The circuit discussed in this article is of a non-contact mains AC field detector which displays the presence of a mains AC field from a distance of more an 6 inches.

Locating Fault in AC Lines without Physical Contact

The circuit can be used for locating faults in house wiring without the need of making physical contact with the inner conductor of the wire and becomes useful in locating the breaks in a wire by pin pointing the area where the AC mains may be blocked due to a breakage.

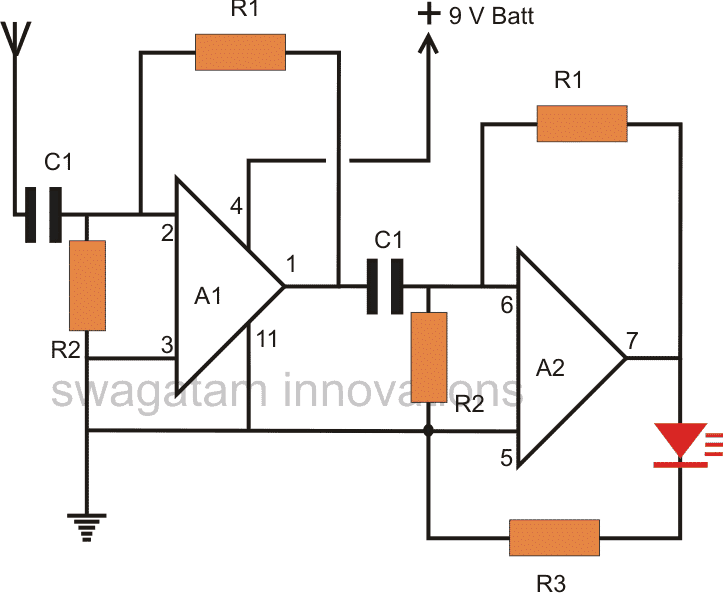

The circuit is basically high gain non inverting amplifier which is configured using a few opamps and a few other inexpensive passive electronic components.

Just a couple of opamps have been incorporated here from the IC 324 for the required operations.

Design Description

Looking at the figure we notice the following things:

The non-inverting input of the IC is grounded making the sensitivity of the configuration to the maximum.

Similarly a feed back loop created by connecting the output of the opamps to the inverting input helps to increase the gain of the set up many folds.

The input is applied to the inverting input 2 of the IC through a blocking capacitor.

The signals entering via the antenna is quickly picked up by the opamp inverting input and sent to the

preceding circuit for the required processing and amplification.

It may be interesting to note that the sensitivity of the design can be simply varied by changing the value of the feedback resistor R1, for maximum sensiticity this resistor can be omitted.

However this can make the circuit a bit unstable and might provide false results.

Second Series opamp Amplifier Function

The next stage includes another identical amplifier which is just the repetition of the previous input stage.

This stage has been included in order to make the response of the circuit instant and so that the circuit is able to pick even the slightest of RF or the AC field within a certain range.

In case the circuit is intended to be used for detecting mains phase only at touching proximity, the sensitivity may be reduced to the required levels or the second stage may be excluded from the design.

The LED connected at the output is used for displaying the presence of the AC field; an illuminated LED identifies the presence of the field while no light from it provides the opposite conclusion.

