In one of the previous posts I have explained the making of a greenhouse temperature controller circuit, here we study how the effects may be enhanced through an automatic water valve actuator and humidity controller circuits. The idea was originally requested by Mr. Leandros Komninos

Technical Specifications

Found one on ebay, these are the detail tehy supply:

1 x RS-360SH Pumping motor

Simple gear-type pumping model, usually used for aquarium, DIY model etcs

Diameter: 2.7 cm

Length: 5.2 cm

Out of the water hole diameter: 4 mm

Rated voltage: 7.2V

Suitable for voltage: 3v-12v DC (marked with a red dot that Terminal is positive)

Seems ideal, but what do you think?. Still looking for a valve system, don't know where to begin!?!? i guess miniature butterfly actuators would be overkill for this.

Oh, here's an additional thought for this setup; can there be an additional set of temp/humidity sensors, and another pump setup as a spray. this would keep the humidity inside the greenhouse ideal. This seems like a setup that might be worth you patenting!

The Design

The requested two designs may be understood with the help of the following discussion:

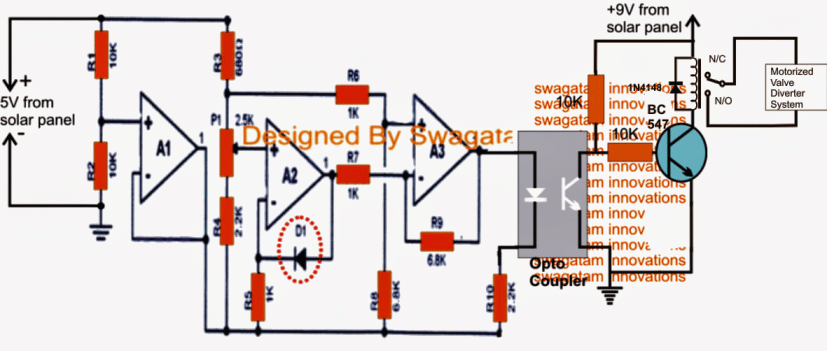

Referring to the first circuit diagram below which is basically wired as a temperature sensor, is enhanced with a relay stage for automatically switching a motorized valve system or actuator which diverts cold water into the greenhouse water supply pipes in an event when the water temperature tends to rise above a predetermined set level.

Temperature Sensor Circuit Diagram

This circuit is quite identical to the one that's explained in one of the previous articles, for a comprehensive study regarding the circuit details, you could refer to the following article:

Greenhouse temperature regulator

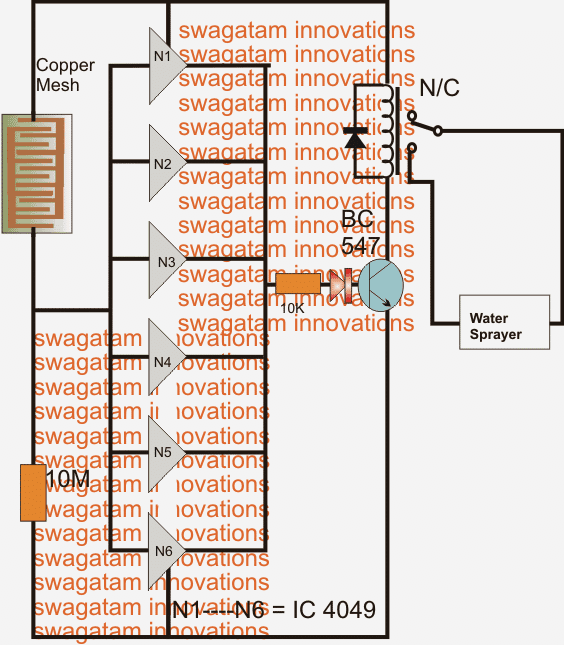

The following design is a simple humidity sensor circuit which could be applied for sensing and controlling greenhouse humidity levels.

As may be seen in the diagram, six NOT gates are connected in parallel for obtaining maximum effectiveness from the devices.

The gates are all positioned as potential difference sensors across their input pins.

The 10M resistor initially holds the inputs to a low logic level since it's connected with the ground supply of the circuit.

The inputs are also terminated to the positive through an appropriately etched PCB to form a closely configured copper mesh layout.

As long as the humidity level is not beyond the undesired threshold, the NOT gates inputs continue to be at a low logic state resulting a high at their outputs which keeps the relay and a connected water sprayer activated.

However, the moment the humidity level tends to cross the set high level it tends to develop a low resistance across the copper mesh PCB forcing the inputs of the NOT gates to become higher in potential until it flips and inverts the individual outputs to logic low, which in turn switches OFF the relay and the water sprayer for the time being.

The 10M resistance may be tweaked for setting-up the desired cut off humidity threshold level.

The LED ON indicates the toggling of the relay and vice versa

Humidity Sensor Circuit