Are you looking for free circuit diagrams, project ideas, and solutions? Are you interested in getting personalized help with an electronics project you're having trouble with?

Feel absolutely free to contact me through the comment box below the articles for getting quick solutions to your queries. I'll try my best to get it done for you absolutely FREE!

For submitting schematics or circuit diagrams you can send them to the following emails addresses.

Email ID

- contact @ homemade-circuits.com

- homemadecircuits @ gmail.com

Work Address

- 401, Unique Orbit 1

- Mira Road

- Mumbai

- India

- Pin Code - 401105

sir how to make 1000watt inverter using SG 3525 ic

Abdulkareem, you can upgrade the MOSFET rating and the battery rating appropriately for getting a 1kva output.

sir 4 MOSFET I build is may be give 1kv sir

also

how can I calculate the output power sir

Yes, it will handle 1kva, you can try MOSFET IRFP2907.

https://www.homemade-circuits.com/high-current-mosfet-irfp2907-for-wind/

I did not have this number but MOSFET ss7509 is work done

the problem is

1 how can I measure current

2 how measure the power

3 thank you

The only way to confirm the power is by operating a 1000 watt load without dropping the output voltage by much…

OK please in inverter circuit how plug buzzer alarm

when

overload or

low battery

temperature

buzzer is announced have problem

Sure, you can try the second circuit from the following article:

https://www.homemade-circuits.com/low-battery-cut-off-and-overload/

thank you sir please help me with 1kw inverter circuit using SG 3525 ic

Please build a basic 100 watt inverter then we can upgrade it to any higher level through simple modifications.

sir irfz44n

irf3205

irf540

which one is higher power working properly

irf3205

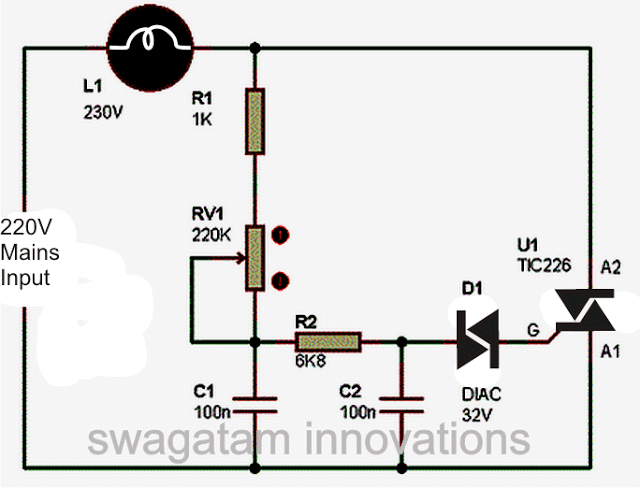

Hi! I’m building a speed control for my old ventilation fan with a 2 uf drive capacitor model

D4E146-AA07-02 with my own PWM control triac.moc3041.555 control with the PWM frequency set to 50 Hz. I’ve got it working fine between minimum and maximum speed. If I lower the speed, it starts to jerk a little more and more when I reduce the speed. Thank you for more suggestions or other connections. I just want to build something of my own. Best regards Göran

Hi, Thank you for your feedback, I am glad you are trying to build something of your own, bit PWM concept does not work well with AC loads, instead you should try phasing control method aas done in fan dimmers.

https://www.homemade-circuits.com/simple-ceiling-fan-regulator-circuit/

Reverse horn curcuit

Car backup alarm curcuit required

You can try the following circuits:

https://www.homemade-circuits.com/how-to-make-bicycle-horn-with-ringtone/

https://www.homemade-circuits.com/car-reverse-horn-circuit/

I have a c band LNBF a round one not a square type but always could not grab all tv channels because the dielectric plate doesn’t work like a waveguide polariser, could you please help with the idea of making a waveguide polariser

I am not too sure about this topic, however you can try the following approach:

A waveguide polarizer can be made using a twisted metal or dielectric helix inside the waveguide. This method is good in converting circular to linear polarization.

Use a thin copper or aluminum strip bent into a helix shape inside the waveguide.

The helix should have a pitch of 90 degrees per wavelength of the center frequency (e.g 3.7 GHz → 8.1 cm pitch).

Secure it nicely inside the feedhorn by using non-conductive mounts.

Wire Grid Polarizer

Place a set of parallel metal wires inside the feedhorn at 45 degrees to the incoming wave.

This might work like a polarizing filter to separate H/V components effectively.

Metal Fin Polarizer

Instead of a dielectric plate you can install thin metal fins at regular space inside the waveguide.

Each fin should be placed at 45 degrees relative to the direction of the signal.

https://www.researchgate.net/publication/245440235_Infrared_wave_propagation_in_a_helical_waveguide_with_inhomogeneous_cross_section_and_application

Hi again. I have built an up and down counter 0-99 with 2 displays with circuits 7447 and 74192. Now I want to be able to stop the counter at a certain predetermined value. I have not been able to do that function yet. Do you have a schematic or something in your collection? Best regards Goran

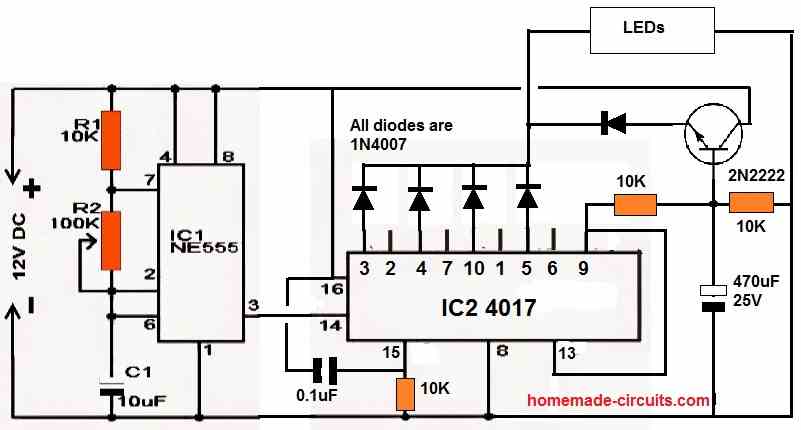

Goran, you can configure a few 4017 ICs to latch the oscillator once the respective 4017 output reaches the last counting figure. An example design is discussed in the following article:

https://www.homemade-circuits.com/making-programmable-timer-circuit-using/

I don’t really understand how to use a 4017 circuit. I was thinking of using the digital display to read the throttle in a carburetor. Lock the display when the throttle is fully open and fully closed. I control the throttle via a stepper motor with associated step control.

I have suggested the 4017 circuit to stop the counter when the desired figure (count) is reached on the display, as per your requirement.

i am working on running 24V BLDC motor using user circuit provided.I am using IGBT 900V 60A.

On running the arduino program the IGBT gets heated up.Please give me solution.

Which circuit are you referring to?

Good day sir.

Please I have some speakers of 32inches, I need to bridge my amplifier so that it can push the speakers, do you have a circuit for bridging amplifiers? Then, can any amplifier be bridge? I know some amplifiers are IC output and some transistor output,

Please your help will be appreciated.

Hi Jeo,

I think you can try the following circuit and check the response:

https://www.homemade-circuits.com/120-watt-amplifier-circuit-using-tda/

Bridged amplifiers work using push-pull method, which is not possible using any amplifier…

Sir thanks for the response, it’s like you never got my question, I said I have speakers and amplifier at my desk, is there a means to bridge the amplifier from stereo to mono so to produce more power that can drive my speakers?

Then Second, does bridging from stereo to mono works with all amplifiers?

Thanks for the circuit, it can’t drive my 450watts 32 inches speakers….I look forward to hearing from you

Yes you can use the stereo outputs to drive your mono speakers. Please specify the power rating of the amplifier, assuming the total power rating of the speakers is 450 watts. i will try to figure it out.

Yes, most of the standard amplifiers can be bridged from stereo to mono.

Thanks for your kind guidance, to my understanding, can I send you an example diagram of what I’m trying to accomplish?

Sure, you can upload the diagram here with your comment, I will check it out…

file:///C:/Users/PATRIC~1/AppData/Local/Temp/msohtml1/01/clip_image001.jpg

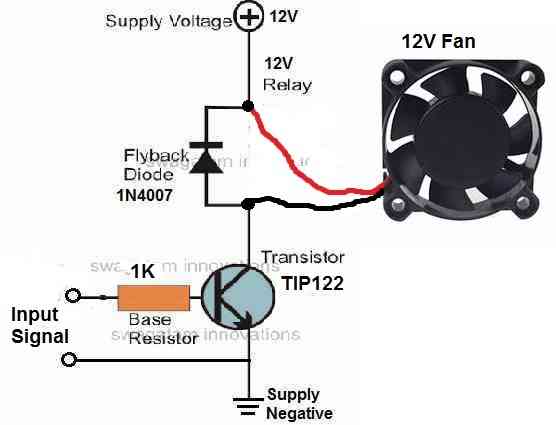

MR swagatam here are the inverter circuit i need to get a suitable circuit to drive the tlp250 which drives the 4 mosfets in each cycle on and off

Hello Patrick,

The file does not open in my computer.

Please save the image in your desktop first and then upload to this comment, I will check it out.

hi, i would like to control a dc model train direction and speed using a triac by troggering it in positive or negative mode using a single pot for foreward reverse and speed. not using a switch for reversing. the train is 12 volt perminate magnet motor thank you. wayne ochano4mizu@gmail.com

Hi, I am not sure how to use a triac to forward reverse motor direction, if I find one I will surely let you know.

Bonjour monsieur en fait j’ai besoin d’un circuit de Power banck genre un circuit qui à une autonomie élevé

Hello Theodore, can please provide more details about the design you are looking for?

Hi Swagatam, you are a genius. My level of power electronics understanding is 2.5 out of 10 (10 being yours)

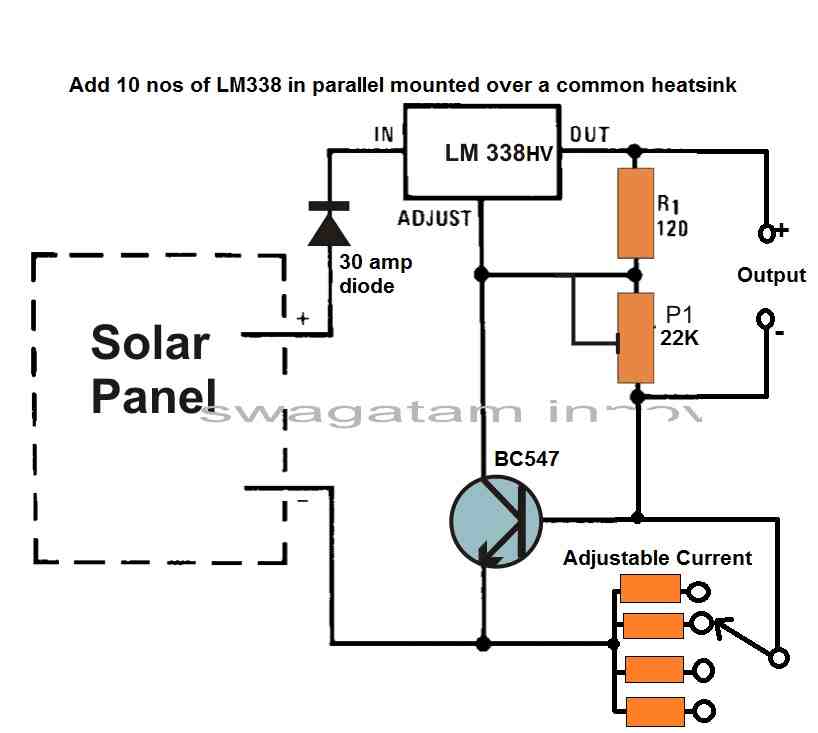

I need help with building something like the Solar Power Manager For 12V Lead-Acid Battery but with more output current on 12v rail.

Currently I have to use 2x of these to achieve my goal.

Loads are , 12v 5A , 12v 2A, 12v 8A and 48v 2.5A (I am using a step up module from aliexpress.)

Battery banks are 12v 36Ah and 12v 18Ah

Ideally, I would like to have this 3x separate modules into a single board with low ripple / noise and single 12v high current rail 20-30A(like a modern ATX power supply)

Any info and pointer to right direction is appreciated.

Charm

No problem Charm, I will try to figure it out soon…

Thanks mate, but my requirement is a bit complex.I will email you the full requirement.

Thanks Charm, I will check it out and let you know if I am able to figure out an appropriate circuit design for the same.

Greating sir, pls can you sujest a circuit diagram to switching regulator and filtering smps boost converter using flyback from 3_5v pulsating DC to 12 constant DC ?