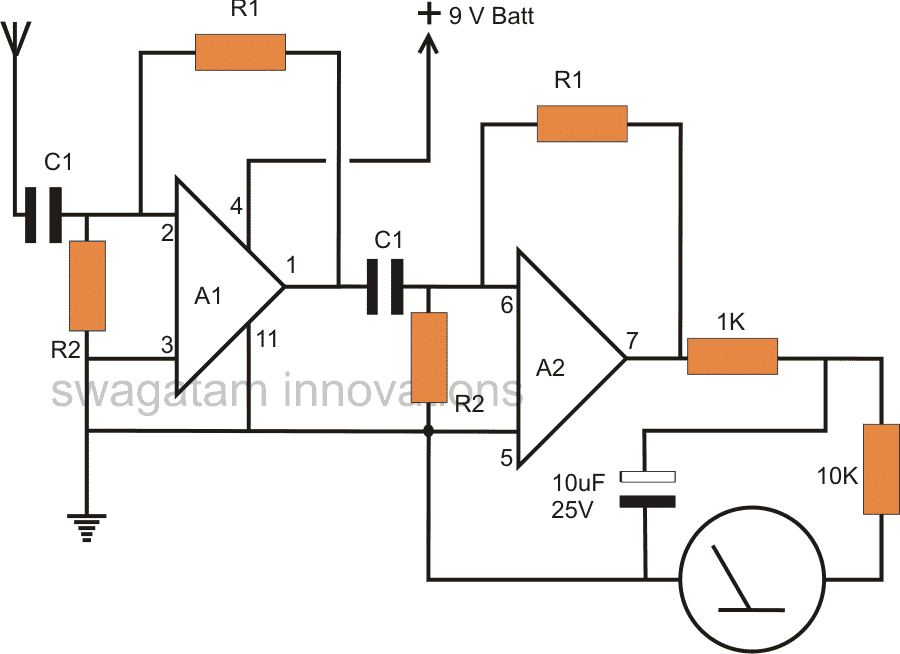

By connecting a 1V FSD moving coil meter at the output, the device can be used to detect and measure the average strength of the AC mains present in that particular vicinity.

Parts List

- R1 = 2M2,

- R2 = 100K,

- R3 = 1K,

- C1 = 0.01uF

- A1, A2 = IC 324

Video Clip:

Feedback from one of the avid followers of this website:

Am a civil engineer by profession based in Bangalore. Am in the construction industry for the last 20 yrs, have a manufacturing unit for modular kitchens.

Here is my requirement to automate the dust collector on or off for three different CNC based machines.

The company does not allow me to physically tap into any electrical but allows me to use a non contact voltage detector.

So I need to process the output of the non-contact voltage detector through IC LM324 and trigger a 12v relay which will switch the dust collector on or off.

The dust collector load is 7.5 hp 3 phase.

I would like to sense the voltage of the conveyor motor of the machine which is 3 phase Ac, 50 htz, 4amp. When this conveyor motor comes alive I would like the dust collector to come on and vice versa.

I have attached the photo of the motor and the specifications in my next mail. This motor has a MPCB which has a 24v control voltage triggering the mpcb. I intend to have a MPCB for my dust collector motor as well.

Kindly let me know if you need further specifications/requirements for the same.

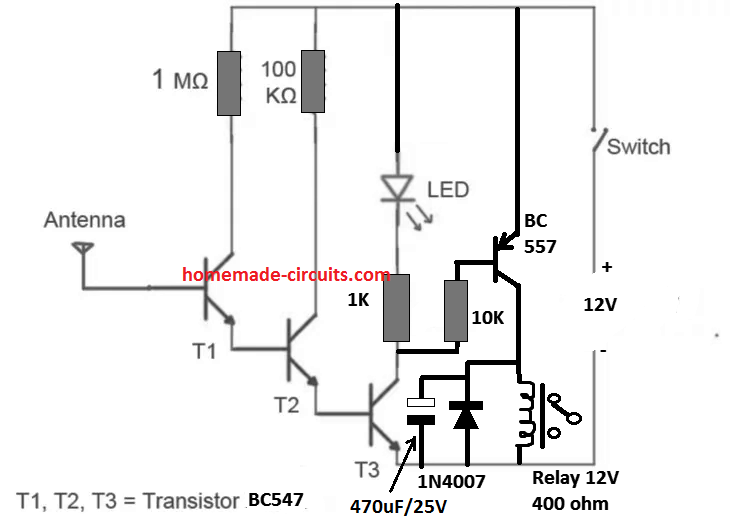

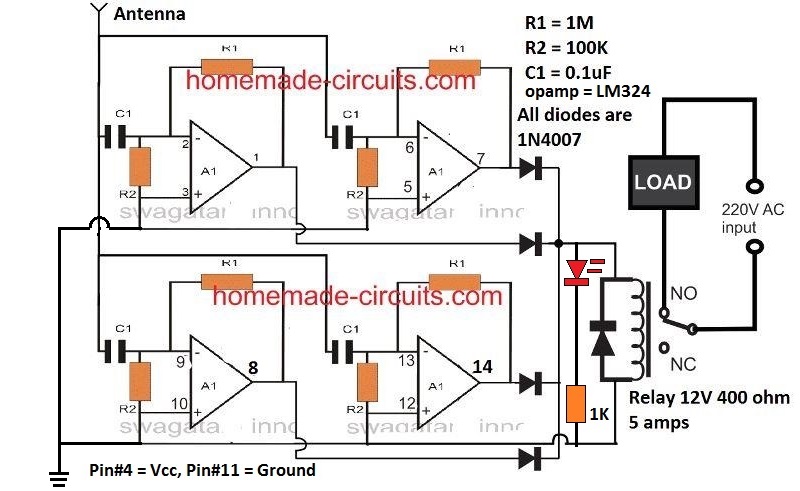

Circuit Diagram

The complete circuit for the above application can be witnessed in the following diagram.

