In this post I have explained how to make a simple variable power supply circuit using transistor 2N3055 and some other passive components. It includes variable voltage and variable current feature, fully adjustable.

Main Specifications

1) Adjustable from 0-30V, 0-60V, and 0-100V, and 500mA to 10 Amp as per user preference

2) Short Circuit Protected when mounted on proper heatsink

3) Ripple free, with less than 1Vpp

4) Output is Stabilized and filtered DC

5) Short circuit LED indicator

6) Overload Protected

Introduction

A power supply circuit that does not include the features of a variable voltage and current control can by no means be considered truly versatile.

A variable workbench power supply circuit I have explained in this article is not only specified with a continuously variable voltage control but is also equipped with the feature of overload or continuously variable current control.

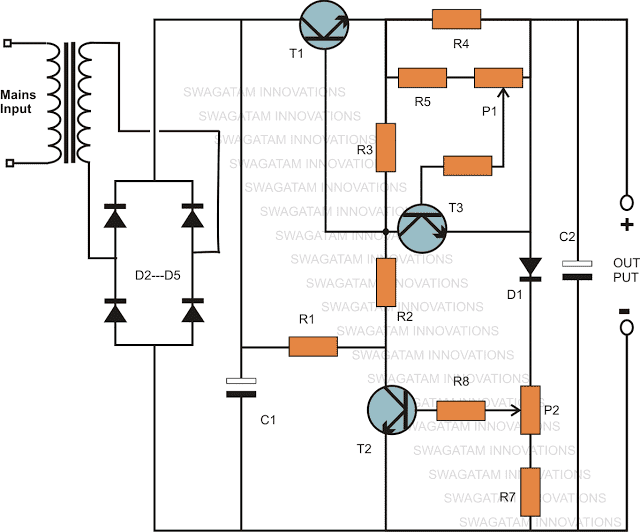

Circuit Diagram

How it Works

A keen look at this 2N3055 based variable voltage current power supply circuit using transistor 2N3055 reveals that it’s actually only an ordinary stabilized power supply circuit, however it yet still provides you with the proposed features very efficiently.The voltage variations are made by using the preset P2, through a feedback configuration employing the components D1, R7, T2 and P2.

The inclusion of D1 makes it sure that the voltage can be lowered right down to 0.6 volts, which happens to be the forward voltage drop of the diode.

If any other specific minimum value is required then the diode can be replaced by zener diode having the required specified value.

Therefore in this variable power supply circuit using 2N3055 transistor, the transformer being a 0 – 40 V, the output becomes variable right from 0.6 to 40 volts maximum, that’s very handy indeed.

For implementing the current control feature, T3 along with P1, R5 and R4 are involved.

The value of R4 is specifically becomes responsible for defining the maximum allowable output current.

P1 is set to choose the maximum range within the value that’s marked or identified by the resistor R4.

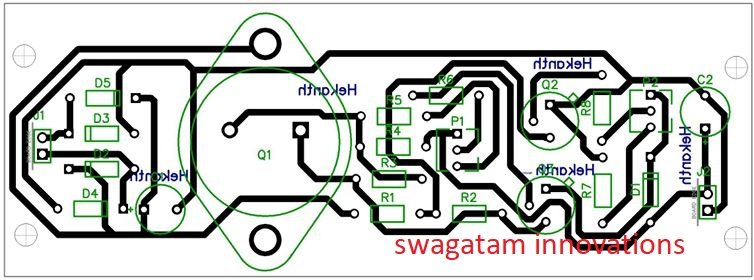

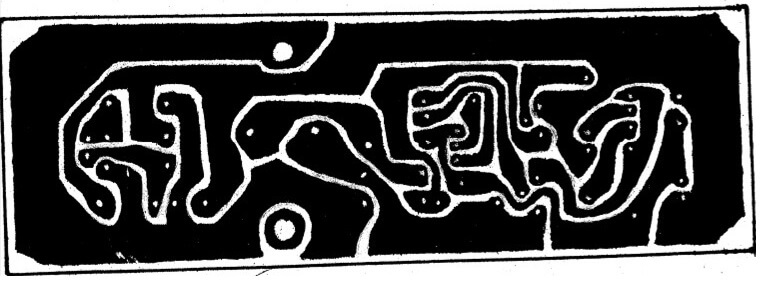

PCB Design

Parts List

- R1 = 1K, 5 watt wire wound

- R2 = 120 Ohms,

- R3 = 330 Ohms,

- R4 = to be calculated using Ohms law.

- R5 = 1K5,

- R6 = 5K6,

- R7 = 56 Ohms,

- R8 = 2K2, P1,P2 = 2k5 presets

- T1 = 2N3055,

- T2, T3 = BC547B,

- D1 = 1N4007,

- D2, D3, D4, D5 = 1N5402,

- C1, C2 = 1000uF/50V,

- Tr1 = 0 – 40 Volts, 3 Amp

2N3055 Pinout Details

If you have any doubts regarding this variable voltage and current power supply circuit using transistor 2N3055 circuit please do not hesitate to ask then through the comments below.

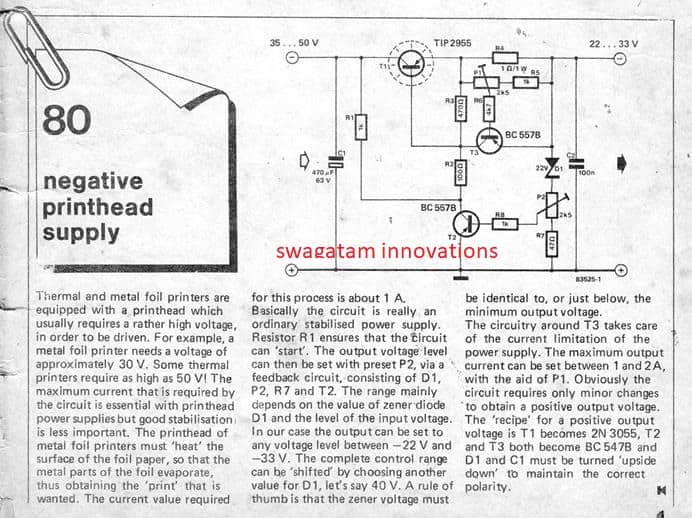

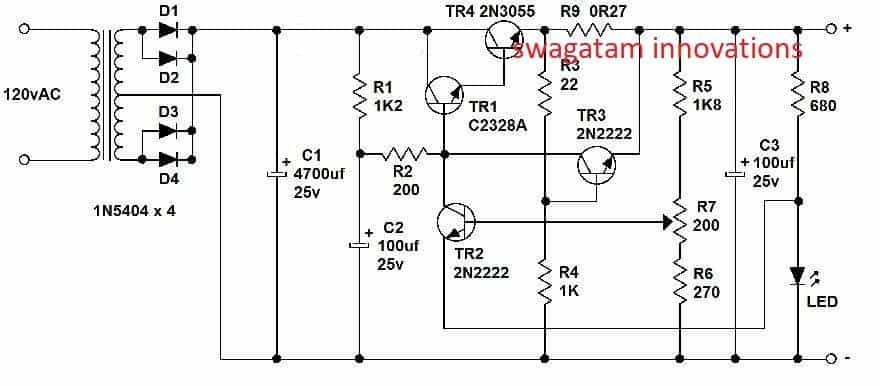

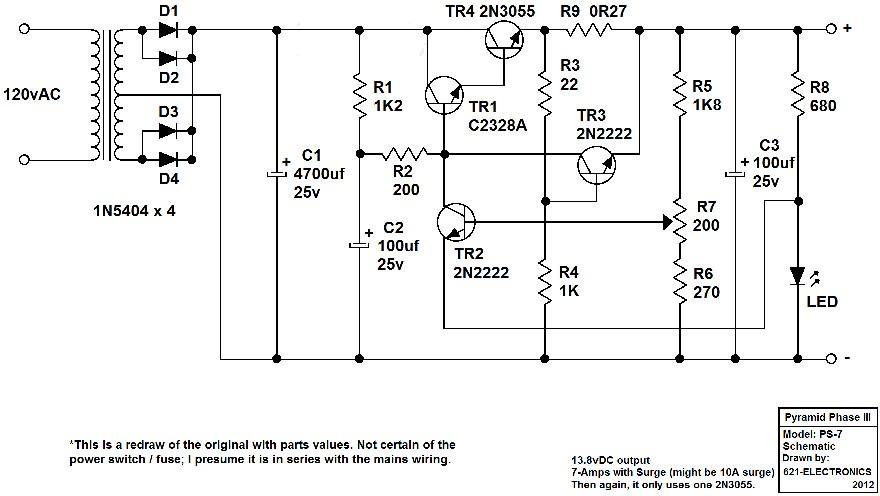

Original Transistor Power Supply Diagram:

The above design was inspired from the following circuit which was designed and presented in the elektor electronics magazine by the elektor engineers:

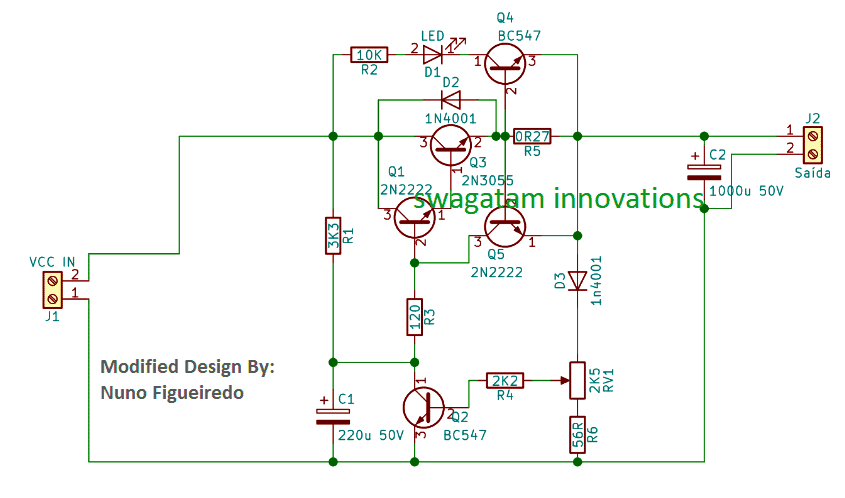

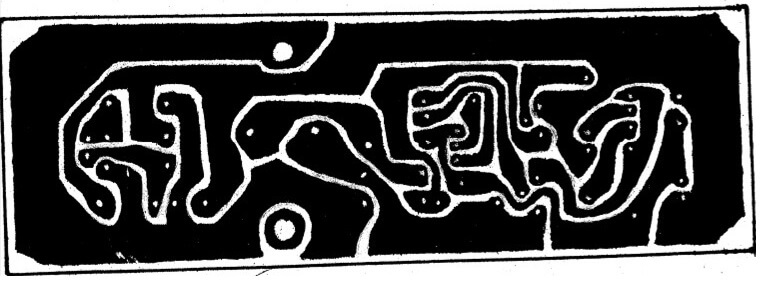

Simplified Variable Power Supply Design using 2N3055 and 2N2222 Transistors

The above designs were assessed and simplified with more effective results by Mr. Nuno. The revised and simplified design can be viewed in the following diagram:

The design features an over-current shut down with LED indication.

