Repairing a mosquito bat is a process in which a malfunctioning mosquito bat is checked for faults using meters and restored to its earlier working condition.

This post provides some general tips regarding how to repair a mosquito swatter bat or racket, through quick steps.

Mosquito rackets today have become an indispensable tool in every house, simply because it not only provides us with an effective way of terminating mosquito, the process also creates a sense of fun and satisfaction.

However these devices seem to have one drawback, they get damaged or nonoperational quite quickly. This is usually due to bad handling or some minor internal technical problems.

Let's discuss some general tips regarding the possible faults with a swatter mosquito bat, and ways to quickly investigate and repair them.

It would be interesting to know that 90% of the time the faults associated with a damaged mosquito swatter bat is due to shorted mesh net, or an exhausted battery.

90% of the time the fault is not associated with the circuit board or its components.

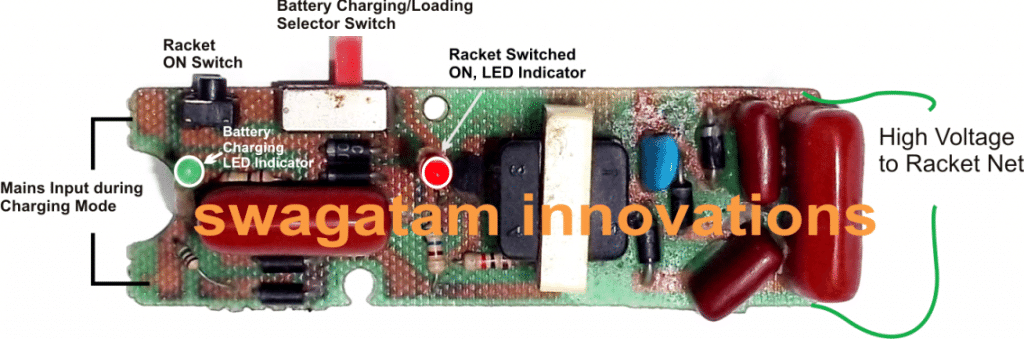

How does a Mosquito racket circuit look like

In the above image we can see a commercial mosquito bat circuit board, populated with many stages and electronic components.

If you find your mosquito bat is no more working (no lights, no sparks), then most probably none of the parts in the circuit may be faulty or damaged.

Do not throw it or submit it into a junk shop because most of the time the fault in a mosquito bat is too basic which can be easily repaired at home using ordinary tools such as soldering iron and a multimeter.

Frequently, it's either the battery that is completely exhausted or may have become unresponsive to the charging cycles.

How to Troubleshoot

For troubleshooting and repairing your mosquito bat you will need a soldering iron, a multimeter and some prior experience with electronic assembly and soldering.

If you are entirely new to this then these operations may not be recommended for you.

Next, follow the steps as given below:

- With great care and concentration open the bat enclosure and remove the circuit board. This is normally done by removing a couple of screws on the bat handle.

- Before disconnecting the wires, take a snap shot of the various wire connections in your mobile phone so that you can refer to the pic in case you forget any of the connections.

- After this, the first step would be to detach battery from the board by desoldering the soldered points. Likewise, detach the high voltage wire from the board associated with the racket mesh.

Check the Battery

- Next, check the voltage across the detached battery wire through V range of your DMM. The reading should be around 3V. A damaged battery might show below 2V indicating that the battery needs a replacement.

- If it shows 3V, then connect it back with the PCB and measure the DC side supply lines ON the PCB with the push button pressed. If the battery has lost its current delivering capacity you may find the voltage dropping drastically, again this may indicate the signs of a damaged battery.

- In the above case, remove the battery and connect the circuit board with an external 3V DC from an AC to DC power supply.

- Very likely, now the DC supply line of the PCB will show a perfect 3V.

Check Output Arc Voltage

Next, it's time to verify the high voltage side operations, which must be checked cautiously using the DC 1000V range in your DMM.

