The IC 4017 can be considered as one of the most useful and versatile chip having numerous electronic circuit applications.

About IC 4017

Technically it is called the Johnsons 10 stage decade counter divider. The name suggest two things, it’s something to do with number 10 and counting/dividing.

The number 10 is connected with the number of outputs this IC has, and these outputs become high in sequence in response to every high clock pulse applied at its input clock pin out.

It means, all its 10 outputs will go through one cycle of high output sequencing from start to finish in response to 10 clocks received at its input (pin#14). So in a way it is counting and also dividing the input clock by 10 and hence the name.

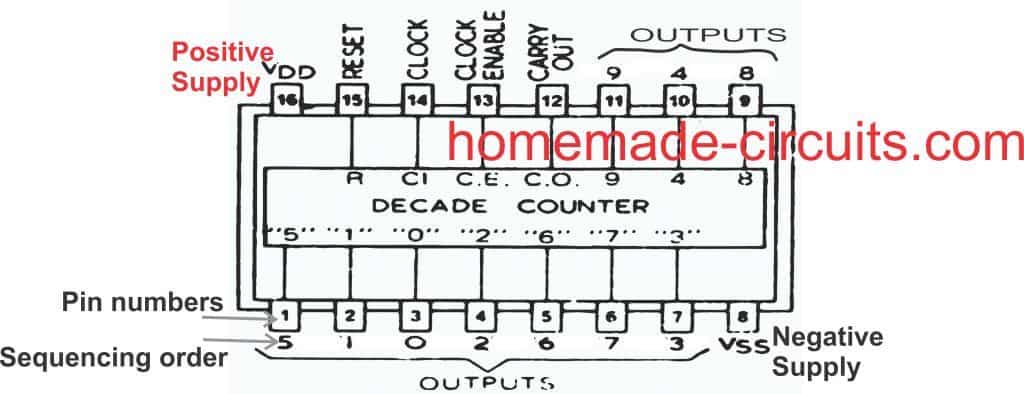

Understanding pinout Function of IC 4017

Let’s understand the pin outs of the IC 4017 in details and from a newcomer’s point of view: Looking at the figure we see that the device is a 16 pin DIL IC, the pin out numbers are indicated in the diagram with their corresponding assignment names.

What do Logic High, Logic Low Mean

The pinout which are marked as outputs are the pins which are rendered logic "high" one after the other in a sequence in response to clock signals at pin#14 of the IC.

"Logic high" simply means attaining a positive supply voltage value, while "logic low" refers to attaining zero voltage value.

When the IC 4017 is initially switched ON, it gets reset, and a logic high appears at pin#3 by default. We will discuss the resetting process in the later paragraphs.

In this position, when the first clock pulse is applied at pin#14, the existing logic high at pin#3 jumps from pin#3 to the next pinout that is pin#2. The logic high remains locked on pin#2 until the next clock is applied on pin#14, which causes the high logic at pin #2 to jump from pin#2 to the next output pinout that is pin#4, and this sequencing of logic high goes on until it reaches the last pinout of the IC which is pin#11, after which the logic high sequence jumps back to pin#3, and the cycle repeats again.

What is the Output pin Sequencing order?

To be precise, the sequencing movement happens through the pinouts: 3, 2, 4, 7, 10, 1, 5, 6, 9, 11...

After pin#11 the IC internally resets and reverts the logic high at pin #3 to repeat the cycle.

Why Pin 15 Should be Grounded

This sequencing and resetting is successfully carried out only as long as pin#15 is grounded or held at a logic low, otherwise the IC can malfunction. If it is held high, then the sequencing will not happen and the logic at pin#3 will stay locked.

Please note that the word “high” means a positive voltage that may be equal to the supply voltage of the IC, so when I say the outputs become high in a sequential manner means the outputs produce a positive voltage which shifts in a sequential manner from one output pin to the next, in a “running” DOT manner.

