In this post I have explained how an effective and efficient, yet very cheap, and stabilized bench power supply can be designed by any electronic hobbyist for safely testing all types electronic projects and prototypes.

The main features that a bench power supply must have are:

- Should be built with cheap and easily available components

- Should be flexible with its voltage and current ranges, or simply must include the facility of a variable voltage and variable current outputs.

- Should be over-current and over-load protected.

- Should be easily reparable, in case a problem arises.

- Should be reasonably efficient with its power output.

- Should facilitate easily customization as per a desired specification.

General Description

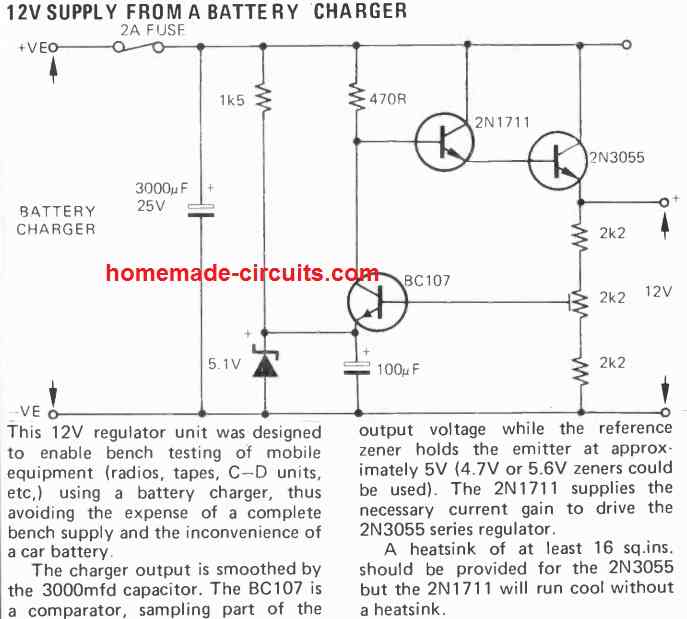

The majority of the power supply designs thus far incorporate a linear series stabilizer. This bench power supply design uses a pass transistor which works like a variable resistor, regulated by a Zener diode.

The series power supply system is the more popular, possibly due to the fact that it is a lot more efficient. Except of some minor loss in the Zener and feed resistor, noticeable loss only happens in the series pass transistor during the period it is supplying current to the load.

However, one disadvantage of the series power supply system is that these do not provide any kind of output load short-circuit.

Meaning, during output fault conditions the pass transistor may allow a large current to flow through it, eventually destroying itself and possibly the connected load also.

That said, adding a short circuit protection to a series pass bench power supply can be quickly implemented through another transistors configured as a current controller stage.

The variable voltage controller is achieved through a simple transistor, potentiometer feedback.

The above two additions enables a series pass power supply to be highly versatile, rugged, cheap, universal, and virtually indestructible.

In the following paragraphs we will briefly learn the designing of the various stages involved in a standard stabilized bench power supply.

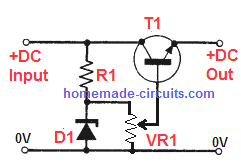

Easiest Transistor Voltage Regulator

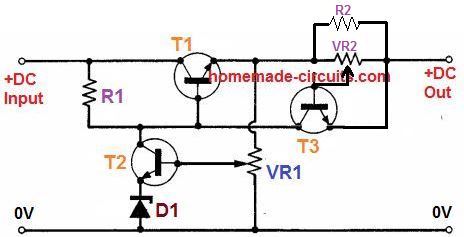

A quick way of getting an adjustable output voltage is to hook up the base of the pass transistor with a potentiometer and Zener diode as shown in the figure below.

In this circuit the T1 is rigged as an emitter-follower BJT, where its base voltage VB decides its emitter side voltage VE. Both VE and VB will precisely correspond with each other, and will be almost equal, deducting its forward drop.

The forward drop voltage of any BJT is typically 0.7 V, which implies that the emitter side voltage will be:

VE = VB - 0.7

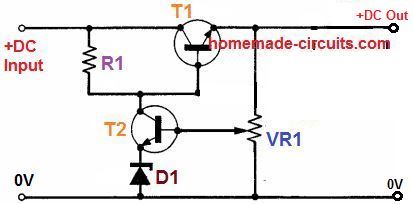

Using a Feedback Loop

Although the above design is easy to build and very cheap, this type of approach doesn't offer great regulation of power at the the lower voltage levels.

