A circuit which enables a user to linearly control the speed of a connected motor by rotating an attached potentiometer is called a motor speed controller circuit.

5 easy to build speed controller circuits for DC motors are presented here, first one using MOSFET IRF540, second one using IC 555, the third concept with IC 4093, fourth design involves the IC 741, while the fifth design utilizes IC 556, featuring torque processing

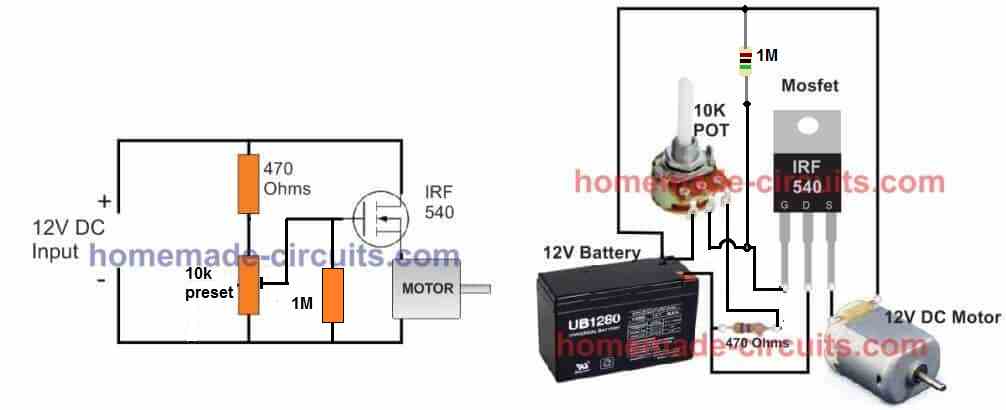

Design#1: Mosfet based DC Motor Speed Controller

A very cool and easy DC motor speed controller circuit could be build using a just a single mosfet, a resistor, and a pot, as shown below:

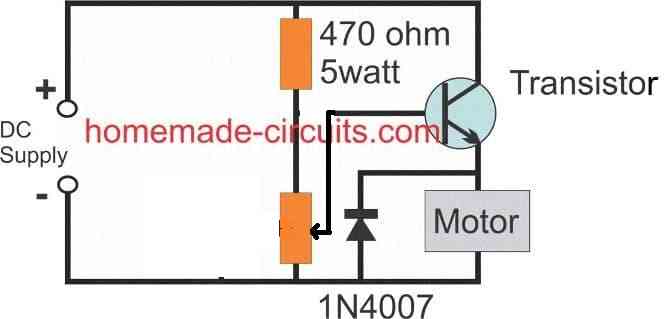

Using a BJT Emitter Follower

As can be seen the mosfet is rigged as a source follower or a common drain mode, to learn more about this configuration you may refer to this post, which discusses a BJT version, nevertheless the working principle remains the same.

In the above DC motor controller design, the pot adjustment creates a varying potential difference across the gate of the mosfet, and the source pin of the mosfet simply follows the value of this potential difference and adjusts the voltage across the motor accordingly.

It implies that the source will be always 4 or 5V lagging behind the gate voltage and vary up/down with this difference, presenting a varying voltage between 2V and 7V across the motor.

When the gate voltage is around 7V, the source pin will supply the minimum 2V to the motor causing a very slow spin on the motor, and 7V will be available across the source pin when the pot adjustment generates the full 12V across the gate of the mosfet.

Here we can clearly see that the mosfet source pin seems to be "following" the gate and hence the name source follower.

This happens because the difference between the gate and the source pin of the mosfet must be always around 5V, in order to enable the mosfet to conduct optimally.

Anyway, the above configuration helps to enforce a smooth speed control on the motor, and the design could be built quite cheaply.

A BJT could be also used in place of the mosfet, and in fact a BJT would produce a higher control range of about 1V to 12V across the motor.

Video Demo

When it comes to controlling motor speed uniformly and efficiently, a PWM based controller becomes the ideal option, here I have explained more, regarding a simple circuit to implement this operation.

Also Read: High Voltage DC Motor Controller Circuit

Using MOSFET as a High Power Potentiometer

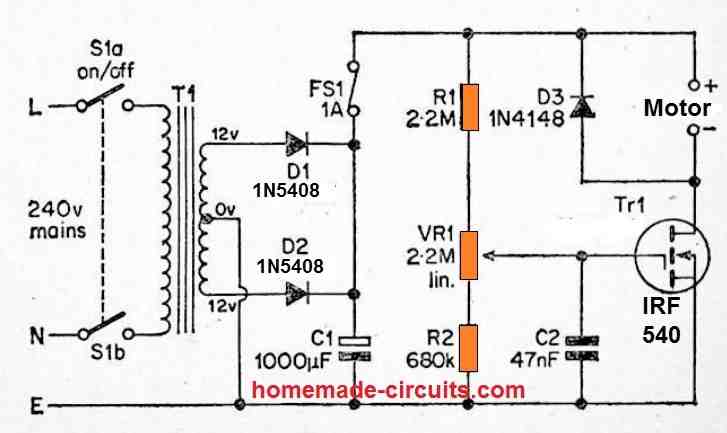

The next figure below shows a very simple DC motor speed controller circuit that employs a MOSFET as a high-power potentiometer (rheostat). The circuit is designed to work with 12 volt DC motors having a peak current usage of below 5 amp.

The mains AC supply is provided through the on/off switch S1 to the primary winding of the isolation and step-down transformer T1.

The push-pull rectifier circuit of D1 and D2 full-wave rectifies T1's output, and the resulting unfiltered DC output is smoothed to a certain extent by C1 to produce a relatively constant DC potential.

There can be a significant level of ripple on this DC output, however it is unimportant in this application. Tr1 provides power to the load and is biased through a resistive divider circuit consisting of R1, VR1, and R2.

The gate bias voltage provided to Tr1 might not be adequate to allow the MOSFET to conduct meaningfully with the wiper of VR1 at the R2 end of its rotation, and the motor will not operate.

Advancing the wiper of VR1 towards the opposite end of its rotation allows a constantly increasing bias to be supplied to Tr1, resulting in a steadily decreasing drain to source resistance.

Because of this, the power delivered to the motor rises in tandem with the motor's speed, until Tr1 reaches saturation (where the motor runs at its full speed).

VR1 may therefore be used to change the motor's speed from minimum to maximum speed.

C2 filters away any amount of mains hum or other electrical noise that could otherwise be picked up by Tr1's high impedance gate circuit, preventing the motor speed from being reduced to zero.

D3 is a safety diode that inhibits any excessive reverse voltage spikes that may occur as a result of the motor's excessively inductive load.