Pin 14 Needs External Frequency (Clock Signal)

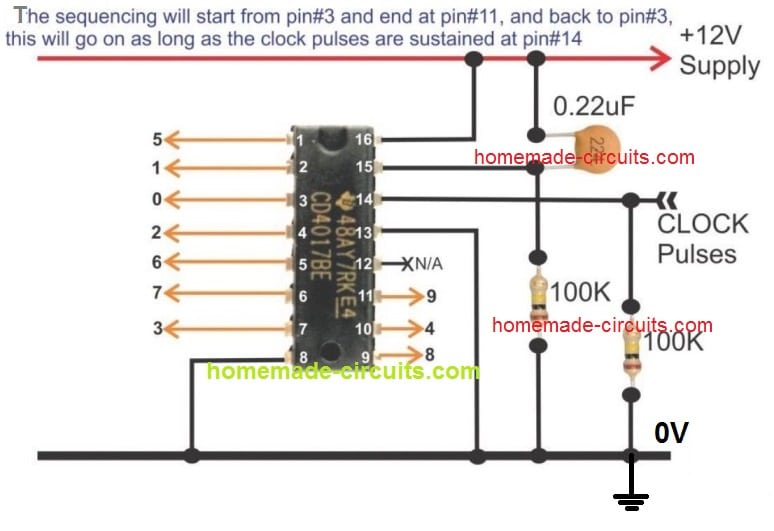

Now the above explained sequencing or shifting of the output logic from one output pin to the next output is able to run only when a clock signal is applied to the clock input of the IC which is pin #14.

Remember, if no clock is applied to this input pin#14, it must be assigned either to a positive supply or a negative supply, but should never be kept hanging or unconnected, as per the standard rules for all CMOS inputs.

The clock input pin #14 only responds to positive clocks or a positive signal (rising edge), and with each consequent positive peak signal, the output of the IC shifts or becomes high in sequence, the sequencing of the outputs are in the order of pinouts #3, 2, 4, 7, 10, 1, 5, 6, 9, 11.

Pin 13 is Opposite of Pin 14

Pin #13 may be considered as the opposite of pin #14 and this pin out will respond to negative peak signals. Meaning if a negative clock is applied to this pin will also produce the shifting of "logic high" across the output pins

However normally this pin out is never used for applying the clock signals, instead pin #14 is taken as the standard clock input.

Therefore pin #13 needs to be assigned a ground potential, that means, must be connected to the ground for enabling the IC to function.

In case pin #13 is connected to positive, the whole IC will stall and the outputs will stop sequencing and stop responding to any clock signal applied at pin #14.

How Pin 15 Works Like reset Pin

Pin #15 of the IC is the reset pin input. The function of this pin is to revert the sequence back to the initial state in response to a positive potential or supply voltage.

Meaning, when a momentary positive voltage hits pin 15, the output logic sequencing comes back to pin #3 and begins the cycle afresh.

If the positive supply is held connected to this pin #15, again stalls the output from sequencing and the output clamps to pin #3 making this pinout high and fixed.

Therefore to make the IC function, pin #15 should always be connected to ground.

If this pinout is intended to be used as a reset input, then it may be clamped to ground with a series resistor of 100K or any other high value, so that an external positive supply now can be freely introduced to it, whenever the IC is required to be reset.

Using Pin#15 to Reduce the Number of Output Sequence

As I have explained above, there are 10 outputs in the pinout order of 3, 2, 4, 7, 10, 1, 5, 6, 9, 11.

The sequencing begins from pin#3 and ends at pin#11, where the IC resets and the sequence reverts to pin#3 to begin a new cycle.

However, suppose you do not want to use all the 10 output sequences, instead want to limit the sequence to 5 numbers only. Meaning, you want to use the output sequencing in order of 3, 2, 4, 7, 10. The sequence is supposed to begin from pin#3 and end at pin#10 and return back to pin#3.

