A timer circuit design which could be used for turning the position of the eggs in an incubator between predetermined intervals of time was requested to me by one of the keen readers of this blog, Mr. Eugene.

The requested circuit has been exclusively designed by me and published here,

Circuit Specifications

Let's hear the whole episode:

I'm raising chickens for derby and I have hen that is laying eggs. For the hen to continue laying eggs, I need to incubate the eggs. I have researched incubator designs and parts and I have already assembled a simple one. I have a digital 220V ac thermostat and in order to protect it, it will only have to drive a 220V relay. This one already worked well.

Now I have an additional info that the eggs have to be rotated or moved upside down 3 times a day in order for the eggs to hatch well. I am planning to make a rows of eggs holder chained or built together driven by a motor such as electric fan swing motor. Its strong and moves very slowly and I think its quite enough. This 220v ac motor will be driven by a 6v dc relay. Now I need a relay driver circuit and a timer circuit that wil trigger the relay driver more or less every 8 hours for approximately 3 seconds only.

I may not have enough words to reach 300 but I think my intention is clear enough. But if the blog requires 300 words, I will try to extend my explanation.

Thank yo very much and I hope you can help me.

Eugene"

Designing an Incubator Egg Timer Circuit

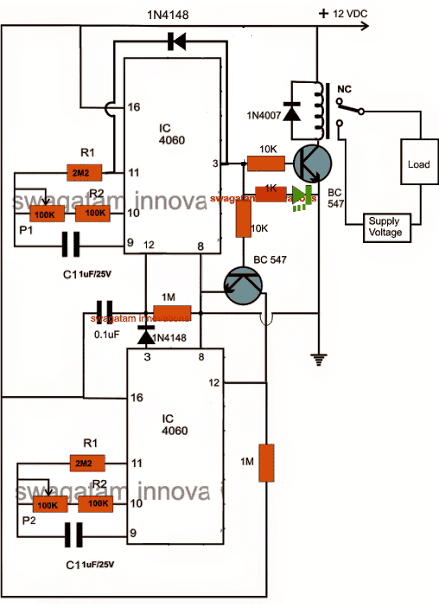

The circuit of the proposed incubator egg timer and optimizer is given below:P1 should be adjusted for the long 8 hour duration and P2 for the short 3 seconds duration.

Circuit simulation:

Looking at the circuit diagram we can see that it consists of two identical IC 4060 stages which are coupled across each other for implementing the proposed actions.

The upper timer stage is intended for producing long time intervals and therefore its output is taken from pin #3, while the lower IC generates smaller time intervals and so its pin #15 is chosen as the output.

When power is switched ON the following things happen with the circuit:

The 0.1uF capacitor resets the upper IC so that it can start counting, during this period its pin #3 is at logic low which keeps the relay driver stage switched OFF, also the lower BC547 is kept disabled, which keeps pin #12 of the lower IC at high logic which in turn renders the lower IC inactive.

After the predetermined period is lapsed, pin #3 of the upper IC goes high, this switches ON the relay driver stage and also the lower IC pin #12 gets reset, this toggles the lower IC into counting mode.

After the predetermined period, pin #15 of the lower IC becomes high, which sends a logic high to the reset pin #12 of the upper IC, resetting it back to its original position......the cycle repeats, and goes on repeating as long as power is available.

The lower section can be upgraded for generating higher time intervals at par with the upper section by replacing pin15 with pin3 as already done in the diagram below.

The relay contacts are wired up to the motor for shuffling the egg orientation.

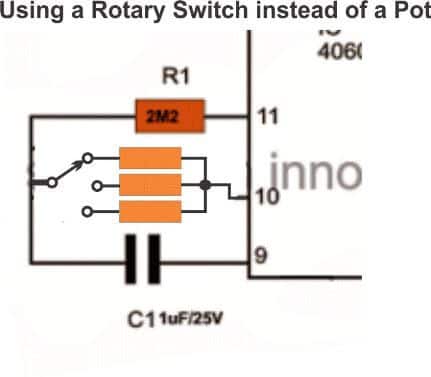

Using Rotary Switch for Adjusting the Time intervals

If you find adjusting the pot difficult and time consuming, you could easily replace them (P1, P2) with rotary switches as shown below. The involved could be also easily calculated with some quick and experimentation:

Hello Sir;

In line with hatched chicks, I would like to build make circular brooder house with an automatic temperature controller. Not using a microprocessor chip is it possible to design a temperature controller which will switch off when the temperature reaches a set high point and turn ON heaters when the temperature is below the set lower values?

Thanks in advance.

Hello Joseph,

You can try the second last circuit from the following article, which uses the IC LM35:

https://www.homemade-circuits.com/how-to-build-simple-electronic/

Hello Mr swag,

This is a good design , but my question is how can I interface a digital display to the circuit to read the predetermined time directly?