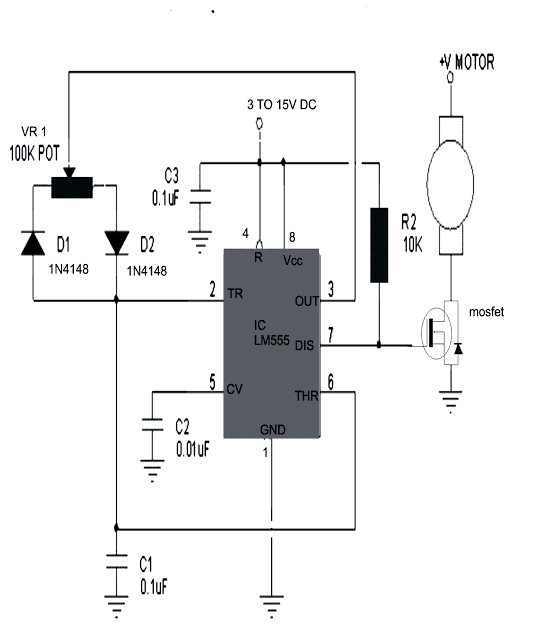

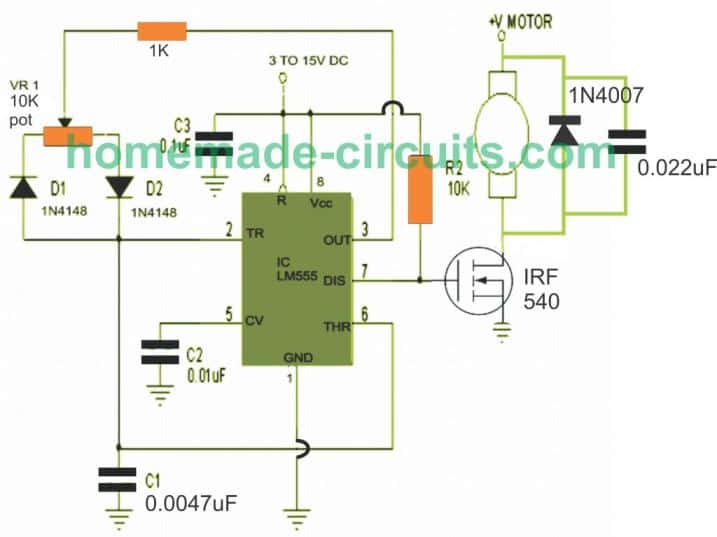

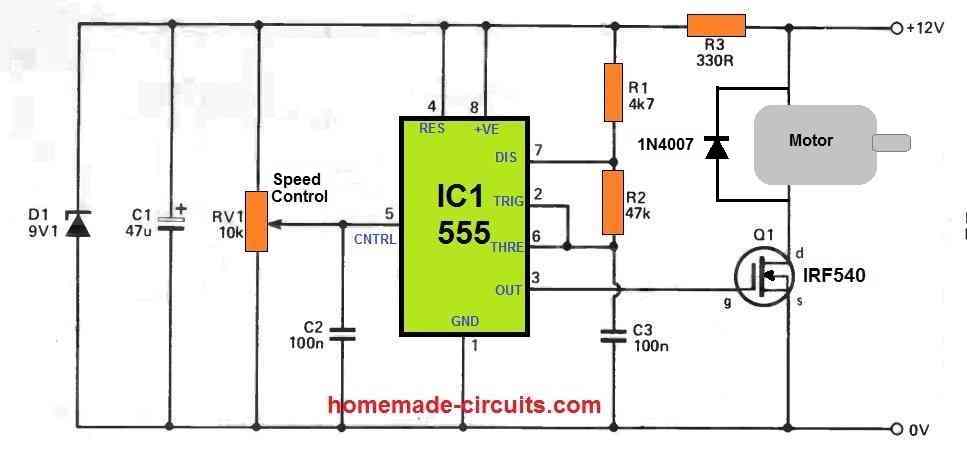

Design#2: PWM DC Motor Control with IC 555

The design of a simple motor speed controller using PWM may be understood as follows:

Initially when the circuit is powered, the trigger pin is in a logic low position since the capacitor C1 is not charged.

The above conditions initiates the oscillation cycle, making the output change to a logic high.

A high output now forces the capacitor to charge via D2.

On reaching a voltage level that's 2/3 of the supply, pin #6 which is the threshold of the IC triggers.

The moment pin #6 triggers, pin #3 and pin #7 reverts to logic low.

With pin #3 at low, C1 yet again begins discharging via D1, and when the voltage across C1 falls below the level that's 1/3 of the supply voltage, pin #3 and pin #7 again become high, causing the cycle to follow and go on repeating.

It is interesting to note that, C1 has two discretely set paths for the process of charging and discharging via the diodes D1, D2 and through the resistance arms set by the pot respectively.

It means the sum of the resistances encountered by C1 while charging and discharging remains the same no matter how the pot is set, therefore the wavelength of the out put pulse always remains the same.

However, since the charging or the discharging time periods depends upon the resistance value encountered in their paths, the pot discretely sets the these time periods as per the its adjustments.

Since the charge and discharge time periods is directly connected with the output duty cycle, it varies according to the adjustment of the pot, giving form to the intended varying PWM pulses at the output.

The average result of the mark/space ratio gives rise to the PWM output which in turn controls the DC speed of the motor.

The PWM pulses are fed to the gate of a mosfet which reacts and controls the connected motor current in response to the setting of the pot.

The current level through the motor decides it speed and thus implements the controlling effect via the pot.

The frequency of the output from the IC may be calculated with the formula:

F = 1.44(VR1*C1)

The mosfet can be selected as per the requirement or the load current.

The circuit diagram of the proposed DC motor speed controller can be seen below:

Prototype Image:

Video Testing Proof:

In the above video clip we can see how the IC 555 based design is used for controlling speed of a DC motor. As you may witness, although the bulb works perfectly in response to the PWMs and varies its intensity from minimum glow to maximum low, the motor does not.

The motor initially does not respond to the narrow PWMs, rather starts with a jerk after the PWMs are adjusted to significantly higher pulse widths.

This does not mean the circuit has problems, it is because the DC motor armature is held between a pair of magnets tightly.

To initiate a start the armature has to jump its rotation across the two poles of the magnet which cannot happen with a slow and gentle movement. It has to initiate with a thrust.

That's exactly why the motor initially requires a higher adjustments for the PWM and once the rotation is initiated the armature gains some kinetic energy and now achieving slower speed becomes feasible through narrower PWMs.

However still, getting the rotation to a barely moving slow status can be impossible because of the same reason as explained above.

I tried my best to improve the response and achieve a slowest possible PWM control by making a few modifications in the first diagram as shown below:

Having said this, the motor could show a better control at the slower levels if the motor is attached or strapped with a load through gears or pulley system.

This may happen because the load will act as a damper and help to provide a controlled movement during the slower speed adjustments.

Another Simple PWM DC Motor Controller Circuit

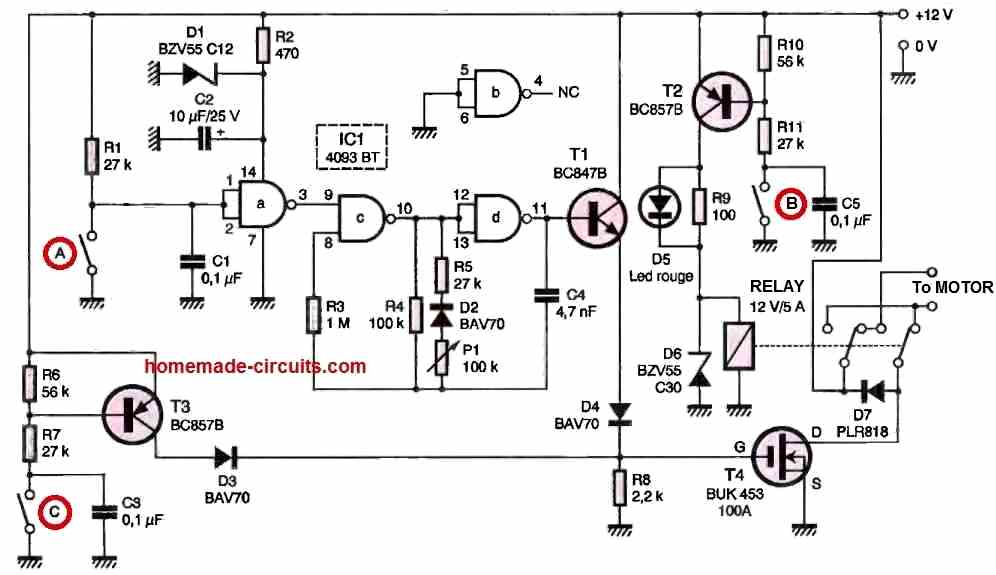

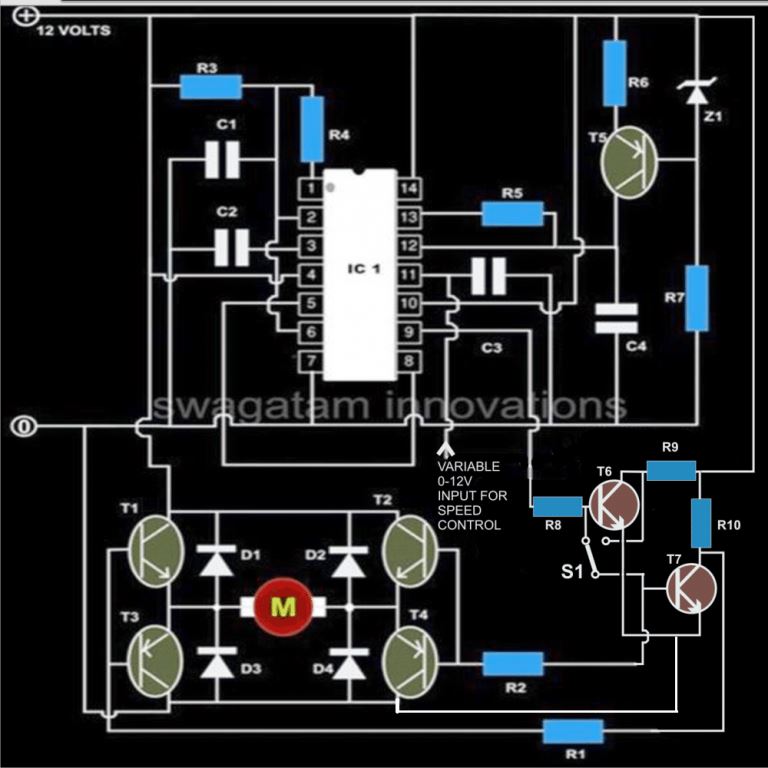

Design#3: DC Motor Controller with Multiple Features

The following DC motor controller circuit provides multiple control features such as:

- PWM Speed Control.

