it, thanks for the clarification.

Few suggestions:

– Can the delay circuit be realized mainly in the software? I think the Arduino microcontroller ensures that on power on, all I/O pins are set to the input direction and in the high-Z mode by the microcontroller electronics. Software must explicitly configure pins for output or PWM. Suppose the Arduino pins that drive BC547 transistors are pulled to the ground with 100k or stronger resistors. Would it be enough to ensure that the MOSFET stages initiate with a delay during the Arduino booting or start-up? MOSFETS will be active once the Arduino application reconfigures the pins driving BC547 transistors.

– The automatic voltage regulator can be realized mostly in the software. Arduino has 6 ADC inputs and is capable of performing tens of thousands of ADC conversions a second. A simple voltage divider with a diode and capacitor as a half-wave rectifier can be connected to the Arduino ADC pin. Arduino ADC pins have about 100k input impedance, so a half-wave rectifier should be good enough. After every SPWM cycle, Arduino can read the output voltage and decide what to do next.

Thank you for your valuable suggestions, it would be indeed very nice if the delay feature and the automatic voltage control are added within the Arduino. Please let us know if you have the necessary programming codes for that.

Yes, if the Arduino pins that drive BC547 transistors are pulled to the ground with 100k or stronger resistors, that would be enough to ensure that the MOSFET stages initiate with a delay during the Arduino booting or start-up.

Would I only need to pull one side to ground or both bc547

both the BJTs….

how can I make closed loop single phase inverter using Arduino

Please go through the above article, everything is explained in it.

Hello sir I want to control inverter out put by varying the the duty cycle values of arduino by push button from 0 to 100% duty cycle at increment or decrement by 1%.

I want to make 0 to 10 volt pure sinwave inverter at 400 Hz frequency and the ac voltage can be controlled by microcontroller at +/- 1% duty cycle variation so that 10 volt AC change accordingly.

Thanks and regards.

Please suggest me the code and circuit.

Hello RK, I wish I could solve your query, however my Arduino coding skills are not good enough, therefore it can be difficult for me to help you with this question.

thanks for reply.

So the CMOS based circuit seams like an inherently better circuit as circuit loading does not affect the arduino outputs? however, I notice there is no feedback mechanism like it the upper circuit. Is it not possible or just not needed because of the buffer?

There’s no loading with the transistorized circuit also due to the presence of the 10K resistors. 10K is quite a high value and will absolutely not cause any loading on the Arduino.

Yes, feedback might not be necessary since the Arduino generates a fixed PWM.

then which circuit would you choose? I am planning to build a low powered 12V, 500ma, to 120V variable frequency inverter.

Also, I have started trying to source components for the CMOS version but find that at Digikey many items are either obsolete or require purchasing large quantities, I’m not willing to pay $3000 to use only 2 transistors. Can you suggest alternate parts?

The transistorized version of the above Arduino inverter is the most efficient one and is a tested design. I would recommened this design. The 10K resistor associated with the Arduino outputs can be even raised to 100K to reduce loading.

I did not quite understand what you meant by “I’m not willing to pay $3000 to use only 2 transistors. Can you suggest alternate parts?” Kindly elaborate

BC547 is listed as obsolete on Digikey. https://www.digikey.com/en/products/detail/onsemi/BC547/976363#product-details-substitutes

BC548 is also obsolete in bulk, but i I buy 6662 of them they are only .05 each. ($333.10) , https://www.digikey.com/en/products/detail/rochester-electronics-llc/BC548/11545848

i forget which one only had a $3000 option. i’ll have to take better notes in my searching

That’s super strange because BC547 is the most standard type of BJT and one of the most used general purpose transistor…. how on earth this transistor can become obsolete??

You can try 2N2222 or any other equivalent transistor, they all will work.

couple more questions about the Voltage regulator circuit.

1) what is a 4V7 zener? 4V, 7V 4.7V? or other?

2) there are 2 led’s shown in series with the gates on BC547. are they required? this will be in a box and used remotely. do they have a troubleshooting purpose?

1) 4V7 = 4.7V

2) Yes they are required, since the LEDs prevent the leakage or the offset voltage from 741 output to reach the base of the BC547 transistors, thus preventing false switching of the transistors..

are they just standard 12V(forward Voltage) Red LED’s?

They are standard 3.3 V, 20 mA LEDs.

one more question about the voltage regulator, is this what you mean by IC741?

https://www.digikey.com/en/products/detail/texas-instruments/TPIC74100QPWPRQ1/1531097

if so, is there a through hole substitute?

741 is an IC, not a voltage regulator, if you are not familiar with 741 IC then I am afraid you should not try this circuit, chances are you might not succeed.

" rel="ugc">

Sorry, I did not recognize the Op-Amp symbol. The regulator I found is Also an IC. Searching on Both digikey and Mouser for IC741 resulted in nothing, so I went the hard way (drilling down) and had to choose a category. Voltage Regulator was just a guess. The wiring for the OP-Amp seams straight forward (other than the LED’s,) and i plan to use a socket so as to not damage the Chip when soldering, so i’ll take my chances. I’m just an electrician with electronics hobby experience not an electronics engineer. Sorry for the dumb questions, but I need this Arduino controlled inverter for one of my other hobbys (Astrophotography) .

No problem, you can go ahead and build this project. The op amp output voltage control might not be necessary since the Arduino is generating a calculated fixed PWM, so the output voltage should be pretty constant.

sir, how to construct a 450w 12vdc-230vac solar inverter?

Aqil,

Please provide detailed information regarding the inverter and the load, if possible I will try to help.

A 12V solar panel and 12V battery supply to a 350W water filter. All i need is 500W (inverter sizing) inverter circuit diagram with code

If you divide 350 by 12, it gives 30 amps, so your transformer must be rated at 6-0-6 30 amps or 32 amps. Please get this transformer then I will tell you how to proceed.

i dont find for step up transformer. i just found for step down transformer…

Step down transformer will do but it must rated at 6-0-6V 32 amps on one side and 220V on the other side.

Okay now proceed to the next step sir

Did you get the transformer?

Yes

Please build the circuit which is explained above using that transformer. You will also need a 12V 300 Ah battery for the 350 watt output

Hello sir, thank you for the Arduino sine wave circuit, can the circuit also be used for 24V DC?

Thank you Emmanuel,

24 V can be also used. For that you will need a 12-0-12V transformer and the +24V will need to be fed on its center tap. The Arduino must be fed with 12 V through a 7812 IC.

Hi…. I really love the first topology. Believe it’s the pull-push topology. However, despite reading, I can’t figure out the use of the diode connected in parallel to the 10 ohm resistor. I thought it should rather face the other direction to prevent current from going back into the arduino.

Glad you liked the post. The diodes make sure that the when the Arduino outputs are 0 logic or during the switch OFF periods the internal capacitance of the MOSFETs can discharge very quickly through the diodes, causing minimum heating of the MOSFETs.