Video clip of the tested prototype:

For PCB Design and other Related Data, you can Download the following ZIP File:

PCB Design for the above Circuit

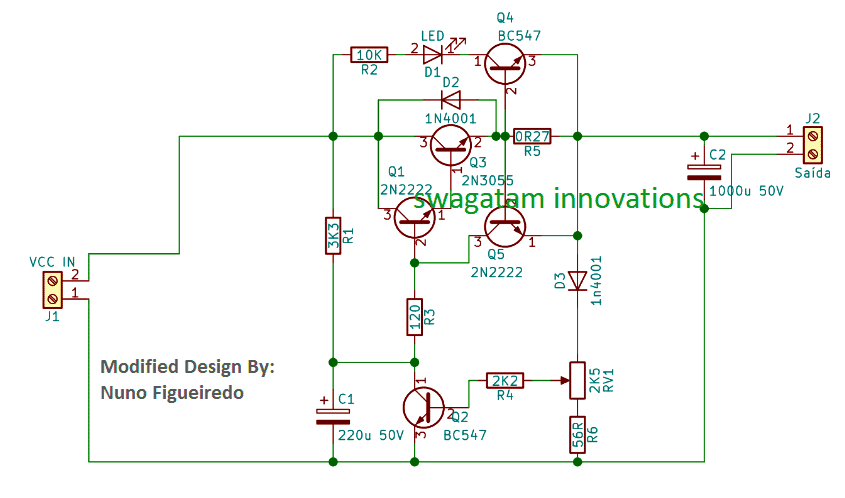

Another Similar Power Supply Design as Referred by Mr. William C. Colvin is presented below for the viewer assessment:

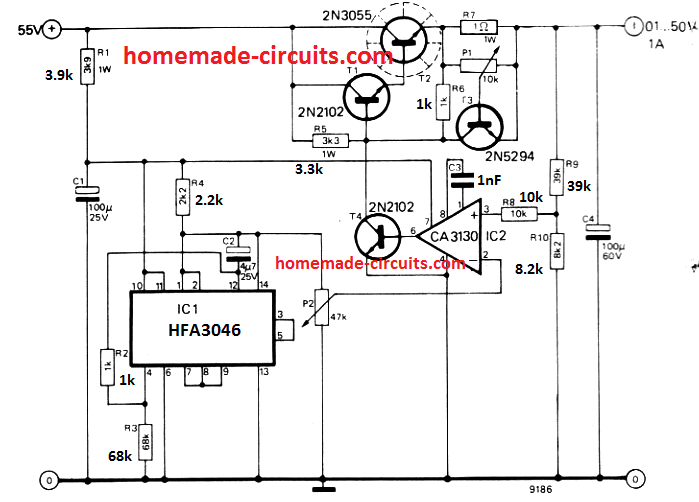

2N3055 Wide Range Variable Voltage Regulator

The key highlights of the circuit are: wide range output: 0.1 to 50 volts excellent load regulation: 0.005% between 0 and 1 amp, decent line regulation: 0.01%, reduced output disturbance: superior to 250 microvolts.

The broad output selection is implemented with thehelp of the integrated circuit CA 3130, that is able to work even with a zero volt input/output differential. In addition, higher extension of the output range becomes feasible through the inclusion of T4 between the IC and the series pass transistor.

The high gain as a result acquired enables a superior level of regulation, and the T1/T2 Darlington pair offers a adequately large current boosting. T3 works like an output current controller.

When P1 is rotated totally anti-clockwise, T3 restricts at 0.6 amps. The limiting circuit becomes inactive when P2 is moved completely clockwise. The regulator circuit specifically operates in the following manner.

The IC CA 3130 analyzes the output voltage given to the non-inverting input with respect to a reference voltage at the inverting input.

The output voltage of the regulator is reduced with a potential divider to protect against damage to the IC.

The reference voltage is determined by P2, which needs to be a top-notch part, since any kind of noise upon its slider arm will probably be transferred to the regulator output terminals.

A additional IC, HFA3046 , offsets the reference voltage intended for temperature variations. The IC is made up of 4 transistors applied as diodes or zener and another transistor for cutting down the output impedance of the reference circuit.

The reference IC furthermore provides a stepped down supply voltage for powering CA 3130. This feature necessitates the use of each ICs in the regulator stage; if IC1 is removed can result in the break down of IC2. Each of the transistors shown in the diagram must be rated with a breakdown voltage of a minimum of 55 volts.

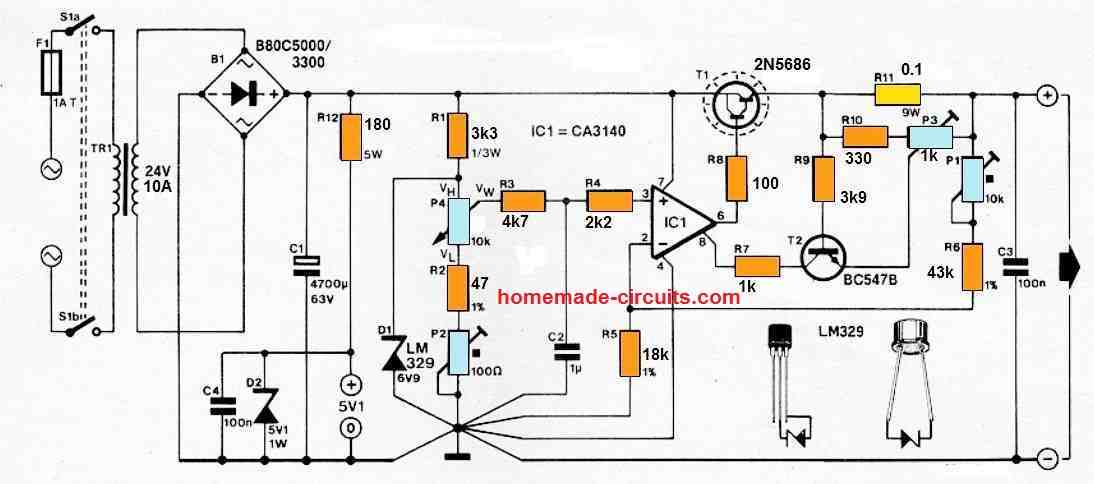

High Current Variable Power Supply

In this high current linear power supply circuit, we have used a 2N5686 transistor instead of 2N3055, so that the circuit is able to deliver a minimum of 10 amp current, and the preset P3 could be used to adjust a current range of 10 amp.

The power supply itself is pretty straightforward to construct. An IC LM329 provides a steady reference voltage of 6.9 V.

P4 is a potentiometer, and this pot is utilized to determine the output voltage using a preset potential divider P2-P4-R2. The power stage of the circuit is made up of IC1 and T1, which operate like an operational amplifier when it comes to positive voltages (negative voltages are not relevant here, obviously).

This non-inverting amplifier is built using an combo of op amp, P1, R5, and R6. This indicates that the voltage at P4's wiper is proportionate to the voltage across the output terminals.

P1 is a potentiometer that controls the peak output voltage, while P2 is used for setting the minimum output voltage from the power supply.

Preset P3 is used for setting up the maximum current limit of the output.

R11 converts the output current to a voltage to accomplish this. When this voltage (controlled by P3) is large enough to turn on T2, the circuit's voltage regulation is superseded by current regulation through IC1's strobe input. The maximum current that can be adjusted is from 0.8 A to 10 A, depending on how the controls are adjusted.

When the output of the power supply are short-circuited, the current must not increase above 25 A to prevent T1 from being damaged and due to over dissipation. The circuit setting up is not complicated. To begin, adjust P4 to highest possible resistance and wait about a minute until Z1 and IC1 reach their typical working temperatures. Next, adjust P1 to get a 25 V output voltage.

Finally, tweak P2 to provide a 250 mV output voltage by setting P4 to lowest resistance. The lowest output voltage of 250 mV was selected on purpose to guarantee that the individual parts always are able to work with a linear region of their characteristics. There are a couple of things to remember here: the earth lines must be routed exactly as shown in the schematic, and T1 must be installed on a 1.5 K/ W heat sink.

use the scan that is below first scan it is cleaned up better I used photo paper which allows scraping ink from pathways after printing with laser printer because i erased text from image there seems to be artifacts of it still showing up in traces so it still needs to be examined before final transfer to pcb.

Thanks very much mike, it is nicely done, I hope the readers will find it very helpful…

also filled Scan2025-02-20_233920.pdf

Thanks very much Mike, I extracted the image from the pdf, here it is:

" rel="ugc">

i am trying to send image again dont see it and trying again

The above image is not clear, but your pdf image is very good, so I have extracted it and processed it as below:

" rel="ugc">

I hope converting the pdf file to zip file is good enough smaller” I did have to take a sharp object to my toner transfer sheet printed out pcb and open up pathways before transfer to pcb which is much easier than cutting copper this is the same pcb layout as the one seen in article minus text writings on it and added copper where possible using it maybe will do more amps ?.

