Simple solar charger circuits are small devices which allow you to charge a battery quickly and cheaply, through solar panels.

A simple solar charger circuit must have 3 basic features built-in:

- It should be low cost.

- Layman friendly, and easy to build.

- Must be efficient enough to satisfy the fundamental battery charging needs.

In this post I will comprehensively explain nine best yet simple solar battery charger circuits using the IC LM338, transistors, MOSFET, buck converter, etc which can be built and installed even by a layman for charging all types of batteries and operating other related equipment

Overview

Solar panels are not new to us and today it's being employed extensively in all sectors. The main property of this device to convert solar energy to electrical energy has made it very popular and now it's being strongly considered as the future solution for all electrical power crisis or shortages.

Solar energy may be used directly for powering an electrical equipment or simply stored in an appropriate storage device for later use.

Normally there's only one efficient way of storing electrical power, and it's by using rechargeable batteries.

Rechargeable batteries are probably the best and the most efficient way of collecting or storing electrical energy for later usage.

The energy from a solar cell or a solar panel can also be effectively stored so that it can be used as per ones own preference, normally after the sun has set or when it's dark and when the stored power becomes much needed for operating the lights.

Though it might look quite simple, charging a battery from a solar panel is never easy, because of two reasons:

The voltage from a solar panel can vary hugely, depending upon the incident sun rays, and

The current also varies due to the same above reasons.

The above two reason can make the charging parameters of a typical rechargeable battery very unpredictable and dangerous.

UPDATE:

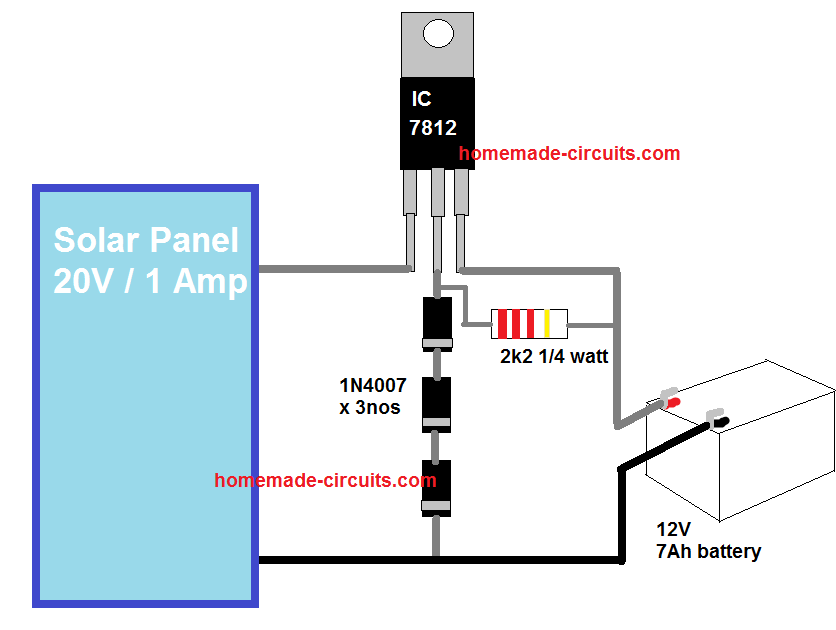

Before delving into the following concepts you can probably try this super easy solar battery charger which will ensure safe and guaranteed charging of a small 12V 7 Ah battery through a small solar panel:

Parts Required

- Solar Panel - 20V, 1 amp

- IC 7812 - 1no

- 1N4007 Diodes - 3nos

- 2k2 1/4 watt resistor - 1no

That looks cool isn't it. In fact the IC and the diodes could already resting in your electronic junk box, so need of buying them. Now let's see how these can be configured for the final outcome.

As we know the IC 7812 will produce a fixed 12V at the output which cannot be used for charging a 12V battery. The 3 diodes connected at its ground (GND) terminals is introduced specifically to counter this problem, and to upgrade the IC output to about 12 + 0.7 + 0.7 + 0.7 V = 14.1 V, which is exactly what is required for charging a 12 V battery fully.

The drop of 0.7 V across each diodes raises the grounding threshold of the IC by stipulated level forcing the IC to regulate the output at 14.1 V instead of 12 V. The 2k2 resistor is used to activate or bias the diodes so that it can conduct and enforce the intended 2.1 V total drop.

Making it Even Simpler

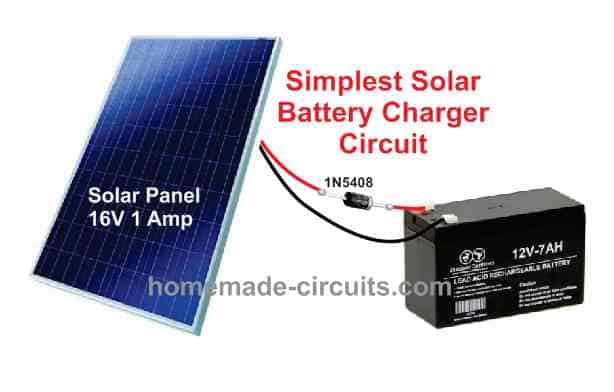

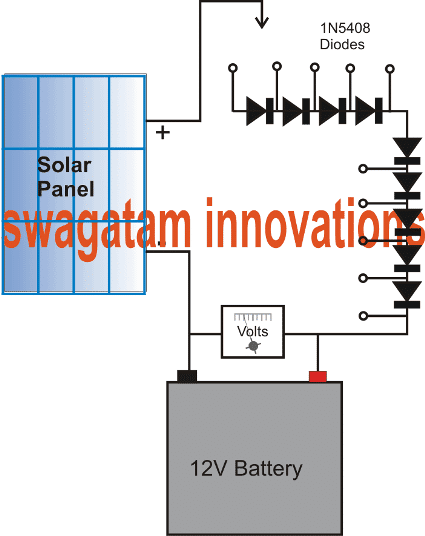

If you are looking for an even simpler solar charger, then probably there cannot be anything more straightforward than connecting an appropriately rated solar panel directly with the matching battery via a blocking diode, as shown below:

Although, the above design does not incorporate a regulator, it will still work since the panel current output is nominal, and this value will only show a deterioration as the sun changes its position.

However, for a battery that is not fully discharged, the above simple set up may cause some harm to the battery, since the battery will tend to get charged quickly, and will continue to get charged to unsafe levels and for longer periods of time.

You may also like this Highly Efficient 0-50V Solar Charger Circuit

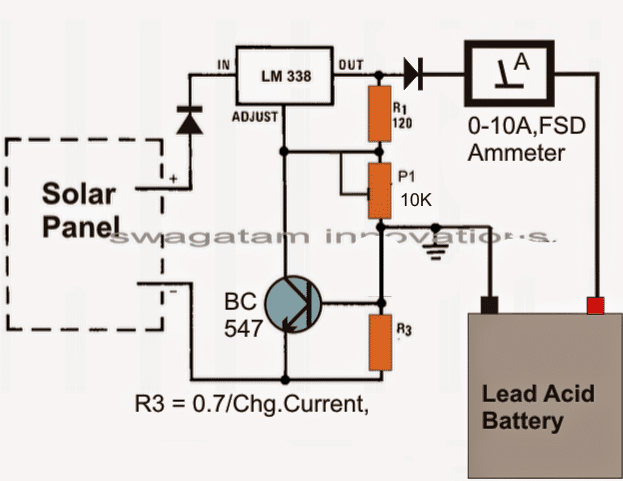

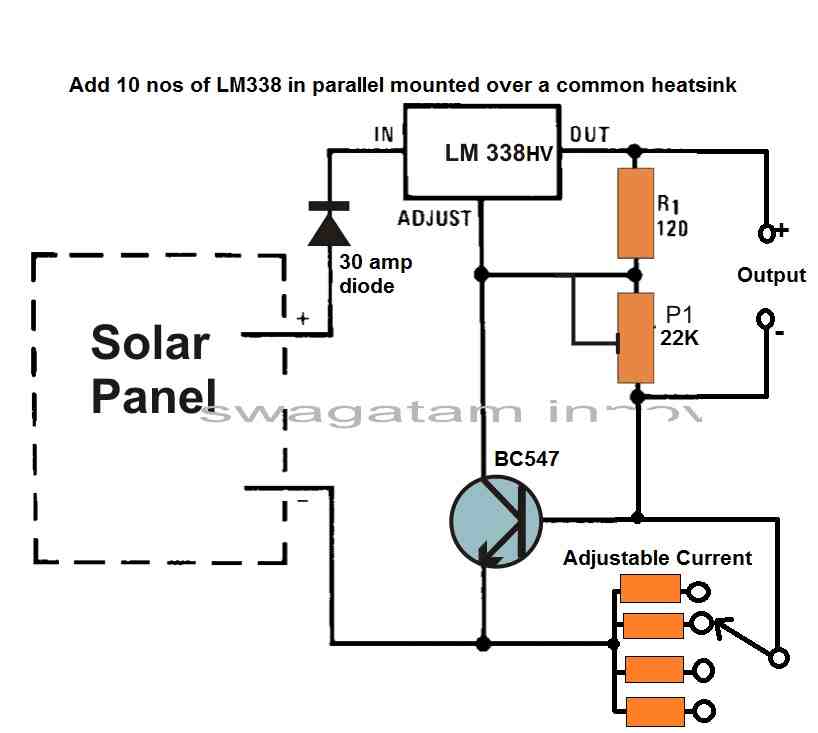

1) Using LM338 as Solar Controller

But thanks to the modern highly versatile chips like the LM 338 and LM 317, which can handle the above situations very effectively, making the charging process of all rechargeable batteries through a solar panel very safe and desirable.

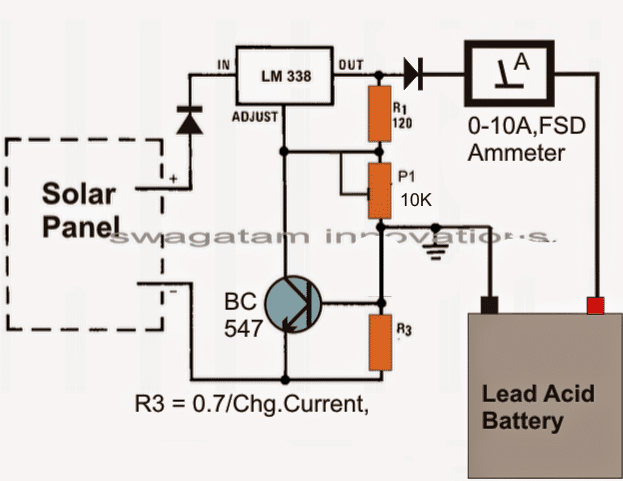

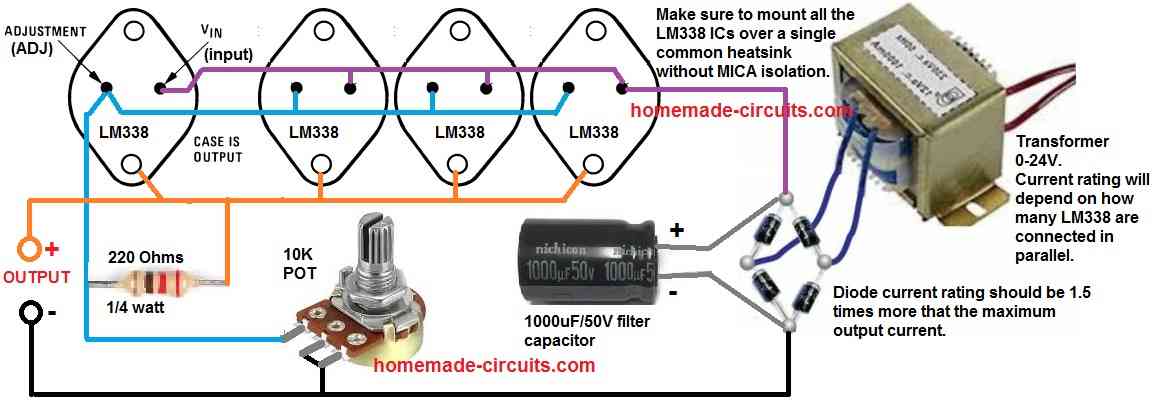

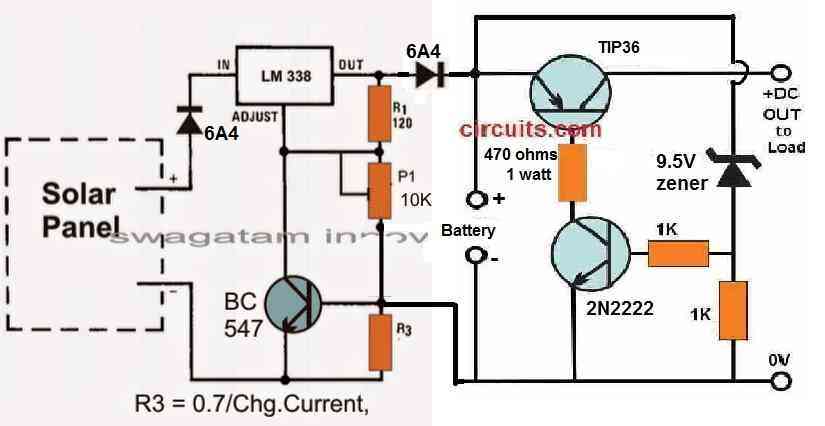

The circuit of a simple LM338 solar battery charger is shown below, using the IC LM338:

Parts List (BOM)

- Resistors

- R1 = 240 ohms 1/4 watt 5% CFR

- R3 = 0.6/Max Battery Charging Current

- P1 = 10k preset

- Diodes are 6A4

- Transistor = BC547

- IC = LM338

- Solar Panel = 18V, 5 Amp

- Battery =12V, 30 to 50 Ah

The circuit diagram shows a simple set up using the IC LM 338 which has been configured in its standard regulated power supply mode.