Thank you for this simple circuit. I have tried it and it is currently working. I need help, please, with a circuit to charge batteries from solar cells. by using arduino and igbt

Sorry, I don’t have an Arduino, IGBT based solar charger with me right now.

Hi Swagatam

I discovered that by connecting an LC circuit to the output of the square inverter circuit the square wave gets filtered into a pure sine wave. I have used an 30A 20-0 transformer ‘s secondary as the inductor and a 2.5MFD capacitor so can you conform that it is a pure sine wave inverter ?

Thank you,

Chaayesha.Naik

Hi Chaayesha,

That is correct and possible, but the results will not not too accurate and efficient. It will not be pure sine wave. Initially try only with a capacitor, if the results are not good then add an Inductor also.

Hi Swagatam

I really want to try doing this, if not with a single IGBT can it be done with an H – bridge arrangement also can you write a code for it please

Hi Chaayesha,

Unfortunately my Arduino coding skills are not good, so it will not be possible for me to write a new code. Also adding a H-bridge can be quite difficult with this Arduino circuit.

Hi Swagatam

I need some help in building a pure sinewave inverter using a single IGBT with the UNO board what i want to do is convert the square wave 240v to dc using FBR then switching it with the IGBT in a sine wave there by converting the squarewave inverter to sinewave because i have some majour issues with the MOSFET blowing up so i will use a square wave inverter board with this circuit so can you please write a program for me

Thank you

Regards,

Chaayesha.Naik

Hi Chaayesha,

Using a single IGBT will not produce a push pull AC output which means the output will not have negative AC cycles, there will be only positive cycles above the zero crossing line.

Also the full bridge concept can be quite complex to design, instead you can use the following concept using 12V battery and a transformer:

" rel="ugc">

Thanks for the replies, I really appreciate your good works. Please can you help me with a circuit diagram of mppt charge controller?

Hillary, you can try exploring one of these articles:

https://www.homemade-circuits.com/?s=MPPT+homemade

Good day Mr swag. I made the inverter as drawn, I used irfp150 MOSFET and the MOSFET gets too hot, what should I do about it?

Hi Hillary, the MOSFETs should not get too hot. Even at full output load the MOSFETs should become little hot, up to around 80 to 100 degrees Celsius. I have tested this circuit, I did not find mosfets getting too hot even with a load connected. Something might be wrong with your circuit.

You can try adding large heatsinks to the MOSFETs and check if that helps to solve the issue.

Good evening sir, thanks for your time and teachings. More grease to your elbow. My question is, how do I add a feedback to an Arduino based inverter with a center tapped transformer?

Thank you Hillary,

Adding a feedback to the Arduino will require additional coding and reprogramming of the Arduino board, which I am not sure how to do. That is why I added a feedback through a external op amp circuit.

I did build your cct and it works great .. Thanks.

I just need to add the over Voltage stage.

With a square wave osc the duty cycle can be varied and the output Voltage can be regulated.

With a Sine wave osc the duty cycle cannot be changed and regulating the output Voltage becomes more complicated.

QUESTION:

Is it possible to have more than one Sinewave array , where the sharp turn at the top of the Sine

is still round but a little more flat thus putting more current into the Transformer.

I think this will work , BUT I dont know how to create the Sine values for more flatter top and keep the freq at 50 Hz.

Can you help with creating these values.

Sounds great! The flat top sinewave can be perhaps created by increasing the microsecond delay 2000 to 3000. This 1000 microsecond increase in delay can be subsequently compensated by reducing the other delays proportionately

Sir please what is the name of that your oscilloscope

It is DSO138

Do have to program the Arduino nano

Yes the Arduinos need to be programmed with the following code:

https://www.homemade-circuits.com/arduino-spwm-generator-circuit/

Thank you for this posting about sinewave inverters. This is a subject I am particularly interested in. I have been involved in designing and building inverters for about 40 years now, where the power outputs are anything from 50 watts to 5KW. I have usually based the batteries on either 24 or 48 volts and have had very good results. I was wondering about your timer circuit to switch on the inverter after the Arduino had booted. The FETs on the output could easily be referenced to 0v via 4k7 resistors with collector tied transistors deriving their power from the 12v + line. The gates of the FETs could then be driven from the emitters of the transistors with a 1K resistor. In this way the output FETs would not conduct until the previous sections had received pulses from the Arduino chip. The timing circuit would not then be needed.

I would be very keen to know what you think about this modification as this has been the basis of most of my inverter designs over the years. I have supplied thousands of inverter systems over the years and many of them are working very well still.

Kind regards

Thank you for asking this interesting question.

An emitter follower driver cannot be used here for the FETs, because the output from the Arduino is 5 V. So if an emitter follower is used, the FET gates would finally get a voltage of around 5 – 0.6 = 4.4 V, which will not drive the FETs optimally, causing a lot of heating on the FETs.

Moreover, we are not sure how the Arduino outputs would respond during the booting phase, that is why a timer is used to ensure a 100% safety to the FETs.

My challenge is that for pure sine wave inverter the transformer input is wind half the battery voltage for example a 24v inverter system 3.5kw the transformer input is wind to handle 12v – 14v for pure sine wave inverter my question is how will the control circuitry divide the 24v from the battery so that the transformer will receive 12v to 14v and also how to determine the transformer input wire guage .

Thank you for replying

It is done by the SPWM waveform, whose average value would be around 12V DC.

Hi

Great article, but nowhere do you seem to mention the power rating, ie how many watts can this circuit drive, I couldn’t find a spec for the transformer – that would have told me too.

Hi, thanks! The power rating will depend on 3 items: The transformer, the battery and the MOSFETs, you can customize or upgrade these three items appropriately to get any desired power from the inverter.

More on this can be studied here:

https://www.homemade-circuits.com/how-to-calculate-and-match-inverter/

Super , great article also

Glad it helped!

Hi

I have a doubt that dose the Automatic Voltage Regulator also increases the voltage when the voltage drops below the set voltage ?

Regards

Hi,

No that will not happen. Voltage regulator will keep the output voltage constant only as long as the output RMS is above the minimum threshold, such as 220V. If the output is over loaded and the voltage drops below 220V, then the automatic regulator will not be able to do anything.

Hi swagatham can you check if the schematic is correct so that i can start building the inverter

" rel="ugc">

Thankyou

Regards

Hi Chaayesha,

Your diagram is correct. I have made a small improvement in the diagram by connecting all the GND lines together, which is very important.

Please do not build the whole circuit at once, otherwise it may have errors and problems.

Build each stage separately, check them separately, if they all work satisfactorily, only then integrate them into one.