Hello Akafec, you can modify the first concept from the following article appropriately to accomplish your specific requirement.

https://www.homemade-circuits.com/12v-car-laptop-charger-circuit-using/

Thanks very much sir i have very little knowledge on circuit design pls how can I connect the control circuit (switching regulator) on the boost converter circuit on the first article you referred me to that is 5v dc to 12v dc

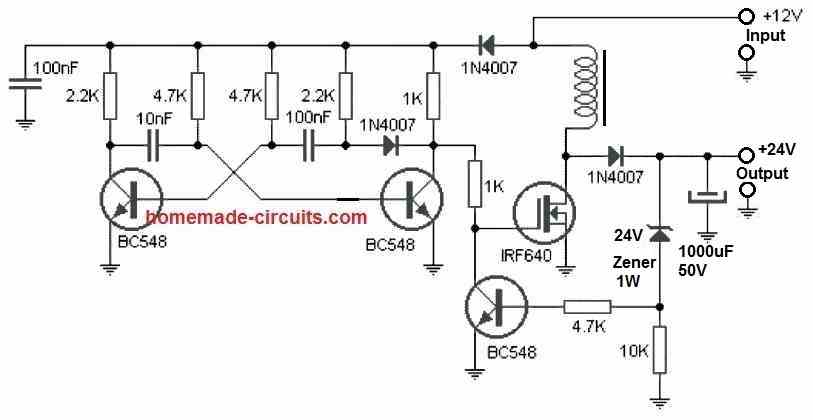

You are welcome Akafac, you can feed the 5V across the “Input” terminals of the circuit:

" rel="ugc">

Thank very much sir pls I’m doing micro generation of electrical energy that’s water will be held at a hide then allowed to flow through a pipe to fall on the blade of a small DC motor which will produce a DC voltage from 3_5v I now want to boost it up to a constant 12v using a switching regulator that will always read the input and output before switching since the output can vary from 5 to even 3.8v but it should supply a constant 12v and I intend to filter the voltage too sir ?

Yes, the circuit which I have referred to you will do exactly that.

This boost converter itself is a switching regulator, a boost converter switching regulator.

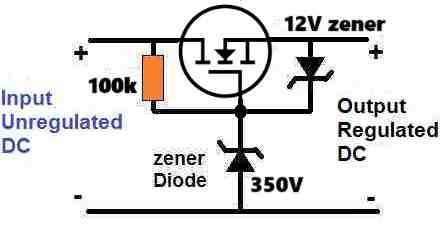

You just have to calculate the coil winding such that it gives a 12V output at 3V input, and then use a 12V zener diode at the output to stabilize this 12V.

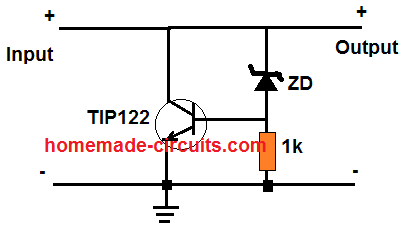

In that case the MOSFET cannot be used at the output, instead you can try a TIP122 BJT

However, please remember that the output power (I * V) will be always sightly lower than the output power (I * V).

Thanks sir but the coil there I don’t know the specifications

Akafac, You will have to put some effort and calculate the inductor value depending on your output/input specifications.

In that linked article I have explained in detail how to calculate.

Can you do it?

No sir

Please provide the maximum output current requirement…

1A or lesser even sir

Pls sir, I’ll be glad to see your solving steps so that if I intend to change the current I can resolve for the inductor value sir thank

Akafac,

Please post your question with the all the details under the following post, I will explain the procedures in details to you:

https://www.homemade-circuits.com/how-to-generate-electricity-from-sea/

I use w1209 thermostats, cheap and very good for egg incubators etc. So cheap there are a lot of poor quality ones being made and sold. Thought I would get schematic and make Gerber file for getting these boards made. Three schematics for w1209 on internet and all incomplete. Many people would be interested in W1209 schematic as there are over 36000 videos on youtube alone, on setting and use. Hoping you might be interested in the schematics I have and making a complete one for everyone to see and use. Best regards

Thank you for the valuable information.

If you have the schematic, please send it to my email ID, I will make sure to update it under the relevant article:

My email ID:

homemadecircuits

@gmail.com

I am referencing two of your projects to see if there is a way to combine both to fit my needs.

the first project is the Twin or Split 12V Battery Charger Circuit with Auto-Changeover, this is a great design and it does work well, I have replaced the relay and driver transistor with this project SPDT Solid State DC Relay Circuit using MOSFET, in the original design, and although it works great I still have one issue to address which I am having a time getting figured out.

What I would like to do is to put some kind of delay to the circuit that would allow only one battery to be connected to the load until just before the other battery gets discharged. To clear this up Batt1 is fully charged and Batt2 is in the charging state, the way you have this setup is that when Batt2 gets fully charged it gets connected to the load while Batt1 is still in use, I get it that Batt2 would boost the load till Batt1 is discharged, realizing that the diodes will keep the batteries isolated. Is there a way to extend the delay to a point just before Batt1 is fully discharged, before Batt2 gets connected to the load. I would like to leave out any mechanical type of switching, possibly using the mosfet circuit above.

Thank you for all you do.

Thanks for this interesting questing.

Can you please post this question under the following article, I will try my best to solve it for you.

https://www.homemade-circuits.com/automatic-dual-battery-charger-with/

Hi, Swagatam,

I assembled On-delay circuit: " rel="ugc">

Everything works fine.

Question: Is it possible to have On-delay function and at the same time make Pin 3 oscillating instead of being constant “High” so I can connect LED to it and make it blinking?

Best regards,

Michael

Hi Michael,

That is not possible in that design.

Instead you can try any 555 astable flasher circuit, and just add a 100uF/25V capacitor between pin#5 and ground, that should do the trick to fulfill your requirement.

Will a flashing LED work?

It will work!

I have a question and the question is, is it okay to use a circuit breaker for AC power from inverter going to appliances, does it a little bit guard the inverter or does the magnet in the circuit breaker affect the inverter performance?

Using a circuit breaker for AC power from an inverter to appliances is perfectly fine and commonly done. It provides protection for both the inverter and the appliances in case of overloads or short circuits.

1. I want a circuit that will automatically allow dc 12v to flow off/on using LDR .

2. 1 want an automatic switch that will always turn on/off ac 110/220 using LDR.

You can explore the following page for more information:

https://www.homemade-circuits.com/how-to-make-light-activated-day-night/

Please, I want you to construct a circuit that can light up and charge a solar street light.

I am having difficulty in getting the main controller. Most of the lights I have are dead and no parts to fix them. I have sent you the picture of the solar street light for you to know the size of the solar light. It has 16 bulbs.

Looking forward to hearing from you soon.

Thanks.

Hello Elisius,

You must provide the complete technical specifications of the solar lamp LED, and also the street lamp. Just an image might not help!

Mr Swatagan , thank you so much for your prompt response.

The solar street light is a 200watts solar, Please ,I would like you to explain to me the more what you meant by technical specifications .

I sent the picture of the solar street light to your email address

. The picture might be of help for you to know the specifications.

Elisius, The picture does not have any information regarding the lamp voltage, current specification.

Please provide the voltage specification of the lamp module and the solar panel, and the functioning details of the controller.

Specifications for the solar street light.

*Input voltage: Dc 6v

*Power supply: Solar

*Light Source: LED

*Power: 200watts

*Solar panel: Mono crystalline silicon: 6v 75watts.

*LED light source SMD 3030 200pcs

*working Mode: Daylight control+Remote control+sensor

*working Temperature: -20-50

And what is the battery specifications?

Your LED module will require 200/6V = 33 amp current.

For this you may require a Li-Ion battery with a capacity of around 8V 325 Ah to last for 10 hours

For further discussions, please comment under the following article:

https://www.homemade-circuits.com/3-simple-automatic-street-light-circuits-explored/

a learner will always stress a teacher, now my question is how can we make a radio call or a walky talkies

For a walkie-talkie circuit, you can explore the following page:

https://www.homemade-circuits.com/?s=walkie+talkie

I want to make to make a small toy house for children to play with 5 foors, but I want to make a lifter using small DC motors found in old DVD players , please help design a the lifter circuit and technic movement design.

What should be the specifications of the movement?

the movement of lift or elevator should be up and down only for example when it leaves down to the second floor it stops for some small time then it continues to the third floor, until it reaches up, then it keeps coming back down while stopping stopping till it reaches down and it will begin going back up again thank you

Ok, I will try to figure it out soon, and let you know…

the movement should be from down to the up floors then down but I don’t know how you will even make the switches

So it will be a continuous up and down and up movement?

the movement should be if a switch is switched for it to go to the second floor it should move from down to the second floor and swagatam please let’s make it almost like a real lifter as long as the switches shall be outside and we shall not make a door for it

Making the movement like aa real lift is extremely difficult, because it will require a lot of coding and can be perhaps be done only through a microcontroller.

I saw a village solar street lights of 40w LED you had made, but please draw for me a design that will use a 7ah/12ah battery with a small solar panel like 10w or 20w solar panel with very good power saving, please draw it without automatic turn on, and the other please draw it with automatic turn on either with relay or without relay. Please make a design of LED either 40w LED or 30w led or below for that village solar street light

Hello Rashid,

Please post this question in the following article, i will try to solve your problem:

https://www.homemade-circuits.com/3-simple-automatic-street-light-circuits-explored/

Hello swagatam, I saw one of your post of making a solar charge controller of 10w solar panel and 7ah battery, so I wanted to confirm if I could use a 12ah battery and the controller would still work well, to be honest can a 12ah battery light 2w bulb or 4w bulb for 12 hours?

The second question is I’m requesting you to make a diagram for a 100w solar panel charge controller minus using a relay please that can charge 70ah battery?

Hello Rashid,

Please post this question in the following article, i will try to solve your problem:

https://www.homemade-circuits.com/3-simple-automatic-street-light-circuits-explored/

Good evening i am very new to Electronics but very willing to learn. i was bought a 3 candle garden light with each candle being powered by x3 AAA 1.5v batteries in series i believe. They currently have a wire from a positive to an LED and the a wire from the other wire to one side of a switch and the a wire with a resistor or some sort to the negative of the third battery.

i would love to be able to convert these to solar so I’m not replacing batteries every week. I sort of understand the circuit diagram but I’d like to make a circuit board with the relevant resistors, diodes and dark/light thingy. i can solder very basically so if given a diagram or better still a step by step diagram that would be great. i have 4.5v solar panels and 6v ones? I’d lime to use the battery holder it comes with which holds the batteries in series if possible? i can send you an email pic of the candle if that helps?

Good morning, and thanks for your question.

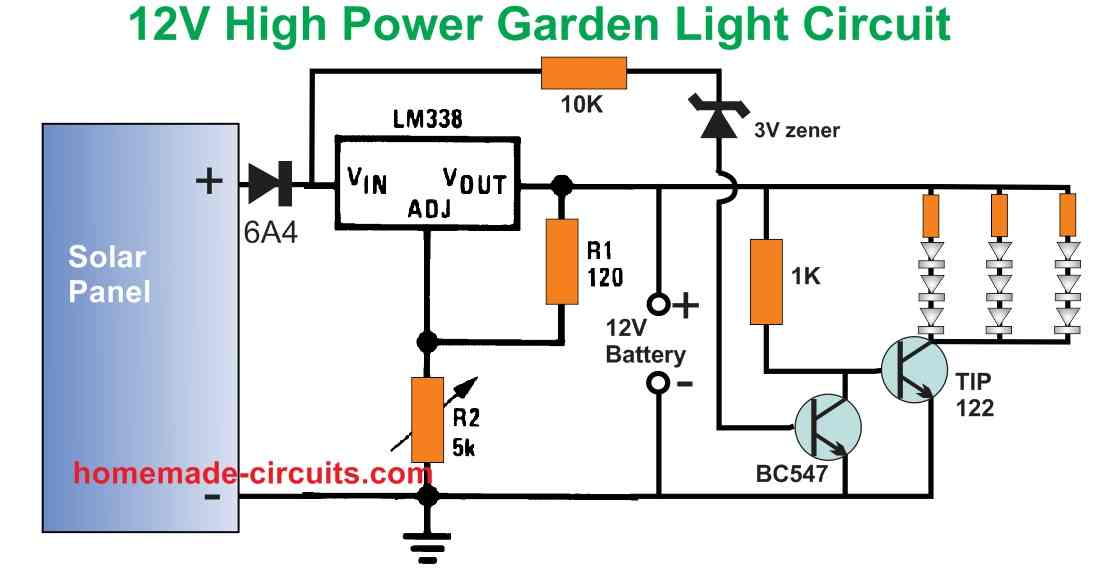

I think the first circuit from this article looks the most suitable for your application:

https://www.homemade-circuits.com/simplest-automatic-led-solar-light/

You can remove the shown LED and its series resistor and replace them with the wires of your LED candle.

If you have any further questions, please feel free to comment under the above garden light article, I will make sure you succeed with this project.

Hi sir, can you give me a diagram for charge controller for 24v lead acid battery using solar panel? This is my final requirement of my subject sir i badly need it :(.. thank youuu

Hi, Hughian,

Can you please tell me the Ah rating of the 24V battery, I will to provide you with a proper circuit…

hi sir, I got 15Ah rating here.

I got two 12v lead acid battery here I will connect them series to get 24v , because my prof said it need 24v and there is no available 24v in the online shop so I ordered two 12v instead.

Thanks Hughian, for the information, do you have any specific requirement in the charger design, like automatic cut-off, trickle charging etc.