Using a Current Control Feature

The specialty of the design is that it incorporates a current control feature also.

It means that, if the current tends to increase at the input, which might normally take place when the sun ray intensity increases proportionately, the voltage of the charger drops proportionately, pulling down the current back to the specified rating.

As we can see in the diagram, the collector/emitter of the transistor BC547 is connected across the ADJ and the ground, it becomes responsible for initiating the current control actions.

As the input current rises, the battery starts drawing more current, this build up a voltage across R3 which is translated into a corresponding base drive for the transistor.

The transistor conducts and corrects the voltage via the C LM338, so that the current rate gets adjusted as per the safe requirements of the battery.

Current Limit Formula:

R3 may be calculated with the following formula

R3 = 0.7/ Max Current Limit

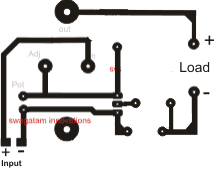

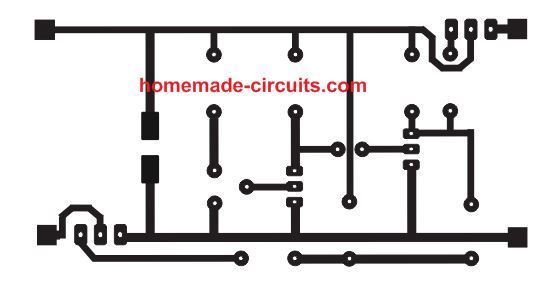

PCB Design for the above explained simple solar battery charger circuit is given below:

The meter and the input diode are not included in the PCB.

2) $1 Solar Battery Charger Circuit

The second design explains a cheap yet effective, less than $1 cheap yet effective solar charger circuit, which can be built even by a layman for harnessing efficient solar battery charging.

You will need just a solar panel panel, a selector switch and some diodes for getting a reasonably effective solar charger set up.

What is Maximum Power Point Solar Tracking?

For a layman this would be something too complex and sophisticated to grasp and a system involving extreme electronics.

In a way it may be true and surely MPPTs are sophisticated high end devices which are meant for optimizing the charging of the battery without altering the solar panel V/I curve.

In simple words an MPPT tracks the instantaneous maximum available voltage from the solar panel and adjusts the charging rate of the battery such that the panel voltage remains unaffected or away from loading.

Put simply, a solar panel would work most efficiently if its maximum instantaneous voltage is not dragged down close to the connected battery voltage, which is being charged.

For example, if the open circuit voltage of your solar panel is 20V and the battery to be charged is rated at 12V, and if you connect the two directly would cause the panel voltage to drop to the battery voltage, which would make things too inefficient.

Conversely if you could keep the panel voltage unaltered yet extract the best possible charging option from it, would make the system work with MPPT principle.

So it's all about charging the battery optimally without affecting or dropping the panel voltage.

There's one simple and zero cost method of implementing the above conditions.

Choose a solar panel whose open circuit voltage matches the battery charging voltage. Meaning for a 12V battery you may choose a panel with 15V and that would produce maximum optimization of both the parameters.

However practically the above conditions could be difficult to achieve because solar panels never produce constant outputs, and tend to generate deteriorating power levels in response to varying sun ray positions.

That's why always a much higher rated solar panel is recommended so that even under worse day time conditions it keeps the battery charging.

Having said that, by no means it is necessary to go for expensive MPPT systems, you can get similar results by spending a few bucks for it. The following discussion will make the procedures clear.

How the Circuit Works

As discussed above, in order to avoid unnecessary loading of the panel we need to have conditions ideally matching the PV voltage with the battery voltage.

This can be done by using a few diodes, a cheap voltmeter or your existing multimeter and a rotary switch. Ofcourse at around $1 you cannot expect it to be automatic, you may have to work with the switch quite a few times each day.

We know that a rectifier diode's forward voltage drop is around 0.6 volts, so by adding many diodes in series it can be possible to isolate the panel from getting dragged to the connected battery voltage.

Referring to the circuit digaram given below, a cool little MPPT charger can be arranged using the shown cheap components.

Let's assume in the diagram, the panel open circuit voltage to be 20V and the battery to be rated at 12V.

Connecting them directly would drag the panel voltage to the battery level making things inappropriate.

By adding 9 diodes in series we effectively isolate the panel from getting loaded and dragged to the battery voltage and yet extract the Maximum charging current from it.

The total forward drop of the combined diodes would be around 5V, plus battery charging voltage 14.4V gives around 20V, meaning once connected with all the diodes in series during peak sunshine, the panel voltage would drop marginally to may be around 19V resulting an efficient charging of the battery.

Now suppose the sun begins dipping, causing the panel voltage to drop below the rated voltage, this can be monitored across the connected voltmeter, and a few diodes skipped until the battery is restored with receiving optimal power.

The arrow symbol shown connected with the panel voltage positive can be replaced with a rotary switched for the recommended selection of the diodes in series.

With the above situation implemented, a clear MPPT charging conditions can be simulated effectively without employing costly devices. You can do this for all types of panels and batteries just by including more number of diodes in series.

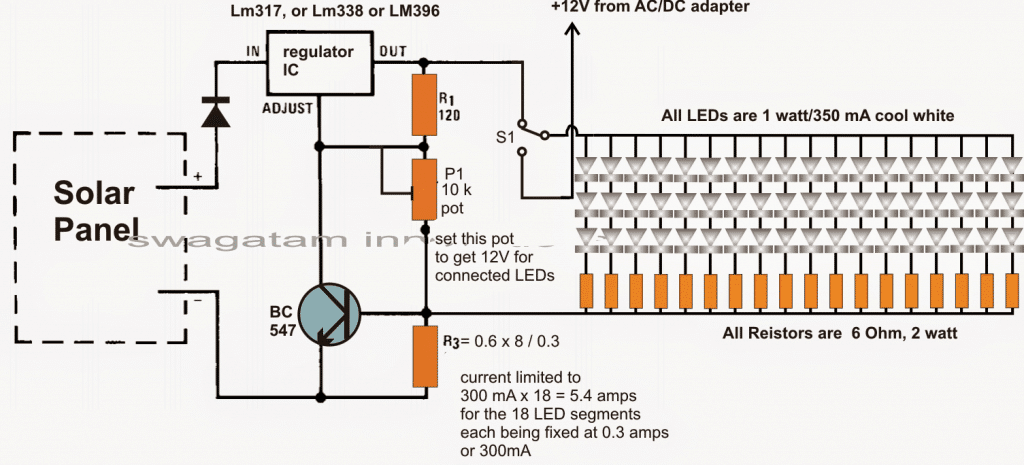

3) Solar Charger and Driver Circuit for 10W/20W/30W/50W White High Power SMD LED

The 3rd idea teaches us how to build a simple solar LED with battery charger circuit for illuminating high power LED (SMD) lights in the order of 10 watt to 50 watt. The SMD LEDs are fully safeguarded thermally and from over current using an inexpensive LM 338 current limiter stage. The idea was requested by Mr. Sarfraz Ahmad.

Technical Specifications

Basically I am a certified mechanical engineer from Germany 35 years ago and worked overseas for many years and left many years ago due to personal problems back home.

Sorry to bother you but I know about your capabilities and expertise in electronics and sincerity to help and guide the beginnings like me.I have seen this circuit some where for 12 vdc.I have attached to SMD ,12v 10 watt, cap 1000uf,16 volt and a bridge rectifier you can see the part number on that.When I turn the lights on the rectifier starts to heat up and the both SMDs as well. I am afraid if these lights are left on for a long time it may damage the SMDs and rectifier. I don not know where the problem is. You may help me.

I have a light in car porch which turns on at disk and off at dawn. Unfortunately due to load shedding when there is no electricity this light remains off till the electricity is back.

I want to install at least two SMD (12 volt) with LDR so as soon the light turns off the SMD lights will turn on. I want to additional two similar light elsewhere in the car porch to keep the entire are lighted.I think that if I connect all these four SMD lights with 12 volt power supply which will get the power from UPS circuit.

Of course it will put additional load on UPS battery which is hardly fully charged due to frequent load shedding. The other best solution is to install 12 volt solar panel and attach all these four SMD lights with it. It will charge the battery and will turn the lights On/OFF.

This solar panel should be capable to keeps these lights all the night and will turn OFF at dawn.Please also help me and give details about this circuit/project.

You may take your time to figure out how to do that.I am writing to you as unfortunately no electronics or solar product seller in our local market is willing to give me any help, None of them seems to be technical qualified and they just want to sell their parts.

Sarfraz AhmadRawalpindi, Pakistan

Highly Recommended for you: Solar Chargers using Switching Regulators

The Design

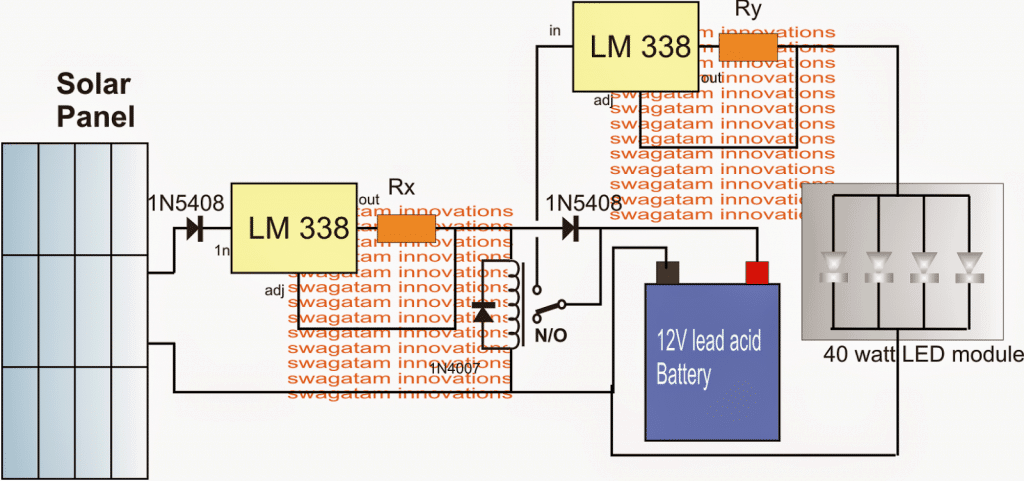

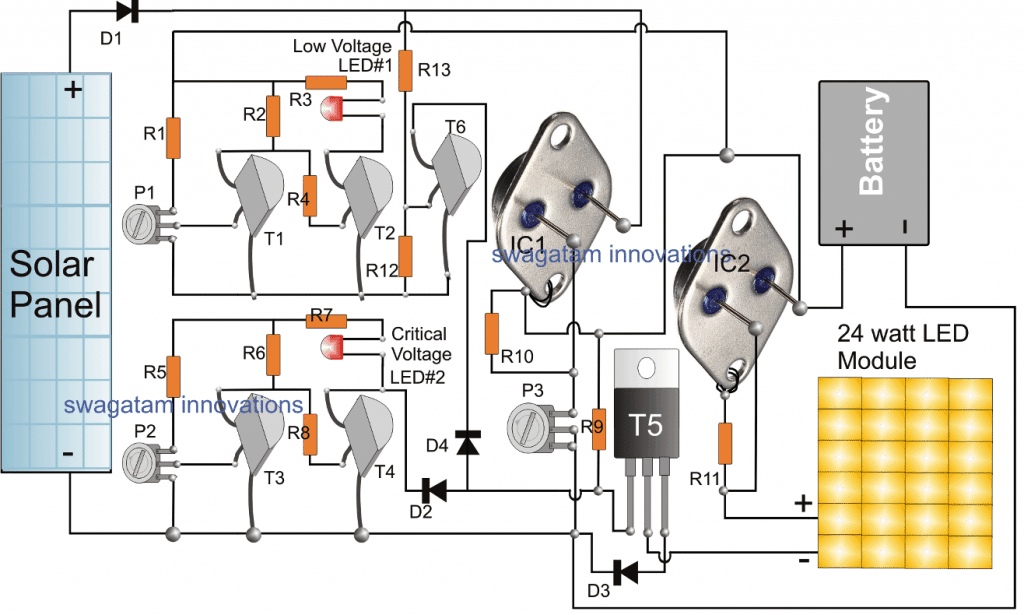

In the shown 10 watt to 50 watt SMD solar LED light circuit with automatic charger above, we see the following stages:

- A solar panel

- A couple of current controlled LM338 regulator circuits

- A changeover relay

- A rechargeable battery

- and a 40 watt LED SMD module

The above stages are integrated in the following explained manner:

The two LM 338 stages are configured in standard current regulator modes with using the respective current sensing resistances for ensuring a current controlled output for the relevant connected load.

