When a DC to AC inverter is operated through a solar panel, it is called a solar inverter. The solar panel power is either directly used for operating the inverter or it's used for charging the inverter battery. In both the case the inverter works without depending on mains utility grid power.

Designing a solar inverter circuit essentially requires two parameters to be configured correctly, namely the inverter circuit and the solar panel specs. The following tutorial explains the details thoroughly.

Building a Solar Inverter

If you are interested to build your own solar inverter then you ought to have a thorough knowledge of inverter or converter circuits, and regarding how to select solar panels correctly.

There are two options to go about from here: If you think making an inverter is much complex, in that case you could prefer buying a ready made inverter which are plentifully available today in all sorts of shapes, sizes and specs, and then simply learn only about solar panels for the required integration/installation.

The other option is to learn both the counterparts and then enjoy building your own DIY solar inverter step wise.

In either case learning about solar panel becomes the crucial part of the proceedings, so let's first learn about this important device.

Solar Panel Specification

A solar panel is nothing but a form of power supply which produces a pure DC.

Since this DC is dependent on the intensity of the sun rays, the output is normally inconsistent and varies with the sun light position and climatic conditions.

Although solar panel is also a form of power supply, it significantly differs from our usual home power supplies using transformers or SMPS. The difference being in the current and voltage specs between these two variants.

Our home DC power supplies are rated to produce higher amounts of current, and with voltages perfectly suiting a given load or application.

For example a mobile charger may be equipped to produce 5V at 1 amp for charging a smart phone, here the 1 amp is amply high and the 5V is perfectly compatible, making things extremely efficient for the application need.

Whereas a solar panel may be just the opposite, it usually lacks current and may be rated to produce much higher voltages, which could be hugely unsuitable for general DC loads such as a 12V battery inverter, mobile charger etc.

This aspect makes designing a solar inverter a little difficult and requires some calculations and thinking in order to obtain a technically correct and efficient system.

Selecting the Right Solar Panel

For selecting the right solar panel, the basic thing to consider is that the average solar wattage must not be less than average load wattage consumption.

Let's say a 12V battery needs to be charged at 10amp rate, then the solar panel must be rated to provide a minimum of 12 x 10 = 120 watts at any instant as long as there's a reasonable amount of sun shine.

Since generally it is difficult to find solar panels having lower voltage and higher current specifications, we have to move on with what is readily accessible in the market (with high voltage, low current specs), and then dimesnsion the conditions accordingly.

For example if your load requirement is say 12V, 10 amps, and you are unable to get a solar panel with this specs, you may be forced to opt for an incompatible match such as a 48V, 3 amp solar panel which looks much feasible to procure.

Here the panel provides us with voltage advantage, but current disadvantage.

Therefore, you cannot connect a 48V/3amp panel directly with your 12V 10 amp load (such as a 12V 100 AH battery) because doing this would force the panel voltage to drop to 12V, at 3 amps making things very inefficient.

It would mean paying for a 48 x 3 = 144 watt panel and in return getting 12 x 3 = 36 watt output...that's not good.

In order to ensure an optimal efficiency we would need to exploit the voltage advantage of the panel and convert it into a equivalent current for our "incompatible" load.

This can be very easily done using a buck converter.

You will Need a Buck-Converter for Making a Solar Inverter

A buck converter will effectively convert the excess voltage from your solar panel into an equivalent amount of current (amps) ensuring an optimal output/input = 1 ratio.

There are a few aspects here which needs to be considered. If you are intending to charge a lower voltage rated battery for later use with an inveter then a buck converter would suit your application.

However if you intend to use the inverter with the solar panel output during daytime simultaneously while its generating power, then a buck converter would not be essential, rather you could connect the inverter directly with the panel. We will discuss both these options separately.

For the first case where you might need to charge a battery for later use with an inverter especially when the battery voltage is much lower than the panel voltage, then a buck converter could be imperative.

I have already discussed a few buck converter related articles and I have derived the final equations which can be directly implemented while designing a buck conveter for a solar inverter application, you may go through the following two articles for getting an easy understanding of the concept.

Calculating Voltage, Current in a Buck Inductor

After reading the above posts you might have roughly understood regarding how to implement a buck converter while designing a solar inverter circuit.