Be careful, and make sure none of your body part touches this side, which might otherwise inflict a painful electric shock.

Begin, by pressing the relevant switch or the push button and checking the response.

If the meter shows a high voltage, the problem may be deemed solved.

To further confirm the actions, try shorting the high voltage side terminals manually with a piece of flexible wire. It should respond with a powerful spark confirming the proper working condition of the board.

Since it's assured that the device needs a new battery, get it replaced with the new one. Get a new battery pack connect the wires across the respective points and reconfirm the procedure. Once done, you can now fix the wires accordingly and restore the board inside the cabinet and fasten the screws.

You have just repaired your mosquito bat.

Check Loose Connections, or Solder Points

In some cases you may find the battery is OK, and mesh network is also undamaged yet no response from the unit.

In such situations you may want to confirm the various joints and weak solder points. Touch-up all the possible solder points with your soldering iron and solder wire, so that all the joints are renewed.

If the problem is with a bad solder point or connection, this action might quickly resolve the issue and restore the working condition of your mosquito racket.

Look for Dented Mesh Net

This is another major issue which causes a mosquito bat to stop functioning and deplete battery quickly. It's a deformed or crushed bat mesh.

Very often while hunting for the mosquito we tend to hit the bat on hard surfaces or uneven surfaces, causing a dent or depression to form on the netting of the bat. This in turn causes the portion of the mesh to get depressed and come closer to the central net.

When this happens the sparks get an easy path across this "shorted" nearby points. This situation makes the actual zapping operations ineffective allowing the mosquito to escape unscathed between the net.

A quick way to check the above issue is to carefully observe the bat net in darkness with the push button pressed.

You may immediately witness a shiny arcing near the dent, indicating a leaking spark across the dented area.

Once the spot is located, check the area carefully and correct the fault by gently straightening the crooked mesh section with a screwdriver. This will quickly render the bat in a working condition, and restore snappy electrocution of the mosquito.

Faults in the Circuit Board

Faults in a mosquito swatter bat circuit board can be very rare. Because the circuit is operated with a 3V battery while most of the parts are rated at much higher levels.

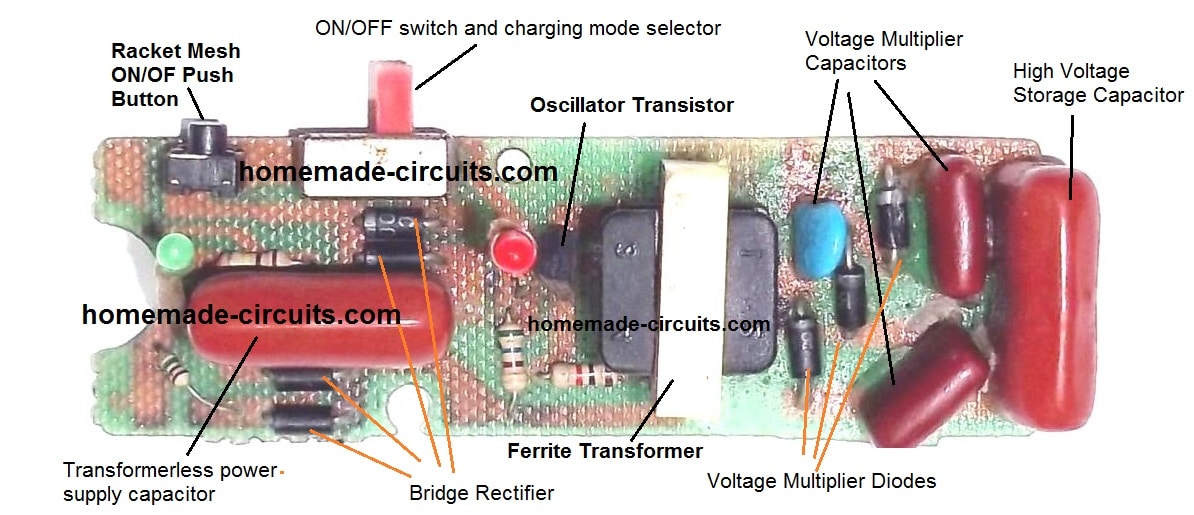

Basically this kind of circuits work using a blocking oscillator for pulsating a high voltage ferrite transformer. Here, the main active component is a small signal BJT which operates in a push pull manner for creating the required pulses across the transformer winding.