The load for the left LM338 is the battery which is charged from this LM338 stage and a solar panel input source. The resistor Rx is calculated such that the battery receives the stipulated amount of current and is not over driven or over charged.

The right side LM 338 is loaded with the LED module and here too the Ry makes sure that module is supplied with the correct specified amount of current in order to safeguard the devices from a thermal runaway situation.

The solar panel voltage specs may be anywhere between 18V and 24V.

A relay is introduced in the circuit and is wired with the LED module such that it's switched ON only during the night or when it's dark below threshold for the solar panel to generate the required any power.

As long as the solar voltage is available, the relay stays energized isolating the LED module from the battery and ensuring that the 40 watt LED module remains shut off during day time and while the battery is being charged.

After dusk, when the solar voltage becomes sufficiently low, the relay is no longer able to hold its N/O position and flips to the N/C changeover, connecting the battery with the LED module, and illuminating the array through the available fully charged battery power.

The LED module can be seen attached with a heatsink which must be sufficiently large in order to achieve an optimal outcome from the module and for ensuring longer life and brightness from the device.

Calculating the Resistor Values

The indicated limiting resistors may be calculated from the given formulas:

Rx = 1.25/battery charging current

Ry = 1.25/LED current rating.

Assuming the battery to be a 40 AH lead acid battery, the preferred charging current should be 4 amps.

therefore Rx = 1.25/4 = 0.31 ohms

wattage = 1.25 x 4 = 5 watts

The LED current can be found by dividing its total wattage by the voltage rating, that is 40/12 = 3.3amps

therefore Ry = 1.25/3 = 0.4 ohms

wattage = 1.25 x 3 = 3.75 watts or 4 watts.

Limiting resistors are not employed for the 10 watt LEDs since the input voltage from the battery is on par with the specified 12V limit of the LED module and therefore cannot exceed the safe limits.

The above explanation reveals how the IC LM338 can be simply used for making an useful solar LED light circuit with an automatic charger.

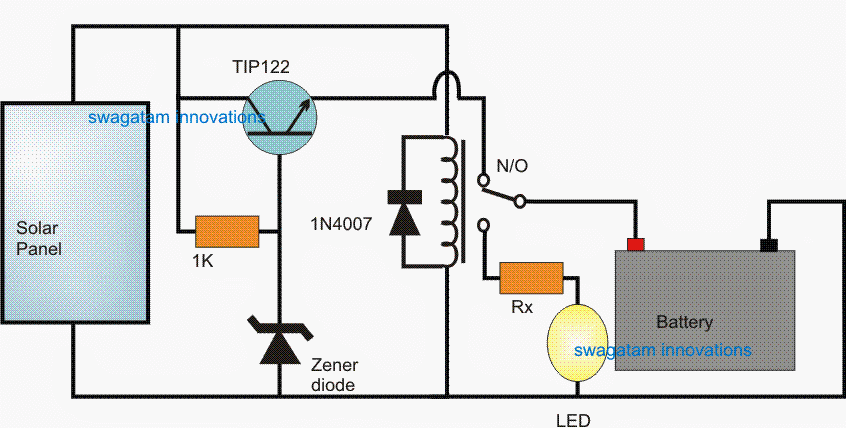

4) Automatic Solar Light Circuit using a Relay

In our 4rth automatic solar light circuit we incorporate a single relay as a switch for charging a battery during day time or as long as the solar panel is generating electricity, and for illuminating a connected LED while the panel is not active.

Upgrading to a Relay Changeover

In one of my previous article which explained a simple solar garden light circuit, we employed a single transistor for the switching operation.

One disadvantage of the earlier circuit is, it does not provide a regulated charging for the battery, although it not might be strictly essential since the battery is never charged to its full potential, this aspect might require an improvement.

Another associated disadvantage of the earlier circuit is its low power spec which restricts it from using high power batteries and LEDs.

The following circuit effectively solves both the above two issues, with the help of a relay and a emitter follower transistor stage.

Circuit Diagram

How it Works

During optimal sun shine, the relay gets sufficient power from the panel and remains switched ON with its N/O contacts activated.

This enables the battery to get the charging voltage through a transistor emitter follower voltage regulator.

The emitter follower design is configured using a TIP122, a resistor and a zener diode. The resistor provides the necessary biasing for the transistor to conduct, while the zener diode value clamps the emitter voltage is controlled at just below the zener voltage value.

The zener value is therefore appropriately chosen to match the charging voltage of the connected battery.

For a 6V battery the zener voltage could be selected as 7.5V, for 12V battery the zener voltage could be around 15V and so on.

The emitter follower also makes sure that the battery is never allowed to get overcharged above the allocated charging limit.

During evening, when a substantial drop in sunlight is detected, the relay is inhibited from the required minimum holding voltage, causing it to shift from its N/O to N/C contact.

The above relay changeover instantly reverts the battery from charging mode to the LED mode, illuminating the LED through the battery voltage.

Parts list for a 6V/4AH automatic solar light circuit using a relay changeover

- Solar Panel = 9V, 1amp

- Relay = 6V/200mA

- Rx = 10 ohm/2 watt

- zener diode = 7.5V, 1/2 watt

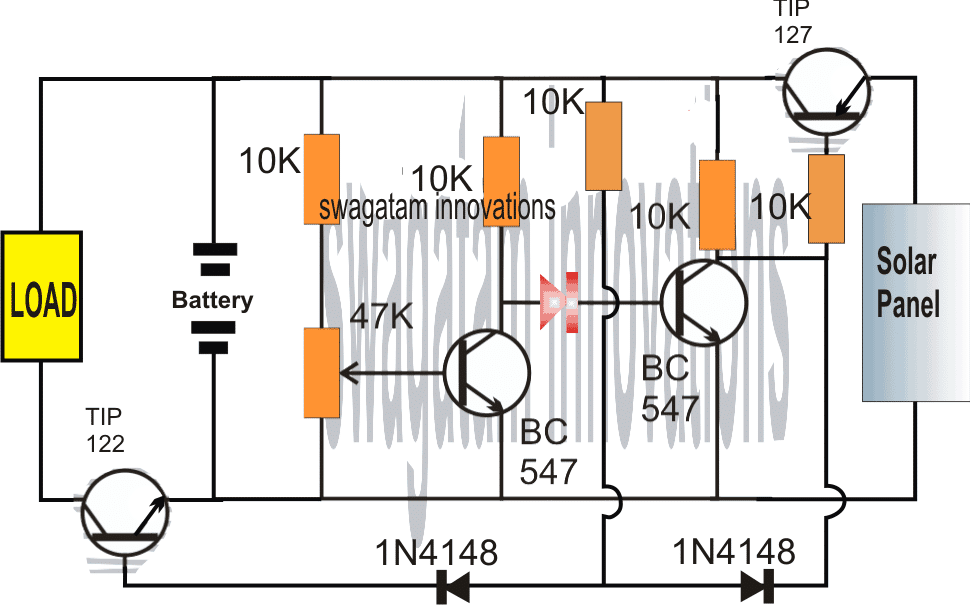

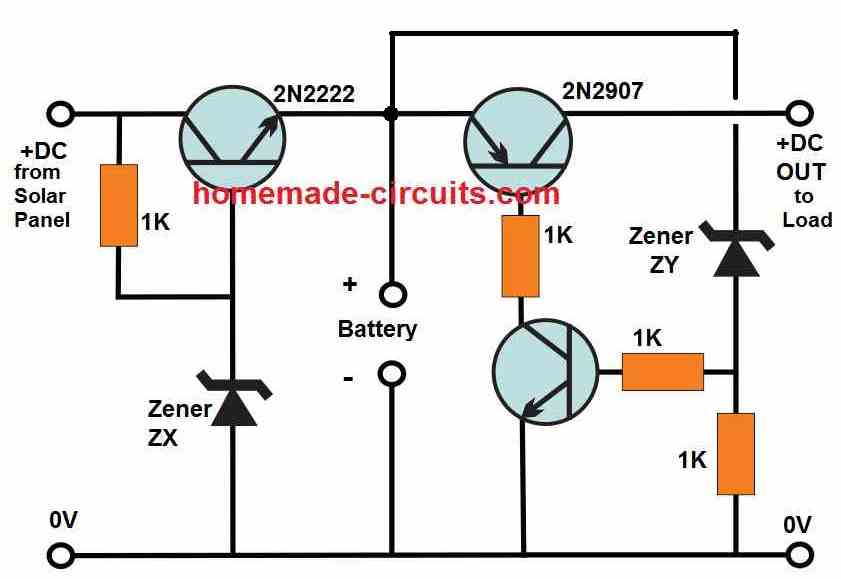

5) Transistorized Solar Charger Controller Circuit

The fifth idea presented below details a simple solar charger circuit with automatic cut-off using transistors only. The idea was requested by Mr. Mubarak Idris.

Circuit Objectives and Requirements

- Please sir can you make me a 12v, 28.8AH lithium ion battery,automatic charge controller using solar panel as a supply, which is 17v at 4.5A at max sun light.

- The charge controller should be able to have over charge protection and low battery cut off and the circuit should be simple to do for beginner without ic or micro controller.

- The circuit should use relay or bjt transistors as a switch and zener for voltage reference thanks sir hope to hear from you soon!

The Design

PCB Design (Component Side)

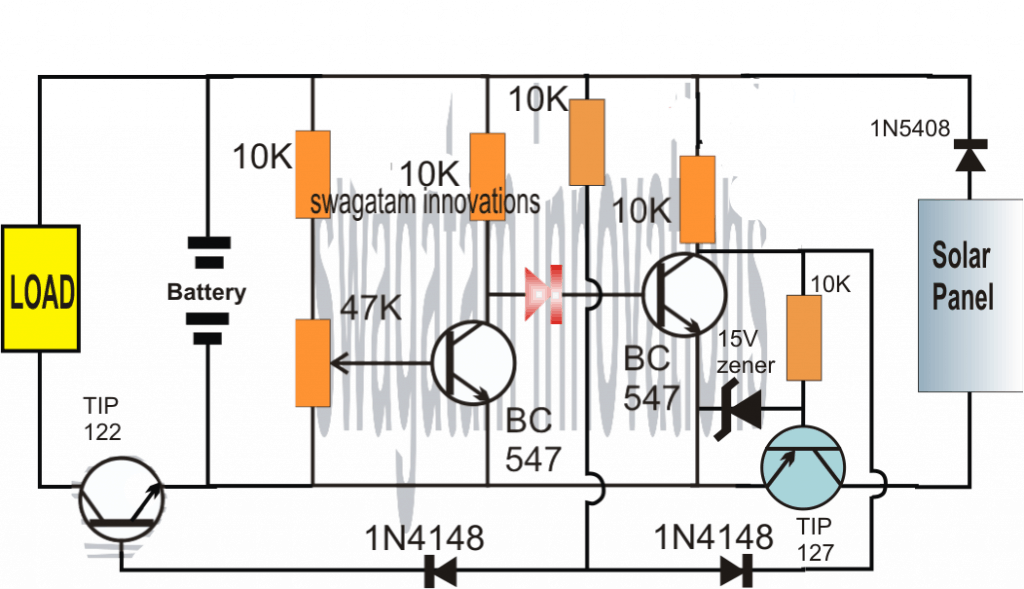

Referring to the above simple solar charger circuit using transistors, the automatic cut off for the full charge charge level and the lower level is done through a couple of BJTs configured as comparators.

Recall the earlier low battery indicator circuit using transistors, where the low battery level was indicated using just two transistors and a few other passive components.

Here we employ an identical design for the sensing of the battery levels and for enforcing the required switching of the battery across the solar panel and the connected load.

Let's assume initially we have a partially discharged battery which causes the first BC547 from left to stop conducting (this is set by adjusting the base preset to this threshold limit), and allows the next BC547 to conduct.

When this BC547 conducts it enable the TIP127 to switch ON, which in turn allows the solar panel voltage to reach the battery and begin charging it.

The above situation conversely keeps the TIP122 switched OFF so that the load is unable to operate.

As the battery begins getting charged, the voltage across the supply rails also begin rising until a point where the left side BC547 is just able to conduct, causing the right side BC547 to stop conducting any further.

As soon as this happens, the TIP127 is inhibited from the negative base signals and it gradually stops conducting such that the battery gradually gets cut off from the solar panel voltage.

However, the above situation permits the TIP122 to slowly receive a base biasing trigger and it begins conducting....which ensures that the load now is able to get the required supply for its operations.

The above explained solar charger circuit using transistors and with auto cut-offs can be used for any small scale solar controller applications such as for charging cellphone batteries or other forms of Li-ion batteries safely.