Hi sir Swagatam,

I just want the circuit an indicator if the battery is fully charge an LED diode will light to indicate it is fully charge, I ill just use my multimeter to manually check the battery voltage if it is low then I will charge it again and LED diode will turn on if it is fully charge. thanks sir.. 🙂

Thanks Hughian,

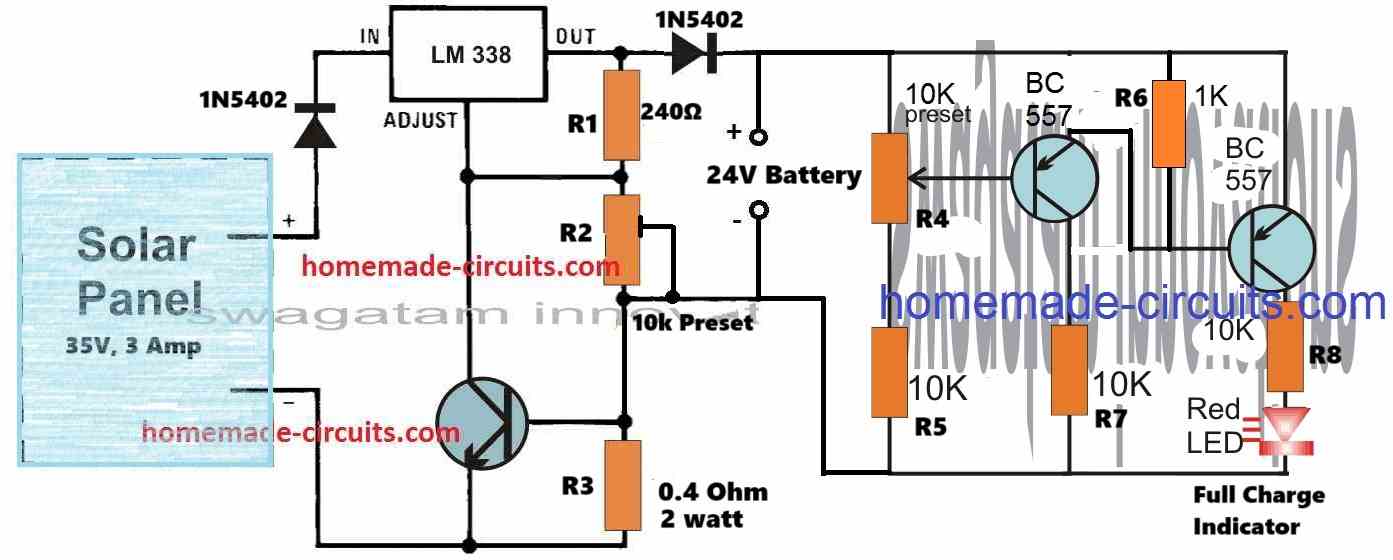

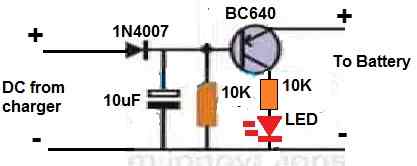

You can try the following circuit:

" rel="ugc">

Please adjust the R2 to get 28V across the battery output points (without a battery connected)

Adjust the R4 preset so that the red LED just switches ON at this 29V.

Hi sir Swagatam,

Sir thank you for that diagram I have a question sir this transistor beside R3, is a NPN transistor? If it is NPN what model is that transistor? Thanks Sir

No problem Hughian,

You can use a BC547 for that transistor. It is a current limiting stage which will limit the output charging current to 1.5 amps suitable for the 15 Ah battery.

Hi sir Swagatam,

thank you very much sir, ill update you if it is working in my part. thanks <3

Thank you Hughian. all the best to you!

Hi sir Swagatam,

My classmate ordered 18V and 30 watts of solar panel, is it applicable to the circuit of the solar panel we ordered? Because the solar panel specs you provide is 35V. Thanks you very much.

Hi Hughian,

18V solar panel cannot charge a 24V battery, you will need a 35V 3 Amp solar panel for charging a 24V 15 Ah battery. 18V 30 watt panel can be used to charge a single 12V 15 Ah battery.

Hi sir Swagatam,

thank you sir for the reply. sir.

You are welcome Hughian….

Hi sir Swagatam,

Im back again 😅 , sir my teacher says it will be best if the charge controller is MPPT, and i honestly do not know what is that. If there is any to modify the circuit diagram you provide to me sir..

Regards,

Hughian

Hi Hughian,

I think your teacher would know better regarding the MPPT specifications and working which he/she wants you to implement, so you can ask your teacher to provide more information about it.

You can also consider trying the following design for the intended MPPT charging method:

https://drive.google.com/file/d/1oYdpFeBemVi_rT8oouiQjs7C_MdGLqjd/view

The previous circuit using LM338 cannot be modified for an MPPT charging.

Hi sir Swagatam,

Thank you very much sir.

Regards,

Hughian

You are welcome Hughian…

Hi Swagatam!

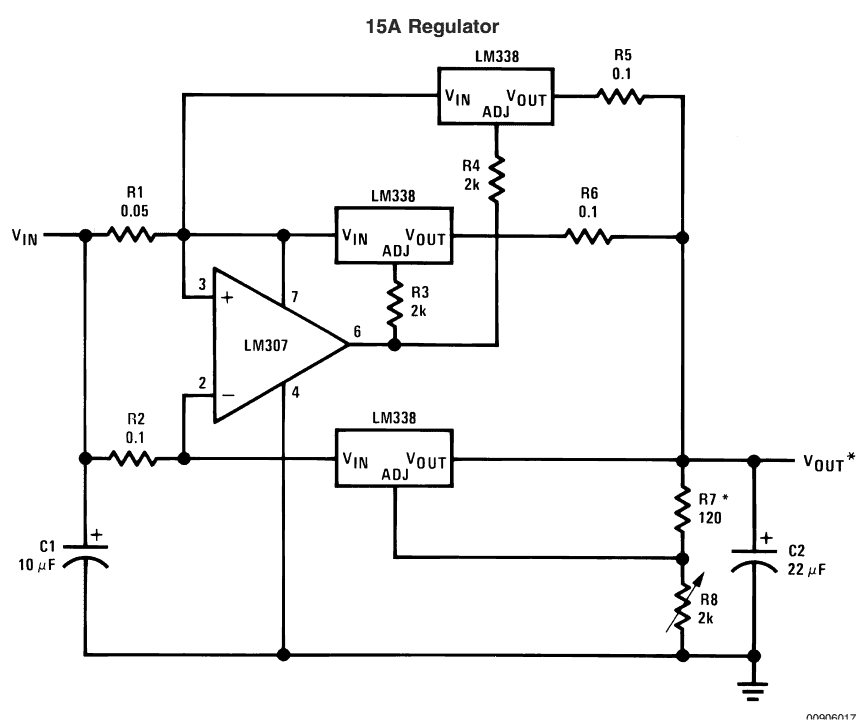

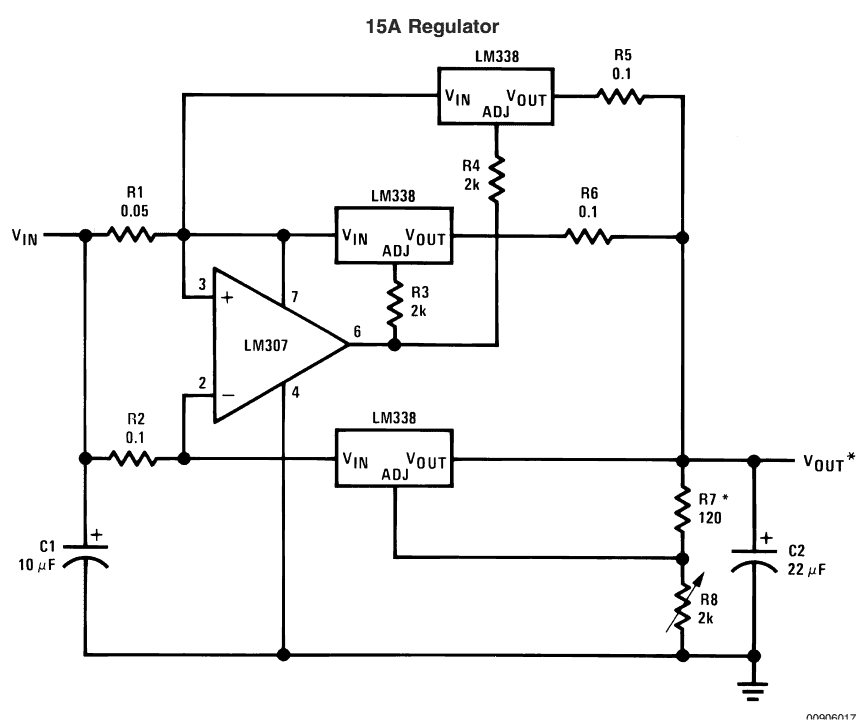

I have built the 15Amp voltage regulator as per the demo circuit given on p.19 here:

https://www.ti.com/lit/ds/symlink/lm338.pdf?ts=1729104861851&ref_url=https%253A%252F%252Fwww.ti.com%252Fproduct%252FLM338

I am assuming the LM358 opamp is to blame for it not working, because it is apparently not as sensitive as the offset input voltage of the LM307.

However, looking at the circuit above, I do not understand how it works. Why? Because the adjust pins of the two opamps with 2k Ohm do not get routed to the output of each regulator like they normally do. Do you think I should invest in a LM307 as per the diagram, or perhaps there is something I need to change in the circuit design?

Any insights would be most gratefully received.

Kind Regards,

Bhakti

Hi Bhakti,

In that circuit the opamp is configured as a voltage regulator which senses the output and limits it as per the adjustment of the potentiometer. This information is sent to the base of the PNP emitter follower which adjusts the LM338 ADJ level accordingly.

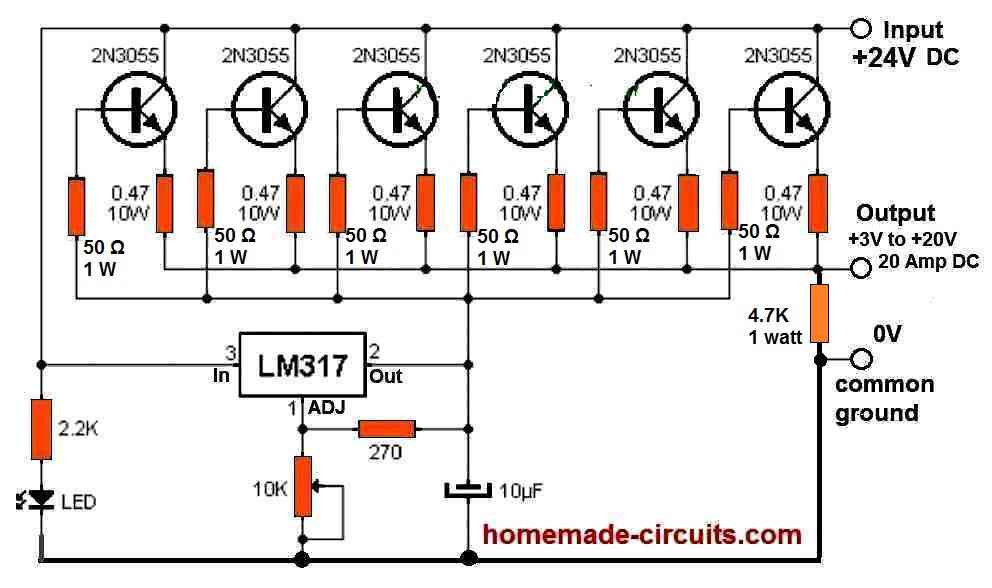

Actually, there’s no need of the opamp stage, you can put all the LM338 directly in parallel and use them, as explained in the following article:

https://www.homemade-circuits.com/how-to-connect-lm338-ic-in-parallel-to-increase-output-current/