This is exactly why a feedback type control is normally employed to get an improved regulation throughout the entire voltage range, as demonstrated in the figure below.

In this configuration, the base voltage of T1, and therefore output voltage, is controlled by the voltage drop across R1, mainly due to the current pulled by T2.

When the slider arm of the pot VR1 is at the ground side extreme end, T2 becomes cut off since now its base becomes grounded, allowing the only only voltage drop across R1 caused by the base current of T1.

In this situation the output voltage at the T1 emitter is going to be almost same as the collector voltage, and can be given as:

VE = Vin - 0.7, here VE is the emitter side voltage of T1, and 0.7 is the standard forward voltage drop value for BJT T1 base/emitter leads.

So if the input supply is 15 V, the output can be expected to be:

VE = 15 - 0.7 = 14.3 V

Now, when the pot VR1 slider arm is moved to the upper positive end, will cause T2 to access the whole emitter side voltage of T1, which will cause T2 to conduct very hard.

This action will directly connect the zener diode D1 with R1. Meaning, now the base voltage VB of the T1 will be simply equal to the zener voltage Vz. So the output will be:

VE = Vz - 0.7

Therefore, if the D1 value is 6 V, the output voltage can be expected to be just:

VE = 6 - 0.7 = 5.3 V, so the zener voltage decides the minimum possible output voltage that could be obtained from this series pass power supply when the pot is rotated at its lowest setting.

Although the above is easy and effective for making a bench power supply, it has a major disadvantage of not being short circuit proof.

That means, if the output terminals of the circuit is accidentally short circuited, or an over load current is applied, the T1 will quickly heat up and burn.

To avoid this situation, this circuit could be a simply upgraded by adding a current control feature as explained in the following section.

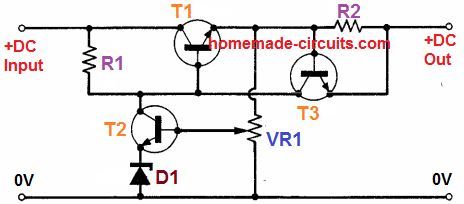

Adding Overload Short Circuit Protection

A simple inclusion of T3 and R2 enables the bench power supply circuit design to be 100% short-circuit proof and current controlled. With this design even an intentional shorting at the output will not cause any harm to the T1.

The working of this stage could be understood as follows:

As soon as the output current tends to go beyond the set safe value, a proportional amount of potential difference across R2 is developed, enough to switch ON transistor T3 hard.

With T3 switched ON causes T1 base to be joined with its emitter line, which instantly disables the T1 conduction, and this situation is maintained until the output short or overload is removed.

In this way T1 is safeguarded from any undesired output situation.

Adding a Variable Current Feature

In the above design, the current sensor resistor R2 can be a fixed value if the output is required to be a constant current output.

However, a good bench power supply is supposed to have a variable range for both voltage and current.

Considering this demand, the current limiter could be made adjustable simply by adding a variable resistor with the base of T3, as shown below:

VR2 divides the voltage drop across R2 and thus allows the T3 to switch ON at a specific desired output current.

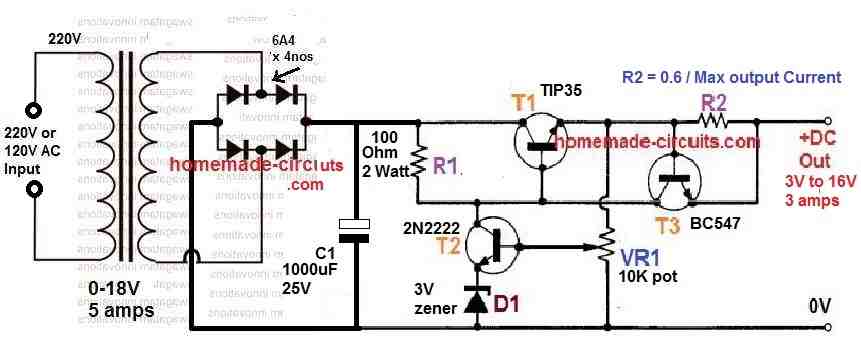

Finalized Design of a Basic Bench Power Supply Circuit

Calculating the Part Values

Let's start with the resistors, R1 can be calculated with the following formula:

R1 = (Vin - MaxVE)hFE / Output Current

Here, since MaxVE = Vin - 0.7

Therefore, we an simplify the first equation as R1 = 0.7hFE / Output Current

VR1 can be a 10 k pot for voltages up to 60 V

Current limiter R2 can be calculated as given below:

R2 = 0.7 / Max Output Current

Max output current should be selected 5 times lower than T1 maximum Id, if T1 is required to work without an heatsink. With a large heatsink installed on T1, the output current can be 3/4th of T1 Id.