For getting a Regulated Charging Supply

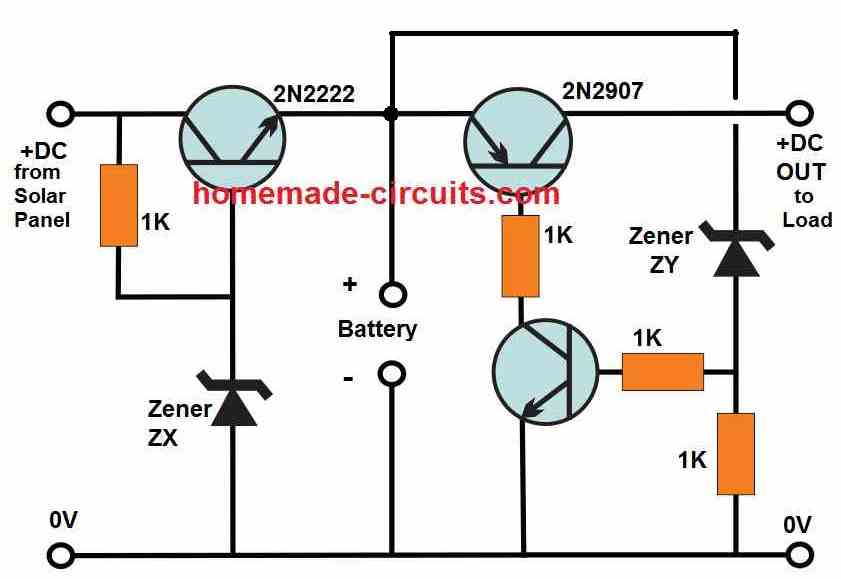

The following design shows how to convert or upgrade the above circuit diagram into a regulated charger, so that the battery is supplied with a fixed and a stabilized output regardless of a rising voltage from the solar panel.

The above designs can be further simplified, as shown in the following over-charge, over-discharge solar battery controller circuit:

Here, the zener ZX decides the full charge battery cut off, and can be calculated using the following formula:

ZX = Battery full charge value + 0.6

For example, if the full-charge battery level is 14.2V, then the ZX can be 14 + 0.6 = 14.6V zener which can be built by adding a few zener diodes in series, along with a few 1N4148 diodes, if required.

The zener diode ZY decides the battery over-discharge cut off point, and can be simply equal to the value of the desired low battery value.

For example if the minimum low battery level is 11V, then the ZY can be selected to be a 11V zener.

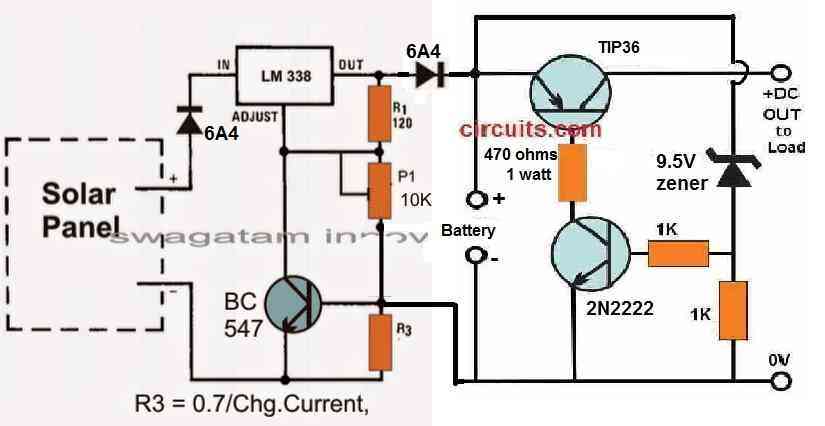

The above design can be also integrated with an LM338 charger circuit as shown below:

6) Solar Pocket LED Light Circuit

The sixth design here explains a simple low cost solar pocket LED light circuit which could be used by the needy and, underprivileged section of the society for illuminating their houses at night cheaply.

The idea was requested by Mr. R.K. Rao

Circuit Objectives and Requirements

- I want to make a SOLAR pocket LED light using a 9cm x 5cm x 3cm transparent plastic box [available in the market for Rs.3/-] using a one watt LED/20mA LEDS powered by a 4v 1A rechargeable sealed lead-acid battery [SUNCA/VICTARI] & also with a provision for charging with a cell phone charger [where grid current is available].

- The battery should be replaceable when dead after use for 2/3 years/prescribed life by the rural/tribal user.

- This is meant for use by tribal/rural children to light up a book; there are better led lights in the market for around Rs.500 [d.light],for Rs.200 [Thrive].

- These lights are good except that they have a mini solar panel and a bright LED with a life of ten years if not more ,but with a rechargeable battery without a provision for its replacement when dead after two or three years of use.It is a waste of resource and unethical.

- The project i am envisaging is one in which the battery can be replaced , be locally available at low cost. The price of the light should not exceed Rs.100/150.

- It will be marketed on not for profit basis through NGOs in tribal areas and ultimately supply kits to tribal/rural youth to make them in the village.

- I along with a colleague have made some lights with 7V EW high power batteries and 2x20mA pirahna Leds and tested them-they lasted for over 30 hours of continuous lighting adequate to light up a book from half-meter distance; and another with a 4v sunce battery and 1watt 350A LED giving enough light for cooking in a hut.

- Can you suggest a circuit with a one AA/AAA rechargeable battery,mini solar panel to fit on the box cover of 9x5cm and a DC-DC booster and 20mA leds. If you want me to come over to your place for discussions i can.

- You can see the lights we have made in google photos at https://goo.gl/photos/QyYU1v5Kaag8T1WWA Thanking you,

The Design

As per the request the solar pocket LED light circuits needs to be compact, work with a single 1.5AAA cell using a DC-DC converter and equipped with a self regulating solar charger circuit.

The circuit diagram shown below probably satisfies all the above specifications and yet stays within the affordable limit.

Circuit Diagram

The design is a basic joule thief circuit using a single penlight cell, a BJT and an inductor for powering any standard 3.3V LED.

In the design a 1 watt LeD is shown although a smaller 30mA high bright LED could be used.

The solar LED circuit is capable squeezing out the last drop of "joule" or the charge from the cell and hence the name joule thief, which also implies that the LED would keep illuminated until there's virtually nothing left inside the cell. However the cell here being a rechargeable type is not recommended to be discharged below 1V.

The 1.5V battery charger in the design is built using another low power BJT configured in its emitter follower configuration, which allows it to produce an emitter voltage output that's exactly equal to the potential at its base, set by the 1K preset. This must be precisely set such that the emitter produces not more than 1.8V with a DC input of above 3V.

The DC input source is a solar panel which may be capable of producing an excess of 3V during optimal sunlight, and allow the charger to charge the battery with a maximum of 1.8V output.

Once this level is reached the emitter follower simply inhibits any further charging of the cell thus preventing any possibility of an over charge.

The inductor for the pocket solar LED light circuit consists of a small ferrite ring transformer having 20:20 turns which could be appropriately altered and optimized for enabling the most favorable voltage for the connected LED which may last even until the voltage has fallen below 1.2V.

7) Simple Solar Charger for Street Lights

The seventh solar charger discussed here is best suited as a solar LED street light system is specifically designed for the new hobbyist who can build it simply by referring to the pictorial schematic presented here.

Due to its straightforward and relatively cheaper design the system can be suitably used for village street lighting or in other similar remote areas, nonetheless this by no means restricts it from being used in cities also.

Main Features of this system are:

1) Voltage controlled Charging

2) Current Controlled LED Operation

3) No Relays used, all Solid-State Design

4) Low Critical Voltage Load Cut-off

5) Low Voltage and Critical Voltage Indicators

6) Full Charge cut-off is not included for simplicity sake and because the charging is restricted to a controlled level which will never allow the battery to over-charge.

7) Use of popular ICs like LM338 and transistors like BC547 ensure hassle free procurement

8) Day night sensing stage ensuring automatic switch OFF at dusk and switch ON at dawn.

The entire circuit design of the proposed simple LED street light system is illustrated below:

Circuit Diagram

The circuit stage comprising T1, T2, and P1 are configured into a simple low battery sensor, indicator circuit

An exactly identical stage can also be seen just below, using T3, T4 and the associated parts, which form another low voltage detector stage.

The T1, T2 stage detects the battery voltage when it drops to 13V by illuminating the attached LED at the collector of T2, while the T3, T4 stage detects the battery voltage when it reaches below 11V, and indicates the situation by illuminating the LED associated with the collector of T4.

P1 is used for adjusting the T1/T2 stage such that the T2 LED just illuminates at 12V, similarly P2 is adjusted to make the T4 LED begin illuminating at voltages below 11V.

IC1 LM338 is configured as a simple regulated voltage power supply for regulating the solar panel voltage to a precise 14V, this is done by adjusting the preset P3 appropriately.

This output from IC1 is used for charging the street lamp battery during day time and peak sunshine.

IC2 is another LM338 IC, wired in a current controller mode, its input pin is connected with the battery positive while the output is connected with the LED module.

IC2 restricts the current level from the battery and supplies the right amount of current to the LED module so that it is able operate safely during night time back up mode.

T5 is a power transistor which acts like a switch and is triggered by the critical low battery stage, whenever the battery voltage tends to reach the critical level.

Whenever this happens the base of T5 is instantly grounded by T4, shutting it off instantly. With T5 shut off, the LED module is enable to illuminate and therefore it is also shut off.

This condition prevents and safeguards the battery from getting overly discharged and damaged. In such situations the battery might need an external charging from mains using a 24V, power supply applied across the solar panel supply lines, across the cathode of D1 and ground.

The current from this supply could be specified at around 20% of battery AH, and the battery may be charged until both the LEDs stop glowing.

The T6 transistor along with its base resistors is positioned to detect the supply from the solar panel and ensure that the LED module remains disabled as long as a reasonable amount of supply is available from the panel, or in other words T6 keeps the LED module shut off until its dark enough for the LED module and then is switched ON. The opposite happen at dawn when the LED module is automatically switched OFF. R12, R13 should be carefully adjusted or selected to determine the desired thresholds for the LED module's ON/OFF cycles

How to Build

To complete this simple street light system successfully, the explained stages must be built separately and verified separately before integrating them together.

First assemble the T1, T2 stage along with R1, R2, R3, R4, P1 and the LED.

Next, using a variable power supply, apply a precise 13V to this T1, T2 stage, and adjust P1 such that the LED just illuminates, increase the supply a bit to say 13.5V and the LED should shut off. This test will confirm the correct working of this low voltage indicator stage.

Identically make the T3/T4 stage and set P2 in a similar fashion to enable the LED to glow at 11V which becomes the critical level setting for the stage.

After this you can go ahead with the IC1 stage, and adjust the voltage across its "body" and ground to 14V by adjusting P3 to the correct extent. This should be again done by feeding a 20V or 24V supply across its input pin and ground line.

The IC2 stage can be built as shown and will not require any setting up procedure except the selection of R11 which may be done using the formula as expressed in this universal current limiter article

Parts List

- R1, R2, R3 R4, R5, R6, R7 R8, R9, R12 = 10k, 1/4 WATT

- P1, P2, P3 = 10K PRESETS

- R10 = 240 OHMS 1/4 WATT

- R13 = 22K

- D1, D3 = 6A4 DIODE

- D2, D4 = 1N4007

- T1, T2, T3, T4 = BC547

- T5 = TIP142

- R11 = SEE TEXT

- IC1, IC2 = LM338 IC TO3 package

- LED Module = Made by connecting 24nos 1 WATT LEDs in series and parallel connections

- Battery = 12V SMF, 40 AH

- Solar Panel = 20/24V, 7 Amp

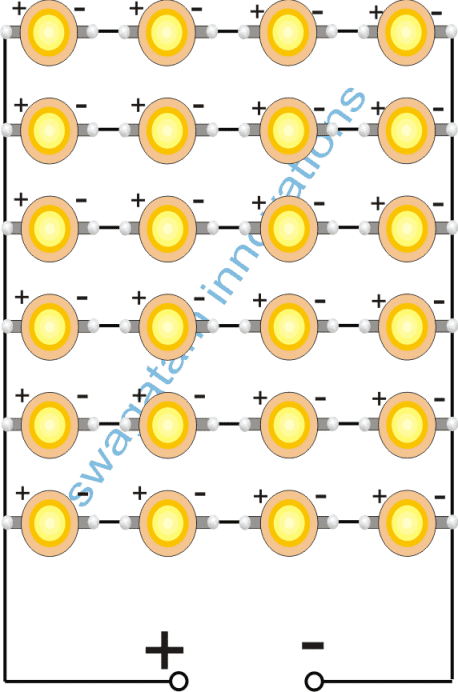

Making th 24 watt LED Module

The 24 watt LED module for the above simple solar street light system could be built simply by joining 24 nos 1 watt LEDs as shown in the following image:

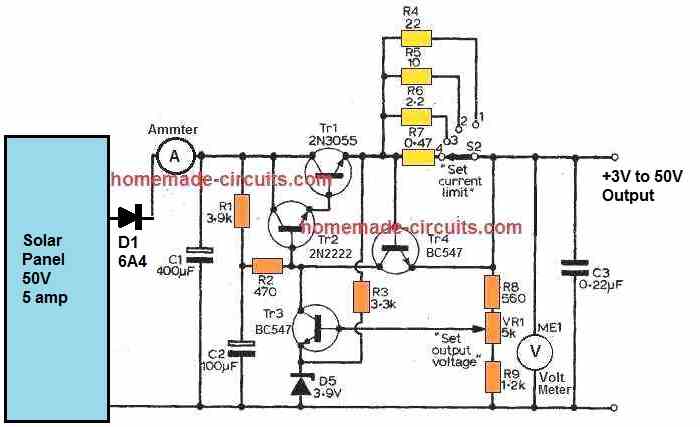

8) Solar Panel Buck Converter Circuit with Over Load Protection

The 8th solar concept discussed below talks about a simple solar panel buck converter circuit which can be used to obtain any desired low bucked voltage from 40 to 60V inputs. The circuit ensures a very efficient voltage conversions. The idea was requested by Mr. Deepak.