- Direct Speed Without PWM Speed Control (with slow Initialization).

- Forward/Reverse.

- Sudden Brake.

When Switch A is pressed, the PWM function kicks in and the motor speed can be regulated by moving the potentiometer P1.

Pressing Switch B ON or OFF causes the motor to change direction between anticlockwise and clockwise motions. Meaning this switch B can be used to enable reverse/forward motion on the motor.

Regardless of the Switch A position, if Switch C is pressed, causes the motor to attain a direct full speed. In this position the PWM function does not work.

If Switch A and Switch C are both open, then the motor will remain switched OFF.

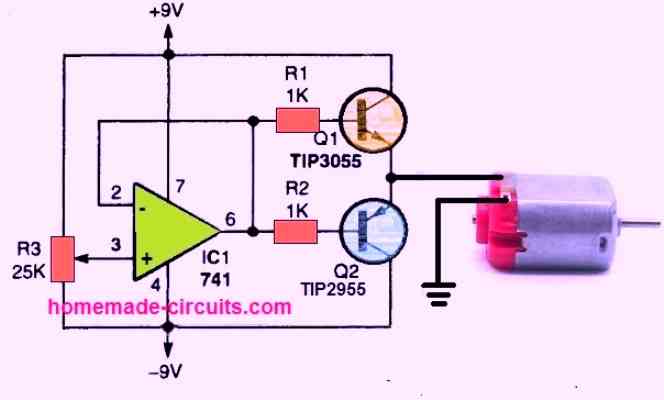

Design#4: Using a Single Op amp

The op amp circuit described below can be used for regulating the speed and direction of a motor. It functions as a voltage follower, with its positive input (pin #3) linked to potentiometer R3, which functions as a dual-purpose controller for motor speed and direction.

At the mid-point of the potentiometer's range, the op amp output is close to zero, causing neither Q1 nor Q2 to conduct current.

Moving the potentiometer wiper towards the positive side will make the op amp output become positive, allowing Q1 to conduct current to the motor and increase its speed.

Adjusting the potentiometer towards the negative supply will cause the op amp output to swing to a negative voltage, resulting in Q2 turning on while Q1 is turned off. This action reverses the motor's rotation direction.

Depending on the rotation direction, the motor's speed increases as the potentiometer wiper is pulled towards either end of its range.

To determine the maximum acceptable DC voltage range for the selected motor, it may be necessary to monitor the voltage variation on the emitters of Q1 and Q2.

Design#5: Using IC 556 for Enhanced Speed Control

Varying a DC motor velocity may appear to be not so difficult and you may find plenty of circuits for it.

However these circuits do not guarantee consistent torque levels at lower motor speeds, making the functioning quite inefficient.

Moreover at very low speeds due to insufficient torque, the motor tends to stall.

Another serious drawback is that, there’s no motor reversal feature included with these circuits.

The proposed circuit is completely free from the above shortcomings and is able to generate and sustain high torque levels even at lowest possible speeds.

Circuit Operation

Before I have explained the proposed PWM motor controller circuit, we would also want to learn the simpler alternative which is not so efficient.

Nonetheless, it may be considered reasonably good as long as the load over the motor is not high, and as long as the speed is not reduced to minimum levels.

The figure shows how a single 556 IC can be employed for controlling speed of a connected motor, we won’t go into the details, the only notable drawback of this configuration is that the torque is directly proportional to the speed of the motor.

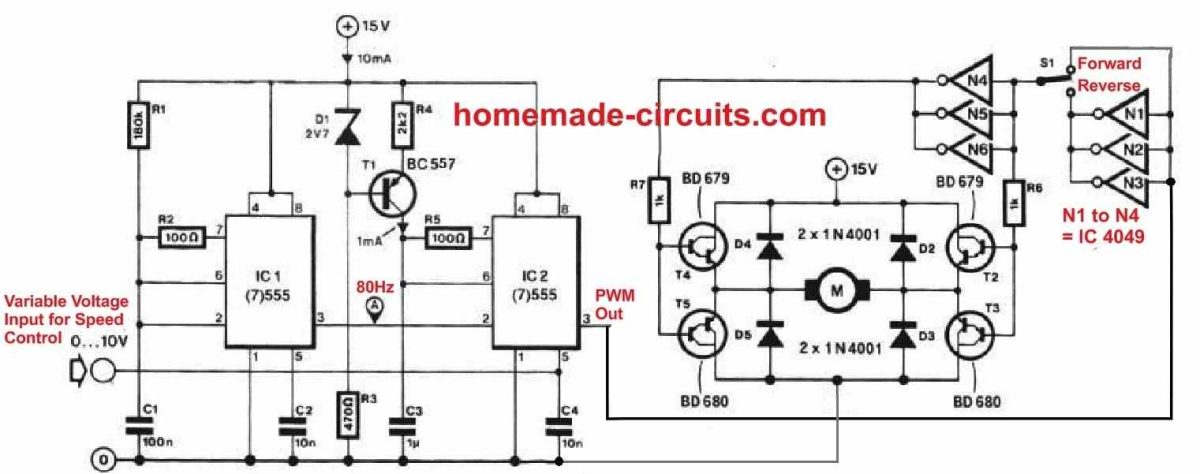

Coming back to the proposed high torque speed controller circuit design, here we have used two 555 ICs instead of one or rather a single IC 556 that contains two 555 ICs in one package.

Circuit Diagram

Main Features

Briefly the proposed DC motor controller includes the following interesting features:

Speed can be varied continuously right from zero to maximum, without stalling.

The torque is never affected by the speed levels and remains constant even at minimum speed levels.

The motor rotation can be flipped or reversed within a fraction of second.

The speed is variable in both the directions of the motor rotation.

The two 555 ICs are assigned with two separate functions. One sections is configures as an astable multivibrator generating 100 Hz square wave clocks which is fed to the preceding 555 section inside the package.

The above frequency is responsible for determining the frequency of the PWM.

The transistor BC 557 is used as a constant current source which keeps the adjoining capacitor at its collector arm charged.

This develops a saw-tooth voltage across the above capacitor, which is compared inside the 556 IC with the sample voltage applied externally over over the shown pin-out.

The sample voltage applies externally can be derived from a simple 0-12V variable voltage power supply circuit.

This varying voltage applied to the 556 IC is used to vary the PWM of the pulses at the output and which eventually is used for the speed regulation of the connected motor.

The switch S1 is used to instantly reverse the motor direction whenever required.

Parts List

- R1, R2, R6 = 1K,

- R3 = 150K,

- R4, R5 = 150 Ohms,

- R7, R8, R9, R10 = 470 Ohms,

- C1 = 0.1uF,

- C2, C3 = 0.01uF,

- C4 = 1uF/25VT1,

- T2 = TIP122,

- T3, T4 = TIP127

- T5 = BC557,

- T6, T7 = BC547,

- D1---D4 = 1N5408,

- Z1 = 4V7 400mW

- IC1 = 556,

- S1 = SPDT toggle switch

The above circuit was inspired from the following motor driver circuit which was published long back in elecktor electronic India magazine.