Yes, the pdf version is smaller and without any issues, i could quickly convert it into a jpeg image.

Thanks very much for the kind efforts, much appreciated.

I am working on the next design and i do not understand why the voltage drop is so much more a 600-ma load bring it to 7-8 volt drop compared to not loaded a 3 volt drop from impute compared to output. a variable workbench power supply and I duplicated the pcb used as a example with much thicker traces similar to first circuit trying to improve it.I have went thru all comments trying to learn all that I can about the large voltage drop and I must say I still don’t understand it or what to do next i have used a jumper for r-5/and r-6 based on comments. I am thinking about doing the idea not explained very well about a Darlington configuration and maybe see what exactly is how to do it if you think that is the solution if there no way to fix the circuit i would like to know but I am trying to learn why its doing that I guess that’s the real point here is learning how things work I don’t understand what’s wrong with it or if that’s normal for this circuit using that pcb design?? thank you for a response ahead of time and I hope you can spare time for me even though i haven’t been to school and don’t know some simple obvious thing about this circuit i am trying to figure this out on my own i don’t want to waste your valuable time anything would be sincerely appreciated I will share the pcb if its ok to i don’t know, it is filled copper and looks different but seems like it isn’t intended to be shared so I think I would need permission ?? also may be flawed ? but does seem to work? 20 vin and 12v out under 600 mA load. no load 17v out from 20vin. should I abandon or try something to improve it I can’t figure it out.

The output voltage will drop if the pass transistor is not able to supply the required amount of current to the load.

Yes, Darlington is the key to this problem, which will help boost the current for the load and solve the voltage drop issue.

You can try a TIP142, which is a Darlington BJT, and check the response.

Sure, you can upload the PCB, i will check it out. If possible please reduce the size of the image to a smaller scale before uploading…

Thank you very much for your detailed analysis.

top side mr nuno build with silkscreen provided and as toner transfer method used with slight changes of components orientation’s the tracks are the schematic exactly q-4 belongs in q-5 position and q-5 replaces it then is spun 180 degrees also spin q-1 180 degrees

Thanks so much for providing the detailed pictures of your prototype. I hope the all the other readers will find these very helpful.

one more

here is another pic cant seem to do more than 1 at a time

i have said mv and mean mA in my post you probably knew that but there it is sorry for any confusion.

Ok, no problem…noted!

hello i am posting some info about the mr nuno version circuit having done the build using the toner transfer method and using the plans provided thanks for that it works nicely as exactly shown in schematic but there is changes to do first before soldering transistors in place as for using silkscreen layout on the board. 1 switch q5 with q4 then turn q-5 the same direction as q-4. 2 turn q-1 around facing away from 3055. 3 beware that the pads for 3055 are arranged c/e/b when facing component ,you likely will need to move it to a heatsink regardless off board a large one, if you use a large adjustment range like 10v difference from input and output no more than 700mv as built by me using same parts as described in schematic cheap parts as a matter of fact except for 3055 i used a 2sc5200 on a 10cm+8cm+15mm heatsink probably twice the size needed but was handy i experienced a 2.6v drop compared to input v that’s better than other designs i have built. the led will start to light up after encountering under voltage. when that happens i have found that 1 extra turn of the 5 k pot what i had gets a clean noiseless output back on track so that is a nice feature, if you have a scope make sure to probe the collector of q-1 or q-3 to see the limit you want to know about on these things when stretching it 10–11 v i used the board as thru hole mounting plenty of room for it. so without mods its doing 700mv no problems and at 10-11v difference from input tried 1.2 amps and it got hot quickly q-1 q-3 so maybe better parts ? will do better. so i hope this is useful for someone and thanks for the whole package on this design. thankyou

Hi, thanks for the update, much appreciated.

However a picture upload could have been even more helpful.

Since this design is a linear regulator circuit, the device will get hotter as the input/output difference is increased.

Nevertheless, thanks very much for your detailed explanation.

thank you for the responce i will use schemtic i did the toner transfer method and did not want to just power up without checking for mistakes first i am a hobbyist and am learning on my own and what i can pickup from others.

Sure, no problem! I understand! Let me know if you have any further doubts.

thanks not so in advance oops/ another question how do i subscribe i see no page to join doesnt just allow password email?

Once your comment is replied by me and approved, you will get an email notification along with a “Subscribe” link, when you click on that link you will be automatically subscribed for all the future comment reply notifications.

i am building the nuno vertion and i would like to know if the silk screen is accurate depiction of componant placement or is the schematic acurate and thus requires complete difrent placement and oreintations of transistors q-4-5-1

The component placement is not critical, so you can place it as per your convenience. I would recommend the schematic placement so that you can align the prototype with the schematic design, which can make the testing and troubleshooting easier.

Dear Sir, Thanks for your prompt response. Could you please guide me to configure the TL431 (R1,R2,R3) as the voltage input in the given circuit is 30V, and my transformer Output is 60V @ 10A.

Hello Imsa, please use 4.7k 1 watt for the R2 resistor. No other changes would be required.

For 10 A current you may have to use a 0.033 ohm 2 watt for R20.

Thank you very much for the sound plans where you sent me to build a power supply – what is interesting for me is the power supply 1.5 -30 volz 10 Amber adjustable as a rule, I would like to thank you in advance

You are most welcome IOANNIS!

Sir,

Can I connect 4(four) Nos.3055 in your circuit above? I like to charge 4Nos 12V 60AH batteries and also use it as a Lab power supply.

Can I use 10K for (P1,P2) ? if so, any changes/replacements in circuit required?

Thanks in anticipation.

Hi Imsa, adding 4nos of 2N3055 to the above circuit may not be a good idea, instead I would recommend you trying the following circuit:

" rel="ugc">

Let me know if you have any further questions….

Thank you very much indeed for your express reply. However, I like to have 58-60V output. with 10Amp. How do I go about it ? Can you please advise?

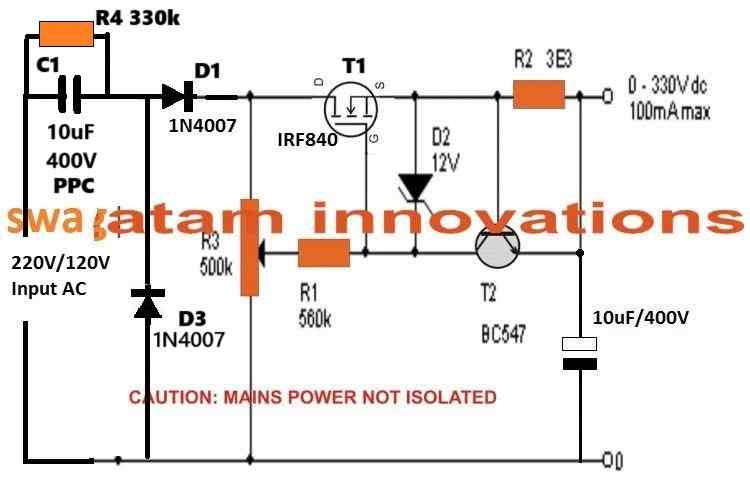

OK, in that case you can try the second design from the following article. You can change to mosfet to any 100V mosfet. Remember not to connect the filter capacitor at the input side, instead connect it at the output side, this will help the mosfet to dissipate proportionately less heat.

https://www.homemade-circuits.com/0-300v-variable-voltage-current/

How to adjust the current from 0-10A in order to make it a Variable Voltage, Current Power Supply ?

You can replace R2 with multiple calculated resistors and use a rotary switch to select one of these resistors for the desired current control.

Sir, I like to have – Adjustable Voltage from 0-60V, and Variable Current from 0-10 Amp. (without using rotary switch) similar to your first circuit above.

I have a Transformer rated at 60V 10A.

Can you help ?

OK, you can try the following circuit, you can increase the input upto 60 V by appropriately adjusting the circuit:

https://www.homemade-circuits.com/universal-variable-power-supply-circuit/

I am having 19.5v 4.5amp Sony LED tv power supply unit I want 0 to 18v&0 to 4.5amp power supply unit using single fet transistor

You will require an SMPS for that, and unfortunately I do not have an SMPS circuit with a variable current feature.

Dear Swagatam,

I also need to make ~150V AC-DC linear voltage regulators. Its current capacity need to be higher than 200 mA. I am not familiar with a transistor based voltage regulators, but I think that I need a transistor based regulator to build a high voltage (~150V) regulated power supply. Can you comment how I can get 150V 200mA voltage regulator? Which components can I change from your 2N3055 based regulator?

Thank you,

Chang

Hi Chang,

I would recommend you to try the SECOND LAST circuit from the following article:

https://www.homemade-circuits.com/0-300v-variable-voltage-current/

However, remember, since this is a linear regulator the transistor might heat up a lot as the difference between input and output voltage increases.

Dear Swagatam,

I am still studying regulated high voltage power supply.

My wanted output voltage can be 100~125V. If I changed a transistor from 2N3055 to MJ15001, do you think I can get 125V output?

I am designing an instrument, which is very sensitive to electrical noise. I might use 2n3055 based regulator for 100V output power supply.

Can you tell me which method(transistor based regulator or MOSFET based regulator) produce lower noise for 100~125V output power supply ?

Thank you,

Chang

Hi Chang,

Yes the main pass transistor can be changed to MJ15001 for handling 125V output.

I think noise can be removed by adding a 100uF capacitor across base/ground of the mains transistor, as done in the following circuit:

" rel="ugc">

The capacitor C1 will reduce noise drastically and make the output noise free.

Dear Swagatam,

I found another transistor 2n3773, Vcb of which is 160V. Do you think that 2n3773 is more safe than MJ150001?

I planned to modify the circuit, designed by Nuno Figueiredo.

Current limit will be 0.2A, so R5 will be 3 ohm.

I will remove Q4 BC547 transistor.

Since the unregulated voltage will be around 130 V,

-2N3055 will be replaced by 2N3773 or MJ150001.