Technical Specifications

I am looking for DC - DC buck converter with following features.

1. Input voltage = 40 to 60 VDC

2. Output voltage = Regulated 12, 18 and 24 VDC (multiple output from the same circuit is not required. Separate circuit for each o/p voltage is also fine)

3. Output current capacity = 5-10A

4. Protection at output = Over current, short circuits etc.

5. Small LED indicator for unit operation would be an advantage.

Appreciate if you could help me designing the circuit.

Best regards,

Deepak

The Design

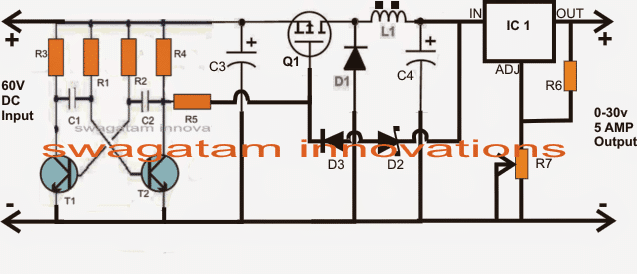

The proposed 60V to 12V, 24V buck converter circuit is shown in the figure below, the details may be understood as I have explained below:

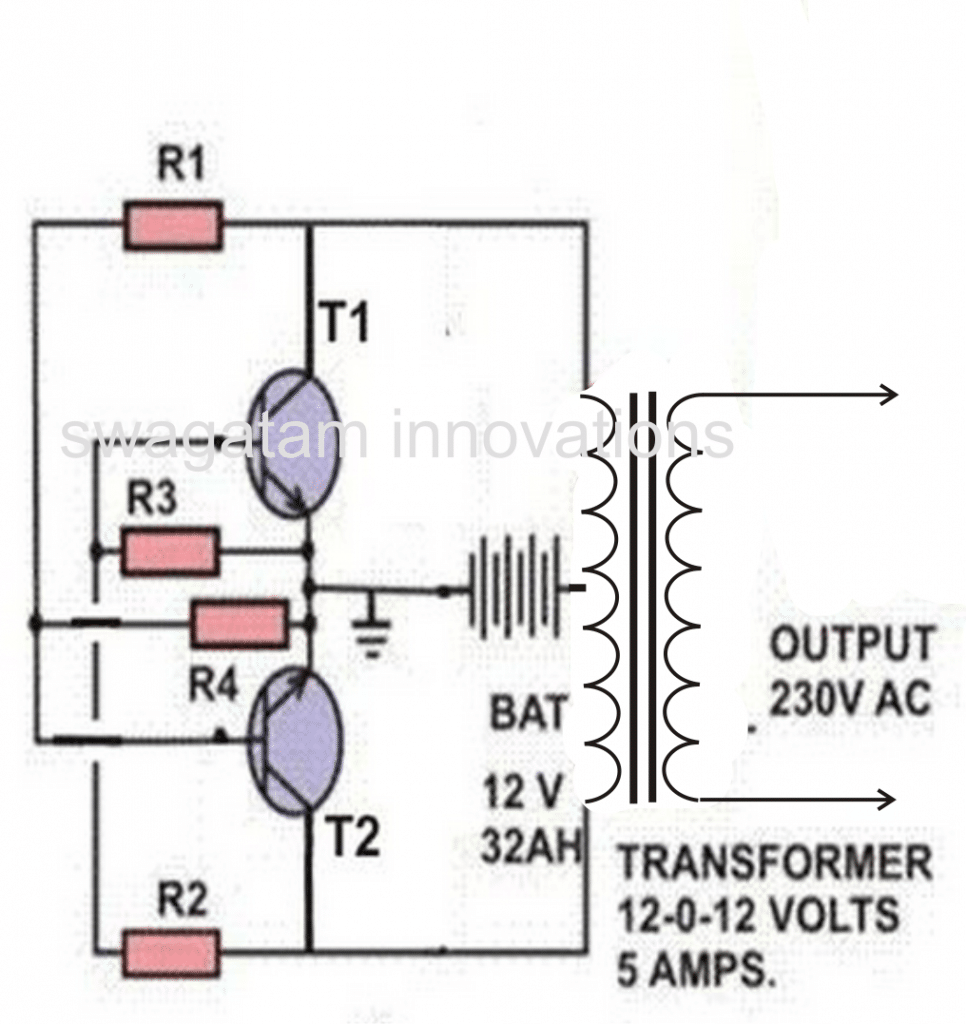

The configuration could be divided into stages, viz. the astable multivibrator stage and the mosfet controlled buck converter stage.

BJT T1, T2 along with its associated parts forms a standard AMV circuit wired to generate a frequency at the rate of about 20 to 50kHz.

Mosfet Q1 along with L1 and D1 forms a standard buck converter topology for implementing the required buck voltage across C4.

The AMV is operated by the input 40V and the generated frequency is fed to the gate of the attached mosfet which instantly begins oscillating at the available current from the input driving L1, D1 network.

The above action generates the required bucked voltage across C4,

D2 makes sure that this voltage never exceeds the rated mark which may be fixed 30V.

This 30V max limit bucked voltage is further fed to a LM396 voltage regulator which may be set for getting the final desired voltage at the output at the rate of 10amps maximum.

The output may be used for charging the intended battery.

Circuit Diagram

Parts List for the above 60V input, 12V, 24V output buck converter solar for the panels.

- R1---R5 = 10K

- R6 = 240 OHMS

- R7 = 10K POT

- C1, C2 = 2nF

- C3 = 100uF/100V

- C4 = 100uF/50V

- Q1 = ANY 100V, 20AMP P-channel MOSFET

- T1,T2 = BC546

- D1 = ANY 10AMP FAST RECOVERY DIODE

- D2 = 30V ZENER 1 WATT

- D3 = 1N4007

- L1 = 30 turns of 21 SWG super enameled copper wire wound over a 10mm dia ferrite rod.

9) Home Solar Electricity Set up for an Off-the-grid Living

The ninth unique design explained here illustrates a simple calculated configuration which may be used for implementing any desired sized solar panel electricity set up for remotely located houses or for achieving an off the grid electricity system from solar panels.

Technical Specifications

I am very sure you must have this kind of circuit diagram ready. While going through your blog I got lost and could not really choose one best fitting to my requirements.

I am just trying to put my requirement here and make sure I understood it correctly.

(This is a pilot project for me to venture into this field. You can count me to be a big zero in electrical knowledge. )

My basic goal is to maximize use of Solar power and reduce my electrical bill to minimum. ( 🙁 I stay at Thane. So, you can imagine electricity bills. ) So you can consider as if I am completely making a solar powered lighting system for my home.

1. Whenever there is enough sunlight, I do not need any artificial light.2. Whenever intensity of sunlight drops below acceptable norms, I wish my lights will turn on automatically.

I would like to switch them off during bedtime, though.3. My current lighting system (which I wish to illuminate) consists of two regular bright light Tube lights ( 36W/880 8000K ) and four 8W CFLs.

Would like to replicate the whole setup with Solar-powered LED based lighting.

As I said, I am a big zero in field of electricity. So, please help me with the expected setup cost also.

The Design

36 watts x 2 plus 8 watt gives a total of around 80 watts which is the total required consumption level here.

Now since the lights are specified to work at mains voltage levels which is 220 V in India, an inverter becomes necessary for converting the solar panel voltage to the required specs for the lights to illuminate.

Also since the inverter needs a battery to operate which can be assumed to be a 12 V battery, all the parameters essential for the set up may be calculated in the following manner:

Total intended consumption is = 80 watts.

The above power may be consumed from 6 am to 6 pm which becomes the maximum period one can estimate, and that's approximately 12 hours.

Multiplying 80 by 12 gives = 960 watt hour.

It implies that the solar panel will need to produce this much watt hour for the desired period of 12 hours during the entire day.

However since we don't expect to receive optimum sunlight through the year, we can assume the average period of optimum daylight to be around 8 hours.

Dividing 960 by 8 gives = 120 watts, meaning the required solar panel will need to be at least 120 watt rated.

If the panel voltage is selected to be around 18 V, the current specs would be 120/18 = 6.66 amps or simply 7 amps.

Now let's calculate the battery size which may be employed for the inverter and which may be required to be charged with the above solar panel.

Again since the total watt hour fr the entire day is calculated to be around 960 watts, dividing this with the battery voltage (which is assumed to be 12 V) we get 960/12 = 80, that's around 80 or simply 100 AH, therefore the required battery needs to be rated at 12 V, 100 AH for getting an an optimal performance throughout the day (12 hours period).

We'll also need a solar charge controller for charging the battery, and since the battery would be charged for the period of around 8 hours, the charging rate will need to be around 8% of the rated AH, that amounts to 80 x 8% = 6.4 amps, therefore the charge controller will need to be specified to handle at least 7 amp comfortably for the required safe charging of the battery.

That concludes the entire solar panel, battery, inverter calculations which could be successfully implemented for any similar kind of set up intended for an off the grid living purpose in rural areas or other remote area.

For other V, I specs, the figures may be changed in the above explained calculation for achieving the appropriate results.

In case the battery is felt unnecessary and the solar panel could also be directly used for operating inverter.

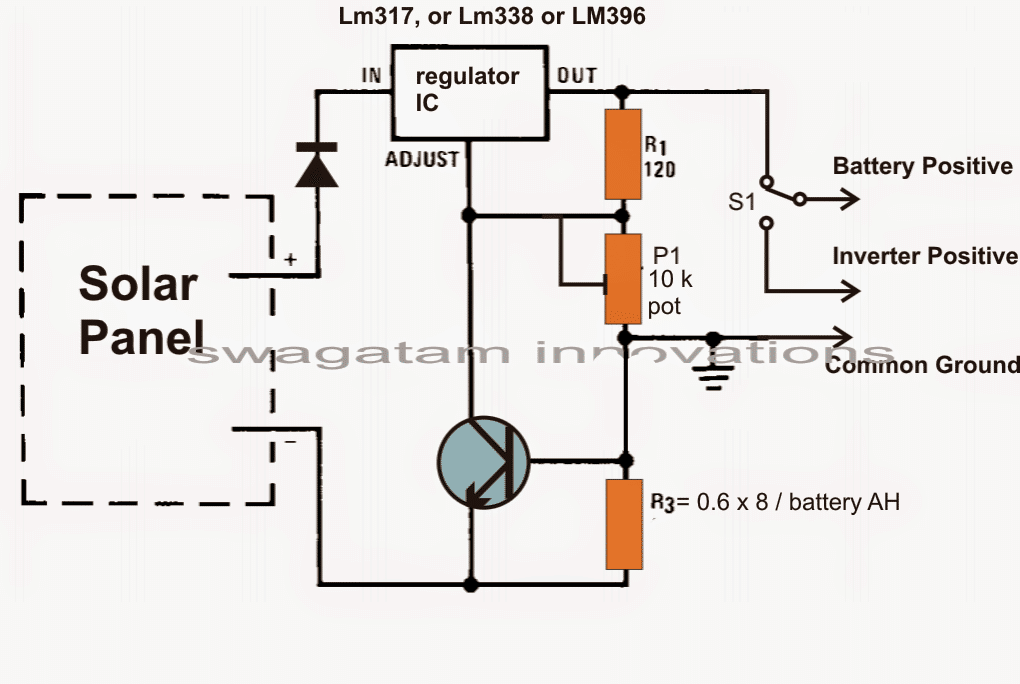

A simple solar panel voltage regulator circuit may be witnessed in the following diagram, the given switch may be used for selecting a battery charging option or directly driving the inverter through the panel.

In the above case, the regulator needs to produce around 7 to 10amps of current therefore an LM396 or LM196 must be used in the charger stage.

The above solar panel regulator may be configured with the following simple inverter circuit which will be quite adequate for powering the requested lamps through the connected solar panel or the battery.

Parts list for the above inverter circuit: R1, R2 = 100 ohm, 10 watt

R3, R4 = 15 ohm 10 watt

T1, T2 = TIP35 on heatsinks

The last line in the request suggests an LED version to be designed for replacing and upgrading the existing CFL fluorescent lamps. The same may be implemented by simply eliminating the battery and the inverter and integrating the LEDs with the solar regulator output, as shown below:

The negative of the adapter must be connected and made common with the negative of the solar panel

Final Thoughts

So friends these were 9 basic solar battery charger designs, which were hand picked from this website.

You will find many more such enhanced solar based designs in the blog for further reading. And yes, if you have any additional idea you may definitely submit it to me, I'll make sure to introduce it here for the reading pleasure of our viewers.

Feedback from one of the Avid Readers

Hi Swagatam,

I have come across your site and find your work very inspiring. I am currently working on a Science, Technology, Engineering and Math (STEM) program for year 4-5 students in Australia. The project focuses on increasing children’s curiosity about science and how it connects to real-world applications.

The program also introduces empathy in the engineering design process where young learners are introduced to a real project (context) and engages with their fellow school peers to solve a worldly problem. For the next three years, our focus is on introducing children to the science behind electricity and the real-world application of electrical engineering. An introduction to how engineers solve real-world problems for the greater good of society.