If none of the above mentioned troubleshooting ideas work, you may start checking the circuit board for a possible fault.

As specified earlier, begin by reinforcing all the solder points with fresh soldering touch ups.

Verify whether or not the problem is solved. If not, remove the transistor and check it with a multimeter. If you find the reading suspicious simply replace it with an identical transistor or a close equivalent. Mostly this transistor will be an NPN and any equivalent having

collector/emitter voltage rating around 30V and current 200mA can be used as a replacement.

The range may include transistors like, 8050, BEL188, 2N2222, SL100, BC182, BC338. More equivalents can be found through this image:

Checking the Diodes

If replacing the transistor does not help, check the diodes by removing each one separately. The secondary side can be especially prone to diodes getting faulty due to high voltage.

So check the secondary diodes carefully, and replace the defective one with a new equivalent.

A Capacitor can be also Defective

The commercial units are notorious for using low quality, cheap components, in order to increase profit margin. This may lead to one of the high voltage capacitors going faulty. A faulty capacitor can give rise to two types of problems in a mosquito swatter bat.

On the secondary side this can result in a suppressed or low voltage output, and on the primary side a faulty capacitor may prohibit the battery from charging optimally or completely inhibit the charging process.

At the secondary side, a faulty capacitor may cause the output sparks to get feeble and weak. If your meter reads the transformer secondary producing a reasonable amount of voltage which may be anywhere between 300V to 700V, but the final terminals generating less, then the fault could be in one of the ladder capacitors.

Assuming you have already checked the diodes or replaced them with new ones, it's time to check the associated capacitors and replace the defective one with a new one. The checking can be done by removing the capacitor and testing them with a capacitance meter.

Battery not Charging

In the above paragraph the faulty capacitor was on the secondary side which was responsible for a suppressed output voltage. On the primary side also you may see a high voltage capacitor which is employed for creating a cheap 220V transformerless power supply.

This power supply is primarily intended for enabling a trickle charging for the battery. If this capacitor goes defective then no voltage will be reach the battery, or the voltage may be insufficient causing inefficient charging of the battery. Check and replace it with a new one and verify by checking the voltage across the points which leads to the battery terminals.

Remember the above explained transformerless charger is not isolated from mains voltage, therefore is lethal to touch, proceed with great caution while testing this stage.

Miscellaneous Faults

In the above sections we have talked about the major and the most likely faults that can render mosquito bat nonoperational. However there can be other faults resulting in the swatter bat shutting down completely.

One of the basic reasons could be a malfunctioning or a broken switch. A mosquito racket will normally have two switches. One is a selector-switch or the ON/OFF switch.

When this switch is in the ON position, the bat gets into a standby mode. In this position the second switch which is a push-button becomes enabled and allows the user to press it for activating the bat mesh for the required fly zapping actions.

In the OFF position the selector switch turns off and disables the bat completely, and also simultaneously turns on and enables the charging of the battery when the unit is plugged in to the mains socket.

If any of these switches become defective, the above explained operations of the bat can get hampered.

Repairing a faulty switch in a mosquito bat is actually quite easy. Disconnect the relevant connecting wires by desoldering them from the switch, and then check the continuity across the switch terminal with a DMM, in the diode range.

A short-circuit reading or loss of continuity on the meter will confirm a damaged switch. Remove and replace it with a new one to complete the repairing of the mosquito swatter bat.

Over to You

So folks these were a few tips regarding how to quickly and wisely repair a fly zapper or mosquito racket at home using ordinary tools. If you have any specific questions regarding this topic, please send them through the comments below, I'll try to solve them ASAP.