In this post I have explained a few circuit concepts which can be employed for converting or modifying any ordinary square wave inverter to sophisticated sine wave inverter design.

Before studying the various designs I have explained in this article, it would be interesting to know the factors which typically makes a sine wave inverter more desirable than a square wave design.

How Frequency Works in Inverters

Inverters basically involve frequency or oscillations for implementing the boost and inversion actions. The frequency as we know is generation of pulses at some uniform and calculated pattern, for example a typical inverter frequency may be rated at 50Hz or 50 positive pulses per second.

The fundamental frequency waveform of an inverter is in the form of square wave pulses.

As we all know a square wave is never suitable for operating sophisticated electronic equipment such as TV, music players, computers etc.

The AC (alternating current) mains that we acquire at our domestic mains outlet also consists of pulsating current frequency, but these are in the form of sinusoidal waves or sine waves.

It's normally at 50Hz or 60Hz depending upon the particular country utility specs.

The above mentioned sine curve of our home AC waveform refers to the exponentially rising voltage peaks which constitute the 50 cycles of the frequency.

Since our domestic AC is generated through magnetic turbines, the wave form is inherently a sine wave, so doesn't require any processing further and becomes directly usable in homes for all types of appliances.

Conversely in inverters, the fundamental waveform are in the shape of square waves which needs thorough processing in order to make the unit compatible with all types of equipment.

Difference between Square Wave and Sine Wave

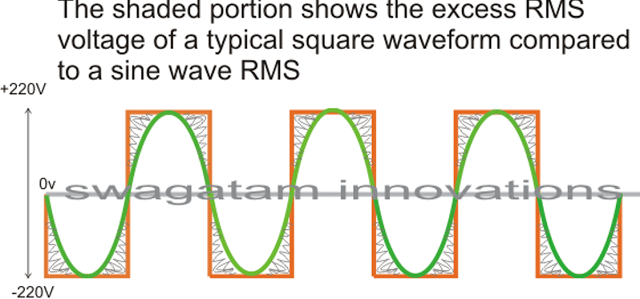

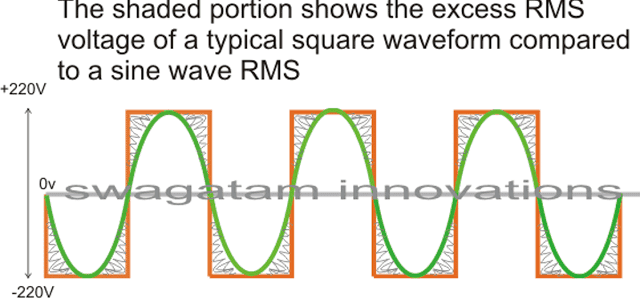

As shown in the figure, a square wave and sine wave may have identical peak voltage levels but the RMS value or the root mean square value may not be identical. This aspect is what that makes a square wave particularly different from a sine wave even though the peak value may be the same.

Therefore a square wave inverter working with 12V DC would generate an output equivalent to say 330V just like a sine wave inverter operating with the same battery but if you measure the output RMS of both the inverters, it would differ significantly (330V and 220V).

The image incorrectly shows 220V as the peak, actually it should be 330V

In the above diagram, the green colored waveform is the sine waveform, while the orange depicts the square waveform. The shaded portion is the excess RMS which needs to be leveled of in order to make both the RMS values as close as possible.

Converting a square wave inverter into a sine wave equivalent thus basically means allowing the square wave inverer to produce the required peak value of say 330V yet having an RMS just about equal to its sine wave counterpart.

How to Convert/Modify a Square Waveform to Sine Waveform Equivalent

This can be done either by carving a square wave sample into a sine wave form, or simply by chopping a sample square waveform into well calculated smaller pieces such that its RMS becomes very close to a standard mains AC RMS value.

For carving a square wave to a perfect sine wave, we can employ a wien bridge oscillator or more precisely a "bubba oscillator" and feed it to a sine wave processor stage. This method would be too complex and is therefore not a recommended idea for implementing an existing square wave inverter to a sine wave inverter.

The more feasible idea would be to chop the associated square wave at the base of the output devices to the required RMS degree.

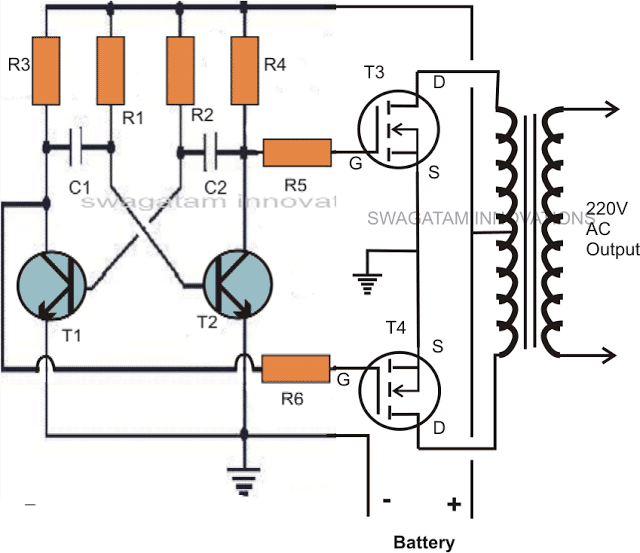

One classic example is shown below:

