In this article I have explained regarding how to design and make your own customized high current wireless battery charger circuit using wireless power transfer concept.

Introduction

In many of my earlier articles I have comprehensively discussed wireless power transfer, in this article we will go a step ahead and try to learn how to design a high current version of the same which can be applied for any high power wireless transfer operation such as for charging an electric car battery etc.The idea of optimizing a wireless power transfer circuit is quite similar to optimizing an induction heater circuit, wherein both the concepts can be seen utilizing the optimization of their LC tank stage for achieving the desired power output at the highest possible efficiency.

The design can be implemented by utilizing the following basic circuit stages in it:

The Transmitter Circuit will include:

1) An adjustable frequency oscillator.

2) A half bridge or a full bridge circuit (preferably)

3) BJT/Mosfet driver stage.

4) an LC circuit stage

The Receiver circuit stage will include:

1) Only the LC circuit stage.

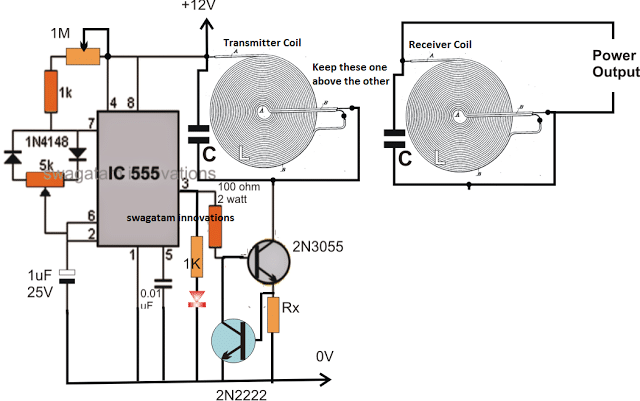

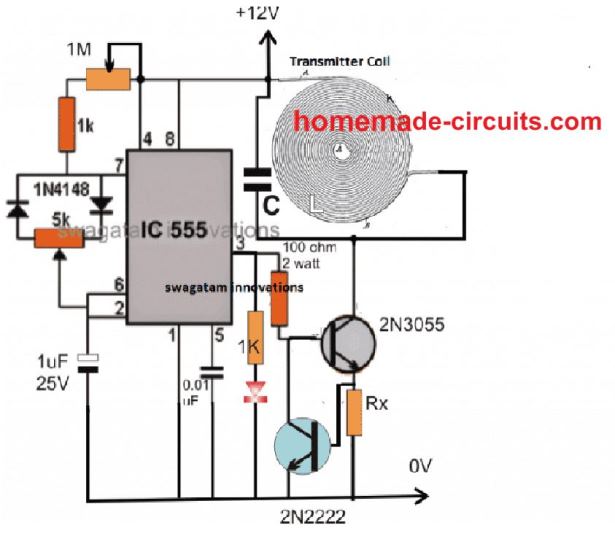

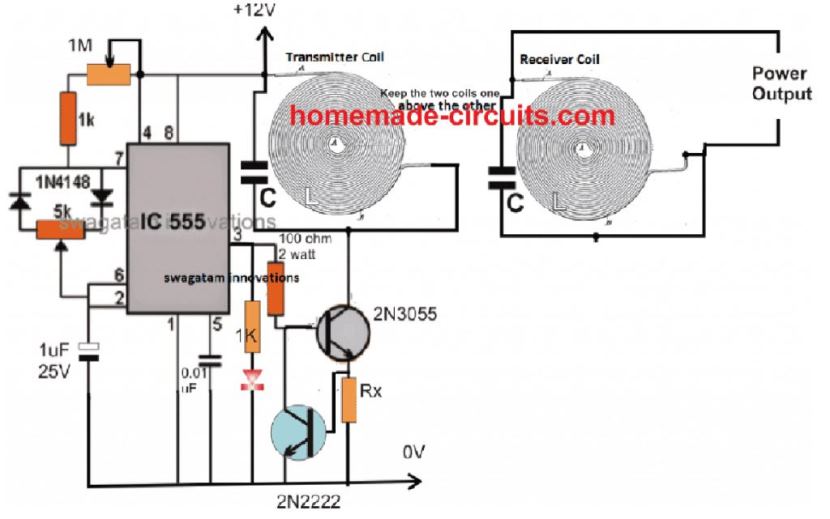

An example circuit for the proposed high current wireless battery charger can be witnessed in the following diagram, for simplicity sake I have eliminated the use of a full bridge or half bridge circuit, rather have incorporated an ordinary IC 555 circuit.

The above design represents the transmitter circuit of the high power wireless battery charger circuit using a IC 555 PWM circuit.

Here the output could be a little inefficient since the conduction process is single sided and not a push pull type.

Still, if this circuit is correctly optimized a decent high current power transfer can be expected from it.

Please remember that the wire inside coil must not be a thick single core wire, rather a bunch of many thin wires. This will allow better absorption of current and therefore higher rate of transfer.

How it Works

The IC 555 is basically configured in its standard PWM mode which can be adjusted using the shown 5K pot, there's another adjustable resistor in the form of 1M pot which can used for optimizing the frequency and the resonance degree of the circuit.

The PWM pot could be used for adjusting the current level while the 1M for peaking the resonance level of the LC tank circuit.

The LC tank circuit can be seen attached with the transistor 2N3055 which powers this LC stage with a frequency corresponding to its base frequency from pin#3 of the IC.

How to Select the LC Components.

Selecting the LC parts optimally can be achieved by following the instructions as furnished in this article which explains how to optimize resonance frequency of an LC tank network.

Basically if you know the frequency value, and either L or C, then the unknown parameter can be easily calculated using the suggested formula or this LC resonance calculator software.

The Receiver Circuit

The coil for the receiver circuit for this high current wireless battery charger is exactly similar to the transmitter coil. Meaning, you can simply use a single continuously running coil from start to end, and add a resonating capacitor across these terminals.

Make sure the LC values are exactly similar to the Tx LC values. The set up can be seen in the following image:

The 2N2222 transistor is introduced to make sure that while adjusting the resonance, the 2N3055 is never subjected to an over current situation. In case this tends to happen the over current develops an equivalent amount of triggering across Rx sufficient to activate the 2N2222, which in turn shorts the 2N3055 base to ground inhibiting it from conducting any further and thus preventing the device from a possible damage.

Rx may be calculated using the following formula:

Rx = 0.6/Max current Limit of the transistor (or the wireless power transfer)

Adding a voltage regulator for charging the battery:

In the above diagram, the output from the receiver should be attached with a voltage regulator circuit such as using an LM338 circuit or an opamp controller circuit for making sure that the output can be safely fed to the intended battery for charging it.

If you have any further queries, please feel free to express them through your comments.

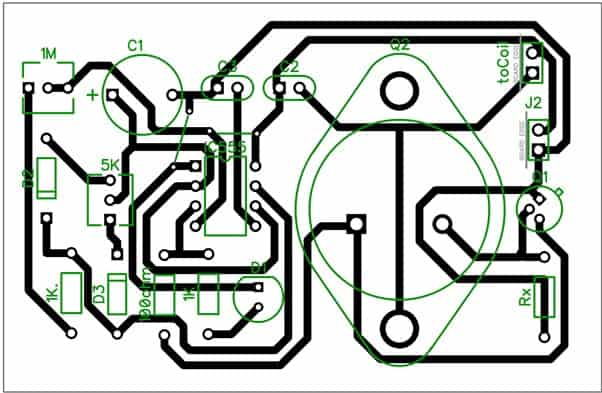

PCB Layout