Thanks Yabagi, you can use the following circuit, and configure with the relay output of the timer

https://www.homemade-circuits.com/5-digit-frequency-counter-circuit/

the frequency input can be from a 1 second oscillator using IC 555….precision may not be critical

hi sir If possible I’ll try the circuits you shared.. Thanks

Thanks Rudrud, please do it and if possible provide a small video clips to my email.

Sir what caps i will ceramic or mylar caps?,.help me sir thanks

you can use any type of capacitor as long as it is non-polar.

Sir all value of capacitor is 1uf/25v?

Ken, it can be 1uF or you can change them as per your own choice, higher values will give higher time delays proportionately….

Sir the capacitor in ic 2 connecting the no.16 pins to the ground,.what is the value sir?,.its 1uf or 0.1uf?,…thanks sir

you can use 1uF there for better resetting action during power switch ON….you can use polarized capacitor, positive lead will connect with pin#16 line

Sir what is the value of the capacitor in IC 2 between pin16 and 1M,..is it 1uf or 0.1uf…because in the 1st diagram it is 0.1uf and the other diagram is 1uf,…..and i can use 3v dc motor as trial motor?thanks sir

Ken, I have already answered to your question, use 1uF it will give a better resetting action. for a 3V motor you will need a 3V supply across the relay contact wiring.

for the circuit make sure it is above 4.5V

Sir i have ac 220v motor it indicates CCW/CW what its mean sir?..it can turn clockwise and counter clockwise?help sir,.thanks

Hi Ken, there’s a lot of information available online, if you search “CCW/CW motor” you will be able to find the answers quickly….

Sir can i use 12.6v as a supply voltage,.?,…and if i put the supply the red LED starts to light right?,..my circuit is not working pls help,thanks

Ken, yes the red will light up on switch ON, please refer to the articles for all the details:

https://www.homemade-circuits.com/how-to-make-simple-programmable-timer/

you can connect a LED/1K across pin#14 and ground to check the timer response, this LED will start blinking while the specific IC is counting

Sir if i remove the resistor P1 and P2 what should be the initial time interval and time limit of the rotation motor sir?,.thanks

Sir if i remove the resistor P1 and P2,..what should b the initial time interval and the limit rotation of the motor?thanks sir ,..the circuit is working sir,.i just want to know the intial time so i can make a switch interval sir,.thanks sir swag

Please see the video in the following article, it will allow you to judge the approximate delay at pin#3. In the video I used 10K at pin#10 and 0.1uF at pin#9

https://www.homemade-circuits.com/how-to-make-simple-programmable-timer/

Sir i made the circuit and its working,.thanks for the design and the assistance sir,….

I am glad about it Ken, keep up the good work!

Sir when i connect led in pin#14 the blink is to slow sir,.what should i do sir to make the blink fast,..and does the capacitor in pin#9 affects the time interval,..how to compute ur desired time sir,.thanks

Try pin#7. Yes capacitor at pin#9 and resistor at pin#10 together are responsible for time delays or the frequency:

https://www.homemade-circuits.com/how-to-understand-ic-4060-pin-outs/

Sir the push button is for reseting purpose?,..because some time when i turn off the circuit and turn on again,the lower ic continues to count,..the upper ic not reseting properly,..

Ken, which push button are you referring to?

Thank you sir for your wonderful work. Can I get PCB layout of it ?? Sir please both side or back side only ,

Only you can sir because you are the best I am waiting please sir

Glad you liked my work Anjali, you can find the PCB design in the following post:

https://www.homemade-circuits.com/how-to-make-simple-programmable-timer/

Sir which type of rotary switch I use pls rply

You can use single pole multiple contact rotary switch, the number of contacts will depend on the maximum number of time intervals you may prefer to use

Yes, thank you sir 🙂

One more questions sorry 🙂

I think it is good to use p1 rotary because it need time interval and p2 need duration of time so p2 should be a 1pot ?

Sir I just think but you are the inventor and you are the master! What is your idea ??

You are welcome Fuzail, rotary switch can be used for both the timers, because the selected resistors will allow you to get the precise time intervals as required by you. First try a randomly selected resistor and check the ON + OF time interval at pin#3, then you can add more selectable resistors calculated proportionately for getting other time delay options

Hii sir,

My name is Fuzail Kareem first txn for your good and helpful work I really like you website and your work

Sir my question is how can I change both on and off time as according to my need sir it why because egg need to turn daily (circut on time ) 3-5-7 time and also It must be necessary to every egg it turn whole I mean front to back and it take time more than 3 second and depend quantity of egg

Pls reply sir

Hi Fuzail, you can replace P1 and P2 with rotary switches and set the timing as per your preferences, please check out the last updated diagram

Txn for your valuable response

Hello i buld the circuit but i have a problem my led is flashing . please help me. Thanks

Sir Swag , P1 and P2 (100k resistor) is a variable resistor?pls help,.thanks

yes those can be 1M pots or presets

Hi! Sir what Load and Supply voltage i wll use in the circuit?,itry to make the circuit and i dont know what to use,pls help me sir,im newbie,thanks

Hi Ken, load will be your motor for shuffling the eggs, and the supply input will be the voltage as per the motor specs.