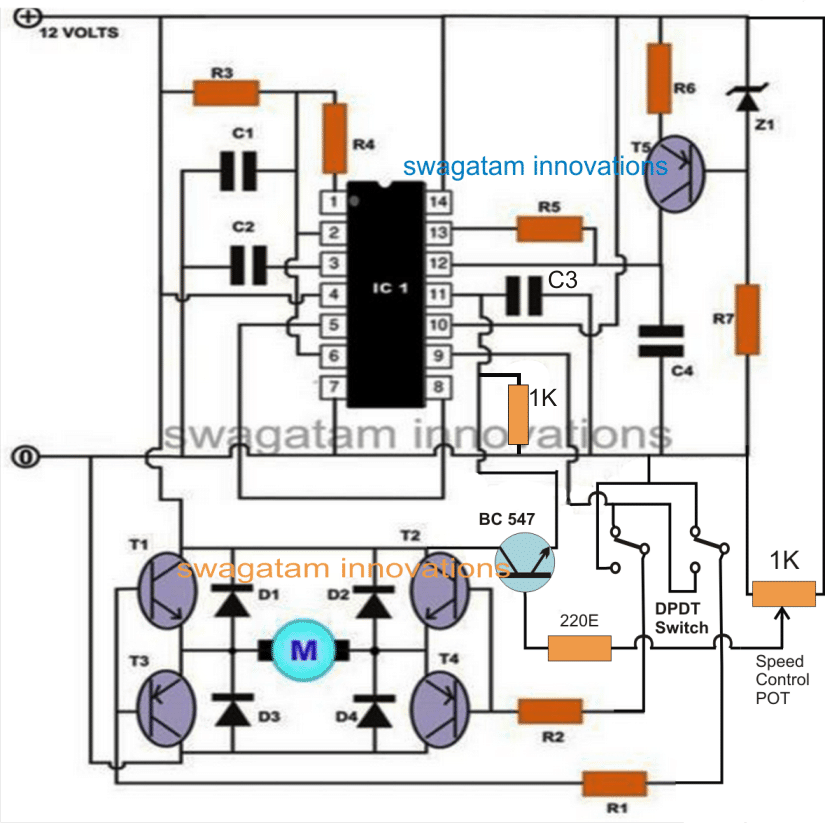

Controlling Motor Torque using IC 555

The first motor control diagram can be much simplified by using a DPDT switch for the motor reversal operation, and by using an emitter follower transistor for the speed control implementation, as shown below:

Improved Torque at Low Speed using CMOS PWM Control

Although the single MOSFET linear motor speed controller layouts explained at the beginning of the article includes the benefit of simplicity, but these may have a handful of down sides.

One of them is that there exists a significant level of dissipation in the MOSFET, specifically when the motor is tweaked for approximately 50 percent of the optimum speed.

This may be certainly not a serious issue however, and just requires the installing of a moderately large heatsink on the MOSFET.

A much more critical concern is that the motor is likely to stall as soon as this kind of linear controller is adjusted for any lower speeds.

This is because the MOSFET in this situation has a relatively high resistance, which offers the supply input with a significantly high output impedance.

When the load on the motor is increased, it attempts to draw excessive amounts of supply current, but this leads to a larger voltage drop across the transistor and a lower supply voltage across the motor.

As a result, the power delivered to the motor does not vary significantly, rather it decreases. Due to this, the motor has a propensity to stall.

Also, there is an opposite reaction in which lowering the load on the motor cuts its current drain, resulting in a greater supply voltage and a significant rise in motor speed.

Using a controller that provides a pulsed PWM signal to the motor, you may achieve much better motor speed management.

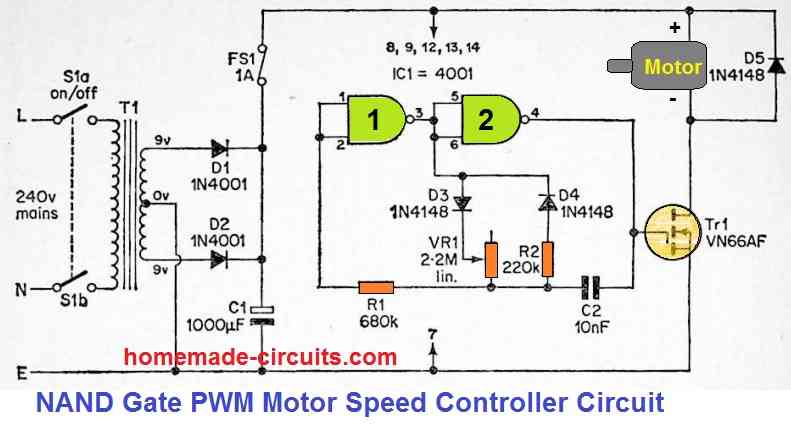

Improved Torque using CMOS PWM Speed Control

One method of implementing this, and the one employed here, is to have a circuit that provides a fixed output pulse duration while altering the frequency of the pulses to modify the motor speed. A low frequency produces long gaps between pulses and feeds a relatively low power to the motor.

When the frequency is increased, there are no noticeable gaps between the pulses, and the motor receives a nearly constant signal.

This results in a high average power in the motor, which runs at full speed.

The benefit of this system is that when the motor is being pulsed, it is essentially getting the full power during the ON periods of the pulses, and is free to consume a large supply current if the load on the motor actually demands it.

As a result, the motor is powered by a sequence of strong pulses that defy stalling and provide improved torque even at reduced speeds.

The following figure depicts the circuit diagram of a pulsed DC motor speed control. Here, T1, D1, D2, and C1 derive a sufficient DC supply from the mains AC supply.

Tr1 is hooked up in series with the motor, but its gate terminal receives the output signal from an astable multivibrator circuit.

This pwm circuit is built using two of the four gates of a CMOS 4001 device, which are utilized in a CMOS astable setup that is quite a conventional design.

A couple of timing resistors can be seen connected between the output of gate 1 and the junction of R1 and C2, which differs from the conventional PWM design.

VR1 and R2 are the two resistors, along with guiding diodes D3 and D4 connected in series with the output of NAND gate 1.

The two diodes ensure that R2 works like the timing resistance whenever the astable's output is high, and VR1 functions as the timing resistance whenever the output is low.

The period of the output pulses is constant since R2 has a predetermined value. The interval between them could be changed by varying VR1.

This will be nearly zero when it is adjusted for lowest resistance. The output mark space ratio is greater than ten to one at maximum resistance.

VR1, therefore, could be adjusted to generate the desired motor speed with effective torque, with the lowest speed happening at full resistance and the highest speed occurring at zero resistance.

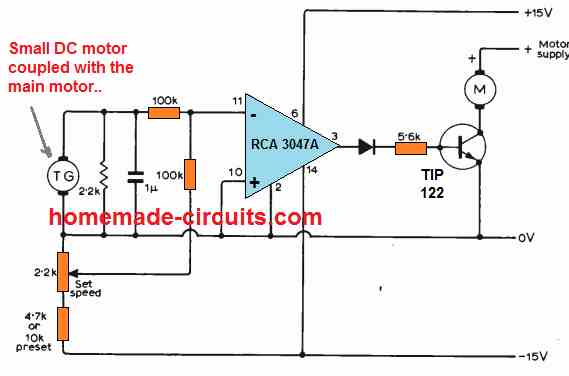

Precision Motor Control using a Single Op Amp

An extremely refined or intricate control of a d.c. motor could be achieved making use of an op-amp and a tacho-generator.

The op-amp is rigged as a voltage sensitive switch. In the circuit demonstrated below, as soon as the output of the tacho-generator is lower than the preset reference voltage the switching transistor be turned ON and 100 % power will be provided to the motor.

Switching action of the op amp would happen in just a couple of millivolts around the reference voltage. You will need a dual power supply, which may be just zener stabilized.

This motor controller enables infinitely adjustable range without involving any form of mechanical hassles.

The op amp output is only +/- 10% of the supply rails level, thus employing a double emitter follower huge motor speeds could be controlled.

The reference voltage could be fixed through thermistors, or an LDR etc.

The experimental set up indicated in the circuit diagram made use of an RCA 3047A op amp, and a 0.25W 6V motor as tacho-generator which generated around 4V at 13000 r.p.m for the intended feedback.