-The two diodes will be replaced by 1N4007.

-R1 will be 1Watt 33kOhm.

-RV1 will be 2Watt 20kOhm potentiometer.

-C1 will be 100uF 200V.

-C2 will be 1000uF 200V.

Do I need to modify more the circuits of Nuno Figueiredo?

Thank you,

Chang

Hi Chang,

Since yur maximum operating voltage is 130V so both the transistors will work and both will be safe.

I think Q1 and Q2 will also need to replaced with a higher voltage transistor. You can replace it with maybe a 2N3501

The remaining specifications look fine to me.

Dear Swagatam,

I designed a 120V, 0.2A power supply using 2N3773, 2N3501, and I confirmed that the 120V power supply is working. Now I have to make a low noise 200V, ~0.3A power supply at the other my project. When I checked your website, I found three options. Can you recommend which option will be best for the low noise 200V, ~0.3A power supply?

1.Variable Voltage, Current Power Supply Circuit Using Transistor 2N3055 , after modifying power transistor (https://www.homemade-circuits.com/how-to-make-versatile-variable-voltage/)

2.0-300V Adjustable MOSFET Transformerless Power Supply Circuit (https://www.homemade-circuits.com/0-300v-variable-voltage-current/)

3.600 V DC Voltage Regulator Circuit Module (https://www.homemade-circuits.com/600-v-dc-voltage-regulator-circuit-module/)

Thank you,

Chang

Thank you Chang,

I think the 0-300V design looks perfectly suitable for your application.

However, to make it safer for the MOSFET, you can add an input current limiting capacitor to this design, as shown in the following diagram:

" rel="ugc">

Dear Swagatam,

When I looked at the 0-300V design, the maximum current is 100mA. Do you know How I can increase the current to 300mA? Thank you,

Chang

Hi Chang,

You can replace the 3.3 ohm R2 resistor with a 1.8 ohm resistor, this will enable to to get the required 300 mA current output.

The formula is:

R2 = 0.6 / Max output Current

Hello,

I want to make low-noise and fixed output linear regulated power supplies.

The current output can be 100mA or higher than 100mA, and the fixed output will be 9V or 12.8V.

When I looked at the ripple noise level of commercial low noise power supply is about 1mVrms.

Can you comment which device (2N3055 based regulator ,or LM317 based regulator ) can produce lower noise power supply?

Thank you,

Chang

Hi,

The LM317 will produce lower noise, especially when the appropriately rated capacitors are connected across its input and output terminals.

Dear Swagatam,

Thank you for your reply. I have a following question about the low noise linear power supply. If I use a second regulator (like low-noise TPS7A47 LDO regulator) after the LM317 regulator, do you think that the noise level will decrease more?

If the second regulator works, can you recommend other low noise regulators?

Thank you,

Chang

Hi Chang,

Yes, since the TPS7A47 is an ultra-low noise regulator it will reduce the noise to a great extent. However if you are using TPS7A47 then what is the need of LM317 regulator? The LM317 can be avoided completely according to me. I will try to investigate more such regulators and let you know, if possible.

Dear Swagatam,

I have never made linear voltage regulator. However, when I read about LDO voltage regulator online, inputs of LDO regulators are usually batteries or kind of “regulated” voltage. The datasheet of TPS7a47 also suggest that the TPS7a47 can be used for post dc-dc converter regulation. I feel that the input of TPS7a47 should be regulated voltage not be un-regulated voltage if it works best. If I am wrong, let me know.

Thank you,

Chang

Thanks for the clarification Chang! I agree with you. The LDO must be fed from a regulated DC supply, therefore using a LM317 based input makes sense.

Dear Swagatam,

I tested linear voltage regulators, using LM317 with LT3045 and LM337 with LT3094. I am happy with my setup although I need further test to reduce some noises including EMI. I think that both LT3045 and TPS7a47 have low noise voltage outputs. I chose LT3045 since the range of its voltage and current is smaller than TPS7a47’s, so its noise level will also be smaller than TPS7a47’s.

Thank you,

Chang

Thank you so much Chang, for updating the valuable information. Appreciate it!

I’m a recently retired software engineer trying to teach myself electronics. I have no trouble understanding the amperage control part of this circuit. I’m still trying to understand the voltage control side of things. Can someone recommend some reading that will help me understand how that part works? Thanks.

I will try to explain you. The transistor T1 is configured as an emitter follower, which means that its collector voltage will be always equal to it base voltage minus 0.6V. Now, the base voltage of T1 is controlled by T2, so at any given instant, depending on the setting of P2, the T2 will try to cut off the base voltage of T1. For example, if suppose P2 is adjusted such that once the collector voltage of T1 reaches 9V, T2 is switched ON. This means that at 9V T2 will switch ON. When T2 switches ON at 9V, T1 base will be cut off at 9V. Now, since T1 base is cut off it will turn off and its collector voltage will begin dropping below 9V. When this happens T2 will again switch ON, and this will allow T1 to switch ON again, and the voltage at its collector will again try to reach above 9V, which will yet again cause T2 to switch ON….and this cycle will keep repeating ensuring that the collector voltage of T1 is constantly held at 9V, so the output will be at 9V. In this way P2 can be adjusted for getting other constant output voltage values. And this is how the output voltage control works.

Thank you very much for your time. I will implement this as soon as I wrap up my current project. I have a lot to learn.

No problem! All the best to you!

Dear sir,

Please sir, for the modified design by Nuno Figueiredo. If the transformer is 2A, will be circuit output current be 2A when R5 is 0.3 ohms?

Thank you sir for your response.

Hi Godfrey,

Yes roughly it will be around 2 amp output

Dear sir,

Please sir, I have a 230v/5 winding secondary voltages 2A transformer.

I have got 24.8v from one winding and 18.3v from another winding on the secondary.

I connected them in series and got 43.9v

Please sir, can I use the 43.9v from the series connection on the modified design by Nuno Figueiredo?

2. Do the values of the components: capacitors, resistors, diodes etc in the circuit need to be modified to suit the 43.9v?

3. What would be the output current of the circuit at 0 – 40V using the 2A 43.9v transformer?

Thank you sir

Hi Godfrey,

Yes you can connect the 43.9V to the circuit designed by Nuno Figueiredo. Just make sure the capacitor voltage rating are around 100V. Rest everything can be as is.

The output current will depend on the value of R5, but the maximum will not exceed 2 amps.

Okay sir, thank you very much.

Please sir, help me with these points concerning the circuit.

1. Will the R5 = 0.27ohms output 2A max current? Or how do I determine the value from Ohm’s law that will output almost 2A max current?

2. What is the wattage of R5 and other resistors?

3. IN4001 is not handy, can I replace with IN4007?

4. Is the LED for Power ON indication or for Over-current shut down indication

5. 2K5 pot is not handy, can I use 5k or 2k pot?

Thank you sir for your response.

Hi Godfrey, here are the answers.

1) When the output current exceeds 2 amps, a potential difference of around 0.6V must develop across R5. For this to happen R5 can be selected by using the following formula:

R5 = 0.6 / 2 = 0.3 ohms.

2) wattage = 0.6 x 2 = 1.2 watts, all other resistors can be 1/4 watt

3) 1N4007 can be used.

4) LED is for over current indication.

5) 5K pot will work

Dear sir,

I have successfully built the circuit, and it’s working. Thank you very much sir.

Am using it to power 12v Yamaha keyboard, though I have observed that the 2N3055 is very hot even with the heat sink I have used. Am afraid if it will burn when I use for some hours.

Please sir, can it be replaced by another transistor or any way to handle the heating effect?

2. Where can I include an LED for Power ON indication in the circuit?

Hi Godfrey,

Glad you could build it successfully.

The transistor heat is directly proportional to the difference in the input and the output voltage. For example if the input is 12V and the output is set at 9V then the heat on the transistor will be relatively less, but if the output is reduced to 6V, the heat will increase proportionately, and if the output is further reduced to 3V the heat will increase even further. So as the input/output difference increases the heat on the transistor increases proportionately. Make sure the input supply is not too large compared to the set output voltage.

You can replace the transistor with TIP35 if required.

You can put an LED across the output terminals of the power supply.

Okay Sir, thank you very much. I have confirmed it by reducing the input AC supply from the transformer, and the heat was less.

Please sir, is there a circuit for variable Ac supply from 24V transformer?

So as to vary the input AC supply from 0- 24V.

Thanks Godfrey, Glad you could solve it.

For controlling a 0-24V AC you can probably try using a triac dimmer circuit. You can try the first circuit from this article:

220V Light Dimmer and Ceiling fan Regulator Circuit

You can replace the lamp wires with the primary 220V wires of the transformer.

Hi Swagatam;

I have the transformer 24 Volts 100 VA(maybe around 4 Amps). I need a voltage and current adjustable circuit to my transformer. I think it is possible to charge a 60 amps battery thru this my transformer. I need your recommendation and suggestion about most convenient of adjustable volts and currents circuit. Lots of thanks

Hi Suat, According to me, the best option is using an LM338 IC for making the required variable power supply. You can use a large heatsink on it and easily charge a 60 Ah battery at 4 amp rate from the transformer.

Hi again;

Sorry, You mean any one of the above circuits replaced by LM338 or I may use the circuit that I had seen with the following parts LM317, 2N3055 and BD139 I will change the LM317 to LM338. Thanks.

No problem Suat, The above circuits do not use LM338, they use 2N3055 transistors. You just need a basic LM338 variable power supply circuit without any 2N3055 transistor, and use the IC directly to get the variable output at 5 amp current output with full short circuit protection. You can refer to the first circuit presented in the following article as an example:

https://www.homemade-circuits.com/ic-lm338-application-circuits-explained/

Regarding the 2N3055 based variable voltage current power supply circuit, are C1 and C2 only used for filtering? I would like to remove the transformer and rectification, and then feed the circuit with a fixed 40VDC that I have available. Should I also remove C1 and C2, and their connections to ground since filtering is no longer needed?

Thanks for this and all the other circuits and instruction you have made available to us hobbyists!