Thanks si swag,…sir what direction of the rotation of the motor?is it clockwise or counter clockwise?,..or both clockwise and counter clockwise?,…

Sir swag,.how can i make the 1st turn of motor is clockwise and the 2nd turn is counterclockwise,…alternate sir,..pls help,thanks

Ken,

You can try the following concept for getting a bidirectional motor operation

https://www.homemade-circuits.com/programmable-bidirectional-motor-timer/

Ken, you can try the following concept

https://www.homemade-circuits.com/programmable-bidirectional-motor-timer/

Sir,whats the value of the relay?thanks

relay can be any standard 12V relay

Can you pls make a egg turner and also DC mother speed control with desirable direction and with two direcation

If possible i will try to update the article with these info soon

Can i use 220V AC supply as Supply voltage?,..pls help,.thanks

yes you can if the load is also rated to work with 220V

Hi.

Anybody can supply me this timer. O anybody compleeted this timer. Call me on 84949 15158

Thanx.

I have built this timer many times with 100% success. It is one of my best designs.

Can i have ur cell number. I need 6 sets or atleast 1 for my hatcher.

Sir I need help on how to make Display on this circuit for temperature with LCD display , is it possible with this circuit? Any link or help will be highly appreciated …

Imran, you can use an LM3915 IC for making a bar graph type temperature indicator circuit, but it will need to incorrectly integrated with the tempwerature sensor.

bro you told to me permanent magnet brushed type to this circuit is that motor dc or ac motor and which motor works with this circuit dc motor or ac motor

it's a DC motor,

the above circuit uses a relay, which means you can use any motor, does not matter whether it is a DC or AC, you just need to connect the relay contacts accordingly with the relevant supply input and the motor

DEAR SIR, Can u please adjust the circuit for every 2 hours interval switch on 3 seconds only for my homemade egg turner. I am new here. Please let me know the resisters for UPPER IC (2 hrs interval) also capacity of potential meter to be used. Also let me know which resisters can be used for LOWER IC (3 seconds) and also explain about the capacity of relay. I am going to use 12v 3.7 RPM motor

Dear Michael, It won't be possible for me, because it will need to be done with practical experimentation.

you can do it in the following manner:

in the above given set up you can keep the P1 short circuit so that only R2 becomes the timing component.

Switch ON power and using a stop watch check after how many seconds the green LED lights. Note this down and from this data you can find out the other required timing cycles using the following simple cross multiplication;

P1+R2/R2 = x/Recorded Time, where x is the desired time interval.

for example if you got 10 seconds from the above experiment and the desired interval is 2 hours (720 seconds), then the formula could be solved as:

(P1 + 100)/100 = 720/10

P1 + 100 = 7200

P1 = 7200 – 100 = 6200K

Remember the above calculation is just an example, and the figures are arbitrarily selected.

Why P1= 7200-100=6200k

how it happen sir,..thanks

Thank you very much sir. If any of friends have already built diagram like 2 hrs off and 15 seconds on, please send to my email id vinokmc@yahoo.co.in. Thank u very much

bro can you please send the list of all components for this circuit i mean how many resisters and how many capasiter ect please bro

bro small dout ani limit switches in this circuit sorry for asking ian completely accounts student thats why i am asking doutes thanks in advance

Balu, this is a timer circuit, no limits are included here, you may have to adjust the speed of the motor to match with the selected timing interval of the circuit

ok which motor is best for this circuit bro

it will depend on the load, that is the number of eggs that may be required to be moved by the motor.

a permanent magnet brushed type will do…

hai bro, can u send the pic circuit board i cant understand your picture so please send some pics of buided circuit board and limit switch s pics please thanks in advance

please click on the diagram to enlarge it, you will be able to see all the components and their numbers clearly.

Bro, can I use 1uf/400v polyester type capacitor

yes you can use it

Hello Sir 1uf/63 capacitor is not available in my location.

What to do?