However, this cannot happen as long as pin#15 is connected to ground. To limit the sequencing to a desired lower count, the pin#15 should be disconnected from the ground line, and connected to output pin which comes just after the last sequence pinout.

In the above example, where we want the sequence to end at pin#10, the next pinout that comes after pin#10 is pin#1, so pin#15 must be connected to this pin#1, to ensure that whenever the sequencing hits pin#1, it is instantly reverted to pin#3 for a new cycle, and the maximum output sequencing is limited to 5 count only.

In the above manner you can limit the output sequencing to any other desired count below 10.

Ground pin and Carryout Pin

Pin #8 is the ground pin and must be connected to the negative of the supply, while pin #16 is the positive and should be terminated to the positive of the voltage supply.

Pin #12 is the carry out, and is irrelevant unless many ICs are connected in series, I will elucidate it some other day. Pin #12 can be left open.

Have specific questions?? please feel free to ask them through your comments...all will be thoroughly addressed by me.

Basic IC 4017 Pinout Connection Diagram

Application LED Chaser Circuit using IC 4017 and IC555

The following example GIF circuit shows how the pinouts of a IC 4017 is usually wired with an oscillator for obtaining the sequential logic high outputs. Here the outputs are connected to LEDs for indicating the sequential shift of the logics in response to each clock pulse generated by the IC 555 oscillator at pin#14 of the IC 4017.

You can see that the logic shift happens in response only to the positive clock or positive edge at pin#14 of the IC 4017. The sequence does not respond to the negative pulses or clocks.

IC 4017 Working Simulation

Video Clip:

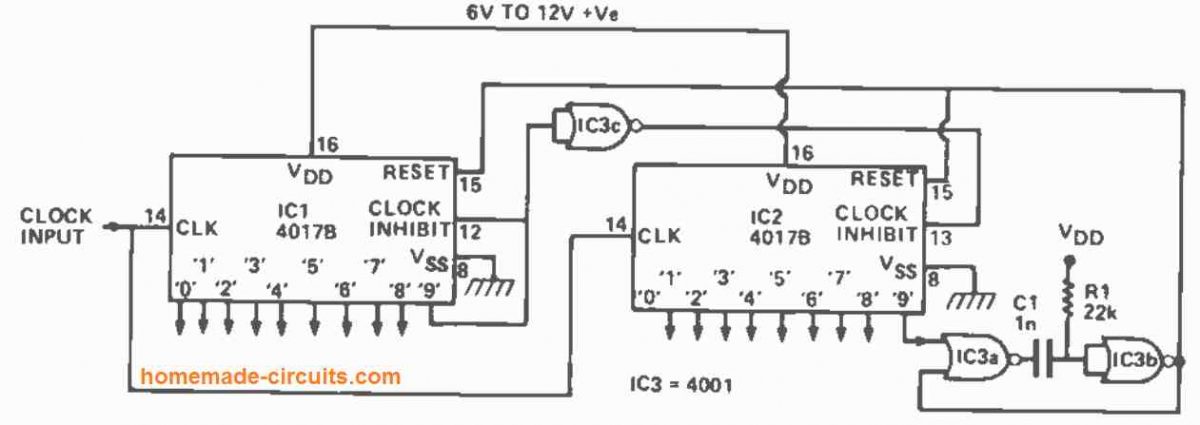

How to Cascade Two 4017 ICs for Getting 17 Sequencing Outputs

The diagram above shows how to connect two 4017s together to create a 10-to 17 stage counter/decoder. It shows how to cascade two 4017 ICs to get 17 sequencing outputs instead of only 10 from a single IC. The circuit is shown configured to divide by 17.

The clock signal is supplied in parallel to IC1 and IC2. As soon as the count falls below 9, the '9' output of IC1 turns low, causing the clock inhibit pin of IC2 to be set high through IC3c, preventing IC2 from being impacted by the clock signals.