The capacitors C1, C2 do some additional work also other than filtering an AC.They eliminate noise and other invisible high frequency disturbances or spikes.

If your supply input is already a filtered DC, then C1 can be perhaps removed, but C2 should not be removed as it makes sure that the switched output from T1 is perfectly stable and without any interference.

Hello sir,

I Want to vary DC Output from 4 volts to 300 Volts, also want to vary Output Current 4 miliAmp to 300 miliAmp, please can you help me to suggest me any circuit

Hello Vinod, one method of implementing would be use a light dimmer circuit, and feed its output to the circuit shown in the following article:

0-300V Adjustable MOSFET Transformerless Power Supply Circuit

So you will have three pentameters to adjust. One from the light dimmer which will determine the maximum range as per the load connected to the MOSFET circuit.

The MOSFET voltage control pot, which will further provide the final voltage adjustment to the load.

The current adjustment pot which will decide the max current output. The current adjustment might not be too accurate unless fixed resistors are employed instead of a pot control.

Hi Sir Swag. hope you are fine. I use a 220V Triac based dimmer to decrease and increase the output AC of a 220 to 30V, 2A Transformer. Is there a way other than dimmer, except wire resistor to do that? I should add that all of the diagrams I have seen in your very interesting and informative site are DC circuits as know better. May I hope to have your reply Sir?

Regards

Veronika

Hi Veronika, using a triac dimmer with the 220V side of the transformer is probably best way to control the secondary side voltage. There’s no other easier way to do this.

Glad you found all the diagrams useful…

Hi dear Sir Swagatam. Thank you very much for your response, good man.

Bye

You are welcome Veronika!

Thanks so much sir. But am a bit confused. I meant maximum output current of 0.2A. If 3ohms should be the resistor and 0.6v is used in the calculation. Is it because of the minimum out put voltage of 0.6v necessited by the diode used. If not, is there any other criterion used to arrive at 0.6v used in your calculation. For me I calculated directly using the transformer specifications.

Hi Moses, the transistor T3 is responsible for cutting off the output when max current is detected. To trigger T3 at the max current a 0.6V must develop across R4….therefore 0.6 V is used as the reference value.

Ok sir now I understand. But sir please, 0.6v is it a rating of the T3 transistor as part of its data sheet information or that of diode. I am asking this in case of using a different transistor for the same purpose. God bless you.

It is the optimal voltage required across base/emitter of all silicon BJTs for switching ON fully. So except Darlington transistors, all BJts will have the same requirement of 0.6 V threshold across their base/emitter for full switch ON.

Ok thanks sir. Am grateful

You are welcome Moses!

Please sir, considering the first circuit above which has transformer rating as 3A, 40V, should we use R4 = 200 ohms in order to obtain maximum of 0.2A (I.e.200mA) using ohm’s law as you pointed out. If so what of the Wattage of the resulting R4 or should we use any of 1/2, 1/4 , …. as desired.

Moses, for 200 mA output current, R4 will be = 0.6/0.2 = 3 Ohm

wattage will be 0.6 x 0.2 = 0.12 watts

Hello sir! Thank you a lot for this design, it helped me with my homework and also it’s a great power supply i plan on keeping around. I come to you seeking help because everything works almost perfect except for the current control., and to a lesser extent the minimum voltage. I’m using almost all the same parts as you except for:

– 2n2222A for T2, T3

– 5k pots for P1, P2

– 2200uF C1, 680uF C2

So the 2 issues are that 1. The voltage won’t go below 1.5V, unless i attach a load that’ll pull a lot of current (somewhere in the amperes). 2. The current control doesn’t work as expected at all 🙁 I attached a 0.56ohm 5W resistor as R4, and i couldn’t get the current control to work. I attached a similar resistor as load and tried to use the current control to limit the current it would draw, but it drew up to 4.5A which is a lot more than i was expecting. Whenever I attempted this T1 burned up and along R2 burned up as well. Not only this but turning the current control knob didn’t vary the current at all.

I also tried the power supply with 50ohms on R4, and the current control worked much better, it capped off the current at 200mA and when i turned the knob it actually varied the current. But this also leads me to question the 0.6/max current = R4 formula, given that the results i was getting for maximum current were much higher. I must also add that i blieve the 4.5A max i got with the 0.56ohm load was actually the transformer reaching it’s maximum current output, given that it’s rated at 3A.

Thanks for any help you might offer and either way thank you for the design! I’m excited to solder it down properly and build a casing around it.

Thank you Ignacio, Glad the circuit helped you!

If you want zero volts at the output, you can remove D1, and R7, and replace them with direct links.

you will not get a sharp cut off with a single transistor current cut off set up. The cut off will be slow and over a bigger range….so if you set it at let’s say for 3 amps, the cut will happen slowly between 2.5 amps and 3.5 amps. The cut off will happen when the current is sufficiently high to create a voltage drop of 0.7 V across R4 and at the base of T3. T3 may start conducting slowly from 0.3 V and reach full conduction at 0.6V.

So you can test the above response with a multimeter across base/emitter of T3.

if you need an accurate current control then you may have to add an op amp circuit in place of the T3 circuit.

Also, please remove R5, it is not required according to me.

Thank you for the quick response! Removing D1 and R7 did indeed help a bit, got the minimum voltage to 1V, but it seems like my higher resistance pot was the main reason i was getting a higher minimum voltage than you were.

Though, I decided to remove R8 cause it seemed about as pointless as R6, and it ended up helping get an even lower voltage! So now I managed to get down my minimum to 0.6V while using a 5k pot 🙂

One weird effect that i have noticed though: When I set the voltage to a medium voltage (so let’s say 22V, since my max is 36 and min 0.6) the voltage will slowly drop for quite a while, not an insignificant amount. For the example of setting it around 22V the source will lose about more or less 2.5V in about a minute or two before stabilizing. It will eventually stabilize but it takes quite a while. I got this effect with and without the current control components.

I don’t know if you ever observed it in your own circuit, but I suspect it might have to do with the capacitors and parisitic inductance of having built my circuit on a breadboard. But i have taken quite a bit of care to avoid messy wiring and even after removing the current control which simplified the circuit greatly I still observed the effect.

Tomorrow I’ll finally solder the circuit with new parts so i’ll let you know if it improves.

BTW, I see you advised Mr. Nuno to create a darlington pair with a 2n2222 and a 2n3055 instead of using 2n3055 and you gave the reason that it has a “better response”, why is this and what does it mean? I don’t mind having the 2 big transistors if it means i get a more stable circuit that’s able to deliver more power.

I think the circuit will exhibit higher stabilization accuracy when there’s a load connected at the output. So if you check the voltage stabilization results with some kind of load connected at the output then you may find the voltage to be much stable which does not deviate from its set position.

Yes Darlington pair offers 10 times more current gain than a single transistor. Increased current gain means more current at the output, and lower heat dissipation for the base resistor R1. With a Darlington it may be also possible to increase the value of R1 so that it generates minimum heat and ensures relatively higher efficiency for the circuit.

Adding a 100ohm load did help a little, but it still exhibits the behaviour, i’ll update you if it improves once my soldering parts arrive. Also it happens more with the higher ranges, around 15-30V, and these ranges also go by incredibly fast compared to the lower ranges, so I bought a logarithmic potentiometer that will also arrive today, and that might help? We’ll see 😛

And I think I didn’t make myself clear with the darlington question. My question was why does a darlington configuration of [2n2222 + 2n3055] have a better “response” over a darlington configuration of [2n3055 + 2n3055]? I know using two 2n3055s gets quite bulky but I really don’t mind the size.

Again, thanks for the replies! Kind regards,

Ignacio Vargas

ps: this is a really nice website, did you build it yourself?

Thank you for the updates.

In a Darlington configuration the second transistor performs the supporting role for increasing the overall gain of the system, it does not directly take part in the voltage control therefore it is normally a lower rated transistor compared to the main transistor. Moreover smaller transistor tend to have higher current gains which makes the configuration highly efficient. If we take two 2N3055 then the overall gain becomes 15 x 15 = 225, whereas using a 2n2222 cause the gain to be 150 x 15 = 2250, that’s a huge difference, this is why we normally incorporate a smaller transistor as the second transistor in a Darlington pair.

I am glad you liked the website, yes it is me who built, with love and support from all of you!.

Okay so for some reason i can’t reply to your reply, so that’s why I’m replying to my own comment.

So reporting on the circuit: even after soldering it it’s equally unstable :/ perhaps it’s cause of the diode or one of the base resistances i removed. Either way can’t do anything about it now ¯\_(ツ)_/¯

Also wanted to report I got an 85 on my assignment!! 😀

The points I lost were because I turned it in late and not because of the circuit 😛

Also that’s very impressive I love the way you’ve structured the site. A little feedback if I may: I’m not getting e-mails whenever you reply to my comments even though I do check the box. And I did check my spam folder and they’re not arriving there either, I’m just not getting them at all. Either way it’s a great site and thanks for all the help really!! Have a good one!

Kind regards,

Ignacio Vargas

Thank you very much for your continued reporting and feedbacks, appreciate it a lot.

You got 85% for this project sounds amazing, glad you could make it successfully.

I am sorry to hear that you are not able to get the revert emails, actually I am not a website developer so I am having problems troubleshooting this issue, but I’ll keep checking until this issue is solved. Thanks very much for updating this information,

Please keep up the good work!

Honorable Swagatam, I would like to get to the point without confusing you too much. I am the first circuit you have published in this article.

(Voltage and current controlled) I want to do. I am thinking of increasing the amperage value by using TYPE 35 transistor, what should be the resistor value we put in the brain of the T3 Transistor. What should be the value of the R4 resistor? Do I need to make any other change? I will be grateful to you if you help.

Mehmet Ovacikli

Hello Mehmet, the base resistor of T3 can be a 1K resistor, and you can completely remove the R5 resistor it is not required. Replace it with a wire link.

R4 can be calculated using the following formula:

R4 = 0.6/max output current

If TIP35 is used for the T1 then you may have to make a Darlinton pair using a 2N2222 transistor with it.