Dinesh, you can use many 0.47uF/50V capacitors in parallel….

sir i am again

cant get 1uf non polar

i just got 474j 450 volt

is it work?? am i use 2 in parallel

Hi Fuzail, yes definitely you can use two of them in parallel, it will work

Hello Sir can I use bc548 and replace c1 47uf/63v ,p1 220 kilo ohm ,R2 470 kilo ohm.please reply me

hello Dinesh,

will do, however P1 and the 1uF parts decide the time length…220K , and 470K are fine, but try using more numbers of 1uF/63 in parallel to get higher delay ranges. it must be non-polar

hello am new in electronics .can someone please provide me with a pcb for this timer

Hello my brother I buy a relay timer FRM01 12v I not how conect my 220volt 4watts engine can show my a diagram Please, I need to turn the egg

with a multimeter in the diode range check which outputs of the relay close or open while the timer is counting or finished counting….with this info you can connect the motor with these contacts accordingly

I have a +5V output in my incubator, the timer circuit should work OK with that, right?

Of course, I need a relay with a 5V coil instead but other than that I don't see any problems.

yes that's correct, either you can use a 5V relay or you can opt for a triac control for the load

I have built it again, i think the upper ic work well, i check with led pin 15 and it blink and i have changed pot with 500k and it work good. But the lower ic become touch sensor. When i touch the output ( NC/NO) relays wired, the led lower ic blinks but when i do not touch it, blinks stop and next on like that, what happen on my circuit, please help sir, i am new on elektronics

the lower IC will not function until the upper IC has finished counting, …..in other words when the lower BC547 is triggered only then the lower IC will start functioning……in other words when pin12 of the IC is held at the ground potential only then it will start counting and functioning.

this is the image sir, please check, maybe something I missed

https://drive.google.com/file/d/0BwFU-bL_-g3deDRxU1QtVGdTYzdvMU1xWEtaZ1VCcVplOGpr/view?usp=sharing

OK, I can see it now, but to trace it correctly from my side would be quite time consuming…so you might have to confirm it yourself with the given diagram…the diagram is cent percent correct.

DEAR SIR, PLEASE SEND SIMPLE DIAGRAM FOR EGG TURNER TIMER CIRCUIT AND THERMOSTAT CIRCUIT FOR CHICK INCUBATOR. I HOPE U WILL DO THE BEST. PLEASE SEND TO ME EMAIL VINOKMC@YAHOO.CO.IN

thanks sir, I almost success to built it, when I connected led across pin 7 via 1 k resistor the led blink fast, and also pin 15 also blink and slowly but the P1 cannot change blink speed, the other hand, the lower IC do not blink. whats going on, I have drown pcb lay out. please check sir, maybe something wrong on the connection that I dont know.

https://drive.google.com/open?id=0BwFU-bL_-g3deDRxU1QtVGdTYzdvMU1xWEtaZ1VCcVplOGpr

Harvest,

the lower IC will function only when the upper IC time period has elapsed and the lower IC is triggered.

your pot may be faulty or not properly selected make sure its value is 1M and its pins are correctly connected

your image is not opening because it's not "shared"

hi sir i use adaptor 12 v 1 a. Nothing diffrence with the firs time, led on and dreary, when i connected led across pin 16 and ground via 1 k resistor, this led on and brightly. When i connected led across pin 15 and ground via 1k resistor nothing happened led still off, would you like to help me this issue,,

Harvest, initially the red LED should be ON brightly, and when the time elapses for the upper IC, red LED should shut off and green LED should illuminate….if connected at pin16 or pin 15 the LED should flash

I think something's not right with your connections or the circuit.

I use 12 volt dc transformerless power supply, when I first operated it, the red led is on but its dreary i think because its current input low, after that i have been waiting long and nothing happened, the red led still on. Whats going on sir? I use 2M for R1

check with a 12V AC/DC adapter for confirming the circuit operations, and anyway a transformeless power supply might not work, it could produce wrong results and might not be capable of the driving the relay….

2M is fine for R1

C1 must be non-polar

Hi sir can i use 12 V transformerless adaptor to be the power supply to this circuit? I have made the adaptor, but im not sure about amp issue, please help,,

Regards

Hi Harvest, the current is not important, but make sure the voltage is strictly within 15V, then it can be safe to use.

Hallo sir,

Im having a prob, at first i made the circuit without led and keep it for aomedays and it was working very good, after somedays i try to add the led but when i power it on relay activates with red led, but when i disconnect the red led the device works good again, what could be tje problem sir? Thanka

hello riya,

try a higher value series resistor with the red LED, use a 10K or 15K resistor and check the response.

Dear sir

Here how i built ur circuit, at first i built the upper ic option and when i power on it was working 100 percent ok, after that i attach the liwer ic option nut after that i connect a led across negative and upper ic pin 7, the led blinks as well but nothing happen with relay or liwer ic ,i added abrand new ic for lower portion, but still works nothing, i waited for long long time but result is same,, is the problem with 4148 diod? Or how can i solve it ? My lower ic ppt is 10k and r2 is 10k where upper on is 100ksl s, thanks.