Hi

Thanks a lot as you said i will build each stage separately and if i have any dobuts while building the inverter i will ask. Also you can share the schematic to anyone if they want to check it or also you can post it on the site. Again thanks a LOTTT!! because no one else would reply on other sites

Regards

You are most welcome! Let me know if you have any further issues! I am always glad to help!

Hi swagatham i am not able to post the schematic link in the website it constantly refreshes so can i send you the file trough E-mail ?

Hi Chaayesha,

Your comments were going into the trash folder because of the “https” in your link. Always remove the https while posting a link.

But no issues I have restored your comment from the trash folder and have answered it. Please check your previous comment for the reply.

Hi

Swagatham Thanks for the reply!. the thing which i cannot understand is the collector from the bc547 in the automatic voltage regulator circuit must connect to the right side or left side of the 10k resistor near the UNO.Also i had questions regarding that if we can use 4MFD fan capasitors (2 in parallel) and if we can use a 10-0-10 transformer instead of a 9-0-9 transformer. And can we add a (IRF9630)P-channel mosfet before the N channel mosfet so that the gate of the n channel mosfet gets pulled up when gate of the P channel mosfet gets pulled down and the 1k ressistor is pulled down of the n channel mosfet.Also will the UNO get burnt if the BC547 from the automatic voltage regulator circuit sends an voltage back to it while trying to regulate the voltage ??

Regards

Hi Chaayesha,

I have already answered to all your questions. Please refer to your previous comment.

Sorry i sent it 2 times. and also i am preparing a diagram with all the circuits and after its done i will share it with you and you just verify if its ok .

Regards

Sure, no problems! Let me know if you any further doubts.

Hi swagatham,

I am designing a puresine wave inverter using irf3205 so can you send me the circuit diagram for it with the delay circuit and Automatic Voltage Regulator circuit

Thank you!

Regards

Hi Chaayesha,

I think you can build the inverter design which is explained in the above article. It has all the facilities that you intend to have in your inverter design. Let me know if you have any further doubts or queries…I will try to solve it for you quickly.

Hi

i am not able to properly under stand how to connect both the delay circuit and Automatic Voltage Regulator circuit together so can you please draw the schematic with both the delay circuit and Automatic Voltage Regulator circuit connected to the circuit in the 4th picture. I am realy sorry for the inconvenence

regards

Drawing all the stages can make the diagram too big to accommodate in the page. Please tell me what you cannot understand, I will try to sort it for you. I would recommend that you first build the basic Arduino inverter circuit with the delay ON feature. Once you build it successfully then I will show you add the automatic output voltage control to the circuit.

For the delay ON timer you can add the following circuit with the Arduino and the battery.

" rel="ugc">

Hi

Thankyou for your reply , i can understand that Drawing all the stages can make the diagram too big to accommodate in the page.So the part that i cannont understand properly is that the collector from the bc547 in the Automatic Voltage Regulator circuit will connect before the 10k (next to the UNO left side) to the mosfets or after the 10k to the mosfet (right side after the UNO) but also the collector from the bc547 in the Automatic Voltage Regulator circuit will supply a voltage to the mosfets and the UNO so will the UNO burn if it gets a reverse voltage ?. And thankyou for the delay part i understood it. and also will a 10-0-10 transformer work in the place of a 9-0-9 transformer also can i use a 4MFD fan capasitor (2 MFD caps in parallel). and I think that if we add a low power (IRF9630) P channel mosfet before the N channel mosfet the delay circuit is not requierd right ?? also if you use a logic level p channel mosfet before the n channel mosfets then the transistor circuit is not requierd ?? correct me if i am wrong thank you .

Regards

The collectors of the BC547 transistors of the Automatic Voltage Regulator circuit will connect after the 10K resistors which are associated with the Arduino output (with the bases of the left side BC547 transistors of the inverter).

The Automatic voltage regulator will not supply any voltage, instead it will ground the base voltage of the inverter BC547 transistors to initiate the shut down process.

It is protected with a 220K resistor and diode so there’s no question of any burning unless you make a wrong connection. If you are not confident then you can use the transformer version of the circuit. Any transformer between 3-0-3V and 12-0-12V will work (500 mA).

I can’t figure out how a P-channel mosfet can avoid the delay circuit? According to me it is better to add the delay circuit for maximum safety.

very interesting. can we convert DC to AC 11w tube using hybrid transformer?

expecting your valuable guidance.

Yes that’s possible. Yu can try the following circuit:

https://www.homemade-circuits.com/electronic-ballast-circuit-for-uv-germicidal-lamps/

Hi Swagatam

I am Designing the H bridge converter, I required Sinusoidal at high frequency (3kHz). Can you guide me on How should I change the Arduino code to obtain High Frequency at Output?

Regards

Hi Leo,

you can probably try the following circuit for the H bridge design, but make sure the battery and transformer are 12V rated.

" rel="ugc">

Changing the code can be plenty of hard work and a lot of thinking. Basically you will have to replace each of the microsecond delays with smaller delays such that they together add up to produce 3000 Hz for each channel.

Hello Swagatam. You have great circuits and great explanations to teach folks about the circuits. Here’s my idea: 55 gal blue drum full of 400 pounds of water is my gravity battery. Pull it up to some height with a block and tackle. My goal is to run a 5000 btu ac for 1 hour. 5000btuas/3412btusper kw is about 1400 watts, and running this contraption would give some cool air for an hour. Then make someone else crank the drum back to to run it again. At first I looked into a 3phase PMA alternator that puts out 12V 3phase at 150 rpm, and has a three phase rectifier, but the spec for the alternator says I need more rpm to get more watts. I have a 1500 watt 12V inverter. Lets say my blue drum spins a Big Pulley like a bike wheel, which turns the PMA or even a 100 amp car alternator and its putting out 24V. Seems like that would put out twice the volts modified sine wave, which would make my window unit very unhappy. So I need a clever linkage to spin the alternator at whatever rpm it takes to keep 12V going into the inverter. Plan B would be to make it completely electronic, but since this proj seems to be mostly mechanical, and just uses a car alternator and a harbor freight inverter, do you know how to make a governor to run the alternator at the right speed? Hope you write back.

Thanks Bob! Your concept looks interesting.

If you are looking for a circuit to limit the speed and the voltage output of an alternator, then yes that can be done through a simple shunt regulator circuit. Is the alternator a 3 phase alternator or a single phase alternator?

Hello Swagatam.

I wish to thank you for all the circuits you make available for free on your site. They are very educational to a amateur radio operator like me. My call is KE4WCE.

My question is where in the code for the Arduino Pure Sine Wave Inverter Circuit would I need to change from 50Hz (cycles) to 60Hz and replace it with what number.

Or if you don’t mind me asking the math formula and a example so I may able to do it myself.