No other changes would be required

I thought of type 41 instead of 2N2222 transistor, wouldn’t it be more powerful if I connect a darlington?

yes TIP41 can be used for the Darlington with TIP35. It will be more powerful

Thank you so much. For your valuable information.

My pleasure!

Great post. I would like to know if any of these circuits have high energy efficiency. I know that switching power supplies are very efficient, but from my experience with linear regulators and also some series pass circuits that I have tried, I found that they dissipate all of the excess voltage in the output devices. Are there ways to mitigate the inefficiency in that regard? The problem I have seen is that let’s say I start with 36 volts, and I use a 5v reference at the base of a transistor. On the output side I will get 5v – base/emitter junction voltage, but the transistor will dissipate the remaining 31 volts and get very hot.

The efficiency will keep decreasing as the input output difference increases. One way to eliminate this high dissipation issue with linear regulators is to use a transformer with multiple taps. Meaning, the transformer should have many selectable voltage outputs, at 3 V, 6 V, 9 V, 12 V, 18 V, 24 V, and so on.

These voltage taps can be appropriately selected depending on the required range and load at the output. For example, if the load is a 5V load, then the 6 V or 9V transformer supply could be selected and so forth, this idea can eliminate the heating issue almost completely.

It’s been a while since I worked in the electronics field. I am looking to build a variable dc bench-top power supply. Specs would be 0-60 vdc with a 10-15 amp output. I would need a pc diagram that I can printout and transfer. Any help would be appreciated.

Thanks

Here’s one reliable design that you can try:

https://www.homemade-circuits.com/0-60v-lm317-variable-power-supply/

for getting 10 amp output you may have to connect 10 ICs in parallel, and mount all the 10 ICs over a single common heatsink.

For the PCB design you can check out the original datasheet here:

https://www.ti.com/lit/ds/symlink/lm317hv.pdf?ts=1597634875056&ref_url=https%253A%252F%252Fwww.ti.com%252Fproduct%252FLM317HV

Hello, do you have a circuit that produces a synchronised main ac output, for a variable ac/dc input? Interested in both actually 😀

You can try the last VFD concept, which will vary the AC output depending on the DC level at pin5 of the IC2

https://www.homemade-circuits.com/single-phase-variable-frequency-drive/

Hi! I have 30V 10A transformer, i need output 30V 10A, R4 should be 0.06 Ohm?

Which wire widht on PCB i need? I think it’s 5mm for 10Amp but where i should put 5mm? Thank You!

Hi, if the input/output both have equal current then current control is not required….you can make the design by Mr. Nuno, and remove the Q5, R5, R2, D1, Q4 stages

But it is not problem if i use standard scheme with current control? I have all compoments. Tell me please which wire widht i need on PCB. Where is biggest current im scheme. Im beginner. Thanks!

use 5mm track for the positive and negative line…put solder on these tracks. you can use the current control stage for reducing the output current.

Hi Swagatam, man do you get a lot of comments friend. I have a quick question, in the circuit modified by Mr. Nuno right under the title “Simplified Variable Power Supply Design using 2N3055 and 2N2222 Transistors” I cannot make out the value for R5, [OR27], the labeling is not traditional. Is that 0.27 Ohms? If so, what is the wattage rating?

Thanks Mike,

Yes that is 0.27 ohms, the wattage will be = 0.7 x the maximum current limit intended for the design.

Hello my name is Mario from Buenos Aires Argentina. I would like to be able to upload a circuit for you to analyze. Where or how can I upload it. Thank you

Where is R6 on the circuit diagram?

base resistor of T3, which is actually not required….you can connect T3 base directly with the pot center terminal

Good day Mr. Swagatam

(sorry for my poor english, and a beginner here in electronics) i tried to build your design circuit but the total output is so low 🙁 around 17mV and after some time it will lower down to 3mV, I also tried to adjust it using the P1 and P2 but it just doesn’t seem to work. BTW i used 12v/3A transformer, is that okay to use? and the 0.6 value of R4 is it in ohms? or amphere? and lastly can i use 5K ohm for the P1 and P2? hopes you help me 🙂

Good day Justine, It seems the T1 is not conducting or there may be some connection fault. Please check the base connections of T1 and also other transistors.

Or you can try the second design without Q4, Q5

also i tried to build your circuit using NI multisim and the output is still in mV 🙁

Sir,

Can the transistor change in this circuit make 50v 30amps adjustable?

Or by reducing amps (aprox.10amps). can use this circuit?

What changes are needed for this?

Guarav, it may be possible if you understand the circuit part by part, otherwise not.

Thank you very much indeed.

will try the circuit and get back to you in case of trouble !

with high regards

Imsa Naga

You are welcome Imsa!

Dear Sir thanks for the quick response.

I am looking at around 15 to 20A power from the circuit. I thought that the TIP36 would get too hot if I use only one, so to be on the safe side I proposed 3 nos.

How ever if this is not advisable I would request you to please suggest a proper circuit for my purpose.

now i am beginning to learn not only electronics but also the use of google drive…!

its now shared…..

Thanks again.

Imsa Naga

Dear Imsa, a single TIP36 mounted on a good heating will do the job, no problems! 3 together will not work correctly!

I am glad you are learning, keep up the good work.

I saw your schematic, just change the 3 TIP36 into a single one with heatsink!

Dear Sir

Having learnt Transformer Winding/Design from your blog, I am now trying to learn little bit of electronics from you. Enjoyed reading

https://www.brighthubengineering.com/diy-electronics-devices/119294-interesting-small-lm317-enhanced-power-supply-circuits-explained/

Very clearly explained indeed !

Now I am very keen to build this circuit to be used as a Bench PSU as well as a 24/12V Car battery charger.

Could you please spare you time to guide me –

a) LM301 Pin-7(V+) and Pin-4(-6V), is it to supplied using a Negative Voltage Regulator? (such as LM7906 )

b) I like to connect 3nos TIP36C in Parallel (circuit attached) https://drive.google.com/drive/u/0/folders/18dWLK9AWoQaK9_BetP3Ux8FO8nowkLXP

How to go about it? Would you please give necessary corrections in the schematics as well as all Component values that are required to be changed ?

c) Can I use either 68pF or 80pF for C4,C5?

Thank you very much in anticipation.

With high Regards…

Imsa Naga

Thanks Imsa, I am glad you are learning from this website!

Yes you can employ LM7906 for the negative voltage.

But 3nos TIP36 can be too heavy and might not be suitable. How much current do you want, is it 75 amps? In that you could use a P-mosfet.

The second Google drive link is not opening, please activate it in sharing mode

Good evening sir,

I want a power supply that can give me from 0V to 50V and 20A. What do i have to change/modify in your circuit so i can achieve that?

Thank you,

Hi Yoshiaki, you can try the following design, it may fulfill your requirement:

https://www.homemade-circuits.com/universal-variable-power-supply-circuit/

Hi man its an awsome circuit but i used different transistor in place of 2n3055 beacose i don’t have that one and all the other components are the same but doesn’t work.Just stays at 19 volts and my input is 20 and when i turn the the pots doesnt change the voltage.Is it of the different transistor or other thing please reply.

No i think about the big 2n3055 transistor i have change it with a different one and the circuit doesn,t work how is supose to work.Thanks for fast reply.

OK, sorry, please tell me the number of the transistor, I’ll check it out

Thanks Dzoro, can you please give the number of the transistor which you used instead of the 2N3055, I’ll check it out!!

The transistor is E13009L thanks for checking it out

It’s an NPN transistor so it should work although not as efficiently as 2N3055, because your transistor has very low gain compared to 2N3055. If the output is not varying there could be some fault in your circuit connections.

Yes i know and i found the problem it was the r2 resistor it was conected directly to the positive rail and i corected it and now it works flawlesly and the minimum voltage i can get is 1.3 volts.And one more question if i use mine transistor as darlington pair is the gain go up and also my efficienty.

Sorry for my english

Glad to know it’s working now. Your transistor is high voltage transistor so not ideally suited for this application, still if in Darligton mode the current will go up many times. You can try it.

I have other transistors do you mind checking them and tell me which one is the most suitable for this psu.

Here are the transistors:

C4924

C5386

C5855

C5297

Please help

All these are high voltage transistors, the earlier one seems to be better than these.

And also the current future doesn’t work at all

You can remove R5 and replace it with direct link and check what happens

The voltage developed across R4 due to overload will be divided by P1, and when this potential becomes sufficient enough to trigger T3 only then the current control will kick in. So set up the T3 area to implement this optimally

I didn’t understand you very well can you be more simple about t3

When there’s an overcurrent the voltage at the base of T3 should be 0.7V, then it will conduct and control over load. This 0.7 will come from R4 when overload happens.

I want to have varible constant current at any time what should i do

good day sir.

i need a 0 to 60 volt, 0.5 to 100 amp, variable volt and variable current power supply circuit diagram. must have fairly low ripple and if i set the the current level to say 20 amps at 5 volt, the power supply must be able to keep up supplying the 20 amps at 5 volt for +/- 1 hour. i will have to be able to use it at much higher amps/ lower volts and vice averse. volts and amps output must stay at set levels as close as possible with only minimal adjustment for amps as the resistance of anodizing bath changes. Yes, i want to use this power supply for dc anodizing aluminium and as a very small or big bench top power supply. i wind my own transformers, so i can make myself a very powerful transformer for this application. at the moment i use a 0 to 15 volt 30 amp regulated power supply that was given to me, i had to replace the rectifier. but i can not control the amps and when things go wrong, they go wrong with a big bang form available amps.

please help sir.

Hi Ian,

I have one suitable design that you could try, as shown in the following article:

https://www.homemade-circuits.com/universal-variable-power-supply-circuit/

By upgrading the transistors VT1, VT2, and R20 accordingly you could perhaps modify the design to handle the mentioned high current input

Good day.

Thank you sir for this circuit diagram, i really appreciate your help.