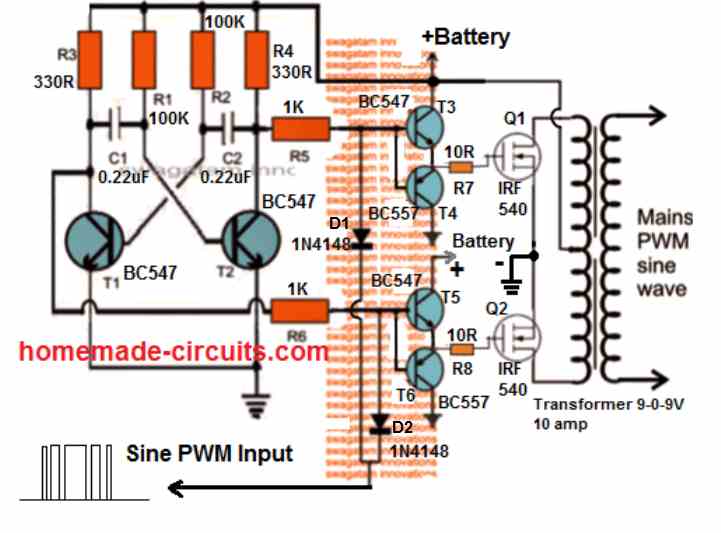

The first diagram shows an square wave inverter circuit. By adding a simple AMV chopper we can break down the pulses at the base of the relevant mosfets to the required degree.

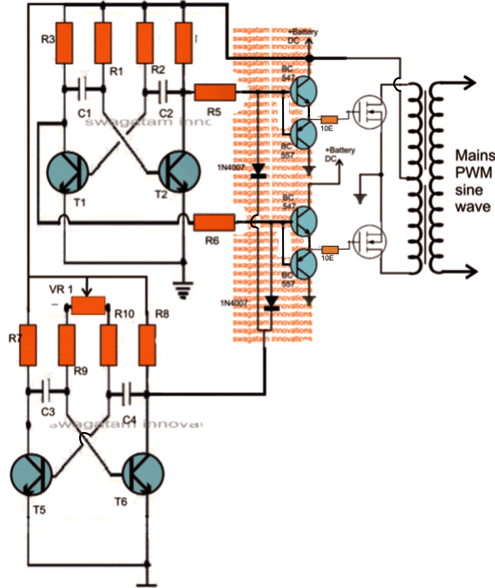

Modified square wave to sine wave equivalent inverter version of the above circuit.

Here the lower AMV generate pulses at high frequency whose mark/space ratio can be suitably altered with the help of preset VR1. This PWM controlled output is applied to the gates of the mosfets in order to tailor their conduction into the stipulated RMS value.

Expected typical waveform pattern from the above modification:

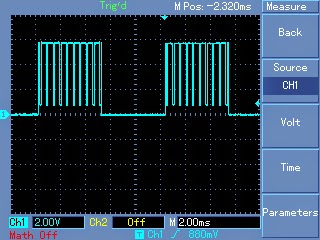

Waveform at the mosfet gates:

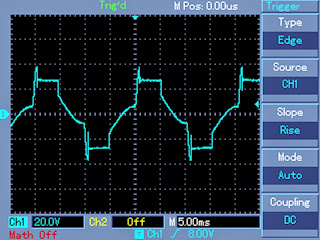

Waveform at the output of transformer:

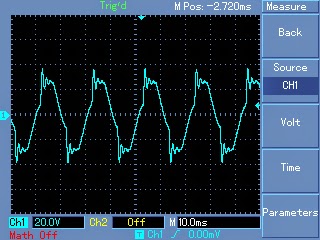

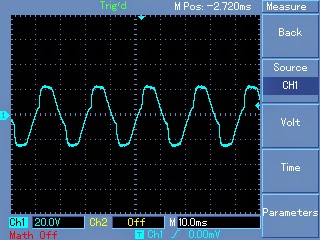

Waveform after proper filtration using inductors and capacitors at the output of the transformer:

Parts List

R1, R2, = 27K,

R3, R4, R5, R6, R7,R8, R9, R10 = 1K Ohms,

C1,C2 = 0.47uF/100V metallized

C3, C4 = 0.1uF

T1, T2, T5, T6 = BC547,

T3, T4 = any 30V, 10amp mosfet, N-channel.

D1, D2 = 1N4148

VR1 = 47K preset

Transformer = 9-0-9V, 8 amp (specifications must be selected as per the output load for correct powre optimization)

Battery = 12V,10AH

Getting Better Efficiency Rate

The above explained conversion or modification will provide around 70% of efficiency with the achieved RMS matching. If you are interested in getting better and precise matching then probably a an IC 556 PWM waveform processor would be required.

You would want to refer to this article which shows the principle behind modifying a square waveform into a sine waveform using a couple of IC555.