Thank You 73’s

Thank you very much Amos,

In the Arduino code explained above we have used the total delay on each channel as 10 ms, since each 50 Hz AC half cycle requires 10ms to complete. For a 60 Hz cycle the completion time of half cycle becomes 12 ms. So you will have to adjust the microsecond time (in brackets) on each channel of the code in such a way that it produces a delay of 12 ms or 12000 microseconds.

Thank you For the fast reply. I am going to have a go at it and see if I can duplicate your circuit. Again Thank you for your time and patience.

73’s

I am glad to help!

HI,

I Build the first most simple’s project on the page. After programming my arduino I founded that my irf540 is heating up and when i checked the frequency on my arduino ouput it was around 500 hz . I am most certain thats why the mosfets heat up. I cannot see what i am doing wrong. Advise please

Regards

Peter

MOSFETs can work with frequencies up to MHz and GHz, so frequency can never be a problem, I have tested the design thoroughly and had no such problems. My MOSFETs also heated up a a little but it was because of the 100 watt load at the output of the transformer. If your MOSFETs are heating up due to an output load then it is normal, simply put a heatsink on it.

And one more thing…. instead of using high voltage capacitors at transformer output for waveform smoothing. can we use low voltage capacitors at the transformer input??? voltage and power handling will be easier… what say??

I don’t think that might be possible, because at the input side everything is PWM based and digital which cannot be transformed into an analogue sine wave….the transformation may be possible only at the output side of the transformer.

Hiii Swagatam, The delay circuit is introduced as a safety. But What I say is instead of introducing a circuit why dont we use aurduino digital output signal to switch the DC supply to inverter circuit. mainly for three reasons, 1) Human error is eliminated. 2) circuit is simplified 3) Delay circuit malfunction hazard is also eliminated. Whats your say in this??

Thanks Vivek,

My Arduino knowledge is not good, so I won’t be able to suggest on this modification. If you think this is something feasible then surely it can be implemented and tried in this design.

Best Swagatam

I may be understanding the circuit diagram wrong but I simulated the circuit and it does not seem to work.

I don’t understand how the positive terminal can be connected directly to the base of the mosfet. What is the reason for the BJT level shifters? Also a positive voltage is applied again directly (resistor in series… so voltage division?) to the bjt. I would like to build this circuit but cannot seem to understand its working principle.

Would it be possible to communicate by email for me to better understand the circuit please?

Kindest Regards Christiaan

Christiaan, level shifters are necessary to enable the mosfets gates to get 12V supply so that they can conduct optimally. If we connect the mosfets directly with the Arduino, the gates will be be able to get only 5V which may not be sufficient for the mosfets to switch ON perfectly.

The first BC547 inverts the Arduino PWM so it cannot be directly used with the mosfets otherwise the mosfets gates would be switched with inverse PWM signals. The second BC547 corrects this issue and makes the PWM same as the Arduino output, but at 12V level

The circuit is fully tested so you can build it and test it for getting the required results, simulation is not required.

Thank you for the response.

That makes sense but wont the voltage to the mosfet be 13.3V since this is more the operating voltage of a 12V battery? Is this still a suitable value?

Then lastly do you have a inverter circuit that does not use a transformer but still steps up from 12V to 230V?

Sincerely Christiaan

Most mosfet gates are designed to work with upto 20V, so 13V is quite OK.

Making an 12V to 230V inverter without a transformer is almost impossible, as far as I know.

Thanks for the replies Swagatam.

This is definitely one of the only sites where you get replies.

What is the wattage of this inberter?

It’s my pleasure Tiaan.

Hello

Can you show the charging circuit?

All the best

J K BARIK

Sure, you can get the desired battery charger circuit from these two articles:

Lead Acid Battery Charger Circuits

Op amp Battery Charger Circuit with Auto Cut Off

Hello sir , can you please tell me how the feedback circuit works and why you connect them in the gate of the Mosfet but not in the arduino .

Lalawmpuia, where do you think the feedback can be connected with the Arduino? It will require special coding for that. Connecting the feedback to MOSFET gates is an universal option which can configured easily without any coding by anybody and with any inverter.

Sir can you please explain how the BC547 collector is connected to the base/gate of the BJT/Mosfet . Since I have a hard time understanding that . Since the emmiter side is connected to ground and does that simply pull down ?

The BC547 collector will pull down the mosfet gate while it is ON, and when it is OFF the mosfet gate will get the switching voltage through the 1K resistor.

How does the feedback works? since the feedback ( bc547) emmiter is connected to the base of the bc547( arduino output ) will it just pull down from bc547 base to ground . Please explain the worling of this feedback . Also I tried your Circuit and code as well but I have burn out 10 mosfet ( 5 times irfz44n and 5 times irf3205 ) in just under 10 seconds . It was too hot to even touch .

When the input voltage to the op amp circuit exceeds the set limit the op amp output and the BC547 conduct and grounds the Arduino BC547 bases causing the mosfets to shut off. As soon as the mosfets are turned off the voltage begins to drop which reverts the opamp output causing the mosfets to switch ON again, and this process continues which keeps the output voltage within the desired range.

Your mosfets may be burning due to some fault in your design, or may be the mosfets are not good quality.

You can in the video the circuit works perfectly even while the circuit is built without any PCB.

Thank you so much .

Hello sir , I have a question about the transformer , if I use a 6-0-6 transformer rated at 3A , at ideal mode , what will be the rated watt of the output ? Since 3A is the highest rated transformer I can buy from our state .

Hello Fanai, it will be 6 x 3 = 18 watts for each half cycle of AC output, that means for one full AC cycle it can be around 36 watts

Hello sir , how are you ?

I have one question regarding the feedback , my circuit is exactly same as your circuit , and the transformer I used is from an old ups , and the question is , the output Voltage decrease to 140V from 210V when connected a load . Will the feedback you posted work in this situation to give 220V constant even when connected to a load ( 60W incandescent lamb) ?

Hello Fanai, no, the feedback cannot boost a low voltage happening due to over load or low wattage transformer/battery, it can only prevent an over voltage. To correct the voltage drop you must ensure that the transformer, battery and the mosfets are appropriately rated as per the load requirement.

k. well the solution i have now will have to do till i have more time. seems the best way forward will be to build an inverter that doesnt have over voltage protection. when i have time i’ll pull the transformer out of the old inverter, check it to make sure it meets the specs of the Arduino. i’ll also grab the heat sinks for the mosfets. then i’ll have another 1000 questions for you. thank you for your help.

Sure, no problem, all the best to you!

this may be off topic, i’m looking at building this inverter but perhaps its better to tell you what my problem is first because you may have a better solution. i have a 300 watt inverter thats doing just fine. but its connected to lithium ion batterys instead of lead acid. the ion batterys are 4p so top voltage is 16.4. the inverter has i high voltage cut off at 15.5. i’m working around the problem by placing a buck inverter between the batterys and the inverter, the buck inverter is set to output at 14.9 volts. this works but seems wasteful. is there a more efficient way to lower the voltage to the inverter ?? or should i build this inverter you describe ?? one last note, i have an old modified sine wave inverter that took 3 months to destroy my refigerator, is made by a company called “trip” (good quaility), its 3000 watts 12 volts, its very heavy, do you think i can strip the transformer and mofets and heat sinks from the trip inverter ? is it worth the effort? so the big question i have for you is this, if you were in my situation what would you do ?