The '9' output of IC1 rises high when the 9th clock pulse comes, inhibiting IC1 from further clocking action, while simultaneously driving the clock inhibit terminal of IC2 low through IC2c, allowing IC2 to respond to further clock signals.

When the 17th clock pulse arrives, the '9' output of IC2 swings high for a brief period, triggering the IC3a -IC3b 15uS monostable. This 15us pulse resets both counters to the empty or '0' states.

After that, the counting sequence starts again by itself. Because the '9' output of IC1 and the '0' and '9' outputs of IC2 are "lost" in the counting process, the circuit only has 17 counter/decoder stages available. By connecting the "free" input pin of IC2a to the matching output pin of IC2, the circuit can be made to count by any number between 10 and 17.

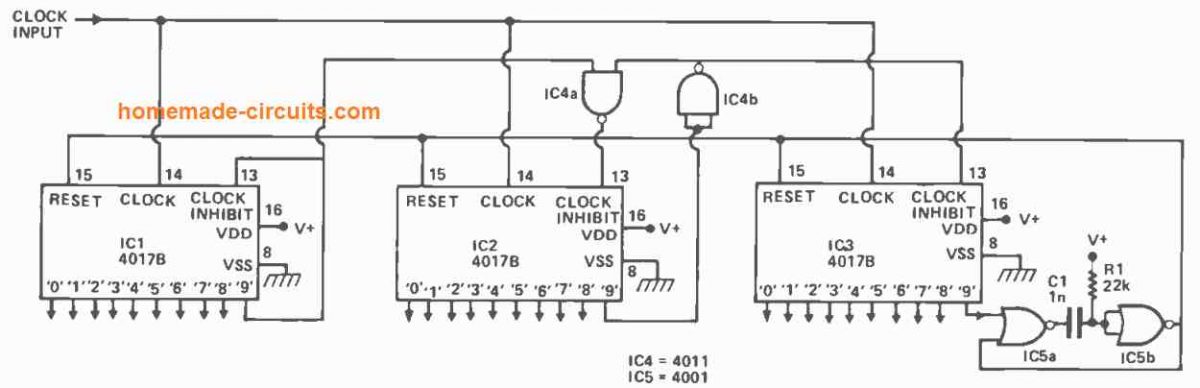

How to Cascade Three IC 4017 for Getting 25 Sequencing Outputs

The configuration for creating an 18 to 25 stage counter/decoder from three 4017s can be seen in the diagram above. IC3 is inhibited by IC4b and IC2's low output '9,' whereas IC2 is inhibited by IC4a and IC1's low output '9,' until the 9th clock pulse. Between the 10th and 17th clock pulses, IC1 is inhibited by its high '9' output, while IC3 is inhibited by IC4b and IC2's low output '9'.

Subsequently, between the 18th and 25th clock pulses, IC1 is inhibited by its high '9' output, and IC2 is inhibited through the high '9' outputs of IC1 and IC2 using IC4c, and the whole circuit is reset to the '0' state by means of the IC5a and IC5b monostable.