If you are not comfortable with formulas and calculations, the following practical approach could be employed for obtaining the most favorable buck converter design output for your solar panel:

Simplest Buck-Converter Circuit

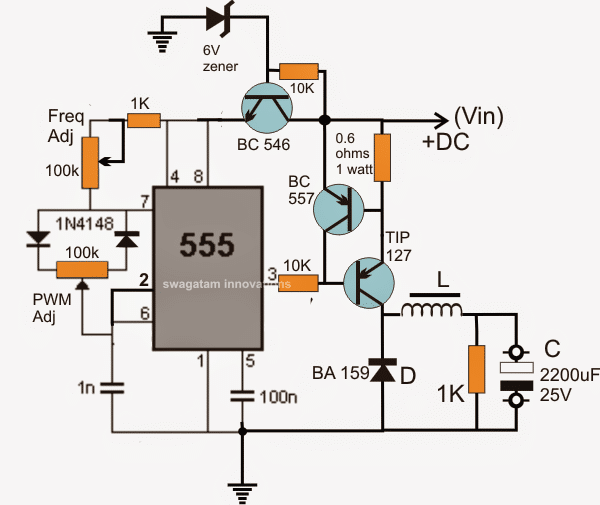

The above diagram shows a simple IC 555 based buck converter circuit.

We can see two pots, the upper pot optimizes the buck frequency, and the lower pot optimizes the PWM, both these adjustments could be tweaked for getting an optimum response across C.

The BC557 transistor and the 0.6 ohm resistor forms a current limiter for safeguarding the TIP127 (driver transistor) from over current during the adjustment process, later this resistance value could be adjusted for higher current outputs along with a higher rated driver transistor.

Selecting the inductor could be tricky.....

1) The frequency may be related to the inductor diameter, lower diameter will call for higher frequency and vice versa,

2) Number of turns will affect the output voltage and also the output current and this parameter would be related to the PWM adjustments.

3) The thickness of the wire would determine the current limit for the output, all these will need to be optimized by some trial and error.

As a rule of thumb, start with a 1/2 inch diameter and number of turns equal to the supply voltage....use ferrite as the core, and after this you can begin the above suggested optimization process.

This takes care of the buck converter which can be used with a given higher voltage / low current solar panel to obtain an equivalently optimized lower voltage / higher current output, as per the load specs, satisfying the equation:

(o/p watt) divided by (i/p watt) = Close to 1

If the above buck converter optimization looks difficult, you could probably go for the following tested PWM solar charger buck converter circuit option:

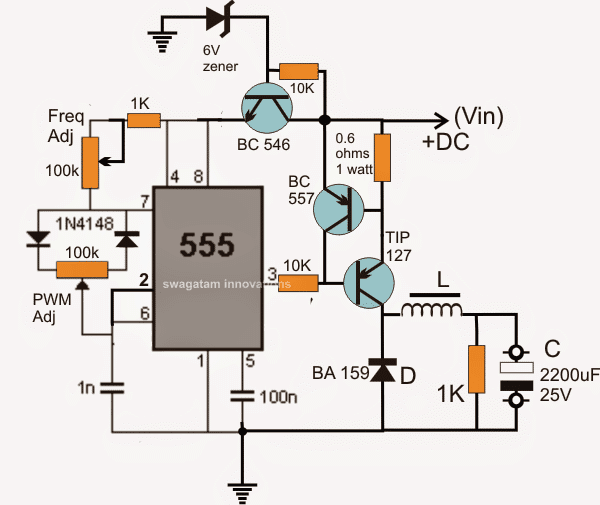

Here the R8, R9 can be tweaked for adjusting the output voltage, and the R13 for optimizing the current output.

After building and configuring the buck converter with an appropriate solar panel, a perfectly optimized output could be expected for charging a given battery.