I am currently working on online content for the program, which will focus on young learners(Grade 4-6) learning the basics of electricity, in particular, renewable energy, i.e. solar in this instance. Through a self-directed learning program, children learn and explore about electricity and energy, as they are introduced to a real-world project, i.e. providing lighting to children sheltered in the refugee camps around the world. On completion of a five-week program, children are grouped in teams to construct solar lights, which are then sent to the disadvantaged children around the world.

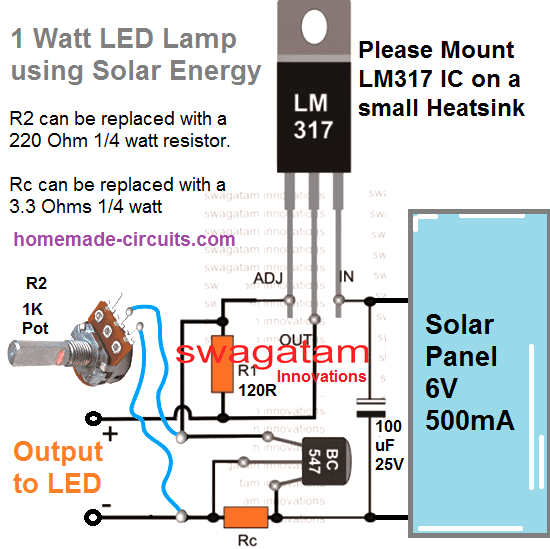

As a not 4 profit educational foundation we are seeking your assistance to layout a simple circuit diagram, which could be used for the construction of a 1 watt solar light as practical activity in class. We have also procured 800 solar light kits from a manufacturer, which the children will assemble, however, we need someone to simplify the circuit diagram of these light kits, which will be used for simple lessons on electricity, circuits, and calculation of power, volts, current and conversion of solar energy to electrical energy.

I look forward to hearing from you and keep on with your inspiring work.

Solving the Request

I appreciate your interest and your sincerely efforts to enlighten the new generation regarding solar energy.

I have attached the most simple yet efficient LED driver circuit which can be used for illuminating a 1 watt LED from a solar panel safely with minimum parts.

Make sure to attach a heatsink on the LED, otherwise it may burn quickly due to overheating.

The circuit is voltage controlled and current controlled for ensuring optimum safety to the LED.

Let me know if you have any further doubts.

Request from one of the avid readers of this blog:

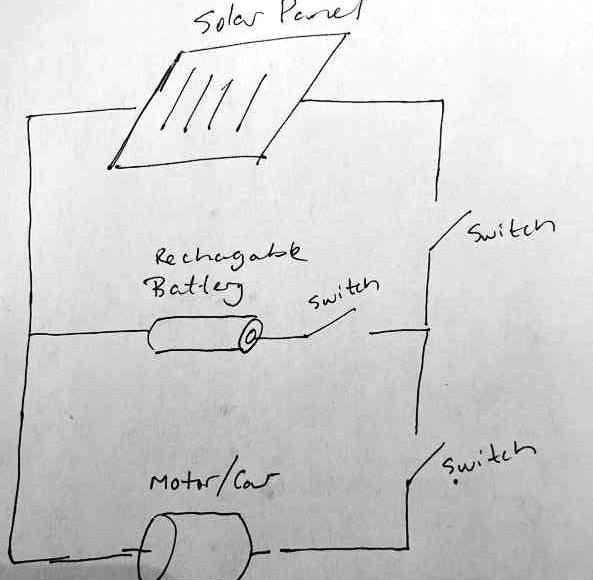

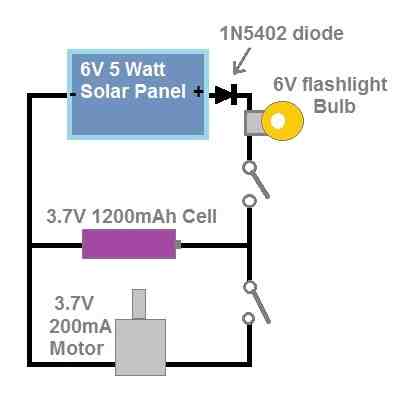

Hi, thank you for everything you do to help people out! My son would like to create a science fair experiment where he can show an electric car running on a solar panel only during the day while charging a battery and running on battery only during the night. For this, we planned to have a small solar panel connected to a battery and motor in parallel (see the attached drawing).

- Will this work?

- Can you recommend a size of solar panel, battery and motor?

- As to not overcharge the battery, should a resistor be added? What size would you recommend?

- Should a diode be added? What size would you recommend?

My Reply:

- yes, it will work.

- Use a 6 to 8V 1-amp solar panel.

- The switch in series with the battery is not required. The remaining two switches are fine. This switch can be replaced with a 4 ohm 2 watt, or simply a 6 V flashlight bulb.

- This bulb will illuminate while charging and will slowly shut off as the battery gets fully charged.

- You can add a diode in series with the positive wire of the solar panel. It can be a 1N5402 diode

- The battery can be any 3.7V 1200mAh Li-ion battery.

- Motor can be any 3.7V DC motor.

More Questions:

Couple more questions, I cannot find a solar panel with those specs, do you think you could send me one on the internet so I can find something similar? Great idea on the flashlight bulb, I assume this would need to be an incandescent light? Do you think this would properly protect the battery or would an additional resistor be needed?

My Reply:

For the solar panel, you can search for a 6V 5 watt solar panel.Yes, the flashlight bulb will need to be an incandescent type, so that the filament can be used to control the current.The bulb should be enough to control the current, no additional resistor will be required.Please find the attached diagram for the detailed schematic.

Have Questions? Please Leave a Comment. I have answered over 50,000. Kindly ensure the comments are related to the above topic.

please calculate for the 40ah battery using lm338

10% of 40 is 4.

so R = 0.6/4 = 0.15 ohms.

and power = 0.6 * 4 = 2.4 watts

thank you for correcting so the resistor is supposed to be 0.12 ohms

how about for sulphuric acid battery

You are welcome.

sulphuric acid battery is same as lead acid battery.

that means for resistor while using lm388 it’s for example 0.6 * 50ah = 30 ohms resistor

For lead acid battery the max charging current will be 10% of its Ah rating.

10% of 50 Ah is 5 ampere, so it will be 0.6/5 = 0.12 ohms, and 0.6 * 5 = 0.3 watts

By the way, you have written the formula and the IC number wrongly, please check carefully before writing.

what is the highest battery ah and the highest solar panel watts, please calculate for me the highest resistor we can put but remember you said the circuit can use lm371 or lm388 so for now I’m beginning with lm371

LM317 can provide a maximum of 1.5 amps, while LM338 can provide upto 5 amps.

For LM317 you can use 1.5 * 10 = 15 Ah battery maximum, and solar panel of 2 amp, 35V maximum

For LM338 you can use 5 * 10 = 50 Ah Battery maximum, and solar panel of 5 amp, and 35V maximum.

The batteries are lead acid batteries.

please let me understand what you meant by resistor you 0.6/battery please check the partlist of lm388 or lm317

Suppose the maximum charging current of your battery is 1 amp.

Then the current limiting resistor across the base/emitter of the transistor can be calculated using the formula:

R = 0.6/Charging current

= 0.6 / 1 = 0.6 ohms

Power of resistor will be 0.6 * 1 = 0.6 watts.

100w solar panel can charge how many ah battery? can we design a charge controller for it? please help

A 100W solar panel can charge approximately 23–28Ah of battery capacity per day, depending on the sun exposure and system efficiency.

you did not name the diodes used in the lm338 solar charge controller, and please write the ratings like for example minimum and maximum input and it’s output voltage rating (the solar panels that can be used and battery ah)

I have added the parts list just below the diagram, you can check it now…

Maximum solar panel voltage must not exceed 35V

Diodes are 6A4

it’s okay help design the solar charge controller for 70ah battery

You can try the following universal charger circuit:

battery 70ah 12v and solar panel 100w

is it possible to use 555 ic in making the charge controller

You will need a 24V 150 watt panel for charging a 70 Ah battery efficiently, a 100 watt panel might not charge optimally…

please help design 100w solar panel charge controller for 70ah battery

Please provide voltage ratings of the solar panel and battery….

1. from your second diagram using lm338 the diagram with a meter, can it also be used for charging 10w,20w,30w with 50w panel or it’s used for a specific type of panel only?

2. from your diagram or let me say your third diagram of 10w,20w,30w and 50w what if not everyone needs very many LED bulbs as you had drew, if it were to skip led bulbs what could we have replaced or what if it could be replaced with 3 or 4 indicator led bulbs?

Hello Rashid,

The LM338 can be used with 50 watt solar panel, provided the panel voltage is below 35V and the current is below 5 amps.

In the 3) design, you can reduce the number of LEDs, and accordingly adjust the current limiting value of the right side LM338 circuit.

Mr. Swagatam, thanks for the tips and information, I’m new with solar panels. I just got the task to design a battery charge for a multiple of solar panel ratings. we have 100w, 200w, 400 and 550 w panels that I need to see if we can design one charge that can accommodate all this panels. here is the situation the 100 w panel has an output of 12 to 19vdc when the 400 & 550 is 40 to 60vdc. I will need an indicator that the unit is on and charging, and a auto cut off when battery is full. output should be 12vdc

Thank you Ernesto,

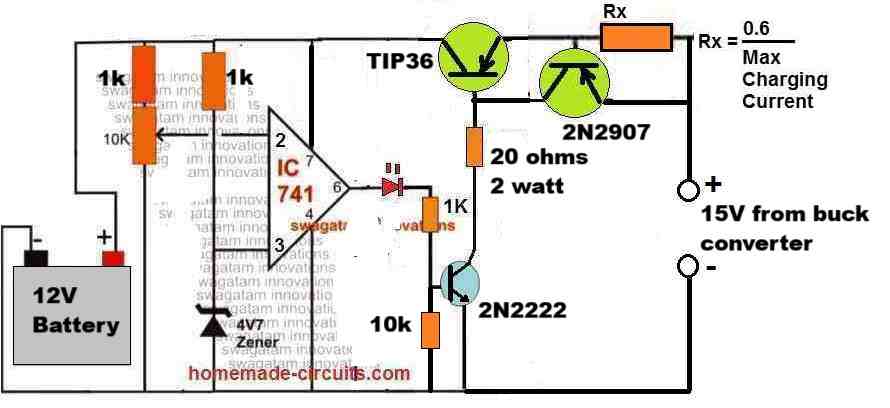

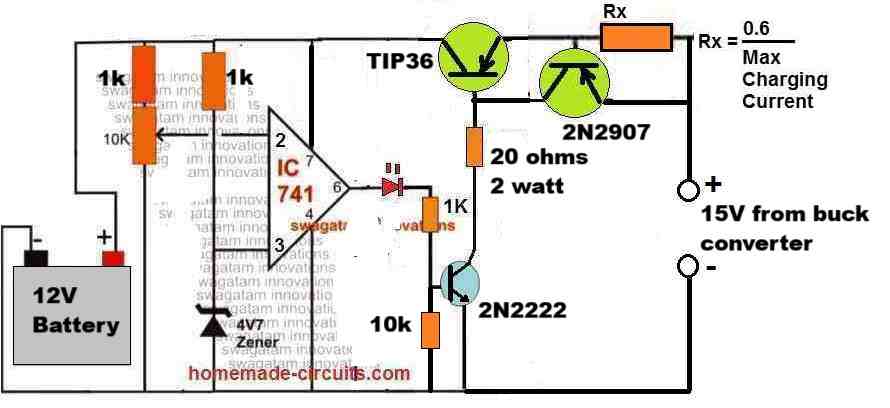

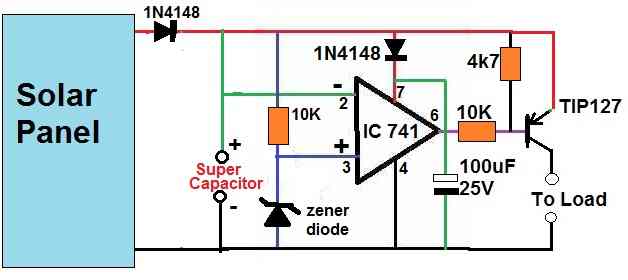

You can try the following universal 12V battery charger circuit with auto cut off and over current protections with all your solar panels, for charging a 12V battery:

However, you will need to add a buck converter for solar panels that are higher than 20V.

The preset associated with the 741 IC can be adjusted to implement the cut-off at around 14V.

Please let me know if you have any further doubts or questions…

Dear Mr. Swagatam, it is a pleasure to greet you and above all to enjoy your very varied designs that are useful for daily life.

My name is Guido Fernández Rosales and I am Cuban living in Havana.

Our country has a very delicate situation in relation to the national electricity system and its production of electrical energy and any solution that can be developed from Renewable Solar Photovoltaic energy to MINIMIZE the impacts of the electricity generation deficit is very necessary.

Regarding the design:

7) Simple Solar Charger for Street Lights

I would greatly appreciate knowing if for a solar Avenue luminaire that is within the following powers; 200/300/400watts, the design you propose can be used or modifications need to be made.

The characteristics of the LED that I want to mount in the luminaire are:

SMD LED MLT-SMD-2835-03350EXX Typical forward voltage 3.0 v DC Forward current 350 ma

Typical Power dissipation 1 w.