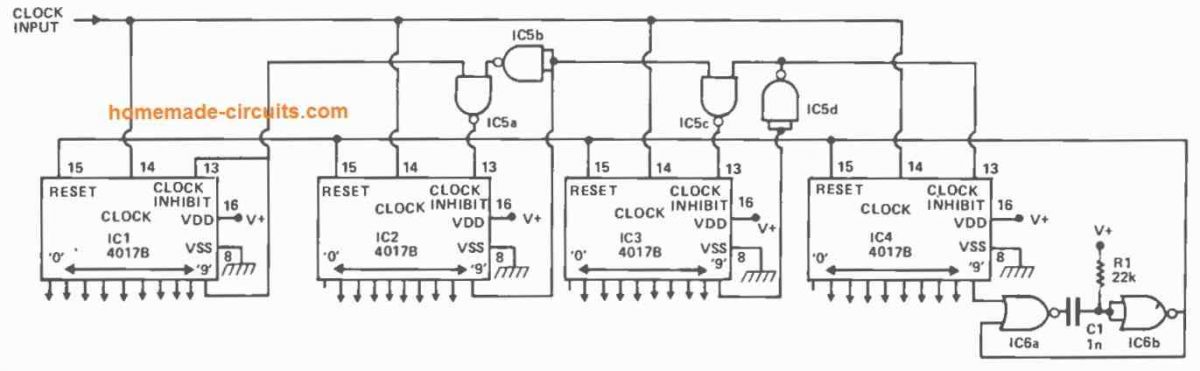

How to Cascade Four IC 4017 to get 33 Sequencing Outputs

Using a divide-by-33 operation, the above setup shows how to make a 26 to 33 stage counter/decoder set. By interposing extra IC2-1C5a-1C5b stages between 1C2 and 1C3, this design may be extended to provide a ny number of decoded output stages. Each subsequent 40178 stage adds eight decoded outputs to the system.

Hi Swagatam,

I cannot get a simple 4017 5 LED chaser to work. Have checked and checked and still cannot see what is wrong. All LEDs flash together and sometimes change but not in the expected order. Same problem I had with previous 4017s but have replaced witha brand new one today and see the same problem. Any ideas what may be causing this? I have pin#1 connected to pin#15 to only cycle the first five outputs. Also have input from 555 to pin 14 with 100K ohms pin #14 to ground…

Do I need to put 1K from the unused pins to ground?

Thanks for any help.

Cheers

Hi Michael,

You just need the following basic setup, please try it with a push button first and check whether the output logic sequences or not in response t each pressing of the push button:

https://www.homemade-circuits.com/wp-content/uploads/2024/10/4017-test-set-up.jpg

Please keep a pause of at least 2 seconds between each pressing.

If it works then your IC is good, and now you can remove only the 1uF capacitor and keep everything else as is, and integrate the 555 oscillator’s pin#3 with pin#14 of the 4017

Thanks for the quick reply. No luck. I added the push button. The circuit starts with pin3 on but nothing happens when I press the button. But all the LEDs have stopped flashing when the button is pressed (=output from 555).

Sorry. Was using a 10uF capacitor. 1uF works for each push to advance. I will try converting to the 555 input and let you know.

Ok no problem, just make sure to remove the 1uF after you connect the pin#3 of 555 with pin#14 of the 4017.

Hi Swagatam,

Actually interesting thing now but I think I have worked out what has been happening…

When I remove the capacitor all the LEDs start flashing in sync with the input at pin14. So same problem returns. Capacitor back in and it works nicely.

My 555 circuit has been adjusted to a 50/50 duty cycle so I am guessing that this has been the reason for the strange behaviors I have been seeing. Must be related to how the 4017 handles the pin14 input.

Thanks Michael, for the updates,

CMOS ICs can be specifically sensitive to RF noise and disturbances, the pin#14 being a sensitive input of the IC might be getting rattled by some sort of RF noise existing in your setup, it is not due to 555 IC’s 50/50 duty cycle.

Anyway, glad the problem is solved now through a capacitor.

Hi Swagatam,

This has been a work in progress for a little while but now that I have a handle on the 4017 circuit I need to incorporate it into a circuit you provided called “motor-control-using-photo-interruptor”. You may recall it was triggered by a flash/pulse and was to run for only a few revolutions.

I can send the image you linked if you cannot locate it. I actually need to trigger the 4017 circuit simultaneously with the pulse that starts the motor and stop the motor after the number of revolutions counted by the 4017 circuit (this is done by a microswitch on a cam driven by the motor. Each rev will increment the counter like in the push button option you sent earlier). So I need to also add a switch which will replicate the pushbutton and after 5 revs turns off the power to the circuit. Does this make sense?

Hi Michael,

Yes I remember it, and it make sense, however when do you want the 4017 outputs to advance, is it when the light of the photo interrupter is just blocked or after it is just released?

Let me know about it, I will try to figure it out.