Dear Riya, you must do exactly as given in the diagram…the resistors should be 100k for the pot and 2M2 for R1….the diodes are OK and must be included…connect LEDs in series with the transistor bases, that is in between base and the 10K resistor of both BC547s….the LED will indicate when and how the transistors are conducting in sequence or if there is any mistake in the IC function..

Hi sir,

Im a new hobbiest, i was looking for a timer for long and i found it in ur blog, but after i made it im having some common probs, that is when i power it up relay activates and red led on, after some time grenn led turns on but red does not fully off ,it deems but keeps on and no change to relay, im using 10k for R2 and 10 k pot for p1 for both ic, my ics ar new and good quality, i made it several time bt problem is always same, and there is no probs wit any resistor,, sir pleaae tell me what can i do?

Hi Riya,

Your circuit may not be correctly assembled, because on power switch ON the relay should not activate. The relay will activate only after the upper IC time has elapsed, and deactivate when the lower IC time has elapsed.

something is wrong in your circuit, may be the transistors are not connected correctly.

On powering the REd LED will be ON, never both.

Hi bro,

its tanvir again, ur great device i made last time was working so good for long but suddenly i see its wrkin wrng, whn i power it up relay activates, and relay transistor bc547 gets extreemly heated. I changed the trans i changed the 10k resis, even changed the 4060 upper ic, but it still hving the same problem, i tried a lot to solve the probs bt couldnt do anything, so can u please help me to solve it? Thanks

Hi Bro,unless the input voltage is increased above 18V or there's some short circuit in the circuit, it's unlikely to become hot or malfunction, or may be the ICs you have used are not of good quality.

Try Using a 12V AC/DC SMPS adapter instead of transformer.

Dear bro,

I made the display driver its working great,, and I'm so happy for it, but bro is it possible at a display witch will show the set time when I'll turn the pots? Thanks

Dear bro, which circuit are you referring to? i can't remember, please comment under the same article..

The circuit was " rel="nofollow ugc"> but my requirement was like when I'll turn the pots, led display will show the times like if set the timer for 4hours and relay for 5 mints these times will appear on the led display… is it possible my brother??

but my requirement was like when I'll turn the pots, led display will show the times like if set the timer for 4hours and relay for 5 mints these times will appear on the led display… is it possible my brother??

It looks difficult with discrete components, sorry bro not possible because display circuits are not easy to design using ordinary components.

ic, its for back EMFs, thank you very swagatam!

Thank you very much Swagatam! IT WORKS! can I remove P1 and replace R2 with my desired resistor value to get my desired timing? Im a programmer swagatam and no background in electonics, thank you very much for guiding me,.. 🙂 what is the use of 1N4007 diode in relay? if i have multiple relay do i need to put diode? can i add fuse or any safety features?

my next project is your Solar Battery Charger, moving to the next level hahaha,..

You are welcome Unknown! yes P1 may be replaced with a suitable resistor for enabling the intended fixed oscillation periods

The 1N4007 will protect the driver transistor from relay coil back EMFs, for multiple relays in parallel a single 1N4007 would be sufficient, individual diodes may not be required. However the transistor may need an upgrade if the relay count is over 2. You can try a 2N2222 or a 8050 in place of the shown BC547.

A fuse is not crucial and may not be required for such low voltage DC operations…

wish you all the best for your next project…keep it up:)

i buy new of components 🙂

what if i only want 2 hour On and 2 hours Off? i will remove the Pin #3 and 1N4148, Pin #8, Pin #12, 1M, Pin #16, and BC547 and it base resistor?

for equal time durations, you can completely eliminate the lower IC stage along with the lower BC547…not the upper BC547 stage…

The 1N4148 will also need to be removed for obtaining a sustained ON/OFF response from the IC.

hi swagatam, i tried to build the circuit, when the power applied the relay activate, the red LED illuminate, the green LED off, On pin #7 I connected 1k resistor and LED to the ground on both IC`s, they are both blinking, after 30 mins the red LED Off and the green LED On 30 seconds, but noting's happen on my Relay, after 30 seconds, the green LED Off the red LED On, but the LED on upper IC pin #7 is not blinking, the lower IC still blinking.

I used 104 cap ceramic type and 1uf/50v cap non polar similar to this -> us.100y.com.tw/product_jpg_original/A011025.jpg, is their something's wrong with my circuit?

Hi unknown, when power is applied the relay should NOT activate….may be the circuit is getting latched at the onset itself….try increasing the 0.1uF at pin12 of the upper IC to 0.22uF or higher and check the response.

I rebuild the circuit, when power is applied, RED On, Green Off, pin #7 Blinking, Relay was not activated, after 30 mins RED Off, Green On, pin #7 stop blinking, but still the Relay was not activated,. i replace all my caps 104, 105 to Mylar type capacitor

It indicates that the relay transistor may be faulty or not connected correctly or may be the base 10K ersistor is faulty.