I will compare the components that needs to be changed to what my local electronics supplier have in stock and buy what i need for my application and if i run into trouble, i will ask for your help and advice. The circuit looks fairly easy to build so i think i should not have any problems.

I am busy building your water level indicator with pump control. i will give you feed back once i am done with the water level project. i must say that i am modifying this circuit a bit to suite my own needs so let us see how good or bad i am with electronics.

Thank you.

Ian.

That’s great Ian, I wish you all the best!

Hi!

I like to build the power supply, but the PCB layout in the article has text in it, is it downloadable in KiCad format?

Hi, the PCB is only for reference, downloading it may not help…you can show the design to a PCB manufacturer who can replicate the design through a software

Where can I add buzzer or led to indicate short circuit or overload

try adding it across collector/emitter of T1

Hello sir Swagatam,

I have been able to build the power supply successfully using the following:

– 60V transfo

– Darlington pair of T1

– 0.4ohm for R4

– 5K pots for P1, P2

– 10K, 5W for R1.

Other components are the same with what is in the schematic.

Initially when I turned on the power supply after completion, it worked very well. I got 1.2V to be the lowest voltage and got 44V as the highest voltage (this is due to the mains supply voltage which wasn’t up to 220V). I varied it back and forth and it worked well. Then later, I turned it on again and saw smoke coming from either the 1N4007, one or two of the BC547 or R4 (those components are close to each other on the board). I couldn’t say for sure which of them smoked. When I turned it on again, none of those components smoked but R2 burnt out. I changed the 1N4007 and changed R2 to 1W, but it burnt out again. I changed R2 for the third time and it burnt out again.

Now I am confused and don’t know which component(s) could be causing the problem.

Please I need you to help suggest which of the component(s) I need to change or how to troubleshoot the problem.

Anticipating your usual prompt response. Thank you sir.

Hello Godson, as you can see R3 is in series with R2, so R2 should not burn. It may perhaps burn if T1, T2 are burnt, just make sure T1/T2 are still OK in your circuit. Alternatively you can try increasing the value of R3 to 1K and check the response

Hello sir Swagatam,

Thanks a lot for the reply. I thoroughly checked the circuit and discovered that one of the 2N3055 that I used as Darlington pair was faulty, so I removed it, and used only one because I couldn’t immediately purchase another one. Surprisingly, it worked well. I also changed T2 and T3 to 2N2222, and R3 to 1k. Everything worked perfectly without any of the components heating up or burning out. I got above 50V as the maximum voltage at the output. With the 5k pot that I was using, the voltage change was too rapid and I couldn’t get some precise values easily, so I decided to change the pot to a 10k multi-turn pot. The voltage change was now much slower and I could get precise values easily. Surprisingly, I was able to get up to 72V at the output.

I will like to eliminate the current-varying pot and its associated components because I don’t really need them for my application, and also, it appears that that part isn’t working well (from comments above). I just want to get the maximum current that is being set by R4 and the transfo. So my question is, which components do I need to eliminate?

Anticipating your usual prompt response.

That’s great Godson, I am glad you could finally succeed. You can eliminate R4, R5, P1, T3 from the design to remove the current control feature in the 1st diagram.

Thank you so much sir.

Hello sir Swagatam,

Thanks so much for this schematic. You recently referred me to it but I’ve not been able to build it because I hadn’t got all the components. I recently got the components, but some are different from the ones in the schematic. I need you to please help me to verify if the components that I bought will work fine.

1. I need up to 60V at the output, so I got a 60V, 3A transfo

2. For R1, I got 1K, 5W, and 10K, 5W resistors

3. For R4, I got 0.39ohm, 3W

4. For D2-D5, I got 1N5401

5. For C1 and C2, I got 1000uF/63V

6. For P1 and P2, I got 5K pot. I couldn’t find 2.5K pot.

All other components are the same with those in the schematic.

Kindly tell me if those components will work fine and give the desired result. Thanks in anticipation.

Hello Godson, all the specified components will work satisfactorily, preferably try to use Darlington pair for T1, and you may increase 1K upto 10K if possible

Hello sir Swagatam,

Thanks a lot for the reply. I am working in it now.

I would like to include digital voltmeter and ammeter and also an LED indicator to show when power is on. Connecting the voltmeter is straightforward.

How do I connect the ammeter?

How do I connect the LED knowing that the output voltage is variable?

I am using a Darlington pair for T1 as you suggested. Will they be heatsinked?

In the main specifications above, you wrote that the circuit has a short circuit LED indicator. It is not shown on the schematic.

Please reply. Thank you sir.

Godson, the ammeter can be simply connected in series with the load positive wire.

In can connect the LED parallel to the voltmeter, but with a rather high value resistor such as a 15K or 22K.

T1 will always need a large heatsink, even if it is a Darlington.

the diagram suggested by Mr. Nuno has the short circuit indication feature.

DearSir,

Assembled the circuit Transformer used is 80V AC @ 500 ma. MJE13009 BJT used for T1 and 13003 BJT used as its darlington drive.T2 & T3 used are also 13003 for the high voltage input.R1 tried from 1K to 3.3K/5W. R2,R3,R4 as specified but 2watts used.I have the following observations.Pl. guide in details.

1> R1 gets very hot & inturn T2 also gets hot. 10W of R1 also gets very hot after 3~ min.

2>There is no response for current control. I have checked the circuit N-times as per your circuit.

(2ohm/3w for 300ma output)

3>When there was overloading (24v,700ma dc motor) R2-120ohms burned alongwith T2.[Not able to confirm whether it

was due to overload or the growing hotness of as mentioned in point no. 1].

4> 2K pots give output upto 65~68v Dc,10K pots are giving the desired 100Vdc output.Why so?

I would like you to help specify the values of R1,T2 for this 100v circuit.Why current control is not responding & lastly how the overload feature functions. And Sir one last querry which shortcircuit protection circuit can be used for such a high voltage.

P.S. My circuit for 0~40VDC @3amps is working fine ,Hence I am baffled with 100v,500ma circuit.

Dear Prashant, If you have used a Darlington pair then the R1 can be increased to a higher value, may be upto 4k7 5 watts or even 10K 5 watts, once this is done T2 will be safeguarded, and will not become hot.

Current control idea very straightforward. When overload is detected or over current is detected, the voltage drop across R4 reaches to a point which becomes enough to trigger T3 which in turn shorts T1’s base emitter and stops it from conducting any further until the situation is corrected.

Dear Swagatam,

The circuit works very fine upto 50v .But now a requirement has arised for to increase the voltage as 0~100vdc & current from 0~500ma max. 1K/5w became very hot and T2 burst. 2N2222A also gets very hot.I have used 2N3773 from my stock[160V transistor as 2N3055 is only rated at 60VDC]. My Transformer is wound at 80V/40VA at 230V AC. Pl. clarify.

1>Is it ok to use 2n37733 as T1 for a variable output of 100 vdc ?

2>What is the value of R1 to be used in case of 100~110 vdc at input ?

3>What should I use in case of T2 for the above output ?

4>What will be the effect of 5K pots as 2K2 are not available for the above needs ?

Kindly help Asap as the project is in incomplete state.

Thank You !

Regards

Prashant Dalvi

Dear Prashant, you can use any 150V transistor for the purpose. preferably use Darlington, 2N3773 will also work.

try the last diagrams, because they have used Darlington topology for T1, which makes sure that R1 can be a low wattage and high values resistor

R8 must be included otherwise T2 will burn

I have a Pyramid PS-7 Power Supply that will not regulate to 13.8 volts so I was wanting to convert the power supply to a variable voltage and current supply it is putting out 26.2 volts from the center tap transformer. The schematic is here at ,has" rel="nofollow ugc"> ,has there been any updates to your circuit or the parts used. Thank you very much.

,has there been any updates to your circuit or the parts used. Thank you very much.

I have updated the original diagram from elektor electronics magazine at the end of the post, which you can refer to for your analysis…

However your design also looks good to me, except the current control stage, which according to me can be made even more reliable by a little modifications.

I’ll try to do it soon and post it under the above article, then you can try this new version of your design.

Thank you very much.

Hi:

I’m sorry about my poor english. I made a test circuit on a breadboard exactly with the same values of schematic. The Vcc IN is 40 V / 2.3 A and i used 0R27 5W on R4. It worked fine, but I have some observations:

1) R1 (1K 5W) goes hot, very hot and T2 gets a litle hot to. Is it possible to use a darlington configuration for T1, increasing R1 and reducing power dissipation?

2) VCC Out is 8-38 , burt i think that D1 should make a drop to 0V6. Is it correct?

3) It seemns that P1 has no control over current. I concted a 12V 1A DC motor and manipulating P1 there is no diference at output.

I apreciate an opinion.

Best regards,

Nuno Figueiredo

Hi Nuno,

you are correct with your analysis.

R1 does get hot, therefore it must be a high wattage. Not sure about T2, since I did not check this in my prototypes.

D1 does make a drop of 0.6V and in my prototype I could get the output voltage to go as low as 1V

yes Darligton would allow R1 to be of higher value and avoid its heating up.

However the current control feature for me too did not seem to show any response, I am wondering how it is supposed to work? As far as I can imagine, the drop across R4 would trigger T3 which would force T2 to conduct more so that T1 base conduction is inhibited…but this action doesn’t seem to be working effcetively.

I have updated the original diagram in the article, tested by the elektor electronic engineers, for your reference and for analysis by all other readers….

…sorry, for the current control I think when T3 is triggered it will short circuit T1 base with its emitter and this would stop T1 from conducting, this makes more sense…

Thank you for the feedback

I’ll try a darlington with 2 3055 (only because I have both), recalculating R1; |I’ll also change t2 to 2n2222.

The current limiter i intend to study and understand before make changes because I’m not a pro, just an hobbist that loves electronics.

Best regards.

Nuno

OK, that’s great, but using 2N2222 also for the Darlington will look much better because two 2N3055 can occupy a huge amount of space and also the response will be not as good as using a 2N2222.