Additional DC Motor Controller Designs:

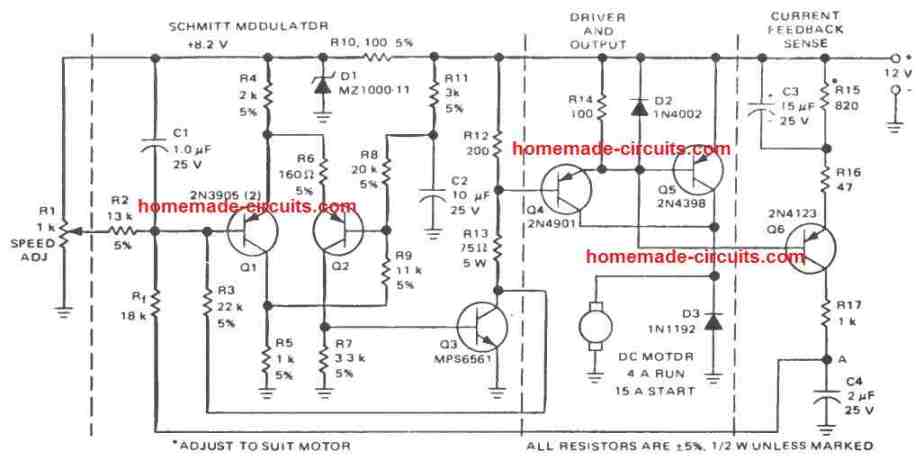

PWM Motor Control using Only BJTs

The following circuit also uses PWM principle for the desired motor speed control, however, it does not depend on any integrated circuits or ICs, rather uses only ordinary BJTs for the implementation. I got this from an old magazine page.

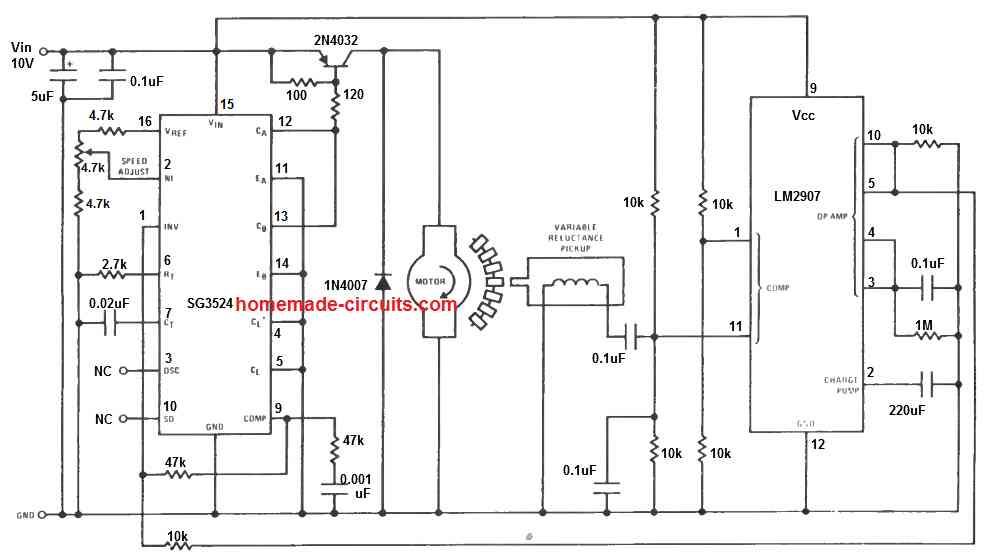

Motor Control Circuits using LM3524

The IC LM3524 is a specialized PWM controller circuit which allows us to configure very useful and precision motor speed control circuits as I have explained below:

The above diagram shows a basic PWM motor control circuit using the IC LM3524. The design additionally incorporates a sensor based feedback control through the IC LM2907.

A small magnet is attached with the motor shaft, such that during the rotations, the magnet goes past closely to an iron core pickup coil transformer.

The mechanism, causes the rotating magnet to induce a sharp electrical pulse in the pickup coil, which is used by the LM2907 as a trigger input and appropriately processed as the feedback control pulse to the LM3524 IC.

The feedback system ensures that the speed of the once set can never deviate from the set point, providing a precise control of the speed. The pot at pin#2 of the LM3524 is used for controlling the speed of the motor.

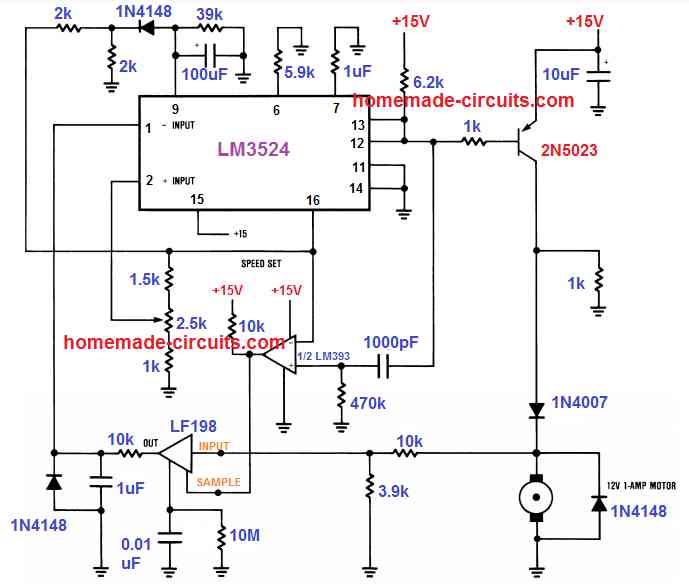

Sensorless Control, Without Motor Back EMF

The next LM3525 PWM speed control design allows the feedback control without incorporating a complex tachometer mechanism, or cumbersome sensor arrangements as implemented in the previous design.

Here, the back EMF from the motor is utilized as the feedback signal and applied to the input of the IC LF198.

In case the speed tends to rise beyond the set level, the LF198 compares the rising EMF signal with the sample reference signal from the LM393 output.

The resulting output is sent to the error amplifier of the IC LM3524 for the necessary processing of the output PWM to the driver transistors.

The controlled PWM due to this sensor-less feedback through the back EMF ultimately enables the motor to remain precisely fixed at a correct speed, as adjusted by the pin#2 potentiometer.

sir——–i have 35 v load needs 3.3 A current—-around 120 w—–i am providing 12 v dc separately to 555——-

——my doubts are

1——- should i connect 35-0 v dc directly to motor +ve terminal and neutral wire to other side as shown——figure

2—–approx weight size of heatsink for 200 watts for mosfet

3—–i have 10 k pot will that be ok

4———-1 kohm of ??? watts resistor should be connected wiper of pot and 3 pin —prevent pot from burning———–i have a doubt

5—-1 peice mosfet like irf 540——sufficient for how max watts

————-thank you——————

Rahul

1) yes you can do that, but first test with a lamp of the same specs for confirming the actions.

2) heatsink will need to be optimized with practical experimentation.

3) yes will do!

4) pin#2 has high resistance so that may not be required but you can add it, there's no harm

5) more than 200 watts if heatsink is adequate

sir————-thank you a lot————-irf 540—datasheet shows 150 w at 25 celcius temperature———–but in real life almost it is impossible—-to maintain 25c so—-i have to keep 2 irf 540 in parallel——–now there i have some problem—–i tried earlier also with other voltage regulators could not make them parallel—-hogging issue 1 regulator taking more load than other—–

———I HAVE BARE PCB–CU CLADED—-I WILL BE ETCHING THE CIRCUIT—AND SOLDER COMPONENTS—-

——-CAN YOU PLEASE POST A PICTURE OR DRAWING FOR 2 IRF 540 PARALLEL IN THE SAME CIRCUIT ABOVE IF POSSIBLE PCB BOARD PRINTED DIAGRAM FOR ETCHING ————THANK YOU

Rahul, Just attach the mosfets over a single common heatsink without mica isolator…..this will ensure there's no hogging issue, and by the way mosfets behave oppositely to BJTs as far current hogging is concerned so anyway this cannot be a problem.

Connect a diode across the source/drain of FET exactly as indicated in the diagram, you can use a 1N5408 diode…

hi sir,

i want to make a wireless system to control 2dc motors.

2 dc motors180v,1.9amp. this ,motor is connected to a AC source.1 bluetooth is connected to a computer as signal sender & 1 as receiver at motor side,i need a motor driver circuit and ac to dc converter circuit also

Hi Lidya, you will require a PWM transmission for this, I have not investigated how to send PWM through bluetooth, so I will have to do some research first before commenting….I'll try to upadte it soon

Hi Sir ,

Thank you for the information & the immediate response.

I think,this was the mistake i made in explanation.

The transmitter bluetooth just send the data from the computer (how much the user want to controll) to the receiving side.

At the receiving side we receives the data from receiver bluetooth & send to ANy microcontroller(i would like to use PIC). This Microcontroller makes the PWM signal for the motor.

My doubt is,

1.how can i connect this specified motor (180V,1.9A,1/3 Hp DC Motor)with the controlling signal?(in microcontroller side we using 5V,)

2.how to convert AC for 180v,19A DC Motor.

Thanks Lidiya, got it now.

you can use the mosfet/motor driver configuration that's shown in the article above and integrate it with your available 5V PWM.