Hi i made this circuit but i used 1uf electrolite caopacitor but it not works? because it should be NP? when i apply power relay activate? is it activate or not?

Hi, even with a electrolytic capacitor the relay should NOT activate on power switch ON, there could be some other fault in your circuit.

Dear sir, I made the circuit and I'm so happy that my circuit work fine more than I expected…I replaced the pots with 1megs and in order to check the blink rates of both the ics I used two leds on both 7 pins of the ics with 1k resister,

And to my dear friend who has commented on this circuit. Plzz take a bit of time to carefully study the diagram and make it… if you do exactly do as said believe me it works 100%

And once again thank you so much sir 😀

That's great Srishan, congrats to you, I appreciate your hard work, and dedication.

Thank you sir…. 😀

Sir I did the circuit but I only need 20 mins on the upper ic… hw can I get it done? And I couldn't find 1uf/25v caps bt I only got 1uf/1000v non polor. Will this make a problem? And does the 0.1uf cap has a voltage rating?

Srishan,

1uF/1000v will also work, use a 1M pot for the upper P1 and set it to get the required timing by some trial and error.

0.1uF can be a 50V disc capacitor.

you right sir i just made an error in wiring the components. i now have to tell you that the circuit is working properly now it's great. i followed your instruction and replaced the upper pots with 1m pots and connected the lower 1N4148 diode to pin 6. now i have 1 hour off and 15 seconds on. now i'd like to increase the upper timer to be 3 hours. i like your circuit thank you very much sir.

that's great Rood, you can increase the upper IC timing by connecting more number of capacitors in parallel with C1, all should be strictly non-polar type.

hi sir could you please guide me to solve my little problem? i have tested the circuit on project board and it worked but i couldn't set the time interval to be different, i upgraded the lower caps and resistor to be higher but it wasn't changing the time interval. the relay was only on about 3 minutes and then of about 3 minutes again. i need 20 seconds on and 2-3 hours off. thanks in advance

Hi rood, something's not right in your circuit for sure.

connect an LED with a series 1k resistor across pin7 and ground of the lower 4060 IC. (cathode to ground)

As soon as the red led shuts off this LED should start flashing indicating that the lower stage has been activated.

If you don't see this response could mean an incorrect wiring or faulty components.

dear sir, led blink or not if the circuit in operation

no blink, only light

dear sir mean led willl light on when 12v switch on and green led will on when motor turn on,rite?

yes that's right.

Hi sir..can I use this.circuit for a hydroponic irrigation system? All I want to do is to run a mini water pump of 12v every 3 hours for 20 mins….. will this circuit do the needful???

Thank you

Hi Srishan,

yes it can be used and will work perfectly, just make sure the relay contacts are rated according to the load amps.

Thank you so much sir…..:D

dear sir what function.of led in circuit. i made this circuit unfortunely the led not lighting when i turn on the power. can u explain. thanks

dear Rizsha,

red indicates upper timer is counting, green indicates the lower is counting.

if none of them are lighting means something's wrong with your circuit.

thanks bro, it happened as i told u before, that i am totally new in this site,,, and i appreciate ur comments ,, as because u are now my honorable teacher.. Thanks

you are welcome bro, I'll try my best to help you out in the field.

and i want to make it digital,, so can u pls help me out ? can u pls draw this device's diagram with a seven segment led or lcd display?

presently don't think about it bro:) when you are not able to make such a simple circuit which is shown above, how would you be able to make a complex digital circuit integration with the above.

dear bro,

thanks for the suggestions, but can u pls show the diagram of 0.1 uf caps connected with the ic pins… or witch number pins will be connected with the cap? and unfortunately i couldn't find any 25v caps here, i'm using higher volts caps, will it harm the device or its activity ? Thanks

bro, connect it directly with the pins16 and pin8 of the ICs…………it surprises me how you are not able to find the supply pins of the IC which are clearly shown in the diagram and which are already connected in your prototype??? higher voltage caps will be fine…no issues.

and bro .. how to supply to this device perfect 12 volt by connecting direct to 220dc volt without transformer… Thanks

bro you will 12V ac/DC adapter for this….what were you using for so long, a battery??

ok bro i'll do it,, now pls give me some safety tips of this device and should i connect any capacitor with the motor for its safety and perfect output…

you can connect any electrolytic capacitor parallel to the motor wires

brother , how to set a nob with the variable resistors and how to measure the interval periods of this device , coz its really tough to wait for long to measure the times of the divice.. 🙂

this you will have to do with some trial and error, make a dial behind the pot knob and mark the minimum, center, and maximum delays obtained across the entire dial radius, once this are fixed the intermediate delays can be marked simply by graduating the dial linearly.