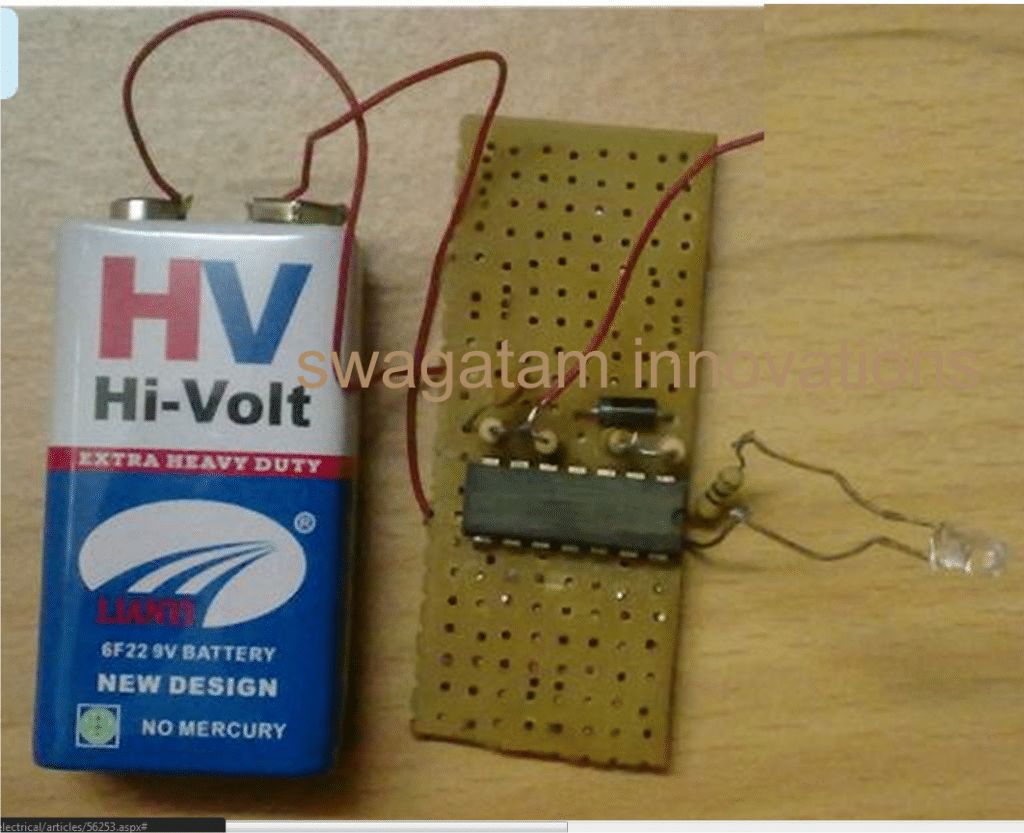

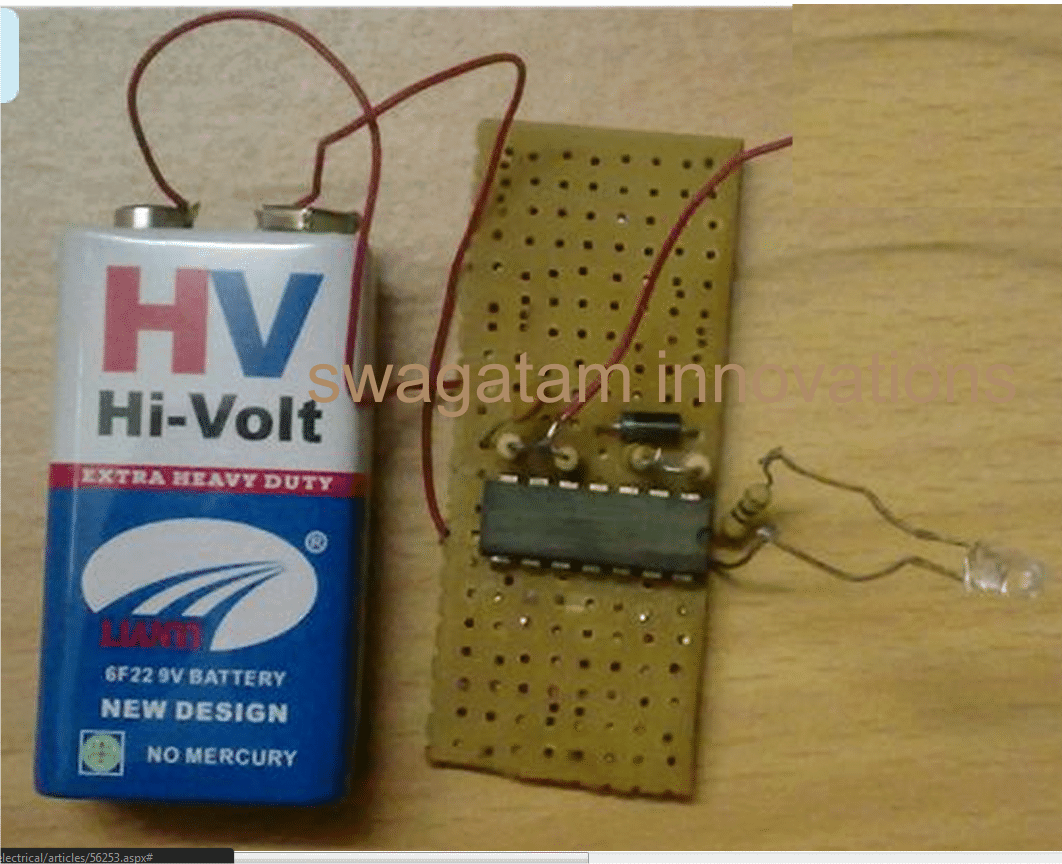

The first design is a relatively easier one using only transistors. The second one is using 4 opamps of LM324. Both are designed to activate a relay in response to an AC phase detection, non contact.

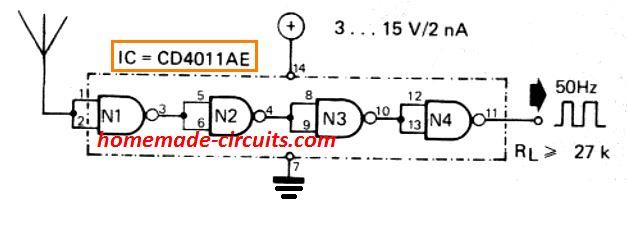

Another Very Simple Mains AC Hum Detector Circuit using IC 4011

The hum receiver is made up of a single COS/MOS IC consisting four NAND - gates (CD 4011). The four gates are connected in series to form signal amplifier like configuration.

The first gate (N1) detects the 220 V or 120 V AC hum radiated by the mains grid electrical line. You must take care not to keep the NAND gate inputs far away from various other sources of RF interference su ch as amplifier