But mofet might not trigger correctly with a 5V source so you can try replacing the mosfet with a BJT MJE13005.

converting the 220V AC to 180V DC could be difficult. A possible solution could be through an appropriately wound coil over a laminated iron core which would drop the 220V AC to 180V AC, which could be further rectified with a bridge diode for the final DC

Thank you Sir.. for the information

you can use the last circuit from the following link:

https://www.homemade-circuits.com/2013/09/simple-electronic-load-controller-elc.html

ignore the bridge rectifier, it's not applicable for your need.

connect the motor across the mosfet drain and 77V input.

the adjustment pot should 1K rated not 10K as indicated in the diagram.

I have a DC motor (77 V and 1.5 A). I want to control speed of 3 such motors simultaneously by PWM. Can you please suggest which IC driver to be used for the same?

I have a microcontroller board (robokits.co.in/control-boards/rhino-robot-control-board/rhino-robot-control-board-avr-based-with-quick-c-compiler) too which has 5 A motor driver on it but output voltage is 12 Volts. An IC which is compatible with this board would be most welcome.

Using same the circuit with triac it can run AC motor….but how???

How many triac are required?

What changes are required in the circuit?

Which triac I can use any specific for high voltages?

connect the gate (left lead) of the triac with the 555 output pin through a 1K resistor

connect the right side lead with the negative of the circuit.

connect the the center lead with one of the wires of the load….connect mains with the other wire of the load and the negative of the circuit.

triac spec will depend on the load spec

Can the motor is replaced with AC motor will it run??

It is possible by replacing the mosfet with a triac

Hai, I bought one motor and one 12v 2amp dc adapter. when I connected the new motor directly to the adapter, the motor is 2 seconds spinning, 2 seconds stopped, spinning, stopped,contiues.. Then I tried with another similar motor (Removed the motor from pcb drill machine,Rating:12-18V, 30watts) with the same adapter, the motor is spinning good. Then I connected both the motors in parallel with the same adapter. Then both motors are spinning good. so can u able to find the reason why the new motor is not spinning continuesly when I connected it separately with the adapter?

And is there any way to find the rating of a motor? Bcoz nothing is mentioned or labled on the new motor. Its plain.

Hai, may be it's due to some improper connection inside the motor or the adapter…because if both the motors are running together then they would do the same individually too.

Connect an ammeter in series with the motor wire and you can get the amp consumption on the meter while its running.

Thanks

Your circuit diagram is ok. I added 7812 for 12v for circuit section. 24v for motor. The mosfet I used is 50n06.

At present I don't have a 470mfd or more value with voltage rating greater than 25vdc to try parallel with motor.I will try once I get it.

My problems started after I connecting the 470mfd to drain and source. But I need it to avoid buzzing sound at low speed.

Anyway once again I connected 470mfd to drain and source. I removed led parallel with motor and connected to mosfet gate and ground. Now the led brightnes varies with motor speed. So visual indication issue solved…..! ( Without the 470mfd, led brightness–parallel with motor –varies with motor speed…….! ).

But motor still rotates at speed more than I want even if 100k pot at its minimum setting. I hope I can solve this by adding a fixed resistor at the middile pin of 100k pot. Not yet tried, will try later..

I am sharing this post here for helping other readers.

OK, thanks very much for updating the info!

you can also monitor the PWM rate at the mosfet gate with a meter for assessing the proceedings correctly.

Hi Swagatham

At last I found an answer for my 470md related problem from your one another circuit.

https://www.homemade-circuits.com/2012/01/how-to-build-simple-pwm-controlled-dc.html

Please read the 2nd paragraph above the circuit diagram starting " However only the average DC voltage is finally fed to the cell phone due to the presence of the 10uF……."

I suspect, my 470mfd did the same roll of the 10mfd in this circuit. So I cannot attain very slow speed after I connected the 470mfd accross the drain and source.

Without the 470mfd, I can control speed of motor + and brightness of an LED with 2.2K series resistor across the motor from 0% to 100%……!

Thanks Anil, yes that could be the issue, the 470uF might not be allowing the motor to switch OFF completely during the OFF periods of the mosfet. You can try decreasing the 470uF to 22uF which might help to control the noise level of the motor as well as allow complete control of the motor speed.

Hi Swagatham

I assembled this circuit to control the speed of a 24vdc, 1ampere, 15000rpm motor(mixer motor from an automatic coffee vending machine). It is working perfectly. But at very low speed, the motor does not rotate. It makes only a humming sound.

When I control the 100k pot, the LED parallel to motor also works from 0 to full brightnes.

Then I connected 470md capacitor to drain and source. Now I noticed the LED always stay at full intensity. Stil I can control the speed. But now POT at lower side the motor rotates at slow speed, say 10% or 20% duty cycle.

I need to modify the circuit with that 470mfd and 0 to 100% duty cycle. What changes should I make..?

Hi Anil,

the circuit is actually providing 0 to 100% PWM output but your motor is not responding at lower PWMs due to lack of torque, you can try connecting the capacitor right across the motor leads and see if that helps, because I cannot see any other possible modification for rectifying this issue in the circuit.

Dear sir thanks for your good response , because I use other mosfet for 220 v 5,ampere dc motor but the out put voltage controled from 145 v to 220 v . But my requirement is 0v to 220 v variable… So plz guide me I m waiting plz sir

Dear Muhammad, the above circuit will enable you to control the motor from 0 to 220V…or at least from 10V to 220V

Thanks swagatam for your good response , I changed mosfet but found not working . Accrording to me that I apply only 220 v dc to only mosfet not connect ground and positive through resistor same as traic to 555 power supply . Sir is I am correct or not ? Dc motor is 1.5 hp. 5ampere . Sir plz send me circuit or guide me with special thanks

which mosfet did you use? the ground connections (symbols) shown in the diagram all needs to be connected together (made common)….in other words the 220V (-) needs to be connected with your 555 IC's 12V (-)…..I hope you have use a 12V DC supply separately for powering the 555 circuit,

Plz reply

Dear sir I use this circuit and found wonderful working …nut now today I have a treadmill 220v dc motor so please guide me that this circuit will work properly or not if yes then changing will be required ? Wating your good response with thanks

Dear Mohammad,

you will only have to change the mosfet and use everything as given in the diagram, you can try FQP6N70 if your motor current is within 5 amp

hi

please give me FYP Project? i am in electronics department.

hi, swagatam bro my teacher gave me your circuit as my semester project, but he add some more thing like mathematical modeling and transfer function of this pwm circuit. will you help me to find out these…please

I am sorry, due to lack of time it wouldn't be possible for me to help you with all the involved calculations.

Sir, can i use this circuit for making a heat regulator for DC 48V 15A heater?

yes you can do it.

R/Sir,

In my design I used 220v dc by using 35 A bridge to power Field supply of the motor.@ I used 6A4 bridge to power Armature supply.But when I am connecting the said cct. one 6A4 get shorted.Then I changed the supply bridge to armature and vice versa.till one diode is shorted.The motor is 1.5 hp @ rating 8amp. named dc shunt. So sir please give suggestion to work this motor. Anothr thing is I was used another cct. having 2n5269 in its output.I used bridge for field. and 40 volt dc for armature. the ccct. works nomally.but actually operation is on 220v.this is the total information about this project.since last month I am following your site. which is very nice @ halpful to all. Mostelywhen I am reading the reply from your site it looks like we are siting in front of you @ you are giving explanation of the project.

lot of thanks.@ wating for the reply.

mukund.

Mukund, I do not have much experience with motors that are designed with two winding, I'll have to study more and only then I would able to suggest you correctly whether your implementation is correct or not.

I'll try to do it soon, once I finish other pending assignments.

keep in touch until then….

R/Sir,

After long time I am making contact.Sir If there is any Idea about controlling the pwm motor with field and Armature with 220volt supply? hopping to be excused. Waitin for your plesant reply.

mukund

R/Sir,

I am willing to control 2hp dc motor.having field 220volt @ armature is 200volt.which cct. is suitable to control the motor by armature supply variation.These motors are used in printing industry. I hope that you will give me a proper guidance.

mukund

Mukund, if it's a DC motor then you can try the circuit that's presented in the above article, it's a PWM circuit and well suited for controlling DC motor speeds

Hi swagatam.