Dear brother ,

i connected the led with pin 5 maybe that was the problem now i connected the led with pin 15 and the motor is working properly..now give me some safety instruction for the device and should i connect any capacitor with the motor's pins? coz i saw it in a remote controlled toy car. and is it possible to add variable resistor instead of 100 k resistors so that we can change the resistance from 10 to 100 k when we need to ? if so wht power of resistor should we use and how to connect it ? thanks … 🙂

Dear brother you can connect a 100uF/25V capacitor parallel with the motor wires, and also a 0.1uF directly across the IC supply pins, a pot can be used for setting the time intervals as shown in the diagram.

One more thing i forgot to say i build the previous one not this one… will it be of with it ?

the diode across pin3/pin11 in the above circuit is crucial, it must be included.

Hallo brother,

It seems that i'm such an unlucky person for this device, coz i made it but it's not working, at first i made it and connect it with power and both of the led and relay turns on and doesn't response with pots,

brother i know there must be a connection problem but the thing is where the connection problem can be if u pls mention some of the miss connections or problems for this troubles i can check it and sort it out… pls brother mention some problems witch could be with this. and is the 4060 ic are sensitive.? should i forget to built it bro?… 🙂

hello bro,

i think you should rebuild it and this time make and test the stages separately.

First build the upper stage and check it's response and then go for the lower stage.

Both the stages are actually identical, simply cascaded to work in tandem.

The lines connected with the earth symbol must join with the negative of the supply.

The positive supply must not exceed 15V.

No, 4060 is not at all sensitive or vulnerable, unless connected wrongly.

Hey brother, its tanvir again , u know wht? i was so frustrated that i couldn't build it, but last night i tried once to build it and and just for interest i connect a led to pin 7 of upper ic via 1k resistor to negative point and i see it is blinking i got excited and keep wiating wht happens and after sometime i see the relay activates… but now there is a problem ,, when i connect a motor with the relay than power the device than the relay activate and turns off instantly …. but when is the motor disconnected the device works properly .. wht could be the problem ? pls mention the problem with details solution so that i can sort it out… thanks brother… 🙂 i am using 400 ohms SPDT relay .. but wht is the correct relay should be??? pls elaborate..

congrats bro, keep it up.

is you motor dropping the supply voltage while switching ON? in that case you will need to use a higher amp supply input.

you can also try putting a 220uF/25V or bigger capacitor parallel to the motor wires and check the response.

i do believe in ur circuit but don't know why i dont have confidence on my parts so that i sent some pics of my parts to ur "homemadecircuits@gmail.com" this e-mail address, did u get it if so then pls reply me that those parts are correct, so I'll have confidence again to rebuild it … , I'm using 400 ohms SPDT relay, is this correct ? … thanks bro .. 🙂

Bro, i have checked your email….all the parts are OK.

I have updated the above diagram with some modifications please do as per the new diagram, i am sure you'll succeed.

dear sir,

according to the description, its told like, pin 15 of lower ic should be used for attaining 3 secs interval.. but when i made a close look of the diagram, no connection are there in lower ic's #15.

how can be this justified..???

dear Arshad, I'll make the necessary corrections soon….pin15 was later replaced by pin3 so that the lower section could also become capable of generating larger time intervals, at par with the upper section.

Thanks ya..

Dear Swagatam,

Thanks for your reply.I would like to know, what changes i need to make in the above timer circuit to get the relay to be switched ON in one hour interval and cut off after 10-15 seconds.

Regards,

Liju

Dear Liju,

you will have to do it with some trial and error.

You can do it by initially replacing R2, P1 with a 33k fixed resistor and see what time delay it produces, if it gives say a 50 seconds delay would mean that a 66k would produce 100 seconds delay and so on……the response would be very linear.

Hi bro,

its tanvir again, i collected some 1 uF and .1 uF non poller caps but there volt value is different and still the circuit is not working properly, i am sending capacitor's pics and 100 K verriable resistors and its connected pins picture also to ur "homemadecircuits@gmail.com" e-mail add,

pls see it and tell me that are these correct components? Now the main thing is i build the circuit and when i'm connecting it with power the 400 ohms SPDT relay sounds energize and keeps ticking after3 seconds for 1.20 minuets then it stops ticking and restart ticking after 1.20 minuets again and it continues, so what the hell is happening and what is wrong i've done? and what is the fault and solution pls elaborate details with pics my dear brother because i cant do anything until i make this device, Thanks bro… 🙂

Hi bro, something could be terribly wrong with the connections or the parts, because the circuit should start working correctly as soon as it's switched ON…I have tested it.

try 1M pot in place of 100k, this will provide a wider range of time selection.

please refer to the following post, it has the same design but with little modifications, could help you troubleshoot the issue.

https://www.homemade-circuits.com/2012/04/how-to-make-simple-programmable-timer.html

Dear Swagatam,

Is it possible to identify the switching time interval of the relay by seeing the the blinking rate of the LED's connected across pin 15 and ground if both the ics. i have used 1u 63v capacitor is there any change in the time interval if the volt rating of the capacitor increases.