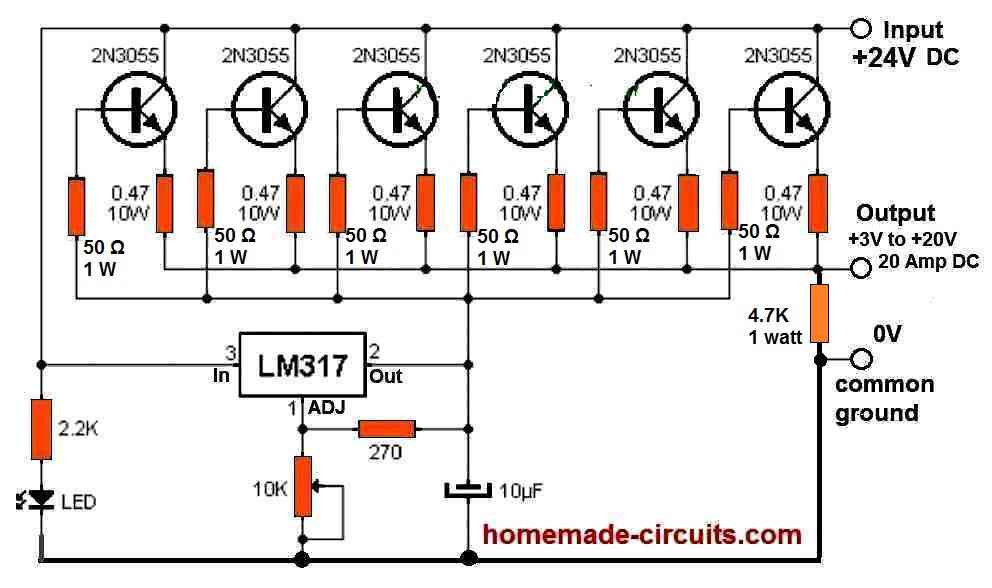

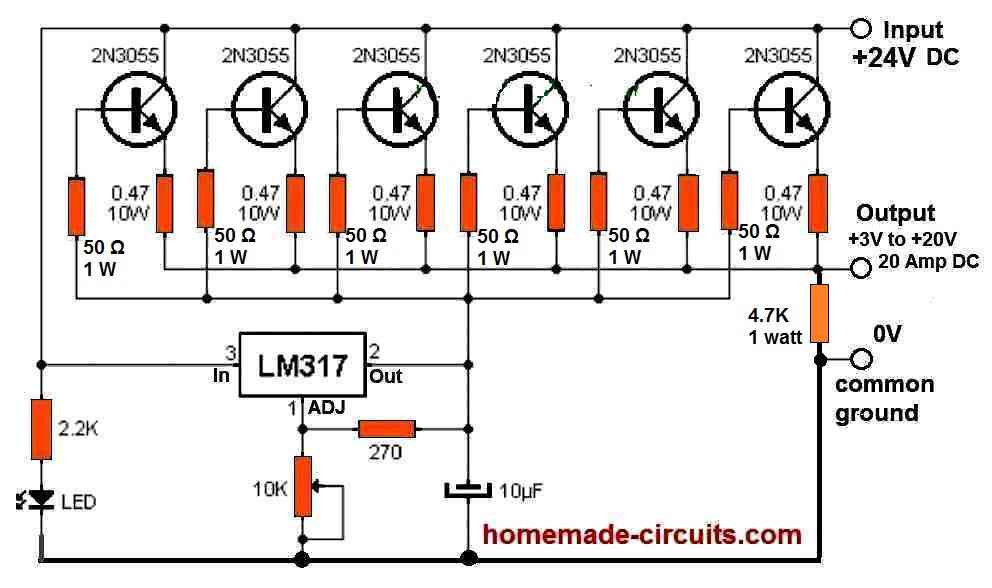

Alternatively you can build a 15 amp regulator using a single LM317 and a 50 amp power transistor, as shown in the following diagram:

" rel="ugc">

You can replace the 2N3055 transistors with a single: MJ11032

HI Swagatam!

Thank you for your prompt reply. Is it possible we are looking at two different circuits? The one I built has no PNP transistor but is the same one you documented here:

https://www.homemade-circuits.com/ic-lm338-application-circuits-explained/#15_Amp_Variable_Voltage_Regulator_Circuit

One reason for building it was an excuse to see how opamps work in different situations.

However, if I can not get this to work, I will just keep the 0.1Ohm 10w at the three LM338 output pins and cross my gingers that this “ballast” solution will work. It will be interesting whatever happens 🙂

Thank you Bhakti,

I may have mistakenly referred to another design of a 15A regulator which uses an op-amp and an PNP, in the datasheet.

In the following diagram which you have used, the op-amp is used as current sensor, when the current across R2 exceeds above the max capacity of the lower LM338 (5 amps), the opamp output goes low and activates the upper two LM338 ICs which provide the extra 10 amps to the load.

" rel="ugc">

The output resistors can be eliminated for the parallel LM338 ICs, if you mount all the ICs over a single common heatsink, very close to each other.

Hi,

After I built this one with no PNP:

https://www.homemade-circuits.com/ic-lm338-application-circuits-explained/#15_Amp_Variable_Voltage_Regulator_Circuit

…I could not see it working. It is possible that I have not thrown enough current at it to make all three LM338s start to work. The LM338 configuration seems quite “unorthodox”. It does not involve the typical 240 Ohm between Adj and Out pin. I decided to experiment by isolating the behaviour of the LM338 with just a 2k Ohm between Adj pin and Gnd. And sure enough, with high resistance like 100k, the LM338 Vout was at a maximum, but when around 2k Ohm, it was just a couple of volts.

Not happy I was learning effectively about opamps, I saw this circuit which maybe similar or same as the one you first described:

" rel="ugc">

Well this interests me, because I can easily see how the opamp is sensing changes in the final Vout. My thought is that it increases the final Vout when there is a heavy load on the final Vout, so that the Vout voltage remains the same? But maybe it has more to do with the balancing of the numerous LM338 which are incorporated in this design? I also don’t see the need for a BD140 PNP when there seems to be maybe only 10mA going through it ( 1.25v / 100Ohm).

Hello Bhakti,

In the following circuit, the voltage across R2 must make the pin#2 of the opamp higher than pin#3 by 0.2V, only then the opamp output would go “LOW” and that would trigger ON the upper LM338 ICs. In short, the voltage

" rel="ugc">

You can calculate the minimum load current required for this using the following equation.

I = 0.2/R2

However, for this the pin#3 must be referenced at 0.2V also, which is not done??

Also, you are right, the ADJ pin of the upper LM338 must be coupled with the lower LM338 for the upper LM338 to correspond to the voltage levels set by the lower potentiometer, otherwise the circuit will not work correctly.

So it seems the above circuit has serious issues, not sure how this was included in the datasheet of the IC

The other circuit which you provided is correct, you can use try that.

Hi, I use w1209 thermostat in my egg incubators. Have purchased over thirty from very cheap to expensive, none work. Sending them back costs more that I paid for them in most cases. Have schematic, photos of both sides of PCB, but no gerber file to get some made by PDB makers. Is there anywhere I could find a geber file for w1209 PCB? Thank you for taking time to read this.

Hi, I understand the problem you are facing, however unfortunately upon checking I too could not find any online source that provides the PCB details for this project.

Greetings Swagatam,

I stumbled on your site while searching for diagrams for generating electricity from the Atmosphere. I currently have a simple small circuit with a few Capacitors and Diodes to generate 1.5VDC but the current is low and voltage is not sustainable with a small led. My main focus here is “Free Energy” as I use that term freely. I know you have posted many circuits and articles about similar subjects but I would like to build a working model that produces continues voltage with a small load. Over-Unity has also been talked about for some time now but it’s really hard to find diagrams of a true working model to build. So, if your able share a Project I could build at home that is sustainable I would love to try and build it to prove “Free Energy” is truly possible.

Thanks,

Sal

Hi Sal,

Have you tried one of the concepts from the following article?:

https://www.homemade-circuits.com/how-to-collect-free-energy-from/

Actually I haven’t tried these concepts practically, so confirming the results may not be possible for me at the moment.

However, I am aware that the key elements in these circuits are the antenna and the grounding (earthing) which must be perfectly done.

The antenna must be as long as feasible and totally isolated from the ground, while the ground or the earthing wire must be thoroughly inserted into the soil, as deep as feasible…

I want to make a motion activated rat trap using 12v power supply, a 12v pir and a linear pull solenoid. It needs to be basic as I know very little electronics. Can you draw a circuit please.

You must know the basics of electronics and how to solder, if not then you must first learn it and then I will provide you with the circuit diagram…

Hello teacher. I need your help. I need a basic electrical circuit diagram of a step-down convector DC-DC Step Down SKU 7915. Can you help?

Hi Valera, sorry I could not find any online information regarding the IC SKU 7915….

Alternator generator with a DC motor set up. While I am im the beginning brain storming phase, How would you stop it safely without causing injury to yourself of the device. In case I want a portable one for camping or leaving my house for several days.

Hi, sorry, I could not understand what type of safety measure are you referring to? Can you please elaborate.

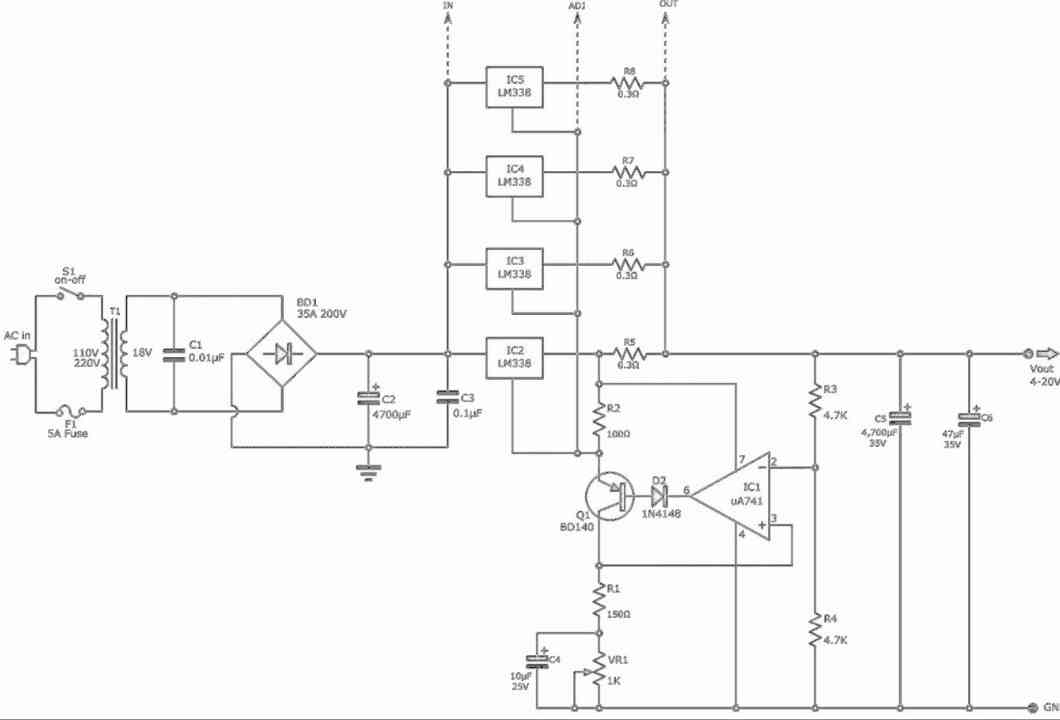

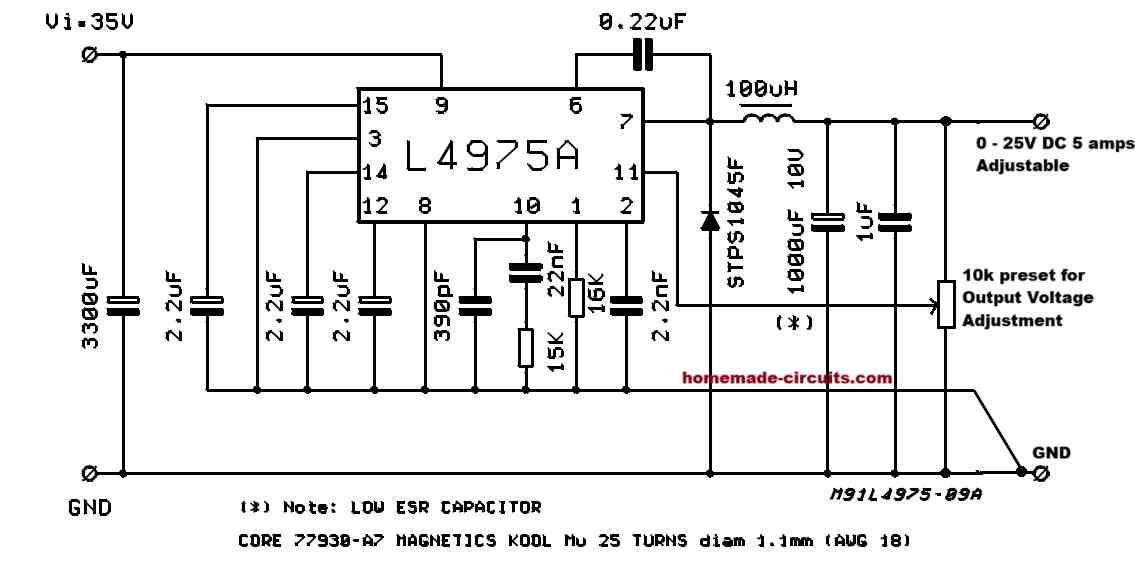

Hello Teacher. I received your circuit diagram for L4975A. It indicates an input voltage of 35 volts. Should I first use a voltage divider to bring the 50 volts to 35 volts and then feed it to the microcircuit? Or can I immediately feed 50 volts to pin 9

Best regards, Valera

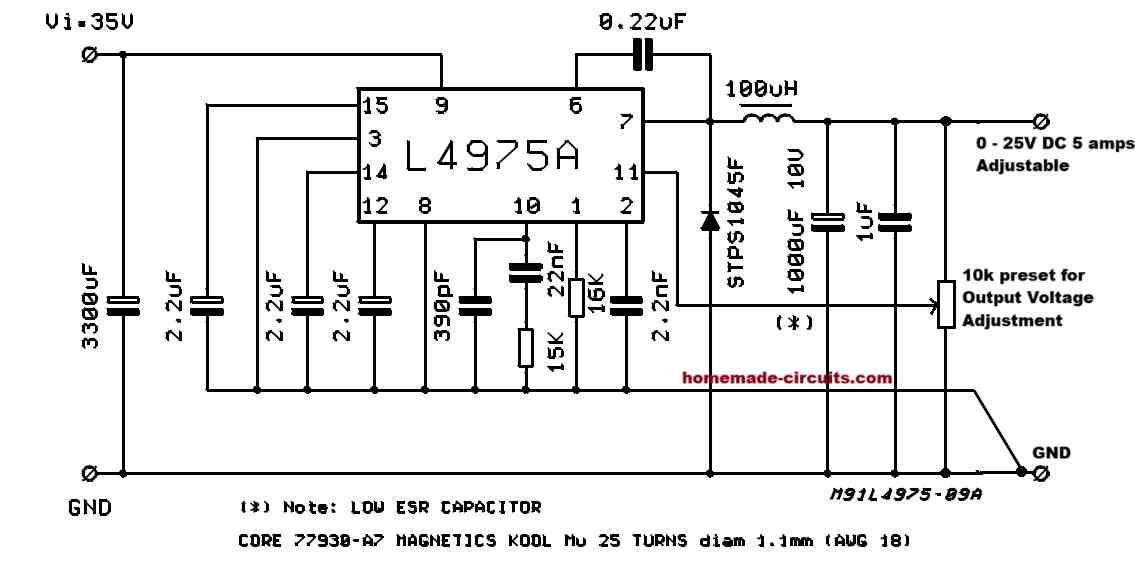

Valera, The L4975A IC’s maximum input voltage is 55V, so 50V can be used in the following circuit:

" rel="ugc">

I received your letter and the diagram. Where is the voltage divider or variable resistance instead of the divider? And one more question – how to determine the internal resistance of a diode floodlight

The 10k preset in the previous diagram is the feedback resistive divider.