Hi Swagatam

I am removing the photointerrupter and replacing it with a microswitch – closed when pushed otherwise open – so it will be the switch circuit that inputs to pin14 on the 4017IC.

Thanks

Thank you Michael,

So after 5 revs you want the power supply to the 4017 IC circuit should be shut off automatically and permanently, which can be reset back manually through a separate push button maybe, is that right?

Hi Swagatam.

So after 5 revs when the microswitch is closed by the cam on the motor, the power to the motor should go off until another starting pulse is sent to the main circuit. At 5 revs as I understand it, the 4017 should already be reset so the next time the motor starts it will be at the start of rev 1.

Hope this helps

Ok, understood, so it looks pretty easy actually.

We simply drive the motor through a PNP Darlington transistor whose base is controlled by the 5th output from the 4017 IC.

As soon as this 5th output becomes high, the PNP driver transistor is turned OFF, which turns off the motor.

So I assume then that because 4017 pin1 then goes low, the next pulse will be able to start the motor again for 5 revolutions. Correct?

Oh, I forgot that at the 5th pulse at pin#14, the 4017 needs to reset also, which means the PNP transistor would switch OFF only momentarily and then turn ON again instantly.

OK, so we can do one thing, instead of pin#1 we can use the pin#3 with the PNP base to shut off the motor, and let pin#1 be solely for the resetting purpose, connected with pin#15.

This should take care of everything perfectly.

Does that mean there will be only 4 revs? Do the pin assignments need to be advanced by 1?

It will be 5 revs:

3 to 2 = 1 rev

2 to 4 = 2 rev

4 to 7 = 3 rev

7 to 10 = 4 rev

10 to 1 and reset to 3 = 5 rev

Ahh good. Forgot the reset will happen at the same time pin1 goes high. The “looping” circuit is also basically triggered by the starting pulse for the motor. So I need the following circuits to work together (a small challenge for you … well maybe not) :-

a) a circuit that has slow fading/glowing LEDs which are on/off with main power source so this happens regardless of any pulse to the circuit (I have this already)

b) a pulse initiated circuit to power the motor which is only active while pin3 on the 4017IC is low (will this control the start of the motor if the initial pulse is also sent to pin14?)

c) a pulse initiated circuit to count 5 revs (each count is manually triggered by a cam on the motor closing a microswitch at zero degrees rotation)

d) a flashing LED circuit that only has power while the motor is rotating (I have this already).

Does this all make sense and can they work together?

Thanks again for your efforts with this project.

All the above things can be designed, but I am wondering how would you stop the motor rotational inertia. Even if the motor supply is turned off at pin#3, the motor shaft may keep rotating due to inertia and keep triggering the microswitch and never turn off?

Its just a small motor. Testing so far indicates there is virtually no inertia once the power goes off. In fact I am thinking I will need a small capacitor to actually push it past the microswitch. Well fingers crossed anyway 🙂

In that case you can try replacing the microswitch with a reed switch for a frictionless operation.

The following diagram should do the job:

https://www.homemade-circuits.com/wp-content/uploads/2024/10/4017-motor-control-circuit.jpg

Hi Swagatam,

Thanks for the new circuit design. It makes sense. I will look into the reed switches a little more – seems they may have an issue with longevity though?

Problem – I have breadboarded the circuit you sent and have sent 7 ICs and a few PNPs to the graveyard. I am using a 12V power source but would think they should handle it. I do need the 12v for the motor to run.

Hi Michael,

The circuit which I provided you is perfect and 100% correct.

12V is the correct and preferable supply DC for any CMOS IC, I hope you are using a CMOS version of the 4017 IC, otherwise it could instantly burn.

The transistor can burn if it is not rated as per the motor current.

Since you said your motor was very small, i assumed that BD140 would be enough for it, nevertheless you can upgrade the transistor to TIP127 for better safety, if required.