Using a buck converter between the battery and the inverter can be indeed quite wasteful, but unfortunately there’s no other more efficient way than a buck converter, except if one Li-Ion cell is reduced, and a 3S combination is used with a 12.6V output supply.

The transformer winding rating must match the PWM average of the Arduino in the above explained concept. The average voltage at the collector of the first BC547 transistor will be the value that must match the half winding specs of the transformer.

So definitely you can salvage the transformer from your 3000 watt inverter but the criteria are it must be a center tap transformer and winding data must complement the Arduino PWM rate. For the mosfets However I would recommend using new MOSFETs, unless you are entirely sure that the mosfets from the old inverter are perfectly intact and good.

Hi Mr

i have built a small circuit using Bc547 & Bc557 as BJT Buffer stage to drive the Mosfets (i’m using IRFZ46)

when i check the ouput of the buffer stage connected to Arduino uploaded with Spwm Code

on DSO138 oscilloscope the output is same as the pattern of the wave in the picture on the page

But on the Drain of the Mosfet its square wave

Why?

My circuit using readymade oscillator SG3524 is working fine

But using the Arduino the output is connected to lamp & is flashing

any idea?

thanks for ur Help

I need another circuit which i didnt know how to contact the page

a small Solid state relay using mosfets which have Com positive or negative 12V

NC NO so i can select which source to use power of

2 12v dc inputs & 1 output \]

Thanks

You must do exactly as shown in the above schematics because it is a tested design, I cannot suggest about any other configuration.

if i connect the oscilloscope to the Drain of the Mosfet should i see the same signal as the arduino output ?

i will test it with 2 npn transistors instead of the buffer stage i have used

thanks for help

Drain waveform should be exactly as its gate waveform.

any suggestions why i get square waveform on the drain when the gate is the same as the waveform in ur pic ?

That is actually not possible. The ON/OFF switching of the drain is dependent on the ON/OFF switching of its gate, and has to be exactly similar. Not sure why it is not happening for your mosfet…

It’s interesting how people solve a problem based on their background. You designed a delay circuit to insure there are no shoot-through conditions at startup. Being a software engineer, I would have done this in software by driving the relay with transistor and an output from the Arduino :-).

Great article, thanks for publishing!

Thank you for the feedback, I completely agree, this could have been solved through a code modification also.

Hi swag, which pin of the arduino do I connect the delay generator to

Hi Nimel, the pin8 and pin9 go to the first BC547 via 10k, this BC547 base is configured with the delay timer network, so it is the pin8 nd pin9 which go to the delay network

Sir, can you please share the transformar specification, required for this project.

Thanks.

Partha, the transformer voltage can be 6-0-6V for a 12V battery. Transformer current will depend on the load wattage. If the load wattage is 200 watt then dividing this by 6 becomes 33 amps and so on.

Hello Sir,

Thanks for the article,i would love to know more on the programming aspect.Please can you explain in detail how the avr side of the above circuit works to protect the circuit,like when the LED lights up,what does it mean,and can i implement it on all other inverter circuit?

Hello Patrick, yes you can use the concept universally with any inverter circuit. More details can be learned from the following artcle:

https://www.homemade-circuits.com/load-independentoutput-corrected/

thanks for the good circuit .

Kindly tell if we want to vary the frequency or if we wants the the output at 1 kHz

Thank you for liking the post!

Yes you an change the frequency to any desired value, simply by altering the “microsecond” values in the code.

As you can see, the above applications works with 50 Hz frequency, therefore the microsecond delays in the code across both the channels are adjusted accordingly to a 20 ms value.

For 1kHz, this total delay for the entire code will need to be adjusted to 1 ms.

Hi,

If you are going to use 1kHz, then you will probably need to design or obtain a transformer suitable for the job.

The 50/60Hz transformers used here will not provide the performance at 1 kHz.

The impedance of the transformer is lower at 50/60Hz than at 1 kHz.

In fact it will be 1000/50 = 20 time higher.at 1 kHz.

https://en.wikipedia.org/wiki/Electrical_impedance

It’s around 700 Hz, which is not too bad for an iron core transformer according to me…in my experiment everything worked fine.

Excellent article.

What would need to change to cater for a 24v battery?

Thank you, no changes will be required, except the transformer and the battery. The transformer can be a 12-0-12V for the primary side

здравствуйте. а можно как-то реализовать между переходами мертвую точку или

dead line

dead time already introduced at the end of the codes for each channel

digitalWrite(8, LOW);

//……

digitalWrite(9, LOW);

}

//————————————-//

Thanks for quick reply on my previous comments. I want to know one more thing how output frequency calculated. For some spacial applicatoin i want to lower the frequency about 10Hz to 15Hz. Please help.

It will depend on the specific oscillator circuit, and the RC parts used in the oscillator. The frequency can be changed by changing the RC values of the oscillator.

Thanks for the reply, but think there is some confusion, The frequency shoud be depends on arduino code coz SPWM is generated by arduino itself…?

Yes, for the above Arduino, the frequency is dependent on the delay (microsecond) set for each of the PWM blocks. You can modify them accordingly to ensure the waveform delay coincides with the frequency timing or the Hz rate

Hi, Nice projects is this, I want to make this same project with 110V DC source, can i replace 12V DC source with 110V? Second thing in place of saperate Power On delay circuit, we can also use Arduino itself for the same.

Hi, thanks, for 110V DC input you will need a 110V transformer connected with the MOSFETs.

you can use the same power for the Arduino and the delay circuit

Good day Sir

I am in the first stage of building the inverter with the AVR(not the isolated version)

I want to know if I connect the collectors of the BC547 in the AVR to the bases of the BC547 outputs of the Arduino,won’t it interfere with the output signal of Arduino?

Thank you

Dean

Hi Dean, it will interfere, but due to the transformer inductance and capacitive filter at the output, the waveform will be leveled of, and we might not see the interference happening at the 220V side.

Thank you for your quick response,I really appreciate it.I will keep you updated on the progress of the project.I noted in Mr Atton’s code,he used pin 9 and 10 on the Arduino.Maybe some people building this project used pin 8 and 9 like on the drawing.Maybe just make a note on that.

Thanks for the feedback, appreciate it!

Hello sir,How to communicate and control conventional inverters from Arduino Micro controllers? I want to turn on/off the inverter through Arduino .please tell me how i can do this ?