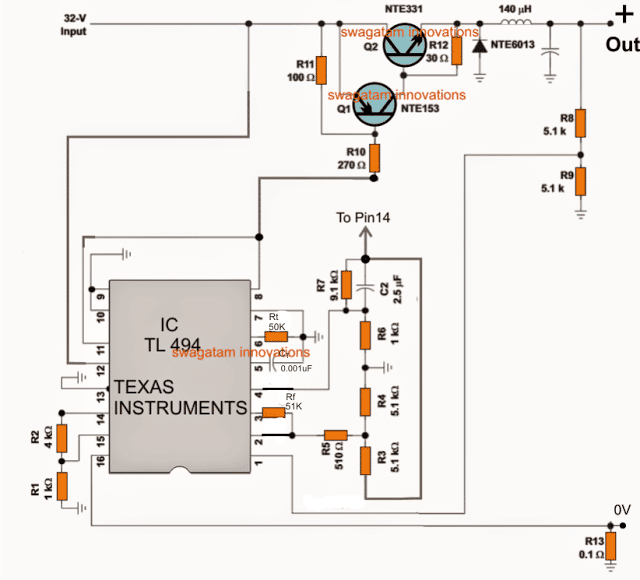

Now, since the above converters are not facilitated with a full charge cut off, an external opamp based cut-off circuit might be additionally required for enabling a fully automatic charging feature as shown below.

Adding a Full Charge Cut-off to the Buck Converter Output

- The shown simple full charge cut-off circuit could be added with any of the buck converters for ensuring that the battery is never over charged once it reaches the specified full charge level.

- The above buck converter design will allow you to get a reasonably efficient and optimal charging for the connected battery.

- Although this buck converter would provide good results, the efficiency could deteriorate as the sun went down.

- To tackle this, one could think of employing a MPPT charger circuit for acquiring the most optimal output from the buckcircuit.

- So a Buck circuit in conjunction with a self optimizing MPPT circuit could help in churning out the maximum from the available sun light.

- I have already explained a related post in one of my previous posts, the same could be applied while a solar inverter circuit design

Solar Inverter without a Buck Converter or MPPT

In the previous section I have explained to design a solar inverter using a buck converter for inverters with lower battery voltage rating than the panel and which are intended to be operated during night time, using the same battery which was charged during the day time.

This conversely means that if the battery voltage is upgraded somehow to match approximately with that of the panel voltage then a buck converter could be avoided.

This may be also true for an inverter which may be intended to be operated LIVE during daytime, meaning simultaneously while the panel is generating electricity from sunlight.

For simultaneous day time operation, the suitably designed inverter could be directly configured with a calculated solar panel having the correct specifications as shown below.

Again we must make sure that the average wattage of the panel is higher than the maximum required wattage consumption of the inverter load.

Let's say we have an inverter rated to work with a 200 watt load, then the panel must be rated at 250 watts for a consistent response.

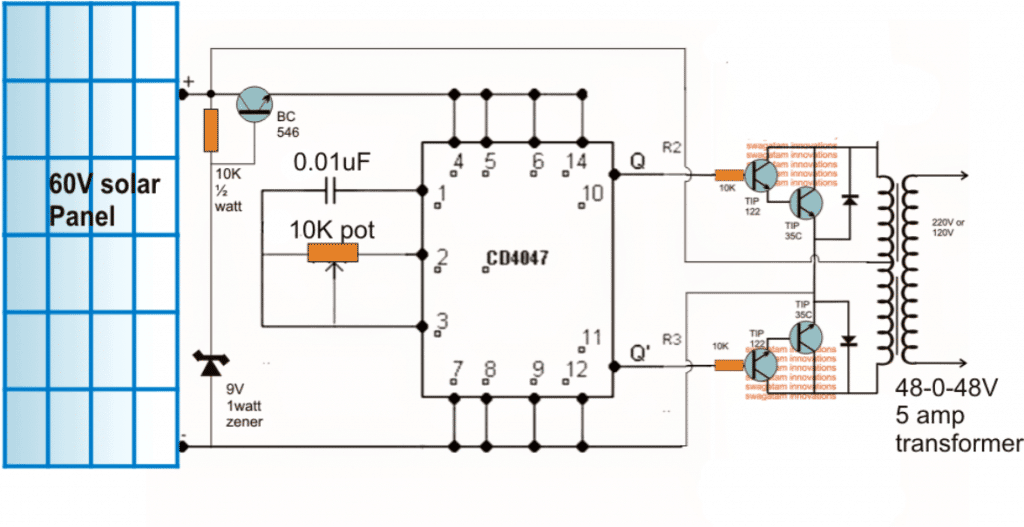

Therefore the panel could be a 60V, 5 amp rated, and the inverter could be rated at around 48V, 4amp, as demonstrated in the following diagram:

In this solar inverter, the panel can be seen directly attached with the inverter circuit and the inverter is able to produce the required power as long as the sun rays are optimally incident on the panel.