Sorry, I am not sure how to determine the internal resistance of a diode floodlight.

Hello Teacher. I purchased L4975A and as you promised I will try to provide a circuit diagram for 4975 with feedback, to obtain a stabilized voltage of 17 volts with a load of 3 amperes. The load is a spotlight and it is desirable to take into account the power dissipation of the microassembly

Hello Valera, you can try the following circuit:

" rel="ugc">

sir

I am from Thane ghodbunder road,

wish to visit you.

please if possible spare few minutes for me!!

Hello Bhupendra, Do you have any circuit related question? In that case you can feel free to communicate with me through this commenting platform, I will try my best to solve it for you. Please let me know!

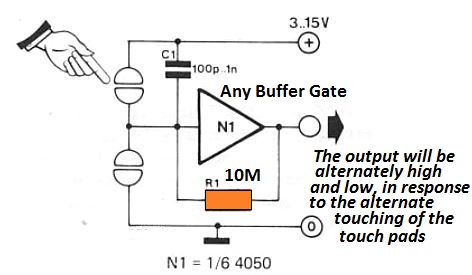

As a model railroader, I have a crossing gate that needs to stay activated through a six-foot zone, and stays activated as long as a train remains in the zone. Could I use a six-foot piece of metal track or maybe a copper wire as a sensor plate with one of the circuits described in this article? Cars are mostly plastic.

Thanks for your question, could you please specify which circuit diagram you are referring to? I will try to figure it out for you…

hello sir,

fi am working on lvdt project.i am using peltron lvdt for measurement .As per the datasheet power supply is 3.6 vrms at 3KHZ and the output is +- 1.2v rms . my requirement is precious 3.6vrms at 3khz generator circuit and for the output i require precious rms to dc convertor circuit. Pls. suggest circuit for this project. thank you.

Hello Sridhar,

You can try any of the transistorized version from the following article, and adjust the relevant RC components for getting the desired effects.

Since your input is 3.6V, only transistorized circuits may be suitable.

https://www.homemade-circuits.com/simple-sine-wave-generator-circuits/

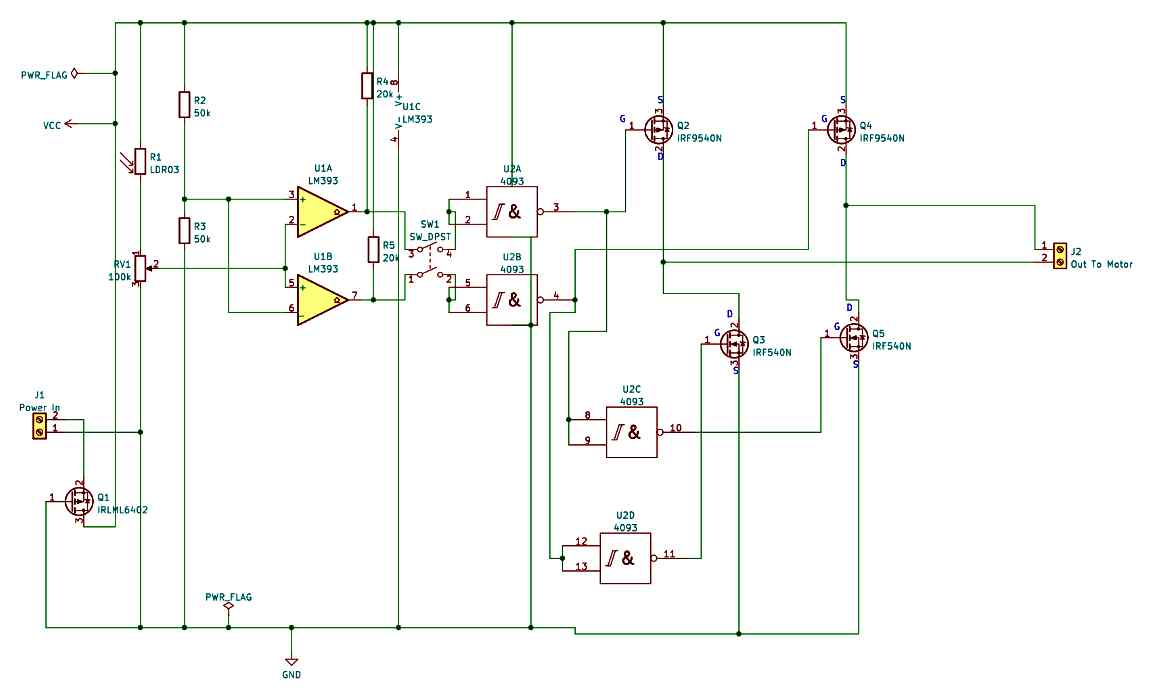

I constructed inverter circuit using irf9540 & irf540, it works perfectly with 12volts transformer. I need to use 24volts or 48volts transformer with the same circuit. What should I do. Thanks indeed.

If you are using P-channel MOSFETs in your H-bridge design, then I am afraid you cannot use a load voltage higher than the Vcc supply voltage of your oscillator IC, unless perhaps you use a boost converter at the oscillator outputs.

Hi Swagatam, I saw your article about a wireless charger (Wireless Charger) and I thought it was great and perfect for my university project. I was wondering about the gauge of the 2 core speaker wire used for the Transmitter and also the gauge for the Receiver.

Thank you Robert,

Sure, you can use it for your university project.

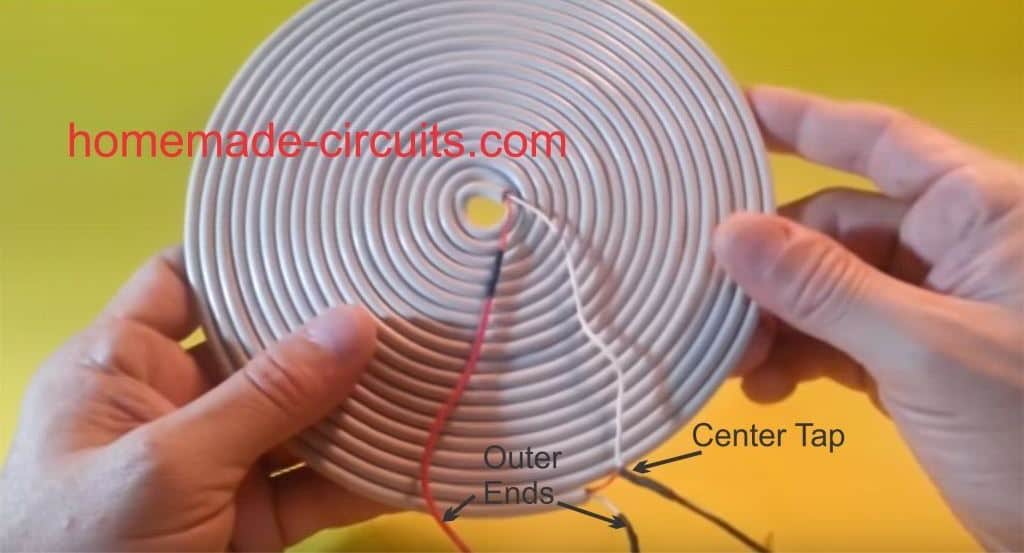

For the transmitter you can use any standard two-core flexible wire as shown in the following image:

" rel="ugc">

For the receiver the wire can be a 0.5mm super enameled copper wire.

Please let me know if you have any further questions.

Thanks for the immediate response! Ideally, how many turns should the Receiver coil be? And what should its ideal diameter be?

Actually the receiver coil can be exactly identical to the transmitter coil, however you can experiment with it to get the most optimal results. It might require some experimentation until the right number of turns and diameter is achieved.

It must be noted that the current output from the receiver coil can be significantly lower than the input current to the transmitter coil, and will be directly proportional to the distance between the Tx and Rx coils.

If the current from the receiver coil is not sufficient, the mobile phone might not charge properly.

Make sure the current to the transmitter coil is at least 3 amp, @12V

Hi, your circuit works like a charm! Right now the only problem that I have is that the out is fluctuating. What can I do to stabilize the Voltage and current output of the receiver coil?

That’s great, glad it is working.

To stabilize the output, please connect a 2200uF/25V capacitor right across the output terminals of the 7805 IC.

Would it be possible for you to send a 10 second video clip of the result to my above emails?… if not, no worries.

Sure! I’ll send the video through your email.

Ok, thanks so much…

Can you recommend an inexpensive place to have circuit boards made? Not for a production run, just one at a time. Thank you!

For the single PCBs the cost can be immensely high, no matter which supplier you choose.

Instead of a PCB I would suggest you to build the prototype over a strip-board.

It has been a while since I etched a circuit board, but I think I still can. It will be much cheaper than having one made. Thank You!

You are right, etching a PCB yourself can be much cheaper and interesting also.

Hello Swagatam, I recently bought a stabilizer Model: URZ3412 – 1000 VA

Input: Voltage range 145-260 VAC

I live in the UK and I need 230-235v. The problem is the stabilizer is set to 260V. It has internal settings but I don’t have its diagram. How can you help me. Thank you. N.C.

Hi Niki,

Unfortunately without a schematic it can be impossible to know which preset setting must be tweaked to adjust the high voltage trip level. Randomly testing the presets can be dangerous, so a schematic is necessary.

Hi Swagatam,

Looking for a circuit that opens a door (motor positive direction), then, upon reaching a limit switch, reverses (motor negative direction) to close again (limit switch ends the cycle). Just using a one-button, start process. Liken this to a garage door that closes immediately after opening WITHOUT the need to press CLOSE/OPEN again.

Hi David, i have an easy circuit design in mind, i will try to post it as a new article, and let you know soon…

I have designed the required circuit, you can find it in the following link:

https://www.homemade-circuits.com/automatic-door-controller-circuit-using-a-single-push-button/

Excellent work! Will begin construction. And extra thanks for the prompt response.

Sure, no problem! All the best to you.

Let me know how it goes.

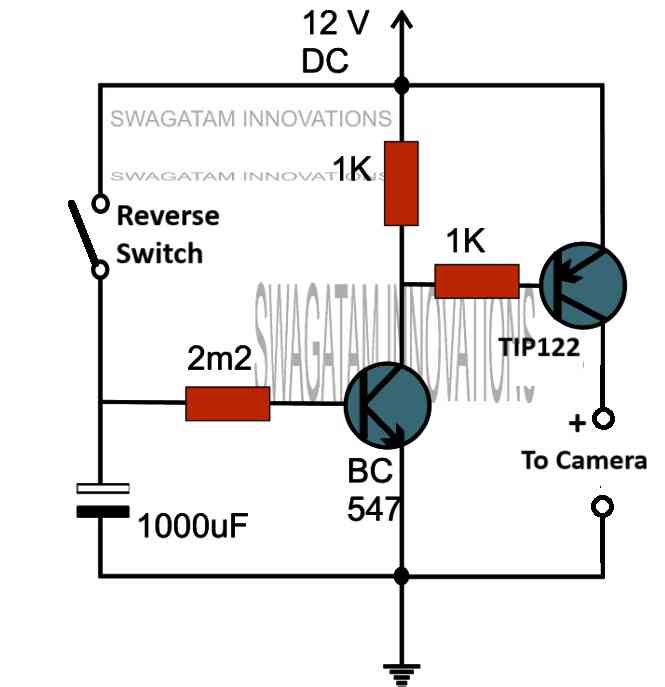

I have a wireless reversing camera (AutoVox TD2) fitted to my car which switches on the screen when I engage reverse gear (power from reverse light connection). It functions perfectly with one exception, when I disengage reverse gear the screen switches off, ie the camera has no more power to it. Is there a way to maintain the power (12v) running to the camera for 10-20 seconds, as I manoeuvre the car, as in parking?