I'm trying to use this circuit to control speed on my radiator fans in my truck

(dual fans, 15 amps each, wired in parallel) based on temperature.

the temp sensor is fastened to ground with one wire out

what I came up with was to put the sensor between the 555 GND so as to vary the gnd supply to the 555 based on temp. I know this is not the ideal way but is all I could come up with.

Also wondering about mosfets, I have a couple that are rated at 30vdc and 70 amps

so by all means one of these should do the job right?

…just find it hard to believe that one of these could power such large fans..

any help will b greatly appreciated, thank you.

Hi Henry,

your idea regarding using the sensor with pin1 of the IC is technically incorrect and inapplicable, so that won't be feasible.

However pin#5 can be targeted for delivering the purpose by using BJTs, mosfets won't be effective, if possible I'll try to figure out the design….

I would be interested to know about the output from the sensor at the peak temperature (at the desired cut of threshold)

Thank u so much swagatham, working perfectly, thanks a lot….

you are welcome Swarajit!

Hi swagatham,

Thank u so much, now the circuit is working perfect, I have two more doubt.

1.) Can I use a common (parallely connected )potentiometer for two circuit ( as I'm using this for a robot car, there will be two motor left and right both working by different but speed should be maintained same)

2.)I want to switch frequently so If I use the switch on after the MOSFET while the circuit is on continuously I'll control the motor through the output, is that cause any damage to circuit?

Thanks Swarajit, I am glad to know it's serving the purpose.

1) you can use a dual pot for implementing a simultaneous operation of the two circuit's PWMs, in sync

2) you can use a DPDT switch in series with the motors, it won't do any harm to the circuit functioning.

Hi swagatham,

I tryed this circuit in bread board,I'm using 12v, 7 amp motor 2nos connected parallel so the load is 14 amps. It is not working when I tune the pot in one place motor start running in full speed and after that not working. I do no where I made mistake please guide me.

IRF540N is the MOSFET

Waiting for your reply…

Regards

Swarajit Alakananda

Hi Swarajit, first confirm whether your 555 is working correctly or not.

remove the mosfet and the motor from the circuit and connect an LED with a 1K resistor across pin#7 and ground of the IC….now adjust the pot around and see if the LED alters its intensity from zero to max and back….if this is not happening then you could assume something to be not correct in your circuit.

Thank u ,I'll conform and reply u…….

Hi swagatham,

Yes as u said something to be wrong in the circuit. Do u have any breef images or vedio to guide, because it will be help me better…

Now my circuit is OK swagatham, the problem is I can't feel much difference in the motor speed

If i use a high amps MOSFET for low amps motor will that be an issue …..

I'm using IRF 540N, For a 7 amps motor..

Hi Swarajit,

using a higher rated mosfet will not harm anything in the circuit

you can try the following design and see if it performs better.

https://www.homemade-circuits.com/2012/05/making-adjustable-electromagnet-circuit.html

Thanks so much Daan,

I think the above 555 circuit can be used without any issues for your application and it's a good and a reliable option to begin with.

The mosfet parameter is not relevant to the circuit, that means any mosfet with any voltage/current specs can be used with the shown circuit.

I have not yet researched on the concept of a resonant HHO generator but I think it's an interesting topic to investigate on, and I will surely look into it and try to post an pertinent article. Thanks and do keep in touch!

Hey Swagatam, I am an engineering student trying to build a pwm to control a 24v 750w motor. This will be used to power a 250lb vehicle with a driver weight of 150lb. I am a mechanical person and am new to circuitry. I can't seem to view your schematic that is supposed to be with this article. But do you think it will work with my application? I plan on using a potentiometer in order to control the speed of the vehicle. Thanks in advance

Hi James, yes definitely the above shown design can be used for your application.

Just make sure the FET is rated to handle 50V 1000 watt, and the 555 IC is supplied with a stepped down 12V through a 7812 IC regulator.

What would happen if this was used on an AC motor? Power all the control ckt with the proper DC voltage, but put the FET in series with an AC motor.

fet will not rectify both the halves of the AC, you can try using a triac instead and it will work.

Dear sir,

I am a mechanical guy,currently working on an electric vehicle and i want to control the speed of my motor using pedal . i am not getting a controller for my motor please help me to build my own i''ll be highly thankful

Motor Specifications are 36volt,43ampsand 1.5hp brushed dc motor

Dear Lokesh,

If possible I'll try to design the required circuit and post it soon in this blog.

Dear Sir,

I am a beginner.

Can I use the above circuit for my treadmill with 180V 6A 4200 RPM DC Motor. I would like to use the mill only for normal walking of about 30 to 45 minutes in normal speed.

Can I reduce the RPM to my desired speed (only for walking with speed of 4 to 6 KM/hour) using the above circuit. If I use the POT, what would be the changes in the RPM when the POT gets in to its maximum and minimum positions. If I can use the above circuit, pl suggest me the appropriate MOFSET for the above load.

I went through all your reply and it is interesting and valuable. I really appreciate your patience and commitment.

Sir, my thanks to you in advance

Shine K P

Thank you dear Shine!

yes, according to me you can use the above circuit for your said application.

The maximum achievable speed is near 95% and the minimum is near 5% so it's pretty efficient with its control spces.

You can use IRF840 as the mosfet.

Dear Sir,

Sorry for bothering you…..

I tried this circuit but in between got stuck because, I am not finding any way to bring 12V dc to IC 555 as my rectified DC is 180V, which I am using for motor, in the board. I believe, I cannot connect LM7812 directly to this volt. Can you please help me on this?

Thanks & regards,

Shine K P

Dear Shine you can use any standard 220V to 12V AC/DC SMPS power supply for this….you can get it in the local market,

even your phone charger will work for the time being.

Dear Sir,

Thank you for your mail…

Sir, then I have to connect Ground of 180V DC supply to Drain pin of MOFSET. Am I right sir?

Regards,

Shine K P

Dear shine,

the drain will connect with the (-) of the motor, please see the diagram above.

The (-) of the 180V will become common with the (-) of the 12V supply…..the motor (+) will connect with the (+) of the 180V supply

Dear sir,

Sorry…..

Now I understood….

Thank you very much…

Regards,

Shine K P

Sorry sir…it was my mistake……

Dear Sir,

I tried this

1)Motor didn't run when the power on

2)When I turned the POT, it started running but immediately 555 got burned and MOFSET as well LM7812 also got hot.

3)Even though the smoke was comming from 555 motor was running.

4)I checked the circuit and found no short circuit.

Sir, what could be cause for this? Can you pl advise me…..

Thanks & Regards,

Shine K P

Dear Shine,

I recommended using a separate 12V AC/DC adapter for powering the IC stage…not a 7812 IC so please build it again and power it as suggested.

also connect a 6amp rectifier diode right across the motor coil in order to safeguard the fet from motor back emfs.,

Dear Sir,

I didn't get 12V AC/DC Adapter but got 15V AC/DC from my nearest shop. That is the reason, I used 7812 to get the regulated 12V DC to IC.

1)Should I use 12 AC/Dc adapter and remove 7812?

2)Sir, I joined both -ves (180 and 12) and grounded wherever it is mentioned in the circuit, even to source of MOFSET. Hope it is correct.

3)Offcourse, I can connect protector diode and will try again.

Thanks & Regards,

Shine K P

Dear shine,

yes, 7812 with 15V input is perfectly fine, and making the negatives common along with the fet source is also perfect….I think attaching the diodes across the motor should solve the problem.

Dear Sir,

I connected the 6A4 diode across the motor, now IC and 7812 are okay but MOFSET is getting hot. I think, the MOFSET got damaged while it got heated last time.Now motor is running in its full speed. No control on POT and MOFSET is getting hot also.I put heat sink for MOFSET and 7812. I noticed, even without inserting 555, motor is running in its full speed.I checked the POT and it is working fine. Let me change the MOFSET. I would require your hep sir….sorry for bothering you.

Regards,

Shine K P

Dear Shine, if without IC the motor is running that surely indicates a faulty mosfet…try using two mosfets in parallel for ensuring better safety to the mosfet and reducing heat dissipation

Dear Sir,

Thank you….noted your suggestion. Let me try this also. Can you please advise me on below

1)PIN 7 of 555 will be connected to GATES of two MOSFETs seperatly. Do I need to need to add 10k again? ie Do i need to add 10k before each GATE?

2)DRAIN of two MOSFETs will be joined together and connected to -ve of motor

3)SOURCE of two MOSFETs will be grounded.

Am I right sir?