The inverter would keep running at a reasonably good power output rate for so long as the panel produces voltage above 45V...... that is 60V at the peak and down to 45V probably during afternoon.

From the above shown 48V inverter circuit it is evident that a solar inverter design does not need to be too crucial with its features and specifications.

You can connect any form of inverter with any solar panel for getting the required results.

It implies that you can select any inverter circuit from the list, and configure it with a procured solar panel, and begin reaping free electricity at will.

The only crucial but easy to implement parameters are the voltage and the current specifications of the inverter and the solar panel which must not differ by much, as explained in our earlier discussion.

Modified Square wave Solar Inverter Circuit

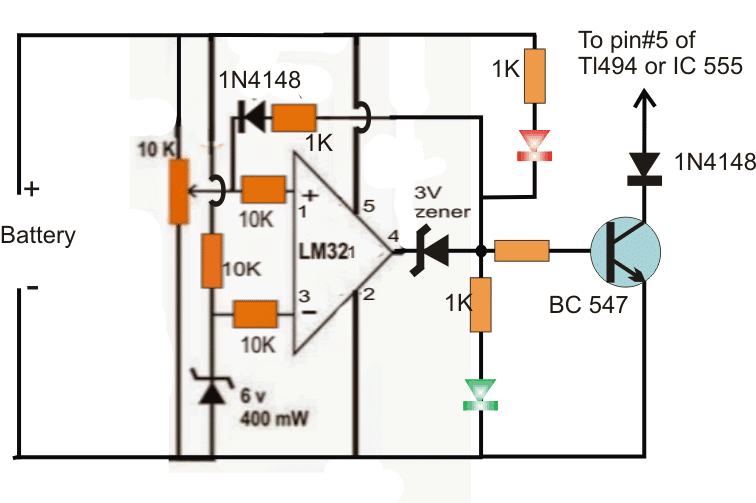

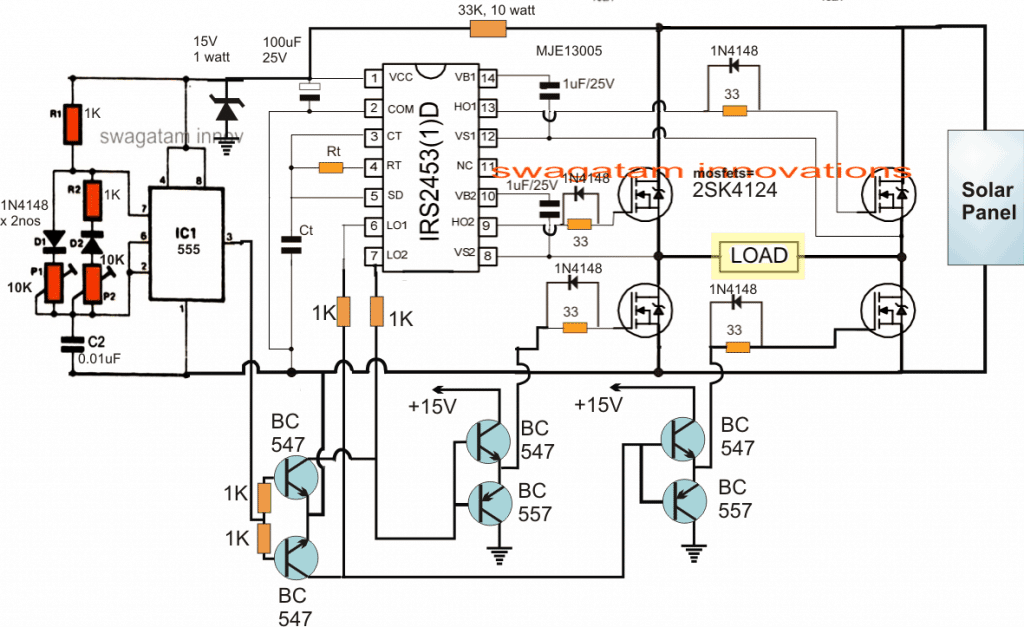

All the designs which are so far discussed are intended to produce a squarewave output, however for some application a square wave could be undesirable and might require an enhanced waveform equivalent to a modified sine wave. For such requirements a PWM operated circuit could be implemented as shown below:

Note: The SD pin#5 is mistakenly shown connected with Ct, please make sure to connect it with ground line and not with Ct.