Hello Arijit, the above explained circuit is switching the inverter ON/OFF 50 times per second, and with PWM

yes ,i saw ,but i will do same thing in grid tied inverter?

Sorry, presently we do not have an Arduino based GTI circuit

Hello Sir,

I need to clear all my basics of circuit designing. Can you please recommend anything on this?

That would be very helpful.

Thank You & Regards,

Mudit

Hello Mudit, you can read the following article;

https://www.homemade-circuits.com/electronic-basics-explained/

Thank you so much. Much appreciated, As a matter of fact, I am kind of your Junior, dipIETE batch 2012-2015.

You are welcome Mudit, Glad to know you are also an dipIETE holder!

Hi Swagatam,

Please assist me with the following:

Please refer to your cct for the Arduino Pure Sine Wave Inverter.

I would like to combine the Arduino cct with the Seven Simple Inverter cct’s ie. UNIVERSAL PUSH PULL MOSFET MODULE WHICH WILL INTERFACE WITH ANY DESIRED OSCILLATOR CIRCUIT

Will it be possible to interface the Arduino with the Push Pull cct by connecting the two 2nd BC548’s collectors to Push Pull cct at the gate of the 1st IRF9540 and IRF540?

I would really like to do this as I like the additional features of the Push Pull Inverter. Especially the transformer with no center tap and the automatic switching between mains and battery. However I would like to keep the Arduino features as well.

Your assistance will be much appreciated.

Regards

Jan

Hi Jan, yes it is possible to interface it with the above Arduino output. But initially try the full bridge without the charger section. You can use the following module, replace the 220 V output points with 0-6V / 220V transformer, and feed the 310V points with 12V battery. Once the working is confirmed then you try adding the battery charger section to see how it responds

Yes the BJT stages will be required, to ensure that the Bridge MOSFETs get the required 12 V for the biasing

Hi Swagatam, . The problem is that the transformer I use does not have a center tap. Do you have any suggestions as to how I can overcome this problem and drive 0-6V transformer with BJT’s instead of Mosfets?

. The problem is that the transformer I use does not have a center tap. Do you have any suggestions as to how I can overcome this problem and drive 0-6V transformer with BJT’s instead of Mosfets?

Ref. All P-Channel IRF9540

I hate to admit that I have been defeated by the Mosfet’s virus. To date I have destroyed about 25 of these devices. My project https://www.homemade-circuits.com/arduino-pure-sine-wave-inverter-circuit/ has been very successful so far. All the modules work very well except for the final stage which is the Mosfet Full Bridge.

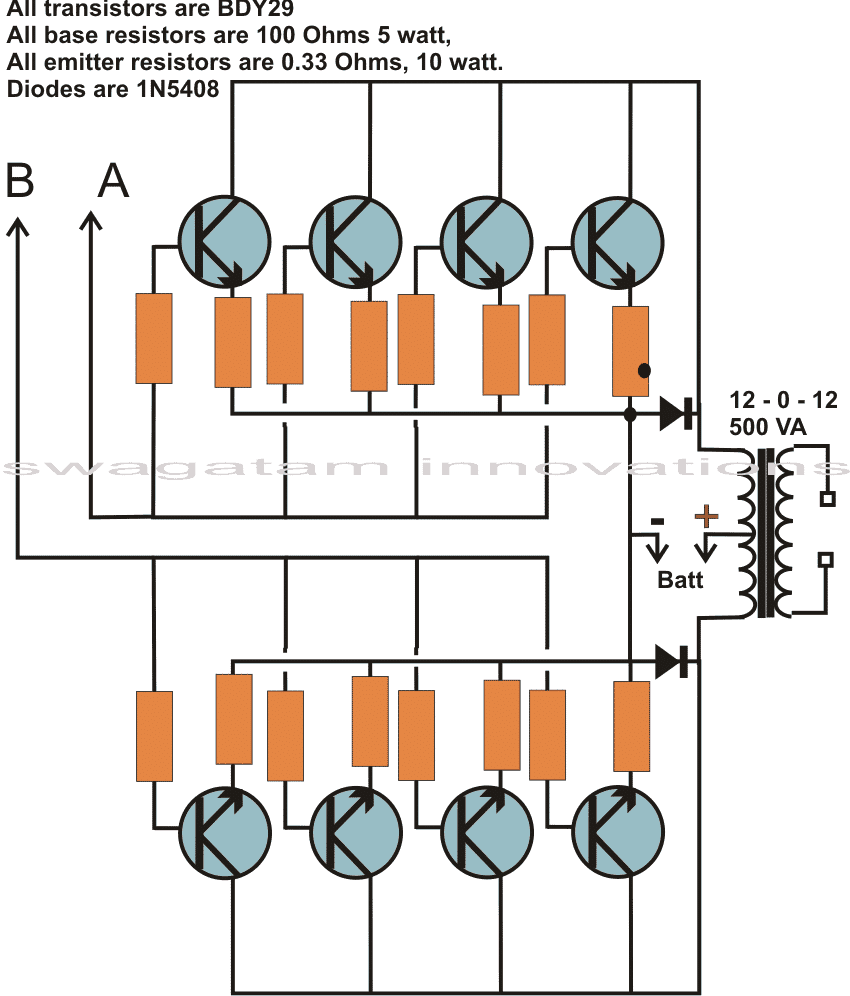

I have decided that it is not feasible to continue with the Mosfet Bridge. Instead I want to rather use TIP3055 (BDY29 is not available in my country) BJT’s as per your https://www.homemade-circuits.com/modified-sine-wave-inverter-circuit-2/ BJT concept as in " rel="ugc">

Perhaps I will have beter luck with the BJT’s than with the Mosfet’s.

Your assistance as always will be much appreciated.

Regards

Jan

Hi Jan, I am sorry to hear that. The following link shows two H bridge based circuits for motor control, which can be also applied for inverter.

https://www.homemade-circuits.com/full-bridge-bidirectional-motor/

The first diagram employs the same P-channel, N-channel MOSFET topology which you found problematic, and the second one is a BJT based design which is probably a more convenient one, but not as efficient as using MOSFET

Thank you Swagatam

I really appreciate your feedback

Regards

Jan

You are welcome Jan!

Hello Sir,

Can I please have the flowchart for the programming code used in the arduino to have sine wave from this inverter circuit.