I wish you all the best…

Hi, mr. Swag:

I followed your advice, because also had more than one 2n2222. Reserching on the web, I made a modification on the circuit and got an efetctive short circuit protection device but, with few components, I couldn’t make a control of current limiter. I’d like to send you a schematic but there is no email here. As you have my email, in case you wish, send me an email and I’ll replay with schematic.

Basicaly, I made a darlington in T1, increased R1 to 3K3 and it get cold. I also extracted R3, R5, P1 and R6 (base of T3). T3 became also a 2n2222 and it’s colector was linked with base of barlington; it’base was linked with emiter of t1; it’s emiter to +V Out (anode of D1).

I also created an led device to advise if it is in short circuit: a resistor (calculated by ohms law – [vin-vled]/iLed. In my case 10K), a let and a npn general purpose (bc 547 it’s good). The resistor was linked in colector of t1 and the outher side to led’s anode. Led’s cathode to npn’s colector witch it’ś base is to emiter of Ti and it’s emiter to Vcc out (D1 anode).

I’m not sure if I was clearly. I tryed this circuit with 40 V cc and got 0.8 until 38V with limit of 2.3 amps. In case of SC, led becames bright and voltage drop to ~0 Vcc.

(BTW: i discovered in my first test that couldn’t reduce vcc min to 0,6 because de cable I used to conect d1 to pot was damaged.)

I hope this information

That’s superb Nino, please send it to my email, I’ll be most happy to check it:

homemadecircuits

@gmail.com

By the way my email details are provided at the end section of the right sidebar or in mobile right at the bottom of the page, inside “contacts”

Ola Swagatam,

poderia me mandar um endereço de imail para que eu possa enviar-lhe um arquivo para analise?

Hello Sir Swagatam

Thanks for your tireless generosity educating and sharing your knowledge and insights.

Could you please explain how in the above circuit the value of R4 is calculated using Ohms law; i.e. how is the figure of 0.6 arrived at, and by using this calculation what will the short circuit current be at any given voltage setting?

E.g. 24V, R4: 0.15 Ohms for max 4 Amps!

Many thanks.

Thank you Husmukh,

the value 0.6 is the optimal conduction base drive voltage for T3.

for the shown calculation the short circuit current would be 4 amps.

However this will depend how P1 is set…if P1 adjustment is set at the opposite end, then the 4 amp will not be effective, and the circuit would be operating at the full input current level

Many thanks for your prompt reply.

So would the inclusion of say a 1k Ohm resistor between P1 and the output of R4 prevent the accidental short circuit overload of of T1?

Or, if the load V, I, is not that critical, then could the value of R4 be set higher to say 4 Ohms 5W or higher for a ‘child-save’ operation?

I’m building this for the kids to play with and would like it to be absolutely fool proof so they can’t blow it up, but use it to learn about electronics.

Kind regards!

You are welcome! You will have to set R4 for setting up the short circuit current, by the way 4 amp will not harm the 2N3055 transistor even if it is shorted at this current.

However to get an extremely reliabe, and foolproof circuit you must try a LM338 power supply which has all the features built in, and is very simple:

https://www.homemade-circuits.com/how-to-make-solar-battery-charger/

Thanks very much Sir, I’ll try that.

you are welcome!!

sir can I use 12v 3a transformer

you can!

Hi Swagatam, I need a 100A power supply, i am using a microwave oven transformer with a welding cable as a secondary and some 100A rectifier diodes, years ago i attached it directly to 3x 40W laser diode bar arrays in series, while it was 5 volts (voltage drop across each array is ~2V) the current was too high and it fried all three (i had no way of measuring current, multimeter only went to 10A.) my question is can i use this NPN BJT:

in place of T1, T2 and T3 instead of a power mosfet across T1? the highest current power mosfet i can find on ebay is 75A which is less than what my new 100A laser diode bar array requires. Or can i use two power mosfets in parallel across T1?

I am also waiting for 4x 200W 1k wirewound potentiometers to arrive and some more transistors so i can put the pots in series with a toggle switch to switch from low range to high range to get an equivalent of the 2.5k pot you specified. (the wirewound pots only go up to 1k so i'm putting them in series pairs with a 500ohm resistor for the range i don't need)

i figure R4 will be .6 milliohm according to your formula, so i bought two 1 milliohm wirewound resistors to put in parallel for .5milliohm = 120A max. i have bought 100W wirewound resistors for all the values in your diagram.

I have a Nd:YAG laser crystal i'm converting from arc-lamp pumped to diode-pumped for power conversion efficiency reasons, it's application is a direct metal laser sintering machine, i have an f-theta lens, mirrors and collimating lenses and i programmed a .DXF file parser in java processing that sends coordinates and laser on/off commands to an arduino DUE controlling a MCP4822 DAC with op-amps, which sends bipolar analog signals to my galvanometers. I have not made the build chamber or powder dispenser yet but after this power supply i will start buying the stainless steel i need.

eagerly awaiting your response, i've bookmarked this page and will continue checking for the next month or so while i wait for my packages to arrive. your expertise means the world to me.

Hi, I am not sure whether T2 and T3 can be replaced with a mosfet or not, but T1 perhaps can be replaced with the mosfet, you can try this with a low current version without changing T2/T3 values, if everything works OK then you can add more mosfets in parallel to increase the current output.

By the way you can also experiment with the following easy concept first, here you can easily replace the BJTs with mosfets:

https://www.homemade-circuits.com/2015/03/100-amp-variable-voltage-power-supply.html

thanks heaps for your quick reply, and i was only meaning to use the mosfets in combination with T1, i was a bit hazy on whether use the high current BJT i mentioned in the first link for T1, T2, and T3 or if the BC547B you specified will still work for T2 and T3.

sadly the variable voltage alone is no good for my purposes, as i need to vary the current as i only have 1 working 60W laser module left which i will use at slower scan speeds. I will be upgrading to the 100W ones later by replacing the emitters i have soldered to the anodes with new ones, on alibaba they're $30 – $50 each but there's a minimum order quantity of ten. Then i will need to change the voltage from 2 to 6V, and the current from 60A to 100A. There is a 50% conversion efficiency from watts to light watts and a 30% conversion efficiency from 808nm to 1064nm through the Nd:YAG crystal, so i'll need 600W. also going to have three groups of three 100W emitters that are pulsed alternately, going to use three more of those BUT30V BJTs, a 555 timer, a 2 bit shift register, some EXNOR gates and some AND gates for that.

You are welcome Ananke,

OK in that case you can try the design which is explained in the above article, I think you should go with BJTs for T1 instead of mosfets, this is to help reduce complications.

You can replace T1 with 15nos of TIP142 in parallel (on heatsink)

This will call for R1 to be beefed up appropriately in terms of wattage, although the value may not require much change due to the darlington nature of the TIP142.

and yes when the circuit is dealing 100A, then T2/T3 might also need to be upgraded for better safety. You can use 2N2222 for T2/T3.

Please let me know if you have any more doubts regarding the application, I'll be happy to help!

Excellent I'll try that, I'll let you know how I go in a month or so when these things get delivered. I've bought a 1k 100W wirewound resistor for R1, do you reckon it will suffice?

When finished I'm going to try using magnetite instead of metal powder in the powder dispenser and a reductive gas such as carbon monoxide instead of inert gas like argon, to selectively reduce and melt the magnetite ore into something like pig iron, with wire bristles on the leading side of the powder dispenser which comes before the powder recoating blade to brush off any slag. I have a few refrigerator compressors I got cheap at the local metal recyclers for drawing a vacuum on the build chamber before filling it with carbon monoxide, and for compressing it into a second tank for impure CO gas with CO2, which can be reduced back to CO using hydrogen gas and electrolysis with a zinc cathode, probably using the same power supply as this one.

sure, thanks! 1K 100 watt should be more than enough for R1.

You project looks very interesting, I only hope the design fulfills your project requirement,

do keep us updated.

Wish you all the best

Yeah i´m pretty sure that the 2N3055 not genuine, so maybe they are all super dodgy. I know that the 2N3055 also comes in a TIP package, maybe i could try one of those. Oh and by the way my R4 is 0.3ohms 50W! (yes 50W, its huge). so if i have done the math right it should be limited to 2 amps? but for some reason T1 shorts out internally causing the output of the rectifier to go straight to R2 and T2 and then it burns. (this is my current theory anyways)

yes that might be possible, the TIP version are usually more reliable.

for the max output current you can simply use Ohm's law to find out how much the resistor can handle….

yeah..if T1 is dodgy then there's no way you can save your circuit or any of the other associated components.

Ok i have done some more troubleshooting now. When i increase the resistance of R4 to something a lot bigger like 24 ohms then i am able to adjust the current. but any low value resistor i try the current limiting just isnt working. and if i short the outputs now it alwauys just lets 2 amps through with no option to limit it.

is there any other resistor i can change for this to work with the normal R4? if i change R3 or R5 will that have any effect?

You can try eliminating R5 entirely and see if that helps, although the circuit should have worked with its existing form, still you can try the above modification and check the results.

Alternatively you can use a Darlington for T3.

I just soldered together this circuit, and when i first tried it out my R2 burned instantly. I found out that it was a dodgy 2N3055 that caused that to happen. So i switched out the 2N3055 and now the voltage adjusting is working. But the current limiting is not. I tried to just put a high watt 24ohm resistor across the output and then turn the current pot but nothing happens. and if i short the output then it destroys the 2N3055. Can you make a educated guess as to what may be causing this? i dont even know where to start troubleshooting this. Thanks

As explained in the previous comment you can connect a high watt bulb and then adjust the current pot and check the illumination level on the bulb, it must vary accordingly.

The 2N3055 is never supposed to burn even if the output is shorted because the current limiter resistor is in series with the emitter of the transistor, which ensures that the current never exceeds the transistors max limit, ofcourse this limiting resistor must be calculated such that it limits anything above 8 amps, and the transistor must be mounted on a large heatsink.

When I constructed this circuit it started working immediately with no issues,and since then I used it for many many years with absolutely no maintenance and all technical negligence, yet it showed no signs of getting damaged, ultimately I had to dispose it off in a good condition, since I wanted a new one with more features.