VR2 can be simply a 1k pot or preset.

T1 should be selected as per the output current requirement. T1 Id rating should be 5 times more than the required output current, if it is to be operated without a heatsink.

With a large heatsink installed, the T1 Id rating should be at least 1.33 times more than the required output current.

The maximum collector/emitter or VCE for T1 should be ideally twice the value of the maximum output voltage specification.

The value of zener diode D1 can be selected depending on the lowest or the minimum voltage output requirement from the bench power supply.

The T2 rating will depend on the R1 value. Since the voltage at collector of T2 will be always equal to Vin, the VCE of T2 should be higher than the Vin or the input supply.

The Id of T2 should be such it is able to handle the base current of T1, as determined by the value of R1

The same rules apply for T3 also.

In general T2, and T3 can be any small signal general purpose transistor such as BC547 or maybe a 2N2222.

Practical Design

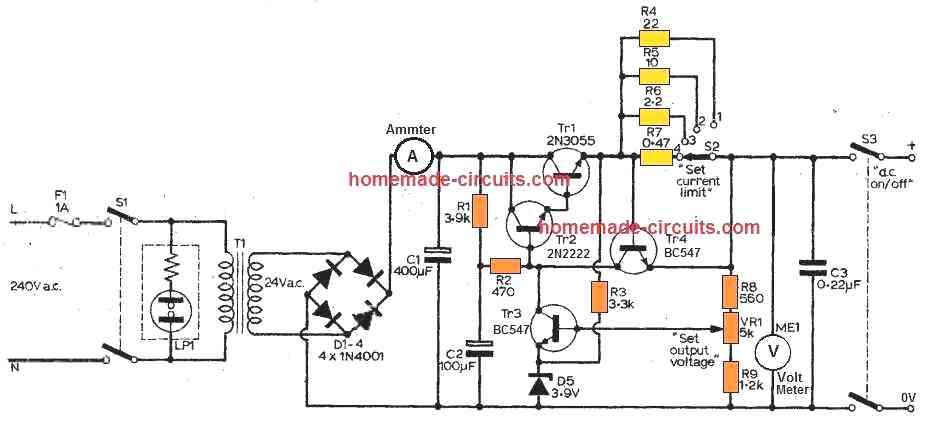

Having understood all the parameters for designing a customized bench power supply, it's time to implement the data in a practical prototype, as shown below:

You may find a few additional components introduced in the design, which are simply for enhancing the regulation capability of the circuit.

C2 is introduced to clean any residual ripple at the T1, T2 bases.

The T2 along with T1 forms a Darlington pair to increase the current gain of the output.

R3 is added to improve the zener diode conduction and therefore to ensure better overall regulation.

R8 and R9 are added to enable the output voltage to be regulated across fixed range, which are not critical.

The R7 sets the maximum current that can accessed at the output, which is:

I = 0.7 / 0.47 = 1.5 amps, and this appears quite low compared to the rating of the 2N3055 transistor. Although this might keep the transistor super cool, it may possible to increase this value up to 8 amps if the 2N3055 is mounted over a large heatsink.