Hello Haritha, I think you can create it yourself by understanding how the SPWMs get converted to pure sinewave when induced with an inductive load like a transformer. It is simple, the varying PWM width correspondingly create a varying exponential curve for the sinewave. So thinner pwms cause the low amplitude rising and falling section of the sine, while the thicker PWMs correspond to the peak section of the sine wave curve

Hello Swagatam .. yeah okay – so before I get going… I have sent you a “request email” to your address..?? I do not know, whether you read those emails or not.?? I just wanted to submit a few circuits, for people to build what I consider to be really smart – plain and straight forward, little UPS circuits. So I am not a real fan of Arduino, for almost obvious reasons. I use microchip PIC’s in which the processor is just a chip.. with of course a V-regulator. (I could say to you… look here… here is a 12V PIC chip.. YES a small PCB with circuits to make up a 12V PIC chip). The driver chips are very plain. I have made up a few circuits, which I can deposit here in time.. I find that after about 2 years of examining the math of whatever is needed, I still believe that I am learning. I do electronics as a hobby-practical, and really am busy with a massive – project, which I have been working on for now – close to 20 years… Whatever I will give here is results / experiments / findings – from my project. I need to ask you – if you are interested..?? cause this is quite an involved system… with a program with which we will use to create to programs for the PIC chips.

So please Sir.. try to revue what I have written in your … LAV…… email address and let me know…

Thank You…!!

Hello Spencer, I appreciate your efforts, however when I checked your email, your contribution appeared to be a promotional article, having external links. Moreover, the codes are not free, the readers have to pay a huge amount for the codes, which the readers will not like. I would have published if it was completely free and did not have those external links. I hope you will understand and bear with me!

good morning sir ,

can u send me the code by mail please ?

best regards

Hello, I am stuck with the 2nd diagram and use an 8v (2 pin) power source and notice that the frequency is much higher than 50Hz (150Hz-200Hz) and the voltage drop when plugged. You can update the full circuit diagram including: “Delay Effect” + “Automatic Voltage Regulator”.

Thank you.

Hello, please use an oscilloscope to check the frequency

I couldn’t find the code to throw in arduino, can you help? thank you. for contact;

The link for the code is furnished in the article itself.

Hi Swagatam

Can I use a ferrite core transformer instead of iron core??

yes you can

Hello, I have 5v DC power and want to increase to 220v sine wave, the power is only 10w-20w, how can I edit the above circuit, or have any circuit that meets the above requirements, please. Thank you very much.

Simply replace the shown transformer with a 3-0-3V / 5 amp /220 V transformer

Thanks you. Can I use Transistor C1815 and IRF530N to replace Bc547 and IRF540 in battery powered circuits (3.8v-5v)?

I tried it with the 5v source, the transformer 6-0-6 / 220v, the noise appeared softly, increasing the power to 12v, the sound was even clearer, was this normal ?, or I had to change the Mosfet?\

Thanks you very much.

There will be a slight buzzing noise which is normal with all inverters. By the way 5V will not work with a 6V transformer, it must be a 3-0-3Vv transformer.

Sorry for bothering you so much, but I’m trying to learn from your circuit.

If I want to use the 6-0-6 / 220v transformer, is there any way to adjust the output voltage into a 220v sine wave with the above circuit and 5v DC input source? You can instruct me to adjust the output voltage arbitrarily with a transformer and arbitrary DC input source, thank you very much.

Sorry, it is not possible to get 220V from a 6V transformer and 5V supply and PWM switching. The transformer primary value should be equal to the average DC present at the Arduino output pins to be able to get 220V equivalent at the secondary

Thank you for patiently answering my questions, I would like to ask one more question of how to calculate the capacitor after the AC 220v power source (DC 5v, DC 7.4v ..). As in your circuit of DC12v source, transformer 9-0-9 it is 0.68uF.

Thanks you very much.

Thank you, sorry i don’t have the formula for calculating capacitor filter with AC frequency..in the video demo I have used 3uF/400V

Hello my friend thanks for the post. Here is my problem if you could help.

I have built a similar circuit now the problem is output voltage regulation, when I connect a load the voltage drops, so somehow the pwm duty must increase accordingly to maintain the desired voltage.

Hello Friend, sorry I can’t suggest the code because my Ardino programming knowledge is not good.

Hi,

In order to implement the full bridge inverter circuit using 4 N mosfets, could I use two voltages:

a) One voltage for the load eg. 24V

b) Another voltage 30V for the nand gate ?

thus avoiding the complications of the precharge circuit ?

Hi, the 30V must be across the gate/source of the high side MOSFETs, not across gate and ground…if you can implement this then it may work. By the way NAND gates would burn at 30 V

Hey Thanks for your Valuable information

I need help with Multiple SPWM generation using Arduino.

If you could help me with it?

Thanks Zain, sorry my knowledge of Arduino coding is not good so can’t help in this regard

Hi! Swagatam, hope your goodself is enjoying good health. First of all i would like to appreciate your work that i have gone through your website, its amazing.

Actually i am working on the voltage regulation and voltage control of Self-excited Induction Generator. First i am using AC/DC (rectifier) from output of generator then i want to supply this DC to the SPWM based inverter to get regulated AC voltage. So i wanted to ask that whether i can use your above explained circuit and its code or not because you are feeding the inverter by 12V battery while in my case its upto 220-480v DC. Kindly guide me on this i would be grateful.

Thanks.

Regards,

Zain Ul Abideen, Founder, ZUPGEN.

Thanks Zain, you will nee a full bridge design for your requirement. You can try the following circuit:

" alt="full bridge design" />

" alt="full bridge design" />

Join the HIN with LIN of the opposite ICs, and feed the Arduino SPWM to these HIN/LIN paired outputs.

thanks for all very good ideas

i will ask you ,can i drive relay of delay using arduino itself using some programming without any additional capacitors or transistors?

Thanks for your greate ideas ….

But i will ask if i can drive the relay of delay using same arduino ?

Sorry I have no idea about it!

Hi Swagatam,

I have tried to put some more MOSFETs together to sum up to about 1500W. Please could you help me verify the correctness of the parallel connection? Find a screenshot in the following link:

https://drive.google.com/file/d/1HY1qj8fi9PRGXQcikYCbFhNuPbHkxVFm/view?usp=sharing

Thanks a lot,

Jackson

Hi Jackson,

That looks OK to me, you can go ahead with it!

I connected the transistors and mosfets correctly as per the circuit provided.or maybe I should use all the three batteries to give 36v.then regulate it to 12v for driver circuit instead of using one battery out of the three to supply the components.then supply the original 36v to the trafo middle wire .can this idea help sir.i am now stuck abit.

Thank you sir for assistance.i am yet to assemble the entire circuit.i will TextBack to clarify the outcome of the circuit.i wanted to use it to simply power light bulbs and television at rural home.thanks.

No problem, wish you all the best!

Hello sir.i assembled the circuit but no success.there is a spark of shot when I connect the 36v from the +ve end of the third battery to the transformer middle wire.out of the three batteries I used one to supply the driver components.then I connected the other two batteries to give 36-38v .so I supply the trafo with the +ve end of the third battery.simply by attaching the +36v with it.but a huge spark is observed at the contact.please help.i used the second code in the article.

Hello Yususf, if you connect everything at a time and check, then you are bound to have problems. The correct way is to check any circuit step wise.