outputs, etc. A copper wire with a length of 2 to 3 cm will be adequate to serve like an antenna for picking up the 50 Hz or 60 Hz hum and to process the signal into a correspnding level of square wave output.

The output may show a risetime of about 20 ns at the output of gate N4. Based on the circumstances, one or two gates can often be eliminated. The current consumption of the complete CD 4011 IC is extremely minimal hence a 4.5 V battery employed as the power supply may be equivalent to almost the normal shelf life of th battery.

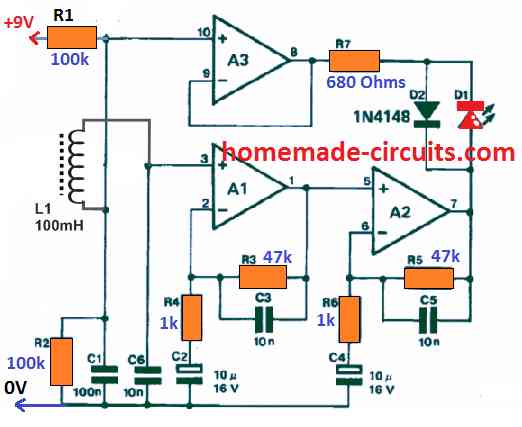

AC Mains Wiring Finder

The next circuit describes a straightforward way of finding conductors which carry alternating current or AC mains. A 100mH pick-up coil with a which is utilized as a detector coil.