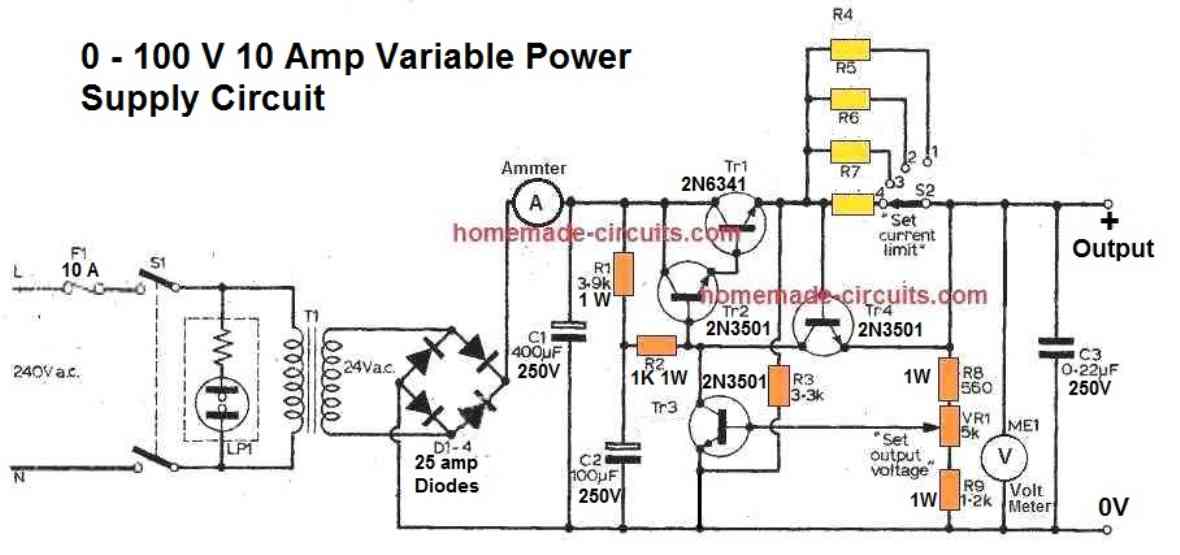

Upgrading to 100 V 10 Amp

The above bench power supply circuit can be upgraded to handle upto 100 V 10 amp as shown in the following diagram. Current can be set using the following formula:

R = 0.7 / Max Current

Decreasing Dissipation to Increase Efficiency

The biggest disadvantage with any series transistor based linear regulator is the high amount transistor dissipation. And this happens when the input/output differential is high.

Meaning, when the voltage is adjusted towards lower output voltage, the transistor has to work hard to control the excess voltage, which is then released as heat from the transistor.

For example if the load is a 3.3 V LED, and input supply to the bench power supply is 15 V, then the output voltage has to be lowered to 3.3 V which is 15 - 3.3 = 11.7 V less. And this difference is converted to heat by the transistor, which could mean a efficiency loss of more than 70%.

However, this problem can be simply solved by using a transformer with tapped voltage output winding.

For example the transformer may have taps of 5 V, 7.5 V, 10 V, 12 V, and so on.

Depending on the load the taps could be selected for feeding the regulator circuit. After this, the voltage adjustment pot of the circuit could be used for further adjusting the output level precisely to the desired value.

This technique would increase the efficiency to a very high level, allowing the heatsink to the transistor to be smaller and compact.

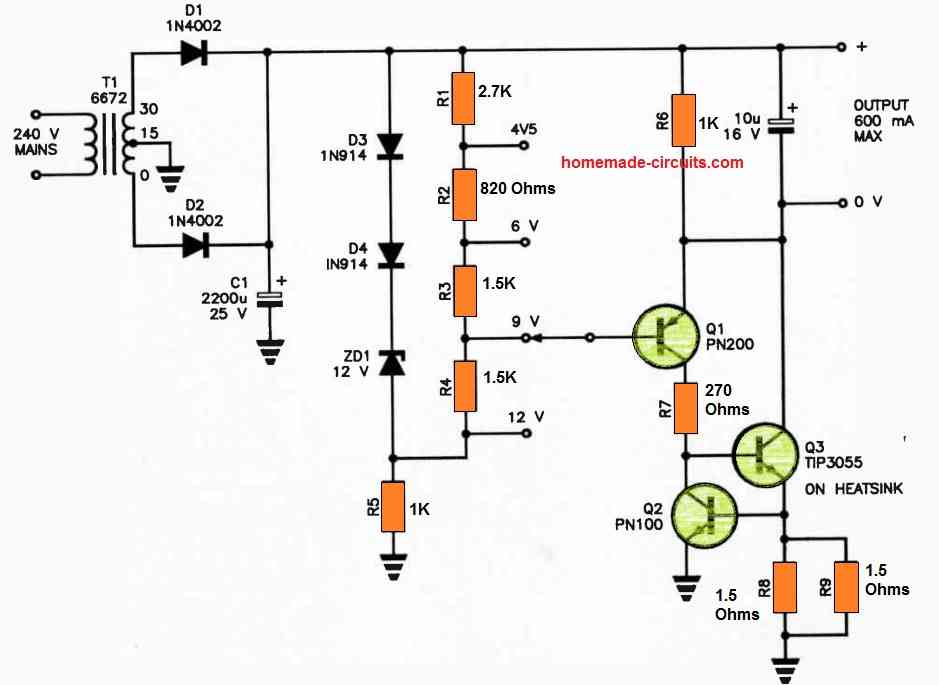

Very Simple Bench Power Supply Circuit with Constant Current Output

This benchtop power supply circuit shown below is a simple and inexpensive option for hobbyists, yet is able to provide a continuously adjustable DC output with a constant current.