Typical Luminous flux 150lm/170lm

I would greatly appreciate your comments and suggestions to develop national production for this type of luminaire.

Thank you so much Guido, for your kind feedback, I appreciate it very much.

I understand your problem and I can definitely help you to solve this problem.

The 7th circuit can be modified as per your requirements, however i would want to replace the transistorized high/low cut off stage with an op-amp stage for an improved performance.

Please let me know the maximum voltage rating of your solar panel, and how do you wish to configure the LEDs? I mean what should be the series parallel numbers in the LED configuration?

Let me know this and I will help you out with an appropriate circuit design.

Can a dc car bulb put in series with a 30watt solar Pannel to charge a 12volts solar Pannel protect overcharging or limits tge current when the battery is fully charged

It can limit current but it cannot stop overcharging of the battery. To stop overcharging you can use a voltage regulator which regulates the maximum charging voltage below the maximum full charge level of the battery.

For example, for a 12V battery you can use a 14V regulator to limit the max voltage to 14V which is lower than the maximum full charge limit of 14.3V.

Thanks and can I use the simple diagram with the 12 volts ,diode and resistor circuit to do that thanks for your timely response

You can use the 7812 circuit shown at the top if your battery is a 12V 7 Ah battery.

Thanks am greatful ,no need to get 7814 .can a 30 watts solar panel charge a 19volts computer power bank ? And does it need a regulator circuit ,or can just be connected directly from the Pannel please

If your power bank has an in-built regulator then no need of any external regulator, if not then you will need an external regulator.

Please what type of regulator can I use as the voltage is 19 volts thanks

You can use the following circuit:

Please replace the pot with a fixed resistor after calculating the output voltage:

https://www.homemade-circuits.com/lm317-lm338-lm396-calculator-software/

Thanks

Hello sir swagatam,i followed this charger circuit and it work,i used it to charge my li -ion battery..but it it was slow charging when i used it my my 40amps battery..how can i make it as a fast charger,or what can i replace for lm338 and bc547 to make it fast charging..i wanna make it in the same diagram..what transistor can you recommend in order to make it high current.. please sir,help me.thanks

Hello Vicferre,

For fast charging of a 40 Ah L-Ion battery you will need at least 20 amp charging current which the shown circuit cannot supply.

If you are interested to use the same IC LM338 then you will need to connect at least 4 of them in parallel.

For complete details you can refer to the following post:

https://www.homemade-circuits.com/how-to-connect-lm338-ic-in-parallel-to-increase-output-current/

Ok sir,i will try to build that circuit design..thanks for helping..i learn a lot from you..can i replace a transformer with 18v solar panel sir? I knew already that 220v source,i am focusing now with my solar panel.

No problem Vicferre, You can use an 18V solar panel, in that case you can eliminate the transformer, the bridge rectifier and the capacitor, just make sure to add a polarity protection diode with the solar panel.

In addition to this sir,,what transistor i must use as replacement for bc547 for fast charging of 40ah battery..i wanna build it in the same circuit design,only the transtor is replace.thanks,

Vicfere, the BC547 monitors the load current level and controls the LM338 accordingly ensuring the the output current does not exceed the load’s specification. For your application current control is not required because the 5 parallel LM338 in the previous design is internally current-controlled and will not allow more than 5 * 4 = 20 amps, which is just what is required for your application. So using 4 LM338 in parallel will restrict the max output current to 20 amps. If you want to make the charging still faster then you can add one more LM338 or maybe two more LM338 in parallel to make the current 30 amps for your 40 Ah Li-ion battery. Just make sure the output voltage is perfectly adjusted to provide not more than 4V per cell for your Li-ion battery bank. At 30 amps your battery may start warming up which again might need to be monitored and regulated appropriately.

…alternatively, you can also consider trying the concepts explained in the following article, which looks cheaper compared to the parallel LM338 option:

https://www.homemade-circuits.com/lm317-with-outboard-current-boost/

Hi Sir,

I dont really understand why do we need the other the tip36 and 2n222 transistors in design 6 with the integrate LM338. Thank you

Hi Sivuyile, the TIP36 and 2N2222 stage prevent the battery from over discharging. It cuts off the battery supply to the load when the battery voltage has dropped to a predetermined minimal level.

My wife is enamored with solar fairy lights for landscaping. However, commercial setups eventually fail in either the solar panel or the charge control chip. I am trying to design/construct my own box and reuse the still functioning LED strings. I am having difficulty finding a chip to control recharging a single AA battery and possibly control the LED string as well. I have attempted a design using a YX805A chip, but the datasheet is in Chinese. My best guess is that this chip can only handle 1.6v which is not enuf to power a string of LED. It seems to be good enuf for a single LED. How do I find a selection of chips that might do the trick?

Thanks for any assistance in advance.

YX805A cannot handle more than a single LED, so it cannot be used for driving LED string lights.

A single AAA cell will neither be able to power LED strings, unless it is a Li-Ion cell.

A 3.7V Li-ion appears to be the most suitable option for operating string lights with multiple LEDs.

If you can provide me with the LED string light specifications, I may try to figure out the appropriate circuit for the solar controller.

I need to supplement a 90 volt bank of solar panels with an AC generator, for shady days, on an off grid system. I currently charge the batteries with a 6000 watt AC generator but only need about 3000 watts.

Can I connect a diode rectifier to the AC output and use a variac to control the voltage to the 80-90v needed charge voltage?

Or what other options might be available?

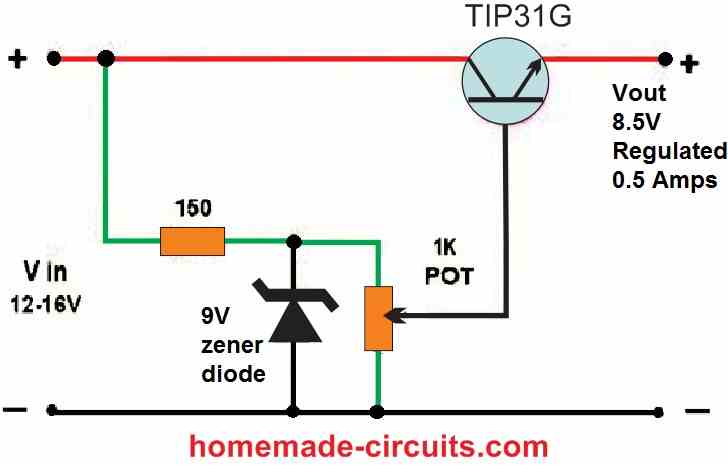

Yes that can be done, additionally you can add a voltage regulator between the battery and the 90V DC from the diode bridge to fine tune the full charge voltage level to the battery. An example regulator circuit is shown in the following diagram:

You can replace the transistor with a TIP150, zener diode with a 90V 1 watt zener, 150 ohms with a 47K 2 watt

The AC source must be connected with the variac, and the variac output with the bridge, the bridge output with the regulator, the regulator output with the battery.

Hello Sir.

I have a solar system with 100W panels powering through a solar controller my lead acid 12v car batteries.

I want to add an emergency battery which consists of a power bank. It should not be using the controller. I thought to connecting a car plug charger (12V/24V->5V) directly to the solar panels, so it would automatically recharge the power bank over USB at day time.

Is there any issue to have the car charger all time directly connected in parallel to the panels/controller?

Thanks for your humble advice!

VESPUCCI

Hello Vespucci,

If your solar panel’s maximum output voltage is below the maximum tolerable input voltage of the car plug charger, then there’s absolutely no harm in keeping the charger connected to the solar panel all the time.

Just make sure the solar panel output voltage never exceeds the maximum tolerable voltage rating of your car charger.

Thanks so much for your help! You are best personality of the internet!

VESPUCCI

You are most welcome Vespucci.

Hello sir, im glad that im successful with my experiment for overcharged and over discharge protection for my 3.7v li ion battery. And thanks to your #5 transistorized solar design.im learning from you a lot.????..i sent you my circuit diagram in your email and its working…next request sir,can you please send me the diagram of pure sine wave inverter,12v to 220v inverter..i knew now on how to charge the batt,and so, inverter is my next project..im so tired of trying those fake inverter in YouTube,,and that was a reason why i ask you a design for this.thanks in advance for helping me..you are my great teacher now.????

Thank you Vicferre,

Glad the circuit is working for you.

Making a pure sine wave inverter can be a little difficult, instead I would recommend you to try a good modified inverter circuit whose output can be transformed into almost a pure sine wave by adding a few 400V capacitors.

The entire circuit can be found in the following post. You can try the 2nd or the 3rd diagram from the following post:

https://www.homemade-circuits.com/modified-sine-wave-inverter-circuit-2/

can you invent a short circuit protection for li-ion batteries as they are very dangerous when shorted

You can supply the Li-ion power to the load through a LM338 regulator circuit which will automatically ensure a controlled current to the load with short circuit protection:

Hello sir,,i followed your design before and i proved thats it was working.I tried your #5 solar circuit design ( transistorized solar charger) and it was working for me,i was using d718 npn transistor and B688 for pnp. I dont have 11v zener for xy,so i made 2pcs of 5v zener in parallel and make it 10v…its effective sir,there was no load if the battery reaches 10v…then i parallel 3pcs of 5v zener to make it 15v for my xz because i have no available 14.6v..my question is that,is it ok to put this 15v?can it control the over charge?and if i have 14.6v zener soon, where can i put a led indicator for my over charge?so that i will know and prove that the solar stop charging because batt is full… thanks for helping me sir again

Thanks Vicferre, Glad the circuit is working for you.

However 14.6V or 15V is considerably high full charge level for a 12V battery, therefore I would recommend adjusting the zener value to 14V, because 14V is optimal overcharge limit for a 12V battery. For adjusting the zener value, you can add a few 1N4148 diodes also in series with the zener to fine tune the value to 14V. The polarity of the 1N4148 will opposite to the zener diode polarity. Sorry there’s no way to add an LED indicator in that circuit.

i dont have in4148 diode sir,but i have many in4007 diode.can i use it?thanks for response ????

Yes 1N4007 will also work…

Ah ok sir, thanks for additional knowledge ypu had given…i have to do a series of test with my experiment.well,i observed for over discharge protection and i prove that already.my next test is how many hours to full change my 12v batt from solar..my additional question sir is that,how many hrs do you charge using your own design?im asking this because i use other npn transistors that available to me… thanks again sir

Vicferre, The charging time will depend on the amount of current supplied by the NPN transistor to the battery. If its around 1/10th of the battery Ah, then the maximum hours will be around 10 hours.

What is that 1/10th mean sir?and what transistor that is fast charging that you can recommend?you’ re helping me a lot, thanks..i will let you know soon the result of my experiment..its compliments to you cause it comes from your design..????

1/10th is the result obtained by dividing the Ah rating of the battery by 10. If your battery Ah rating is below 10 Ah then you can use a TIP122 transistor

Ah ok sir, thanks

Engr. Good morning sir,

Please help,

1) I need a simple circuit diagram of solar battery charger using MOSFET..

Cut off at 14V..

Battery voltage 12V.

2) Secondly. How do I use Op-amp ICs for battery charge controller, like LM358 or LM741

Hello Sunshine,

1) You can modify the circuits from the following article for your 12V battery. Replace the 22K resistors with 1K and remove the parts from pin#7 of the opamp, and connect the pin#7 directly with the positive line:

https://www.homemade-circuits.com/make-this-48v-automatic-battery-charger/

2) For op amp battery chargers you can refer to the following article:

https://www.homemade-circuits.com/opamp-low-high-battery-charger/

Okay sir, thanks so much, let me work with the solution you provided for me..

I appreciate

No problem sunshine.

Good morning Sir!

Thanks for always being there to assist us. I love your circuits because they are relaible.

Sir, I have this questions.

1) As per design #5, the last or simplified version of the circuits which of the transistors work for full charge cut off, and which work for low voltage cut off?

2) According to another article you wrote on “4 lithium battery charger circuits” , you said we can charge a lithium battery with 14% of the rated voltage when there is a full charge cut off circuit. I wish to find out if I desire a full charge voltage of 12V using the above mentioned simplified circuit, can I use a zener (Zx) that is 12V(1.14) +.6 ? Considering that there is a full charge cut off

Thank you Ngang,

1) The transistor 2N2907 works like a low voltage cut-off switch.

2) The full charge voltage level of Li-ion batteries generally come in multiples of 4.2V. So For a 12V li-ion battery the fully charge level will be in multiples of 4.2V which will be 12.6V. However for better safety your can take the value of 12.4V instead of 12.6V.

So Zx value should be around 12.4 + 0.6 = 13V.

Please kindly help me to have comprehensive charging controller circuit diagram that suitable for 12v 40mah battery 12v 100mah 150watt solar panel

Thanks for you uncommon guide

The best idea is to use a LM317 based circuit, and adjust its output to slightly lower than the full charge level of the battery. It will keep your battery correctly and optimally charged.

Hello sir, i wanna try to follow the #5 solar circuit…can i use 7v or 6v zener in zy?please help me,i wanna know how to build that… thanks for reply

Hello Vicfere, the ZY value should be set depending on the low voltage cut-off threshold of the battery. What is your battery’s low voltage cut off threshold?