A current-carrying conductor generates a magnetic field and holds a minute voltage in L1, which is amplified through opamps A1 and A2.

Capacitors C2 to C5 occupy a value that makes sure maximum amplification in A1 and A2 with signals about 50 Hz. Throughout the positive half-waves of the AC network, D1 stays lit.

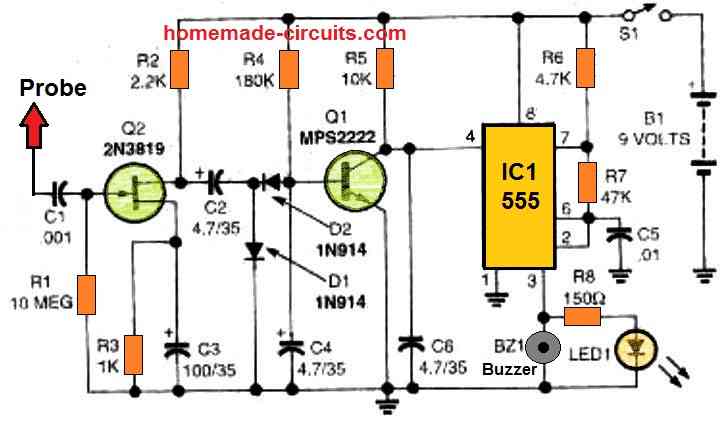

AC Phase Detector with Buzzer

Refer to the schematic diagram below. Via C1, the probe plate is linked to Q2, which is a very high-impedance amplifier. Although C1 is not required for the circuit's efficient functioning, it is important for its safety. C1 will prevent any deadly voltages from being unintentionally attached to the probe. After Q2 amplifies the input AC signal, it travels via C2 and D1 to produce a negative voltage clamp.

D2 rectifies the clamp output such that only negative voltages impact Q2. R4 typically switches on that transistor. However, while the clamp is active, Q2 switches off. Pin 4 (the reset line) of IC1 is freed when Q2 is turned off. R5 provides a positive voltage, allowing IC1 to start oscillating. A piezoelectric buzzer and an LED are driven by the output of IC1 (pin 3). R8 controls the current flowing to LED1. R6, R7, and C5 determine the frequency at which I C1 oscillates.

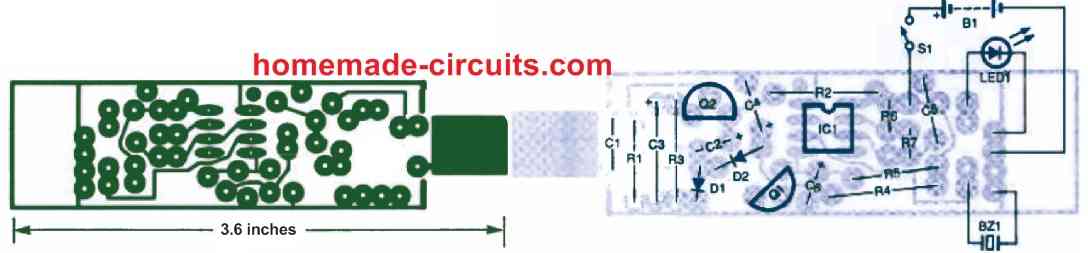

Install the PC board into the enclosure to ensure that no parts interfere with BZ1, S1, LED1, or B1. With the help of the below overlay diagram as a reference, hook up from those elements to the PC board. While wiring BZ1, the black lead, including the negative terminal of B1 and the cathode of LED, is connected to the common ground.

Testing

Hookup the Electrostatic Voltage Probe to a 9-volt battery. LED1 should glow momentarily when S1 is pressed, and BZ1 would beep while C4 charges. If this occurs, the circuit is most likely in good functioning order. The last testing is to place an extension cable close to the probe which is inserted into a wall socket with S1 is closed. The cable must be positioned against the flat side of the probe; aiming the probe end towards a AC cable will yield no results.