In this case first you must begin by checking the Arduino output waveform, and frequency, and confirm it. Then connect the BC547 stages and check the waveform and frequency across the collectors. Then connect the MOSFET and the transformer, and switch ON the Arduino first, and then after a 10/20 seconds switch ON the battery on the transformer center tap through a fuse.

In this way you won’t burn anything and get successful results, and also will know how things are proceeding across all the stages.

Thank you sir.i hope a 3-5A fuse will be fine .for the waveform across the collectors of BC547.is there any other method to verify a waveform other than an oscillocope.i will check the voltage across the collector and emitter of each BC547 to ascertain proper switching.then will see the results.for the frequency,I lack a frequency meter but I think the code surely is a 50hz through the two pins.i used the second code with arrays ,hope it’s ok for the same purpose.

Yusuf, without an oscilloscope and frequency meter it would a trial and error method. so a small scope is the recommended option if you do not wish to lose more devices. You can cheaply purchase a DS0138 Dso138 2.4″ Handheld Pocket-Size Digital Oscilloscope for just $25 online for the testing

Hello sir.i connected the BJTs all two pairs without mosfets and measured at collectors.still one channel reads 9.5v and 9.5v while other only 0.75v amd 2.45v.i wonder what problem.i will try to check and tell you again.

Hello Yusuf, the BJT first stage will invert the Arduino PWM ON time and therefore will show 30% duty cycle…the second stage will invert the first BJT stage 30 % PWM back to 70% replicating the Arduino output, which will be used for switching the MOSFETs.

Hello sir.i disconnected the mosfets from the BJTs and measured the transistors after switching the arduino.i first put meter at DCV and obtained 0.55 and 9.75 for one channel.then the other channel read only 0.03 and 1.55.very low indeed.i then put meter at ACV and first channel read 0.5v and 20.4v.the other channel only read 0.00 and 2.5v.i thought problem was code so itried to interchange the pins 9 and 10 but still the problem remained for the same second channel.so is it the transistors with problem or what.the first channel seems to be ok.(0.55v and 20.4v at ACV.)(0.5v and9.75v at DCV).

Hello Yusuf, as per my reading the DC level which is average DC of the PWM will be 70% of the supply level. For Arduino output this should be around 3.2V for 5V supply, 8.4V for 12V supply, and for 36V this could be around 25.2V DC

Ok sir.so I got 9.70v across collector but I supplied the driver with 13 v.is this approximate.then should the value be the same for all BJTs or can vary from first pair to second pair.here am confused.but the other Chanel still has problems as I said.produces low values .only 1.45v reading instead of 9.7v. then you said 36v supply should produce average of 25.2 v according to the code.but you said earlier that maximum supply for BJTs is 12v DC.did you mean 36v of transformer centre tap.please clarify this point sir.

Yusuf, if you can get 3.2V at the Arduino output, the other values across 12V and 36 V will automatically adjust to the appropriate MS values

Sorry sir.i did not understand.you mean I should get around 25.2v across the collectors of BJTs or what did you mean.excuse me sir.but I supplied the BJTs with around 13v from battery.please clarify.

I guess you meant 36vdc supply should read around 25.2v at the mosfets stage.across drain and source.for(24v 0 24v trafo)

Yes that’s right, I was actually pointing out the duty cycles relevant to the various voltage levels used in your design.

Morning sir.so how do I measure the 3.2v from Arduino output.however one channel produces low values while the other seems ok.my connection is pretty perfect.one channel reads 7.1v and 9.65v at collectors.the other only 0.5v and 1.55v.anyway guide me on how to measure the 3.2v.from which points.i saw in comments you used 1N 4148 diodes across output and you got 3.2v.please assist.

Hi Yusuf, you simply have to connect the positive prod of the DC voltmeter with the Arduino output, and the black prod with the ground terminal or the negative terminal of the Arduino.

Please delete the code and upload it afresh and then check the response again

Yusuf, if you separately measure the Arduino outputs it will show the RMS for the half cycles, so this average should be around 1.75V

I apploaded the second code again .I connected both output pins one at a time as you said and both read 2.38v .I used a multimeter.the code is the same without alteration.

The total delay of the code is 14 millisecond, or 7 millisecond per half cycle. One full code cycle is supposed to be at the rate of 50 Hz, or 20 millisecond. So 14ms is 70% of 20ms, or 7ms is 70% of 10ms (half cycle half code).

Since Arduino works with 5V, 70% of 5V is 3.5V for full code.

PLease measure by connecting 1N4148 diodes from the two outputs and join their cathodes together and then check the output from cathode to ground

Ok.you mean I should connect anode of diodes to the outputs and join the cathode of diodes together.then measure cathode intersection point with respect to ground.hope it’s that way.

yes that’s correct!

Ok sir.i connected diode cathode end with respect to ground and read 3.25v with multimeter.hope it’s fine.hope I can connect the BJTs now to next step.

I got 3.25v with the diode connection.i will integrate the other circuit(BJTs one pair at a time and measure the value.hope it should be around 8.5-9v at collector and emitter.thank you

OK great!

Hello sir.problem comes when I connect the second pair of BJTs.with one pair both BJTs read same reasonable value.after second pair one channel has low values.voltage at Arduino output is same for both pins(3.25v)

Both the channel codes are identical so the PWM timing should be also identical, I think an oscilloscope will solve the problem quickly

Hello sir .the circuit now works very fine I tested with18w bulb and it glew bright.problem is I only used one pair of BJTs .so is there a problem for that.for the spark it is no longer.i used a 1000mf 25v cap to stabilize the battery power.i will measure output voltage and let you know.my question is can it survive with one BJT stage..

Yusuf, you must connect exactly as shown in the second diagram along with the delay generator. If you use only the first BJT stage, it will produce 30% power at the transformer output, meaning your voltage will not be 220V, it will be 90V

Thanks sir.i will check on that and try to rectify by adding the second buffer stage.is it a must for the feedback circuit.moreover,what about the battery charging circuit you recommended,I hope it works accurate with no problem.i am yet to assemble the battery charger meanwhile.

Hi Yusuf, the problem has occurred because you couldn’t implement it correctly, and you are doing it without proper tools and understanding. All my circuits will work perfectly without problems provided you do them with proper understanding and knowledge…you may find the battery charger also very difficult to build if you do it without understanding the details…so please make sure you learn and understand the stages and the concepts perfectly before trying them because all circuits will require some serious adjustments and tweaking for getting the desired results.

Hello sir.hope u fine.i have faced a problem concerning the voltage level across the BJTs.the voltage drops to 3.5 volts and realized that batteries are low.once I contact the +36 volts to the transformer center.the bulb glows quite bright then becomes dim immediately.i did not use a fuse but I did not expect that to be the reason of that.please help.i am yet to recharge the batteries are try it again.