Regards,

Shine K P

Dear Shine, the 10k need not be repeated, pin7 needs to be connected with each mosfet gates via separate 22 ohm resistors.

next, drains will join together and connect with the motor negative, sources will join together and connect with the ground

Dear Sir,

Thanks….Let me try…

Regards,

Shine K P

Dear Sir,

I tried with two MOSFET and connected 22 ohms resistor also. It was working fine.When I applied the load (I started walking), the motor was about to stop but when I increased the POT , motor started running for my desirable speed for walking but suddenly MOSFET got burned. There was some noise from motor while in low RPM. 6A4 diode is already connected across motor coil.

Can you please advise?

Regards,

Shine K P

Dear Shine, which mosfet have you used? Please confirm if those are adequately rated as per the load.

Dear Sir,

As you suggested, I used IRF 840. My DC motor is 180V 6Amps.

Regards,

Shine K P

Dear Shine, that's perfect, the IRf840 are rated to handle 500V at 8amps so it shouldn't be a problem…there could be two possibilities either your motor is drawing over 16 amps when loaded or the mosfets are not original.

you can try connecting two more (4 total) mosfets in parallel in an identical fashion as explained previously and check the response

Sir can i use two Motor in parallel

yes you can do it if the total amp is within the max rating of the mosfet

hi,

what power supply and mosfet should i use for a 180 to 220vdc motor, as well as adisplay in the circuit to show the motor rpm

An IRF840 mosfet could be tried, power supply should be DC and as per the maximum rating of the motor….for RPM you'll have to procure a ready made RPM meter and integrate it with the motor.

Hi, that's completely rubbish…if the motor is specified to run at 12V it can be safely connected with any 12V supply (regardless of the amp rating of the supply).

shunt resistor may be required for protecting the power supply (SMPS) from the back emf that may be generated by the motor…. so its the power supply that may need protection with a shunt, not the motor.

The above may be true only with big heavy duty motors only….not in your case.

Thanks for the clarification… so the shop man cheated me by giving a damaged motor itseems :-(… Now am having a 12v, 0.28A DC motor. I like to use this motor in ur above circuit. so Could u tell me that wat mosfet i can use for this??

mosfet may not be necessary, you can use a TIP122 in its place and connect the motor as indicated (across collector and positive)

Hai, I bought one 12v dc motor. I connected it directly to the 12v adapter. Then the motor is running in a pulse mode. Means like clocks seconds needle moving. running, stopped, running, stoped. like that. When i asked abt this to the shop man, he told that the motor got damaged due to directly connected to the 12v power supply, a 12v motor should not directly connected to a 12v power supply, It should connected through shunt (resistor). But he dont know what resistor have to put.

Could u tell me, is that correct which he told?? and wat resistor i have to connect between the motor and the power supply if I want to connect the motor directly to the 12v power supply?

Now I bought another motor which is rated 12v ,0.28A. I like to connect this motor to ur above circuit. so still do I need a Shunt (resistor)?? and wat value, rated mosfet I can use for ur above circuit?

Is this circuit 0 to 100% duty cycle? I want the frequency to be constant 60 Hz. How would I do that?

Using this formula? F = 1.44(VR1*C1)

Based on your circuit you put 100k for vr1 and 0.1u for c1. Frequency will be 0.0144 hz?

No it's only from 50% to 100%, and frequency will not be constant if duty cycle is changed for this circuit.

the pot control is for speed control, it has no relation with current….use a 2amp fixed current power-supply for getting the required current restriction.

In the diagram no resistor is indicated, but you can use 100ohms with the gates, will be OK.

4amp will not give you 15amp….you will need a 15amp supply for that.

Connect the mosfet leads in parallel, use separate resistors for the gates.

And do not short circuit the positive with drain, this will instantly blow off the mosfets.

use IRF540 mosfet and 15amp power supply, this will drive the motor with the specified power.

Thank you for you speedy response. I would have commented earlier but i was waiting for an email telling me you responded. (never came) could you please verify for me the value of R4. i believe that should be 2k ohms.

also one other thing, From what i gather, adjusting pot at pin 5 will control the duty cycle, but could you please explain how i would go about adjusting the frequency should i need to. I have built your other PWM circuit and it worked great. (using one 555ic)

I remember a time back when i was in air force tech school when i could of done all this with my eyes closed. they were very thourough. its amazing to me how only in a few years i could forget so much!

My replies here are supposed to reach the commentor in their email IDs, you should find these discussions in your email inbox, according to me.

Although the frequency has no relevance to the motor speeds, it can be controlled by varying R1 or the 180k resistor value.

I am sure the discussions here will help you to restore all you had learned back:)

So much SWAG! 🙂

Im trying to build a PWM controller for a dc motor that runs a fluid pump. I know it would need 0-100% control, but I also think that your constant torque circuit would be better. (since i need to deliver exact amounts of fluid) However the constant torque circuit you provided shows a bi-directional motor and I could not follow your text instructions for making it single direction. I would like to be able to adjust frequency, and pulse width. Circuit will a regulated 8v from the batterypack/power supply. Can you maybe point me to a good instructions page to build for this? (motor "on time" will be determined by a lookup table using a micro processor, but thats a whole nother issue)

Thanks JC,

Please refer to the following diagram, you can try this design:

1.bp.blogspot.com/-jONLYQ8Ehro/UkD_gzAjA-I/AAAAAAAAFSk/nt6vxMDF9RU/s1600/ELC%20circuit.png

Connect your motor across the drain and positive of the circuit…please ignore the bridge rectifier it's not meant for us.

The shown PNP transistor is BC557 and not BC547 as wrongly given in the diagram.

The pot at pin5 of IC2 can be used for controlling the speed,

The mosfet can be replaced by a power transistor, if desired. In this case use ordinary 555 IC, and not 7555.

Thanks Buddy:) appreciate your enthusiasm!

The 100% constant torque would be a better option as it presents more efficient PWM control over the motor, here's the article which are to referring:

https://www.homemade-circuits.com/2011/12/constant-torque-dc-motor-speed.html

Regards!

for zero to 100% speed control you will have to make the following circuit, the above circuit will not provide 100% control:

4.bp.blogspot.com/-G-E1CvLaU4U/UOfhAH6C0ZI/AAAAAAAACas/nsaEsevlY6k/s1600/reverse%20forward%20dc%20motor%20speed%20controller%20circuit.jpg

I couldn't understand the relation between heatsink mounting and motor positive connection.

You are most welcome!

It's my pleasure!

?? Sorry can you explain

For confirmed results the cap C1 may be replaced with a 0.01uF if a 50k pot is used. rest will remain as is.

correction: 50k pot will not need any mods in the circuit….

Could you use a 50k pot instead with out changing any other components? Thanks

yes, will do.

The power supply rating should have a voltage rating exactly matching to the load……current is immaterial, but should be higher than the load, if it's lower, the voltage will drop.

The mosfet can be anything…just needs to be rated at least twice to the load rating, if it's higher no issues, but preferably shouldn't be lower.

n-channel, rated higher than your motor Voltage and Current specs

HI,

You may misunderstand me… You know my motor have 18k rpm in no load and about 5k rpm when connected to 4v 3 amp battery and about 10k rpm on 6v 4.5ah battery.

For got about my stupid TDA7274 circuit. its giving me about 700-900 rpm to me which is not any value and its not giving me any airflow that can I feel from 12" far.

So I want to through the Circuit to the dustbin as its useless and the IC is getting about too many hotter, you can feel that it can cook your rise in 10 minutes. So I am pretty sure the circuit will not last long and it can be make any damage as its hotting up.

Now I want your help, I hope you seen my motor and which fan I connected (s10.postimg.org/7da0t1c6h/2013_07_16_02_25_04.jpg)

Please give me any circuit that can drive my motor with this fan (load) at 2-4 k rpm. I found that my motor is stable on this RPM but it getting hot if I it go to more that 5k rpm.

Please don't leave me alone here. want your help,

Awaiting to hear from you.

Regards,

MD

The motor maximum RPM will be as per it's rated specification, it cannot be increased beyond that.

A speed controller will only reduce the RPM from the specified high value to the lower levels.

Anyway, you may try the circuit given at the bottom of this page:

https://www.homemade-circuits.com/2011/12/constant-torque-dc-motor-speed.html

The same circuit can be used for your application too. Just make sure the IC circuit gets around 12V supply derived from the 90V supply.

The motor can be connected with the 90V supply directly in the manner shown in the diagram.