The above solar inverter circuit using using PWM sine wave can be studied elaborately in the article titled 1.5 ton AC solar inverter circuit

From the above tutorial it is now clear that designing a solar inverter is after all not so difficult and could be efficiently implemented if you are equipped with some basic knowledge of electronic concepts such as buck converts, solar panel and inverters.

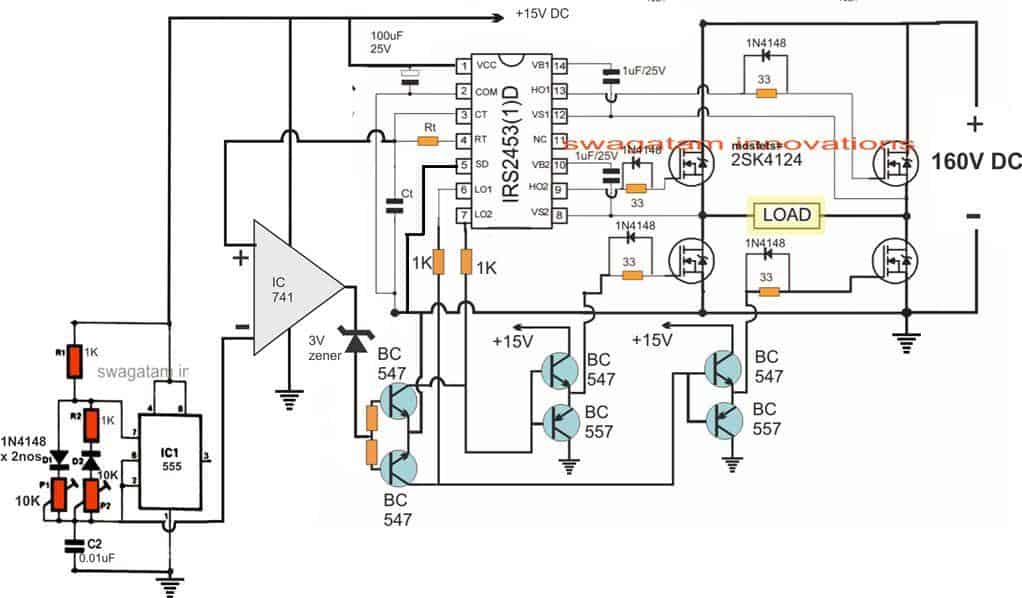

A sinewave version of the above can be seen in the following diagram, which works using an SPWM chopping for the low side mosfets :

Still confused? Do not hesitate to use the comment box for expressing your valuable thoughts.

Remember, a solar inverter is as easy as hooking up any standard inverter to a solar panel, ensuring that the solar panel voltage is only slightly higher than the inverter operating DC specs.

If you want any customized solar inverter circuit of your choice designed by me here, please feel free to put the request through the below comments, I will try to fulfill it as soon as possible.

Conclusion

Designing a solar inverter can be a complex process that involves a good understanding of electronics, power systems, and solar energy. Here are some general steps to consider when designing a solar inverter:

- Determine the load requirements: The first step in designing a solar inverter is to determine the load requirements. This will include the power requirements of the load, as well as the type of load (i.e., resistive, inductive, or capacitive).

- Determine the solar panel specifications: The second step is to determine the specifications of the solar panels that will be used with the inverter. This will include the voltage and current output of the solar panels, as well as their maximum power point (MPP) voltage and current.

- Choose the inverter topology: The next step is to choose the inverter topology that will be used. There are several different types of inverter topologies, including transformer-based and transformerless designs.

- Select the components: Once the inverter topology has been chosen, the next step is to select the components that will be used in the inverter. This will include selecting the power semiconductors (i.e., MOSFETs, IGBTs), capacitors, inductors, and resistors.

- Design the control circuit: The control circuit is an important component of the inverter, as it regulates the voltage and current output of the inverter. The control circuit will include a microcontroller, voltage and current sensors, and a feedback loop.

- Build and test the prototype: Once the design is complete, it is important to build and test a prototype of the inverter to ensure that it meets the specifications and performance requirements.

It is important to note that designing a solar inverter can be a complex process that requires a good understanding of electronics and power systems. It may be helpful to consult with a qualified engineer or to use a pre-designed inverter kit or module.