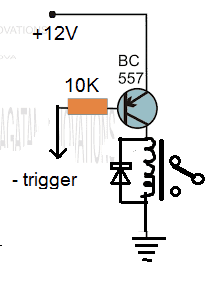

Please try the following circuit, it will fix the issue instantly:

" rel="ugc">

The delay OFF time can be tweaked by adjusting the values of the 2.2M resistor or the 1000uF capacitor, or both.

Thank you for your prompt reply!

You are welcome. Let me know if you need any further help…

Very kind of you, thanks again!

Can I connect this circuit by joining the wires in parallel, is there a need for any diodes to prevent current reversing if I do ?

For the +/- supply connections, you can add a 1N5402 diode in series with the positive (+) supply line to safeguard against an accidental reversal of the supply polarity.

For the output from the TIP127 there’s no need to add a diode, since the camera device would be having an internal diode with its own circuit.

Please note that the pnp transistor is mistakenly shown as TIP122, it should be actually a TIP127.

Hello Swagatam,

I am interested in your project Mobile Phone Controlled Robot Car Using DTMF Module. I need to buy it. Can you give me details to purchase it.

Thank You Chaitanya,

I understand your requirement. However, I do not build or sell readymade kits nowadays, so selling the unit may not be possible for me.

Hi ,

By reading all the comments, i am overwelmed to see a mosquito window powered by electricity. I am not a technical guy to build it but looking for such products to purchase.

My colony has high presence of mosquitos and every now and then someone is getting sick.

Hence a sincere request to buid the mosquito window. I am willing to bear all expenses related to the creation and installation of such window. However, if similar products are already available in the market, I would appreciate it if you could share any relevant links or information to purchase them.

Thank you for considering my request. I look forward to hearing from you soon.

Hi, I am glad you found the post helpful.

I can understand your problem and i wish somebody could help you in this regard.

Let’s hope someone on this forum listens to your request and builds this project for you.

By the way, if you search amazon you should be able to get such products ready-made also.

Hello Swagatam,

I’m interested in understanding how an MPPT really works.

I’ve studied the circuit https://www.homemade-circuits.com/mppt-circuit-using-lm317-ic/

but I cannot detect the part that is making up the PWM in this circuit.

As the LM317 is a linear circuit, that cannot, in my opinion, be part of PWM and will produce a lot of heat.

Can you please destroy my doubts about this part !

Thanks Wolfgang

Hello Wolfgang,

Actually in this concept the LM317 is configured as a switching regulator. Here’s what the datasheet of the LM317 says about this configuration:

Low cost adjustable switching regulators can be made using an LM317 as the control element. The figure shows the simplest configuration. A power PNP is used as the switch driving an L-C filter. Positive feedback for hysteresis is applied to the LM317 through R6. When the PNP switches, a small square wave is generated across R5. This is level shifted and applied to the adjustment terminal of the regulator by R4 and C2, causing it to switch ON or OFF. Negative feedback is taken from the output through R3, making the circuit oscillate. Capacitor C3 acts as a speed-up, increasing switching speed, while R2 limits the peak drive current to Q1. Efficiency for the regulators ranges from 65% to 85%, depending on output voltage. At low output voltages, fixed power losses are a greater percentage of the total output power so efficiency is lowest. Operating frequency is about30 kHz and ripple is about 150 mV, depending upon input voltage. Load regulation is about 50 mV and line regulation about 1% for a 10V input change.

I am curious if you are interested in build/code/test and selling some relatively simple prototype devices PC/arduino (or other such devices – we use PSoC LP5 a lot, but whatever you prefer) prototype devices, for example the timed temperature programmer you described (https://www.homemade-circuits.com/programmable-sequential-temperature/#comments), I will use them some chemical instrumentation research that I do – I used to do this myself but I havent kept up and my students have learned chemistry, its an uphill struggle with a soldering iron or coding. Let me know… (you can get my website by googling my name)

Hello Purnendu,

I appreciate your interest in this field, and I really wish I could help you, however building and testing a prototype practically may not be possible for me at this moment.

I googled your name on internet and found interesting details about you on Wikipedia and other sources.

Thank you so much for commenting in this blog. Please keep up the good work.

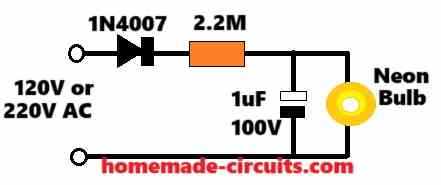

Hello, trying to replicate a neon bulb that flickers like a flame. I repair vintage clocks and the click in question has a neon bulb with a 220k resistor that us supposed to simulate a dancing flame. I trued using some new neon bulbs with a new 220k on one leg and I get a steady glow. What am I missing? Do I need a special bulb or? Thanx in advance Greg.

Hi, Please do the connections as shown in the following diagram, it should work:

" rel="ugc">

I am planning to use a 220 volt induction heater probably 15 kw or 25kw.

I plan to use the induction heater in an unusual way.

I want to use it to heat pipes filled with different chemicals. The pipes will be sealed and heated to approximately 400 f. This will significantly increase the reaction of these chemicals. These chemicals need to cool down before I can remove them from the pipe.

My idea is to heat one pipe at a time. When the proper temperature is reached, I will turn off the electricity to that coil. Then I will turn on the electricity to the next coil in the line.

In the meantime the pipes that have already been heated will have time to cool.

I am not sure how to wire this. I know you can purchase stove top induction cookers with four different burners. I assume all four burners can operate at the same time. Also, they can operate with just one or two burners.

Can this work by going through a series of relays?

I would very much appreciate any advice that you may be able to offer me.

Thank you very much for your help.

I think you can turn ON/OFF the induction heater units through separate SPST switches, a relay is not necessary. The setup can be something similar to the following design. You can add individual ON/OFF switches in series with the supply line of the respective induction heater units.

https://www.homemade-circuits.com/tap-water-induction-heater-circuit/

Topic: Extending the working high voltage limit of a ready-made SMPS.

Low-power conventional SMPS (2A/24V for example) are rated to work between 100 to 240V. Is there a posted circuit which could be added externally to extend their working high limit to 380V?

Please note that I don’t mean just protecting them from a high voltage (by disconnecting them for example).

Thank you.

Hello Kerim,

The working high limit of an SMPS is around 285V RMS that is equal to 285 x 1.41 = 401V

Thank you for your prompt reply.

You likely refer to SMPS units which are different from what our local retailers have (imported from China). At best, they may work up to 260Vrms before they burned.

It seems that your 401V is a peak voltage. I meant by 380V the 2-phase voltage (Vpeak = 537 V)

Ok, but that looks very high, I do not have any circuit at the moment with me , which can control a massive 537v for the smps, a linear regulator can be used but that might heat up a lot.

The input current of such SMPS is relatively small. So, a hi-voltage MOSFET (with a diode bridge) could be made to act like an active hi-voltage zener (about 200V when on). It will be connected in series with the SMPS. It is shorted (actually its lowest voltage drop is a bit above its Vgs threshold) when the mains voltage is below a certain limit (for example, when the instantaneous voltage <300 V, peak of 212 Vrms). And it turns on above it (sine tips). An opto-coupler will likely be needed to isolate it from the mains level sensor which drives its gate.

Yes, that’s right, since the current is relatively small a mosfet regulator might work in a source follower manner.

An isolation might not be required according to me.

https://www.homemade-circuits.com/0-300v-variable-voltage-current/

I wish that isolation is not required.

If I understood you well, the mains instantaneous voltage sensor (to drive the MOSFET gate) and the source pin of the MOSFET can have the same reference node. I personally can’t see how this could be done.

I am actually referring to the following circuit:

" rel="ugc">

Now your solution is crystal clear, Thank you.

I will try to simulate it.

Sure, no problem.

I simulated it. Then I built it to test it with 24V/1A SMPS.

I did it because I was worried about the new lowest voltage limit. Usually, it is 90Vac at full load. First, I tested with a load of 8 // 220R/5W (about 873 mA). The lowest voltage became 115Vac. But it decreases to 110Vac with 6 // 220R/5W (about 655 mA). Finally, by adding 2uF/400Vac at the regulated output, the lowest voltage decreases from 110V to 100Vac. This result seems suitable for my application.

Thank you again for your help.

OK, great, thanks for updating the information. Appreciate it.

It seems I can’t receive notification emails from you (in the inbox or spam folder).

I wonder if you may have an idea on how this could happen.

Thank you.

Sorry, I don’tknow how to solve this, because if I am able to get the test notification then you should be also able to get it. You can perhaps try commenting with a gmail or an Outlook account and check if that works.

It may be a silly question. Should the ‘bell’ button (at the left of ‘POST COMMENT’) be pressed or not to get back an email (I mean for other readers).

What confuses me is that its pop-up text is the same after pressing it.

Usually, the pop-up message tells what will happen if the button will be pressed. And after pressing it, its message reverses too.

The bell button by default is enabled to notify the entered email IDs. If you press it and if you see a cross mark on the icon, that means the notification is disabled.

I just read your reply on the other page (4046).

It seems it is out of our control to let your notification emails reach my inbox. So, I will try to visit your pages, once a while, on which you may reply.

Sure, no problem.

Sometime back, I had posted a question regarding countdown timer with display. You had kindly replied and I had added my response etc. I would like to find this thread again.Can you please help?

Thanks and best wishes!

Hello Dr. KV,

I think it is in the following post, please check it out.

https://www.homemade-circuits.com/best-ic-4060-circuits-and-projects/

Sir, I need some assistance in stimulating a circuit which is ground fault circuit interrupter (GFCI). RV4145 is one of the GFCI’s. I faced problems while simulating a part of leakage current detection. Basically I want to simulate a current transformer (CT). It will detect leakage current of 5mA. The turn ratio is 1:1000. CT primary is line and neutral of the power supply. During normal condition, the CT won’t operate as the line and neutral will cancel out the current. During fault, 5mA current will flow and is sensed by CT. Its secondary will step down the leakage current by factor of 1000. Then there is an IC (RV4145) which has 8 pins. 1. Feedback, 2. NC, 3. V Reference(13 v), 4 Ground, 5. SCR trigger (signal is sent to scr which will trip the relay), 6. +vs (26) here, 7. Op amp output, 8. NC

CT secondary is connected to pin 1 and 3.

What i did is I connected a sinosoidal current source of 5mA tp primary of CT. Then sets coupling factor to 0.001 in proteus which gives 5 uA in secondary. The secondary is then connected to op amp which gives voltage output (which forms op amp output at pin 7). Then two comparators are connected which is regulated by 4 zeners (6.2 V each), and it creates v reference at pin 3.

Please sir can you please provide assistance in solving this. Im new in this and i can’t figure out how to solve this.

Hi Zoya, thanks for asking this question, I understand you want to solve a circuit simulation problem, however since I do not use softwares to simulate my circuits, my knowledge of circuit simulation is not good, so I am sorry i won’t be able to help you in this regards. I hope someone else on this forum is able to solve this for you.

Thank you for the reply. Can you please tell me where i can find such forums. I new in this and i really need some guidance. I hope you understand this. I actually want to use in proteus, where line and neutral will be the primary of CT, and the secondary will give current differential. Please help me in this. My question is similar to this project of your.

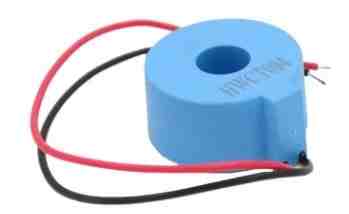

https://www.homemade-circuits.com/load-current-control-through-current-sensing-transformer/

I understand your problem, however my knowledge regarding proteus simulation is not good, so I cannot solve it for you. Did you try searching for “proteus related forums” online? Please give it a try.

Sir, I need a simple circuit to detect the flow of water and if there’s no water flow (with time delay) then there should be a buzzer alaram. As I already have a water level controller I wish to connect this to the power supply which is connected to the motor.

With regards

Gargi.?