The buzzer must sound consistently and the LED must glow. Disconnect the extension cord; LED1 and BZ1 too should be turned off. The Electrostatic AC phase sensor is operating effectively if it satisfies this test. Loop the wires from B1, S1, and LED1 around the edge of the PCB between the board and the box before mounting it in the box.

Between B1 and the PC board, place a waste bit of plastic, cardboard, or a clean PCB with no copper on it. Close the case and cover the probe with a section of heatsink piping where it emerges from the container. To ensure that no bare PCB metal is visible, trim the tubing slightly longer than the probe itself. Walking across your home and checking several extension AC cables would be an excellent test. It's worth noting that you'll be able to tell exactly which side of a parallel-conductor lamp cable has the LIVE wire. The voltage probe might buzz occasionally as you move the device along the AC cord, in case the cord is made of twisted pairs.

Test Results

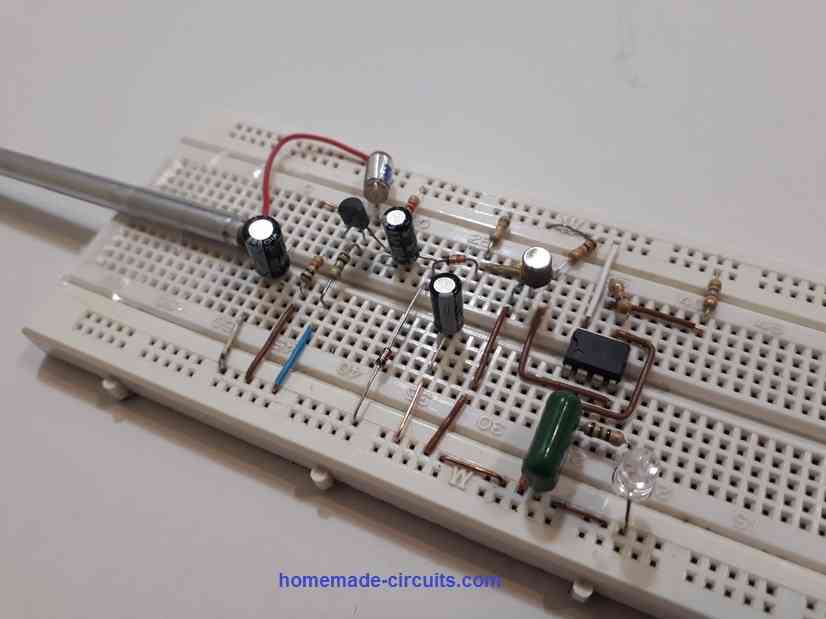

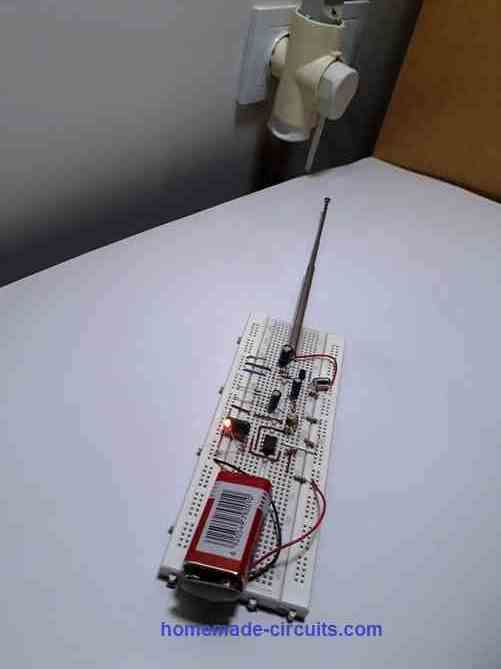

The above circuit was successfully built and tested by Mr. Ali, who is a dedicated electronic enthusiast and a regular visitor of this website.

The following wonderful images and the video test result was contributed by Mr Ali, for our viewing pleasure:

Now, to answer the question asked in the video by Mr. Ali regarding why the sensitivity of the circuit was different from different angles is because the radiation pattern of the AC mains 50 Hz or 60 Hz is different at different angles.

This might depend on the inductors or the wires arranged in different patterns inside an electrical device or an electrical board which might cause the electrical frequency to be more dense and powerful at certain angles compared to the other angles.

To reduce the sensitivity of the circuit, you can simply reduce the length of the antenna.