All of the components are readily available at electronics retailers. The simple 15V step down transformer is used which allows it to deliver up to one amp of output current.

A full-wave rectifier converts the AC input voltage to unregulated DC. A zener diode and two other diodes provide a regulated reference voltage for the regulator circuit.

Resistors R1 through R4 are connected to the reference voltage to produce output voltages of 4.5, 6, 9, and 12 volts. Resistor R5 provides bias current for the zener diode.

Three transistors, Q1 and Q3, form a conventional series regulator. A 10uF capacitor across the output terminals helps to reduce the AC impedance of the power supply.

Q2 along with the resistors R8 and R9 constitute the current control circuit stage which enables a constant current output.

Resistors R8 and R9 determine the output current limit, or simply the constant current value.

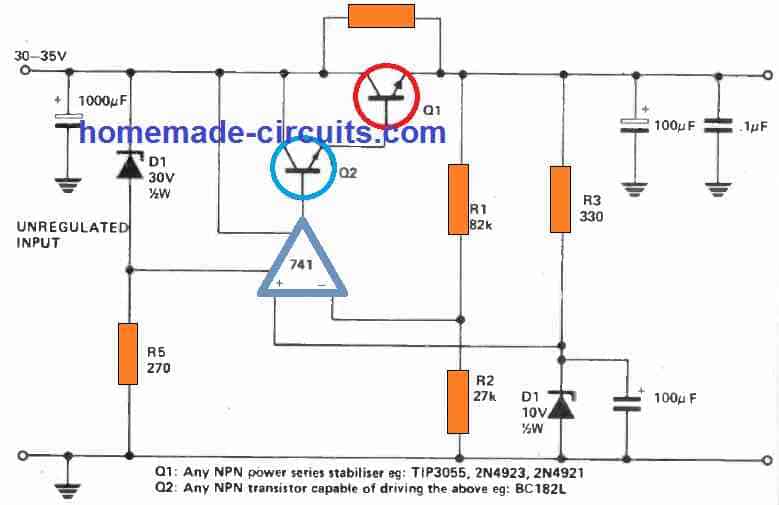

Op Amp Controlled Precision Bench Power Supply

The working procedure of the opamp controlled bench power supply circuit is fairly basic uncomplicated, since regulated power supplies can be simply as particular forms of feedback amplifier.

In this concept, the R1 and R2 generate a refernce sample signal from the output supply, which is by another reference voltage created by D2.

The resulting correction signal is supplied back through the 741 on the series pass transistor Q1.

Observe that the circuit stability has been enhanced by providing the reference source R3 -D2 through the stabilized output rather than from the unstabilised input as is usually done inother bench power supplies.

To ensure that the circuit initiates as soon as switched on, a leakage resistance R4 is placed in parallel with the series pass device.

This means that the feedback loop begins to run as soon as power is switched ON.

Absolutely no regulation is sacrificed because of R4, since it is the general output which is sampled by R1 -R2, therefore, the impact of the ripple current moving through R4 gets adjusted through the feedback.

Making the Output Adjustable

The output may well be made adjustable by changing R1-R2 with a potentiometer, however in its existing layout, the circuit can't be forced to regulate under the zener voltage value of D2.

When uninterrupted adjustment of the output voltage is necessary, the reference source R3-D2 should be furnished through the unregulated input, with accompanying minor lack of stability.

The quantity of power the circuit is able to offer will be limited primarily by the current handling capacity of Q1 and the maximum power capacity of the unregulated supply.