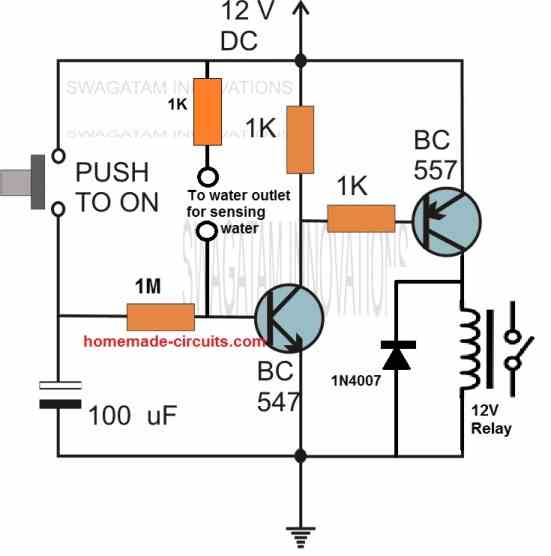

Hello Suresh, you can try the following concept:

" rel="ugc">

Hello Swagatam to both you and your”gang” or team. I’m a highly ki accomplished technician with thorough exp in almost all consumer electronics eqp right from valve,s. But my strength is in analogue and not digital.As I’ve executed many projects for many ppl, I have a core issue in ex a control unit for a small domestic luggage lift that has to be installed in a building of 5 floors. The only issue here is getting the lift to anyone who summons it. The lift should have floor buttons in order to send it to its desired”destination. Ideally the should be only a call button which will summon the lift. “The whole operation of proposed to be hauled by a winch, appropriate counter weights, door alarm, overweight activator, intercom B/w car and desired destination, and everything else which has been already worked out.I need serious assistance in this particular aspect and I will def tell you how it’s panning out. Thought assistance in this cnnx will be deeply appreciated. Thank You Very Much.

Thank you Prasanth, for this interesting question.

What you are asking is actually a full fledged lift operating circuit which might involve relatively complex digital circuit configurations.

Actually I had tried to design a lift circuit before but failed to do it.

If possible I will give it a try, if I succeed I will surely let you know..

Fantastic

It Is 24 V to 400V ( 0-1Amp )

You can try the first circuit from the following article:

https://www.homemade-circuits.com/12v-car-laptop-charger-circuit-using/

It is a CV circuit but not CC. For CC you will have to add additional stages.

You will have to use a 400V zener diode and adjust the inductor coil to get above 400V.

I am in need of designing of 12 V to 24 to 400v ( 1 map ) Boost converter variable CVCC type of supply pls help

Hello,swagatam I want to discuss about 12 volt solar pan type induction . Should I get your cell number ? Thank you.

Hello Shabbir,

You can feel free to discuss it here through comments, if possible I will try to solve it for you.

Hello Swagatam! Happy New Year!

Swagatam, I have long wanted to create a neurostimulation device and I am tormented by the fact that I do not have enough knowledge and experience to create a circuit diagram of my device.

I want to create a TRNS (transcranial random noise stimulator). It uses an alternating current of random frequency (from the range of 100-640 Hz) and random amplitude (from the desired range of -1.5 to 1.5 mA). How to force the current to take this form?

tRNS stimulation differs from tDCS in that instead of constant direct current delivery, current levels are randomly generated, with a Gaussian distribution around a specific mean intensity. Other parameters related to the stimulation electrodes, like position and size, are similar to tDCS.

Do you know what a schematic diagram of such a device might look like?

Thank you Nikita, and a Happy New Year to you too!

I think I may be able to design this circuit.

So it should be basically a randomly varying current source (AC) with a randomly varying frequency, right?

And the voltage range can be anywhere between 10V and 60V, I guess.

Let me know your thoughts on this?

I would really like to share my thoughts on this matter if only I had them. I have much less knowledge and understanding on this issue than you. Therefore, it would be better to entrust this to you.

Probably the most useful thing I can do here is to send links to sites that have information about trns.

?fit=753%2C499&ssl=1 (this shows what the current shape should be)

?fit=753%2C499&ssl=1 (this shows what the current shape should be)

https://en.wikipedia.org/wiki/Transcranial_random_noise_stimulation

https://brainbox-neuro.com/techniques/trns

" rel="nofollow ugc">

?fit=753%2C499&ssl=1" rel="nofollow ugc">

I am new to electronics and planned to create this device in the future when I mastered electronics well enough.

Ok, got it, thanks very much, I will look into those articles for the related specifications and try to figure out an appropriate design for the project.

I will publish the design as a new post, I will notify you once it is done?

Of course, thank you very much!

Hello Nikita,

I have published the post, you can find it in the following link:

https://www.homemade-circuits.com/transcranial-random-noise-stimulation-trns-circuit/

I need help with a circuit controller. It would help if I could upload a diagram to explain how I want the lights to function, but I will try to explain. This is for 12V DC, 9 LED lights (these are small LEDs, sort of like a side marker light, I do not know the amperage draw). I need an easy to program controller, something like all I have to do is make simple delay/time changes (I am not a programmer), and something I can seal from the weather, and not be bulky for mounting.

There a 9 LED lights, they are to be mounted horizontally (from left to right 1-9). The controller needs to control the lights as such:

All on at max brightness (this would be the start of the cycle), if at start all are at max brightness then they would all need to have their brightness reduced to say 50% ish, Light 1 would increase to max brightness then decreases to say 50% brightness as Light 2 increases to max brightness, then decreases as Light 3 increases and so forth.

After a cycle or two of progressive increase/decrease across all lights (at the end of Light 9), all lights will go to max brightness for a short cycle (like 5 seconds) and then enter the progressive increase/decrease phase. This is a continuous loop. Hopefully you get the idea

Basically, I want the LEDs to give a wave affect.

Your help is appreciated

Thanks for posting your circuit requirement! I will design it and post it in a new article. I will let you know once it is done.

I have tried to design the circuit, you can find it in the following link

https://www.homemade-circuits.com/led-light-wave-effect-generator-circuit/

Thank you very much for the circuit and quick turn-around. Once I get it built, I will let you know.

You are welcome. All the best to you!

Thanx for all these wonderful circuits. Recently my dryer motor burned due to overloading and even fuse cannot save it. The motor is 40W, 220v. B4 buying a new motor, I intend to do some research to have some circuit in series with motor itself so it can detect overload and disconnect it. Please let me of any effective circuit probably with some adjusting customization to fine tune it with motor specs. Thanks and regards

Thank you Sak, You can refer to the last circuit from the following article. You will require a relay control or an triac control to auto cut off the motor when over current is detected:

https://www.homemade-circuits.com/dc-motor-protector-circuit-over-voltage/

I want circuit for break of motor.

In put: 200 VAC, 2 Phase

Out put : 110VDC

Break voltage 110 VDC, 2A

Sorry, I did not understand what you mean by break voltage?

Hi! I m from Turkey.

I need a schematic to control two relays with timer. I saw some schematics at this page. But i couldnt use them. They have some differences. Would you please help me.

The timer has 2 adjust. Toff and Ton.

When I turn on circuit it waits as t-off time. Then relay 1 is on as t-on time. Later r1 is off and waits again t-off time. After that relay2 is on during t-on time….it runs till I switch off.

T off 0-3 minutes

T on 1-5 minutes

…..

Turn on

1 min wait

3 min run R1

1 min wait

3 min run R2

1min wait

………..cycle

Turn off

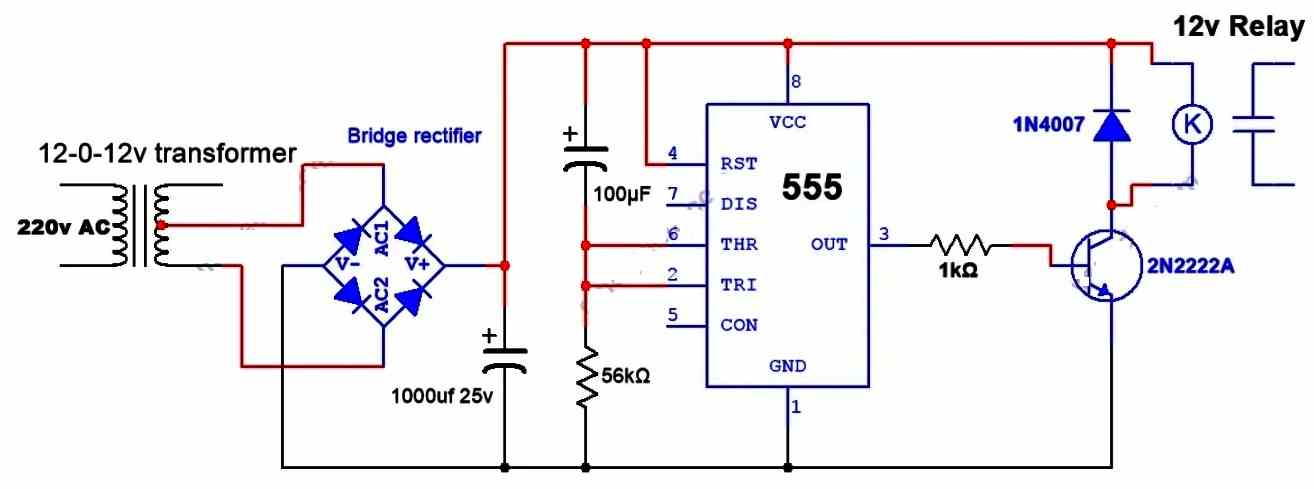

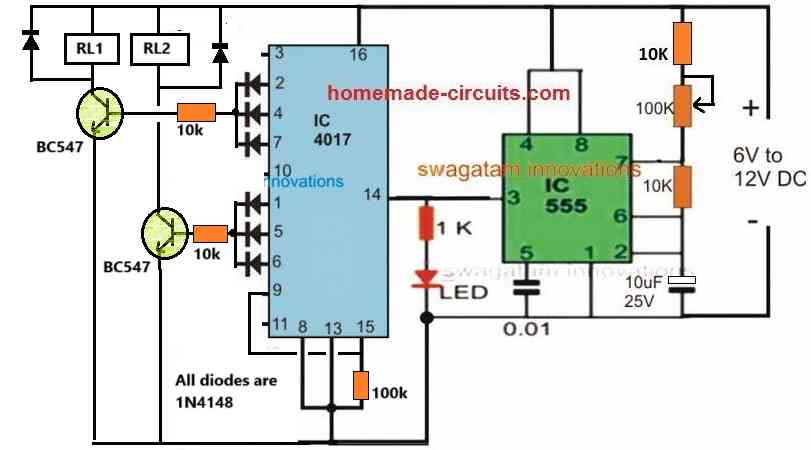

Hi, I have designed the circuit for you. You can find it in the following link. Make sure to adjust the 100K pot to get 1 minute ON/OFF duty cycle from the IC 555. I think you may have to use a 1M pot instead of 100K for getting 1 minute ON OFF duty cycle.

" rel="ugc">

Hi Swagatam I have a Texas Instruments processor that initializes a ULN2003A to switch a GND signal to an opto isolator which already has 12v present which switches a SMPS on . the problem is that according the circuit the processor should send a high/positive signal to the ULN2003A but it sends a GND signal when measured at an input of the ULN2003A relative to the 12v on the opto isolator, As the ULN21003A needs a positive input to initiate a GND output via open collector output.

How can I generate a high/positive signal for the ULN2003A input from the low/GND input of the processor..

BTW there is a brief 1.1V odd measured at the input of the ULN2003A at power on , then the input pulls low or to GND

Hi Andrew, I think the following design will do the job for you.:

" rel="ugc">

Please ignore the relay and the diode, you can simply use the collector of the transistor to acquire the positive signal in response to a negative or ground signal from the processor at the base (trigger input).

Hi, This is regarding Piano, Guitar Sound Effect Generator Circuit. I would like to understand what exactly the input given to start button. Does it accepts External Audio signal from a Musical instrument from its Piezo Pickup. So that i can get a sound of say Piano, Flute from the Audio signal given from my string instrument like Guitar or Mandolin ? Will it capture and deliver the exact pitch of a musical note as a piano or flute sound given from input Audio signal?

Hi, that circuit is a sound effect generator, it is designed to generate a special note resembling guitar or piano by its own, as per the settings, and in response to the pressing of the start button. It is not designed to accept external frequency inputs.

Thanks for Clarification. Do you have any solution for my requirement. I have seen such a device developed by Roland ( GR-55 Guitar Synthesizer). I know it may be very difficult to develop. I will be happy if i get only violin and flute tone. I intend to use a foot switch to trigger.

Yes, it can be indeed very difficult to design an identical circuit, however I have a guitar amplifier circuit which will accept external signals and amplify it accordingly….I would recommend the second design from this post:

https://www.homemade-circuits.com/100-watt-guitar-amplifier-circuit/

Hi, we have problem of stray dogs in our society and it is getting worse day by day. can I get some ultrasonic dog repellent circuits to reduce the problem? Do these ultrasonic sound dog repellent really work? what is its working range? If I can get some tried and tested solution it will be a great help.

Hi, you can try the second last design from the following article, it is a tested design:

https://www.homemade-circuits.com/dog-barking-preventer-circuit/

Hi,

I’m interested in controling the BP of a 10 gallon pot of beer. I have a hot plate 220v 25A that is manually controlled. I thought at first to use PWM through an opto isolator to a 30A triac. This may be ok but would I be better off trying to use phase angle control like a light dimmer? The on time allowed to be altered by the R adjust; effectively PW modulation. I don’t have clear idea on the best approach.

The triac considered is T3035H. I started off committed to PWM but prior to actually implementing same it occurred to me that I should be treating this as triac’s were intended.

Do you have any suggestions?

Thanks,

Keith

Hi, both the techniques are good and will allow you achieve the goal, however the light dimmer method can be much easier to build and implement. Please let me know if you further queries.