Regards,

Liju

Dear Liju,

yes surely that's possible…..all the outputs switch at a particular pin order sequence where pin3 produces the slowest frequency and pin7 the highest….the order increments at the rate of 2x.

you can refer to the following post for more info on this:

https://www.homemade-circuits.com/2011/12/how-to-understand-ic-4060-pin-outs.html

Dear bro thanks a lot for the circuit of humidity controller,, I'll make it but I'm so disappointed that i couldn't collect caps 1uF/25volt non polar or .47 uF non polar so that i couldn't make the egg turner circuit… and by the way, my name is Tanvir… 🙂 Thanks

Dear Tanvir, no issues you can other values also for the capacitor, it should be non-polar that's all….for increasing time delays you can increase P2/R2 values to any desired higher levels.

taholeto ami lucky akjon expert vi pelam obossoi onek kichu sikhte parbo…isn't it?… 🙂

surely Mr.green, feel free share your thoughts here…. by the way I have published the humidity controller circuit you requested for, you can see it here:

https://www.homemade-circuits.com/2014/03/programmable-humidity-controller-circuit.html

Dear bro… I'm a completely new hobbyist for electrical projects…. and I'm gonna make an incubator for my pigeons and ur circuit of auto egg turner is just awsm…. but as because i'm so new here i got the positive power connection but witch is the negative power connection pls mention it for me… and i completed this circuit on a breed board but when i connect with 12volts with positive and earth connection my lower ic gets hot and the heat keeps increasing …. so pls tell me why this is happening witch will be so great full to you…Thanks, Tanvir

Dear Bro, with reference to the following diagram, the line which is connected with pin4 of the IC is the negative line and must be connected with the negative of the 12V supply.

The IC should not become hot….there could be some major fault in your circuit connections, please check it properly.

https://www.homemade-circuits.com/2011/12/how-to-build-simple-electronic.html

Hallow bro I'm so grateful to u for ur reply its now working well.. 🙂 and now i need to know also about egg turner circuit, witch one is the negative port to connect with power ? is these 4060 ics are cmos or another ?unluckily in this circuit my lower 4060 ic is also getting hot and the heat keeps increasing, wht could be the problem? and what is the procedure to make caps parallel? if u pls explain I'll be grateful, and i am making an incubator by ur circuit for my pigeon eggs, for wht humidity is so important, so can u pls provide us a programmable humidistat or hugrosta's easy and simple circuit diagram witch can produce humidity to fixed level in incubator chamber by an watering source? coz it will make the incubator perfect and complete. Thanks a lot… 😀

That's great Bro!

In the above programmable timer circuit, the line which shows an "earth" sign is the negative line.

Yes, the IC4060 is a CMOS IC.

The IC will become hot under two conditions, if the supply voltage goes above 16V or/and if its outputs are shorted, so you would want to check for those….

I will surely post a simple programmable humidity controller soon in this blog and let you know.

…….caps can be made parallel simply by joining their leads together…..for example you can see the following diagram which shows caps connected in parallel:

https://www.homemade-circuits.com/2012/08/high-current-transformerless-power.html

Thats just great bro…:) I'll be waiting for Ur programmable humidity controller eagerly witch will make my incubator completed as early as u give me the circuit and pls draw the circuit with details of ports, connections and component's picture so that we as a new comer can understand that easily and enjoy Ur help ,, I'll checkout the fault and of timer circuit and let u know… 🙂 Thank u so much brother,, R U Bengali ?… 🙂

It's my pleasure bro! I'll try to post it soon with all the necessary details, yes I'm bengali.

Hii sir… what amp rate should I supply this circuit??

Hi Srishan, use a regulated 12V power supply, Amp rating is not crucial but it should not be less than 100mA

Awesome….thank you sir…..

And I made the incubator temperature circuit and it works perfect… Thank you for it 😀

you are welcome Srishan.

Done, It's published here:

https://www.homemade-circuits.com/2013/09/simple-electronic-load-controller-elc.html

It may take a little time, but you will surely get it.

Hi Aponso,

I'll try to design a simple circuit and let you know soon.

Hi Sam,

Are you looking for the incubator thermostat circuit?

Here it is:

https://www.homemade-circuits.com/2011/12/how-to-build-simple-electronic.html

Dear Chandana,

Please provide information about your requirement specifications, I'll try to work it out accordingly.

Hi Chandadna,

The timing can be extended by increasing the values of the Pots and C1s…..you can try 1M pot instead of 100k and put a couple of more 1uF caps parallel to the existing ones, this will provide you with a higher timing range.