Thanks sir for the reply…i sent you message to your email…in addition to my question,can i use the the #5 diagram as a charger to my 3.7v li ion battery.i will only replace 5v or 4.1v zener to xz and 3v or 2.5v zener to xy…is it possible?im just trying to experiment ????. I want protection to my battery.thanks for response

Yes you can experiment with those zener diodes, but for the 3.7V lithium ion cell make sure the emitter voltage of the 2N2222 does not exceed 4.1 V. Check this before connecting the 3.7 V cell. Make sure to have a 1K resistor connected across the emitter/ground while setting the 4.1V. You can remove the resistor once the voltage is set.

Swag I just built No.5 on the list, this thing is awesome!! I am just using a cheap solar cell from a calculator and am getting 4 continuous volts, and the connected 18650 battery isn’t hardly draining at all, I currently am lighting a 1/2 watt LED and system is stable! . Thanks for this awesome circuit, I build a lot of your designs and postings and this one I think is better than a joule thief…..P.S. Swag in No.5 circuit is that a 47K trimmer pot from the transistor base into the voltage divider? Wasn’t quite sure, so I built it with a trim pot, not sure how to use it, and where would be the best place in the circuit to insert an LDR, so LED only on at night…thanks again Swag for all you do

That’s great Mike, glad you could build it successfully. Yes, the 47K is a trimpot, which must be adjusted to switch OFF the associated transistor when the battery has reached a low voltage.

For LDR connection you will need another BC547 transistor stage. Base to one terminal of LDR, other terminal of the LDR connected with the battery positive.

Also, base to ground through a 10K resistor.

Collector to the base of TIP122, and emitter to ground.

Ok sounds good thanks, why is it a 47K trimmer and not a 50K? Is there some relation to the circuit that you need 47K? Reason I ask is the case of trim pots I bought a while back (generic blue box shape) all are even number values….thanks Swag

Mike, The value is not at all critical, you can use a 50K preset without any issues or maybe a 30K preset, or a 20K preset etc they will all work.

Ok thanks Swag, have a great weekend

Hello Swagatam, I bought two 55ah batteries connected in parallel and 150w solar panel with solar controller on January this year. Now the batteries can’t be charged properly coz the just blinks even in a sunny ☀️ day some times. Do you have best solar controller circuit that I can replace it with…..about 60A and above? Pliz refer me. Thanks in advance.

Hello Morris, please specify the battery voltage and the solar panel max open circuit voltage.

Hello Swagatam, the batteries specifications are 12v 50ah each and the panel is mono 18v 150w.

thanks

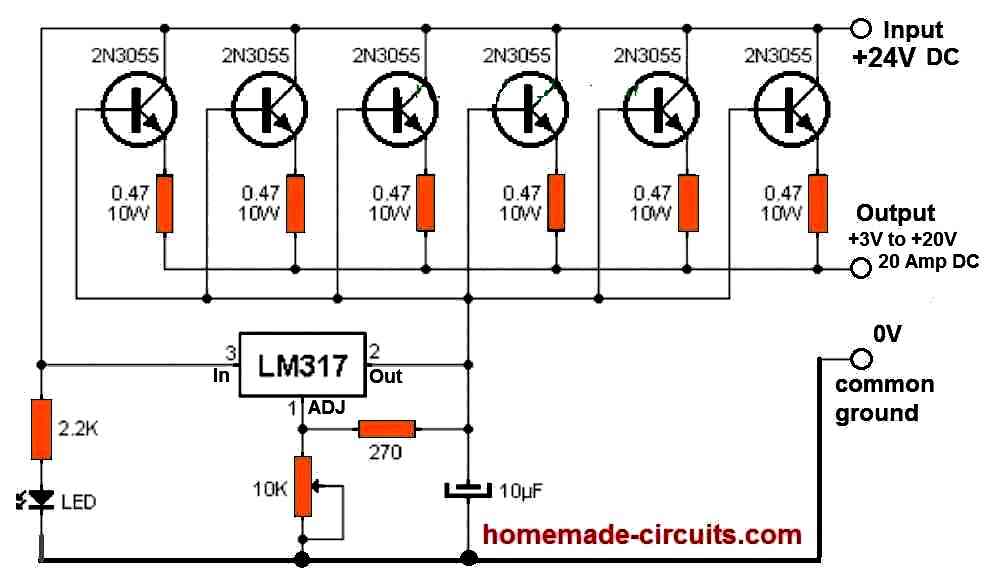

OK great, you can try implementing the following circuit. Your two 50 Ah batteries in parallel will require around 15 amp current for charging optimally. Adjust the 10K preset such that the output voltage to the battery is not more than 14 V. Adjust this without a battery connected. Use a 1K ohm 2 watt resistor as the load (across the output) while confirming this output voltage.

Hello sir, connecting the 1k resistor across output means that i should connect one end to positive and the other end to the negative? Secondly, will this circuit auto cut the the power to battery upon reaching the charge threshold?

Thanks

Hi Morris, The 1K must be connected across the points which is marked as +3 to +20 V and the 0 V ground line.

The full charge level of a 12V lead acid battery is around 14.3V, but since we are adjusting the charger output to only 14 V, so cut off is not required….the battery will be charged at 90% and will have a longer life, and can work without an auto cut off.

Ok thank you very much. Another question, can it be used to charge 12v battery for example if the solar is 300watts 18 and the battery is 300ah 12v?

Secondly can you refer me to another circuit of the same design that can be connected to solar panel 300watts 36v to charge 200ah 12v batteries connected in series if my inverter is a 24v.

Thanks.

The answer to your first question is, yes the proposed circuit can be used to charge your 300 Ah 12V battery from an 18 V 300 watt solar panel.

The answer to your second question is: You can use the very same circuit to charge your series connected 24 V 200 Ah battery from a 36 V panel. Just make sure to replace the LM317 with an LM317HV IC

Can the lm 317 be connected in parallel to handle the charging process or one is just enough? Thanks. And if the connection can be done in parallel what about the prest?

For 20 amp current you may require 20 to 30 numbers of LM317 in parallel which is not a good idea. Just one is enough if 2N3055 transistors are connected.

Hello Swagatam, I got an original lm317t. So in the diagram you have shown me i just connect 6 pieces of 2n3055 in that maner and one lm317. That will be just enough to charge the two 50ah batteries connected in parallel?

Secondly, if I want to charge a 24v battery with the 36v solar using the same circuit. Do I tweak the prest so that the output voltage reads 28v if in the case of 12v100av should be at 14v?

THANKS.

Hello Morris, yes that will be quite enough.

For 36 V you can use the same circuit but make sure to replace the LM317 with LM317HV. After that you can tweak the output voltage to 28 V using the 317 potentiometer.

In the circuit you sent to me, the 10k is not a preset it is just a potentiometer with three terminals like that of an amplifier for adjusting voltage?????????

Thanks.

Actually it should be preset or a trimpot so that the output charging voltage can be firmly fixed to a desired particular level.

I have a question sir,maybe it is considered as short circuit if we connect+3 to 20v output across 0v ground..if it work, what is the purpose of that?thanks

If you connect 3V across a 24V source, it will act as a short circuit and destroy the 3V source. There’s no purpose of this application.

Hi Swagatam. I am so thankful for these post. You really open my understanding of electronics. I am a mechanical engr. who loves building stuffs from mostly scratch.

I have an 18v solar panel ( don’t really know the power rating, it was initially used on a large street light) which I will like to use for charging three pairs of 18650 batteries in parallel while using them in series to power up a load. Can you please help me design the charging circuit capable of taking 10amp load with low battery and over change cut off. Thanks

Thank you Breno1,

I appreciate your interest.

I think you can try the last circuit from the following article. It should do the job for you.

https://www.homemade-circuits.com/opamp-low-high-battery-charger/

Thanks Swagatam for the response, but the I checked the circuit you recommended and it is a 12v battery charger. However what I want is a simple charger that will charge 3X 3.7v 18650 batteries in parallel from an 18v solar panel, while delivering 11.2v to a load in series. Please.

No problem Breno1, I will try to design it for you, however I could not understand what you meant by…”while delivering 11.2v to a load in series”

Do you mean you want to charge 3 X 3.7v 18650 batteries in parallel, and simultaneously power a load of 11.2 V, both from a 18 V solar panel?

@ Swagatam, you got the first part of charging the batteries in parallel. However, the load will also be powered by the batteries (24hrs), and it takes 12v Max. 9v min. So, while the batteries are being charged in parallel, they should also be delivering power in a series connection to meet up the voltage requirement of the load.

Thanks Breno1. Well, that can be very difficult to achieve. I cannot figure out how to set two configurations for the batteries, one in parallel for charging and second in series for powering the load. Sorry, no ideas for this configuration.

Thanks Swagatam for being straight. Though my main aim is just to charge the batteries safely while using them to power a load. My problem only got complicated when I read an article that says it’s not safe to charge those 18650 batteries in series.

If there is any way to charge them safely in series then I will go for that please.

Thanks again.

@Breno1, Generally speaking there’s no harm in charging Li-ion batts in series provided all are new and have identical characteristics. It happens very rarely that one of them alters its characteristics causing issues with the series charging. If you are still concerned then you can charge them in parallel first and then once fully charged you can connect them in series manually.

An automated version of the above operation can be extremely tedious to achieve.

@Swagatam, ok in that case I guess I need a 3 to 5 amp charger to charge them in series while connected to the load?

If so please recommend one you have designed or maybe modify one to charge 12vmax., 9v min. From a 18v solar panel.

OK, great, in that case I can provide you simplistic design which will always keep your batteries charged and in a topped up condition using a constant voltage and constant current. Meaning it won’t a cut-off at 12V and restore at 9 V, rather it will keep the batteries charged constantly at 12V, ensuring that the 12V is never exceeded or reduced.

I am suggesting this type of charger because building and setting up an auto cut off type of charger can be quite difficult for you, since you are not from an electronic domain.

Let me know if that’s OK with you.

@Swagatam Yes that will do. Thanks

@Breno1, You can try the following design:

You will have to adjust the P1 potentiometer such that the points across the battery terminals get exactly 12 V. Please do this without connecting a battery.

Since 12 V is much lower than 12.6 V which is the actual full charge level of your battery, an auto cut off is not required, because the battery is never going to reach the full charge level.

@Swagatam. Thanks for the circuit. And I guess that 6A4 diode means 6.4amps diode?

You are welcome Breno1.

“6” indicates that the diode can handle a maximum average forward current of 6 amperes.

“A” typically refers to a standard axial lead diode package.

“4” signifies that the diode has a PIV of 400 volts.

Hi @Swagatam, thanks for the explanation. I still have one more issue though. How do I make up a 9.5v zener, as I can only find 9v zener to buy? Secondly you didn’t indicate the wattage of the 120ohm, 1kohm, and R3 as you did for the 470ohm resistors.

Hi Breno1, you can add a 1N4148 diode in series with the zener diode to convert it into a 9.5V. The cathode will face downwards and the anode upwards.

120 ohms and 1K are all 1/4 watt rated.

R3 = 0.7 / max charging current.

Max charging for your battery must be ideally 1.5 amps.

R3 = 0.7 / 1.5 = 0.46 ohms or simply 0.5 ohms

wattage = 0.7 x 1.5 = 1.05 watts or 2 watt, wire-wound type

Each of the battery is 3500mAh and I will double them before connecting in series (i.e three pairs in series).

Hi hope you doing well ????

What is the normal voltage, and current to charge a 12v 6A QLink

If it’s a li-ion battery then 3 amps, if it is an smf then 1 amp.

Juris

At the first circuit with IC7812 the rezistor is not needed because IC have Iq=6 to 8 mA to ground.

The voltage also may be set with to rezistors, one from output to Ic ground pin and other from Ic ground pin to ground.

Hello

Please can you help me on how to charge a 10,000mah battery 3.7v

Using 8v 8W solar panel

Hope to hear from you thanks

Hi,

8 W 8V signifies 1 amp current.

Even if you use a buck converter and reduce the 8V to 4.2V for the cell, still the solar current would be 8W / 4.2V = 1.9 amps.

1.9 amps is too less for a 10 amp Li-ion cell…..the current must be at least 5 amps for optimal charging, meaning the panel wattage must be at least 20 to 25 watts.

thanks for variety of charger circuit..

exiting awaits me.to do and expirements. your such a an electronic circuit expert.

mr. swag..

good evening..im one in a billion of your avid fan. and hope you can help me building an ebike charger circuit.

its a 48v. 32aH Carbon Graphite battery according to the ID mark product spec. i prefer very simple and cost effective. thank you very much and happy new year.

Thank you so much Michael, and Happy New Year to you!

I would recommend you the last circuit from the following article:

https://www.homemade-circuits.com/make-this-48v-automatic-battery-charger/

Sir, I want to design a circuit which can store energy from a little 6v solar panel into a super capacitor and when it reaches a certain amount of voltage (or gets full) it Suddenly releases its energy into a 500 mw , 3 to 6 v water pump for 6 seconds .

I would appreciate your help

Hello Khorshid,

you can try the following design:

The zener diode value decides at what level you want to dump the capacitor to the load.

that was really helpful Swagatam

” for learning more from you ” , can we make it with just transistors ?something like transistor latch circuit with modification to start suddenly not gradually .

thank you

Thank you Khorshid,