Hello,

I am working on designing a led strip which must operate in the following manner:

Blink—> Blink—>Blink—>Fade ON.

Is there any possible way to achieve this without using any microcontroller IC?

Please help me out !!

Thank you in advance.

Hello,

It may be possible in the following manner, ON-OFF-ON-OFF-ON-OFF-Fade ON.

Could you kindly help me make the circuit. As of now, I have two separate circuits:

1. Blink circuit, using 555 timer.

2. Fade ON part using transistors

But I have no clue how to cascade both the circuits to operate in Blink–>Blink–>Blink—> Fade On.

If there is any other way, I would humbly request you to kindly guide me.

The Blinking effect proposed by you can be interpreted as ON-OFF, ON-OFF, ON-OFF, then Fade ON. This may be difficult to achieve using your two circuits, however it may be possible using an IC 4017 and IC 555 together.

If the above effect looks OK to you then I can provide you with the circuit idea.

Thank you so much for your insights. If you don’t mind, could you kindly help me make the circuit? I would be very grateful.

No problem, I will try to create the circuit, can you please tell me what do you want to illuminate, I hope it is LEDs. If it is LEDs please provide the specifications of the LEDs, quantity, voltage, current etc.

Thank you so much for your support. Yes, I want to illuminate LEDs.

total number of LEDs: 29

Voltage: 2V

Current: 25mA

Kindly let me know if you need any further information.

No problem, you can try the following concept. Make sure to use proper resistors with the LEDs:

" rel="ugc">

Thank you so much. I am very grateful. I will definitely try this circuit out.

You are most welcome, let me know if you have any further questions.

hello brother, I am an electronic repairer not a programmer, please I need some information from your experience. in this diagram of Arduino 3 phase inverter circuit, my question is that I can change the MOSFETs with a smart power module (FSBS15CH60) because I have many treadmill motor controller boards which have an error on the microcontroller?

tanks

Hello Nassih, I checked the datasheet of the FSBS15CH60 and from its internal schematic it seems the module can be used as the inverter output stage in place of individual mosfets. However, the pinouts of the module will need to be replaced correctly otherwise there can be serious problems.

Hi Swagatam,

I would like to control an 8-channel 12V Relay Module with a normal pulse switch to use on my vehicle. When I checked the parameters the IN1 to IN8 does not have any input specficiation. On some websites, 0 to 1.2 volts but polarity is not mentioned. My source voltage is from 12 to 14.2v max @ vehicle running condition. Product link below mentioned

" rel="ugc">

" rel="ugc">

Hi Anuraj,

The relay you are referring to is a 12V DC relay, since this value is printed on the relays.

Design#3: DC Motor Controller with Multiple Features

https://www.homemade-circuits.com/dc-motor-speed-controller-circuits/

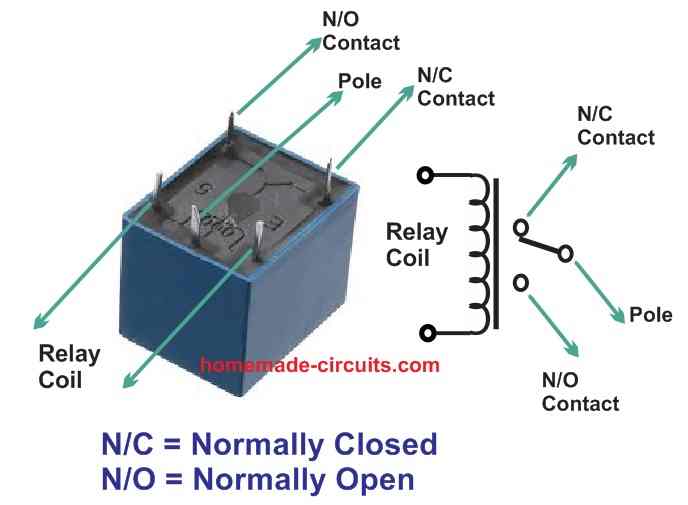

hi sir i have small clarification required on this relay you given in this (12V/5A) dual channel its looks like two pole contact, please explain me little more about this section.

Hi Pradeep,

It is a DPDT relay. The upper contacts shown in circles are N/O and N/C pairs of contacts. The switch action is shown by the pair of moving contacts of the relay connected to the lower circle which forms the common pole of the relay. When the relay is powered the movable pair of contacts connect with the pair of N/O contacts, and when the relay coil is not powered the movable pair of contacts connect with the N/C pair of contacts.

In the circuit this relay is used to execute the reverse/forward rotations of the motor.

I read your excellent article about heating element control with triac.

I would like to make a control of a 230V ceramic heating element (5-10watt) with a BT136S 600D triac and an ATtiny as a pulse generator. How do I calculate the pulses so that I can change from 65C to 80C in four steps?

I’m thinking of controlling it a with a push button and some LEDs for indicating temperature. Can you help?

Thank you Flemming,

Can you please show me the link of the article so that I can check it out for the details?

Sorry late reply, I’ve been down with corona, but are fine now. I just searched, heat and triac, and read what was there…. So I thought I maybe could reach out to you for help. I only know a little about electronic circuits.

What is the input voltage like, is it AC 220V or 120V? If yes, then I would recommend you an ordinary triac based light dimmer circuit as explained here:

https://www.homemade-circuits.com/how-to-make-simplest-triac-flasher/

I’m wondering about a delay on, then delay off circuit, with no button, 5v DC. I have a usb port, I would like to power on a linear actuator ~5 seconds after the USB port supplies power to my circuit, then turn it back off after ~0.5 seconds and remain off until the USB port is powered down, then repeat the cycle when the USB port is powered on again.

You will require a two stage programmable timer circuit for this application, as explained in the following article:

https://www.homemade-circuits.com/how-to-make-simple-programmable-timer/

Good afternoon!

I’m a complete amateur, who took a micro-electronics class in high school. I now have a deaf son that has recently started school. He has a tendency to make a lot of noise because he can’t hear himself and he can be a disruption to the rest of his class. I would like to make a noise visualizer, that would allow him to self correct because he can see when he is making noise. I came across this post (https://www.homemade-circuits.com/simple-audio-spectrum-analyzer-circuit/) and it seems like this might be what I need for this application, but want to confirm that there is a chance this will work for what I need before I invest too much time or resources into building this project. Does it sound like this is the correct circuit for an application like this? Thank you!

Hello Tom,

I would rather recommend you the following circuit which is a tested design and looks more relevant to your requirement. Hope it does the job for you.

https://www.homemade-circuits.com/wireless-music-level-indicator/

Hi Sir,

I am given a project to design a Printed Circuit Board (PCB) for a power factor correction circuit for a single-phase load using all required power and electronic components. Can you please give me a circuit for this design and ideas to proceed further.

Thank You

Hi Tashi,

Sorry I do not have a PFC circuit with me right now, however I think you can find some important information in the following article:

https://www.onsemi.com/pub/Collateral/HBD853-D.pdf

Hi looking for large motor activated by an phone

Hi, you can refer to the following post:

https://www.homemade-circuits.com/gsm-pump-motor-controller-circuit-using/

Hi there mr. Swagatam, I want to convert a 2-0 volt signal to a 4-20mA current signal, the sensor needs 5VDC power and the output signal should be 24VDC. I’d need to flip the signal and convert it. what would be the best way of doing this?

I was thinking of using 2 non inverting opamps, one as a buffer and the other to increase the span of the signal, maybe 0-10V. My issue is just to convert the voltage signal to a reliable 4-20mA signal.

What do you think is the best voltage to current conversion circuit?

Hello Gerhard, are you trying to convert a 2 V into 24 V (4 – 20 mA) signal? What is the current capacity for the 2 V signal?

Hi again,

About 998EX sensor and delay circuit, I forgot to mention that I need this delay circuit to be simple and if possible with npn transistors or N mosfet.

I am very grateful for the content of your website, and I have refreshed my knowledge with the explanations that you offer of each published circuit. My best regards for the great work you do in favor of the world of electronics.

Thank you so much.

Hello Sir, i need help with a delay circuit,

I want to use an ADEMCO 998EX infrared movement sensor so that when it detects movement it activates a relay for a period of 3 to 5 min. This sensor works as follows: it has two output terminals to notify the detection. This output is normally open when the sensor is not connected to power, and when the sensor is powered with 12v, it takes 1 minute to balance the temperature it senses in the place (during that minute the output remains open) and then, it changes to activated waiting for an infrared movement (in this state the output changes to closed and showing 1kohms between its two output terminals). When the sensor detects any infrared movement, the output changes to open for 2 seconds, and returns to closed waiting for another movement detection. Internally, the sensor has a SPARTAN SIP REED NormallyOpen relay (COTO 9007 series 4 terminals) with a resistance of 15 ohms in series on one of its output pins. It also has two common diodes, each one with the cathode attached to each output terminal respectively, and their anodes attached to the negative of the circuit. I think they are for protection.

I need a circuit that detects the open condition of the sensor output, and in response, activates a relay for 3 to 5 min with a buzzer. The buzzer should be kept active during that time even after the sensor output changes to closed again. After the 3-5 minutes are over, if the circuit detects the open output condition of the sensor again, it repeats the activation of the buzzer during the 3-5 min again.

Hello Victor,

I think you will need an IC 555 based monostable timer circuit for the mentioned application. A transistorized circuit might not give proper results.

Greetings Sir Swagatam,

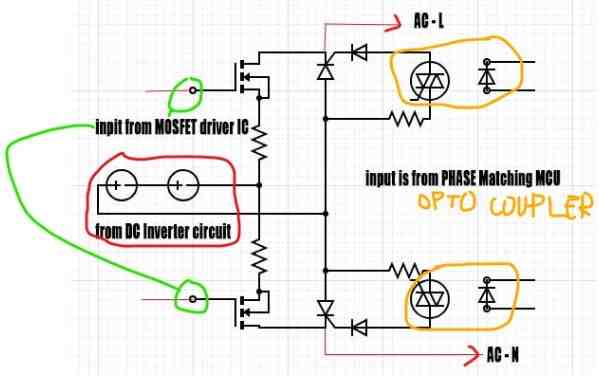

I am glad that I have found your website. I am searching for information regarding GridTied inverters and would like to ask for your expertise in explaining the circuit diagram (I have traced it from a defective unit). Is there a way that I could send you the diagram via email? Would really appreciate your feedback.

Hello Dexter,

I understand that you want to learn the details about a grid-tie inverter schematic, however honestly, I don’t think I would be able to help you because grid-tie inverters are very complex projects and I do not have specialized expertise in this field. Still, if you want me to give it a try you can upload the schematic to any free image hosting site and provide me the link here I will check it out and see what I can do?

Hello Sir, Only this particular circuit that am trying to understand its function. This is actually the GTIE (DC-AC) inverter output that merges with the grid. Alright, I will take your suggestion and thank you for replying.

Sorry Dexter, I am having difficulty in understanding the schematic, because it doesn’t seem to be in proper order. Where are the opto-coupler LED connections going? I guess the opto-coupler LEDs should be connected with the mosfets and the SCRs must be integrated with the grid line?

I am not sure, I may be wrong.

Sorry if my schematic is sort of confusing but the optocoupler LED goes to another section of a MCU (with code embedded) that controls inverter phase matching. The mosfet along with the scr that outputs the generated ac voltage back to the grid is where I get lost. Is the mosfet along with the scr a valid circuit do you think?

It seems the mosfets are switching the DC supply across the SCRs, but i can’t figure out from the schematic how this is being implemented, even I am lost. Moreover once the SCRs are triggered ON, they are going to get latched and the gate synchronization from the opto-couplers might have no effect on the SCRs.

You are absolutely right that grid-tie inverters are very complex projects. Just to give you an idea about the circuit am trying to learn and demystify: https://ibb.co/VThbV8z

Am so grateful for the time you spent helping out. Will keep you posted.

You are most welcome, I hope you will be able to solve the issue soon.

schematic for your expert review and thanks =)

" rel="ugc">

Hello Sir,

I hope all is well with you,

I am interested in your website and I want to publish my article on your website.

Can you add my article?

Please let me know your terms and conditions.

Waiting for your reply.

Many thanks.

Hello Fannii,

The terms and conditions are simple.

The post should not have any external links.

The article should be regarding a circuit idea with a circuit schematic.

Hi, I find your website very informative and enhance learning. Are you open to business cooperation? Feel free to contact me via email. Thanks!

Hi, glad you liked the website, however presently we are not open to guest post submission or any other business format.

Hi sir,

Sir I’m having these small MacPower inverter with 42000mah (155wh) rated, I need to know if I can use 12v 50w solar panel for charging it, the dc input of the inverter is 15v 2A, and one more thing, I’m about to replace the lithium battery inside, hope these is okay?

Hi Tunji,

for a 42 Ah Li-ion battery the optimal charging current should be around 20 amps, but your solar panel can supply a maximum of 50 / 12 = 4 amps which is too low to charge the battery.

Moreover a 12V panel output will not be able to charge a 15 V battery.

OK sir but my charger is rated to be 15v/2A, what can I do sir, and thank you so much for response

Tunji, 2 amp current is very less for a 42 Ah Li-ion battery….it might take 2 days for the battery to get charged.