The output from the above mentioned circuit can be similarly fed to the gate or the base of the relevant power devices which are present in the existing square inverter unit.

A more comprehensive approach may be witnessed in the this article where an IC 556 is used for extracting precise PWM based modified sine wave equivalents from a square wave sample source.

This waveform is integrated with the existing output devices for implementing the intended modifications.

The above examples teach us the simpler methods through which any existing ordinary square wave inverter may be modified into a sine wave inverter designs.

Converting into an SPWM

In the above article I have explained how the waveform of a square wave inverter could be optimized for getting a sine wave kind of waveform by chopping the square wave into smaller sections.

However a deeper analysis shows that unless the chopped waveform is not dimensioned in the form of SPWMs, achieving a proper sinewave equivalent may not be possible.

To satisfy this condition an SPWM converter circuit becomes essential for carving out the most ideal sinewaveform from the inverter.

The basic idea is to chop the output power devices with sine wave pulse width modulation, so that the power devices force the transformer winding to also oscillate in the SPWM mode and ultimately generate an optimized pure sine wave at the secondary side. The magnetic induction of the pulsed SPWM across the transformer winding finally gets the shape of a pure sine wave due to the inductive filtration of the transformer winding.

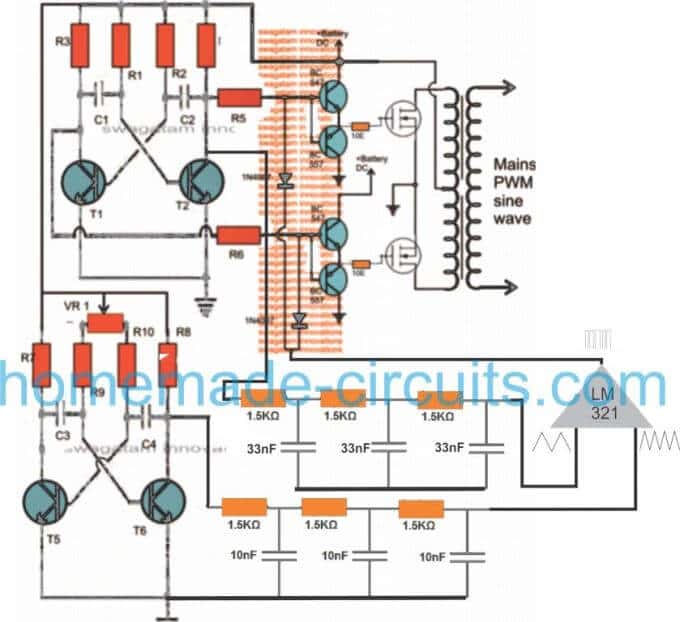

The following diagram shows how this could be effectively implemented with the concept discussed above.

Through one of my earlier articles we understood how an opamp could be used for creating SPWMs, the same theory could be seen applied in the above concept. Two triangle wave generators are used here, one accepting the fast square wave from the lower astable, while the other accepting slow square waves from the upper astable and processing them into corresponding fast and slow triangle wave outputs, respectively.

These processed triangle wave are fed across the two inputs of an opamp, which finally converts them into SPWMs or sine wave pulse widths.

These SPWMs are used for chopping the signals at the gate of the mosfets which ultimately switch the waveform over the connected transformer winding for creating an exact replica of a pure sine waveform at the secondary side of the transformer through magnetic induction.

How to Calculate the Part Values

Astable Multivibrator Frequency (Square Waves):

Formula: f = 1 / (0.693 * (R1 + 2 * R2) * C)

For the fast square wave generator:

Let R1 = 10k ohms, R2 = 100k ohms, C = 10nF (example values).

ffast = 1 / (0.693 * (10000 + 2 * 100000) * 10e-9)

ffast = 1 / (0.693 * 210000 * 10e-9)

ffast = 68 Hz

For the slow square wave generator:

Let R1 = 10k ohms, R2 = 1M ohm, C = 100nF (example values).

fslow = 1 / (0.693 * (10000 + 2 * 1000000) * 100e-9)

fslow = 1 / (0.693 * 2010000 * 100e-9)

fslow = 7.1 Hz

RC Integrator Cutoff Frequency (Triangle Wave Generators):

Formula: fc = 1 / (2 * π * R * C)

For each RC stage assume R = 1.5k ohms and C = 33nF.

fcstage = 1 / (2 * 3.1416 * 1500 * 33e-9)

fcstage = 1 / (2 * 3.1416 * 0.0000495)

fcstage = 3223 Hz

For three stages the overall response rolls off steeply approximately at the same fcstage.

Op-Amp SPWM Generation:

The op-amp compares the fast triangle wave (carrier) and the slow triangle wave (modulating signal). The output is high when the carrier is greater than the modulating signal. This generates a sinusoidal PWM (SPWM).

Gate Drive Requirements for MOSFETs:

Formula: Ig = VSPWM / Rg

Assume VSPWM = 10V and Rg = 1.5k ohms.

Ig = 10 / 1500

Ig = 0.0067 A (6.7 mA)

This ensures the MOSFET switches efficiently.