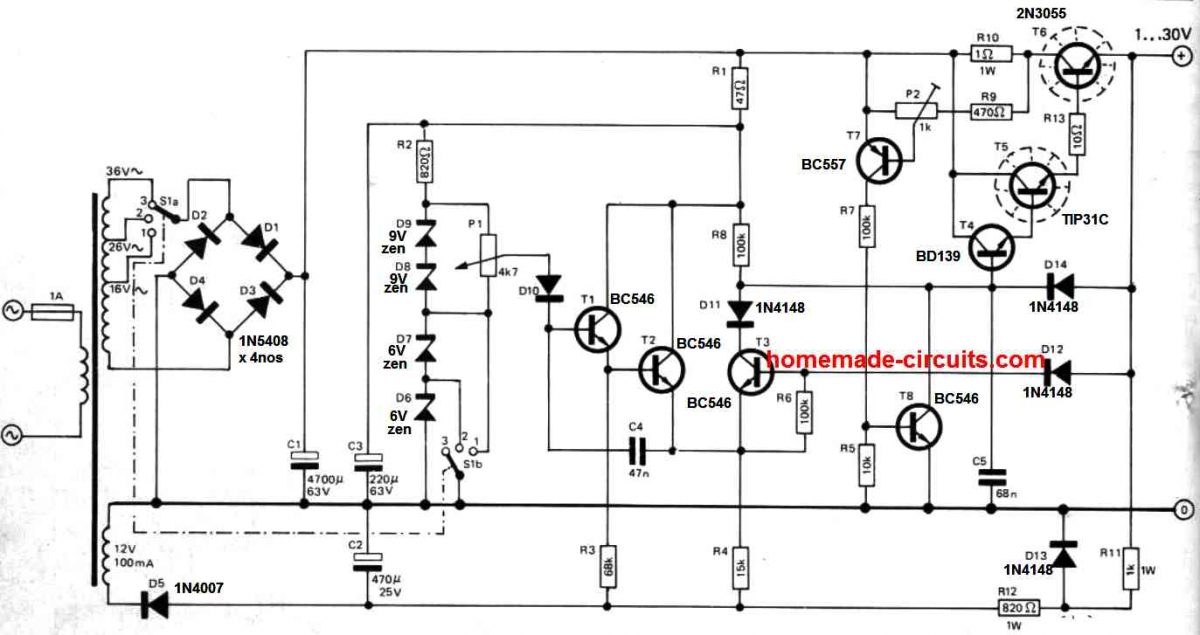

More Elaborate Bench Power Supply Circuit

A regulated bench Power supply are normally a useful gadget for any hobbyists or engineer.

Despite the truth that IC based voltage regulators have become very easily accessible, a circuit only employing ordinary discrete components can be appealing.

In order to save power, and to restrict the dissipation across the series regulator, the entire 0-30 V control range is further divided into 3 scaled-down voltage ranges.

All the 3 ranges matches with a suitable secondary supply voltage (determined by the position of S1a) and a proper reference voltage (determined by S1b).

So that you can get a consistent control of the output voltage to a minimum of0 V, a negative auxiliary supply needs to be added.

In this bench power supply circuit, this is extracted (by means of D5 and C2) via a different 12 V winding over the mains transformer. A different option could be to incorporate an additional separate mains transformer.

The final results tested on the bench prototype are pretty decent: ±35 V mains voltage swing induced just ±25 mV swing of the output voltage, with full load 1 amp load attached to the output. The A.C. ripples of the output (hum) had been lower than 15 mV.

How it Works

The circuit functions in the following manner.

A reference voltage, extracted through the zener diode(s) D6 -D9 and fixed using pot P1, is directed to the transistor T2 base by means of D10 and TI.

T2 and T3 work like a differential amplifier; wherein the base of T3 receives the output voltage by means of DI2. This differential amplifier's output is applied, through D11, on the base of the combined series regulator made up of transistors T4, T5 and T6.

Although the configuration might look a bit complex, it works like a typical regulator circuit; it maintains the output voltage virtually fixed over an extensive range of output currents.

Transistors T7 and T8 along with connected parts form the current limiter stage. As soon as the voltage over R10 gets to a particular value (as fixed by P2) T7 begins conducting.

This, consequently, causes transistor T8 to get biased and starts conducting; which reduces the base drive to transistor T4, and the situation decreases the output voltage hence the output current continues to be inside the predetermined boundary.

When S1 is selected at position 1, that compares to an output range of 0-10 V, setting at 2 allows 10-20 V and adjusting at position 3 provides an output range of 20-30 V. P1 is used for tweaking the range as fixed by S1.

The highest amount of output current can be established using pot P2. This P2 pot could be either pre-programmed to supply a highest output current of 1 A or employed like a variable output current control.