Let me know if you happen to troubleshoot the issue…

Hi Swagatam,

Still persisting with this. Have fried numerous 4017s I will send you the full circuit schematic once I get it finalised and perhaps you can why its popping my ICs. In the whole circuit its only the 4017 that cant handle it. Can I send the KiCad file or do I just send a image? What is the best email for this?

Hi Michael, you can send the image of the schematic too my email, I will check it out and continue the discussion under this comment…

homemadecircuits

@gmail.com

Hi Swagatam,

I have built the above circuit from the LED Chaser simulation GIF. Checked and checked but my LEDs do not really chase. They flash randomly with the clock signal from the IC555. I have even swapped the IC4017 to be sure. I have pin1 connected to pin15 as I am only using 5 LEDs connected to pins 3,2,4,7 and 10. I have diodes between the LED cathode and ground. Any ideas as to why they are flashing and not chasing?

Hi Michael,

Is the LED at pin#3 of IC 555 flashing correctly, as per the following diagram which you built?

https://www.homemade-circuits.com/wp-content/uploads/2011/12/hnet.com-gifmaker-2.gif

Your pin#15 connection with pun#1 is correct, and this should allow the 5 LEDs through pin#3,2,4,7,10 to sequence.

Diodes between LED cathode and ground are not required, instead you must resistors.

The above circuit connections are perfect and should enable your 5 LEDs to sequences as intended, please check your circuit again and let me know.

Hi Swagatam,

Thanks for getting back so quickly. The 555 LED is flashing correctly and consistently.

What resistance should be used normally? And how should this ususally be determined?

Thanks

Michael

Thanks Michael,

If your 555 is blinking correctly, then the 4017 output must also sequence accordingly and correctly.

To calculate and set the output flashing rate of the IC 555 you can use any online “555 astable calculator software”

Let me know if you have any further issues…

Actually the 555 LED may be wrong. It is blinking …. not flashing. So, it is ON when power starts and then blinks OFF about every second (10 blinks over 7-8 seconds). The setup for the 555 seems ok though. Have checked it against the sample circuit again.

Thanks

10 blinks per 8 seconds is nothing bad, it looks fine to me.

I think something may be wrong with your 4017 IC, I hope you have correctly connected pin#8 and 13 of IC 4017 with ground.

Also please make sure the voltage input is strictly between 5 and 12V DC.

You can also try adjusting the IC 555 10k resistor to tweak the PWM of the input pulse fed across the pin#14 of the 4017 IC.

Hi again

Just wondering about the 555 LED. Should it be more OFF and flash ON, or mostly ON and blink OFF (which is what it’s doing now).

Thanks

Hi,

the ON/OFF time is not critical because the 4017 pin#14 will respond and trigger only to the switch-ON rising edge of each pulse…

Thanks, Swagatam! The 1 uF cap and 100 ohm resister in series with the output from the CD4017 to the transistor base worked perfectly. This allows the 555 one shot to work properly. Thanks again for your help!

That sounds great, Norman! Glad it worked, and thanks for updating the info!

Hi Swagatam,

I think I have found a way around the problem. While testing, I found that the FLM038A can be triggered with a +voltage pulse without a transistor. Therefor I split the TTP223 touch module output with two 10K resistors. One of the split signals is used to trigger the advancement and play of the FLM038A and the other split is used to trigger pin 14 of the cd4017. Each time the touch switch is touched, the 4017 advances with nothing connected to its outputs except pin 11. Pin 11 drives a transistor through a 10K resistor that grounds pin 2 of a 555 one shot. The 555 one shot output drives a transistor to ground the Piezo Siren. Works on the breadboard, so I am now going to build it. I still would like to know if there is a way to produce a short pulse from the outputs of the 4017 for future reference. Thanks!

Thanks for updating the info Norman, Glad it is solved now.

I have replied to your earlier comment regarding how to use 4017 with a short pulsed output, please check the comment reply.

Hi Swagatam,

Is there any way to convert the outputs from a 4017 to a single short pulse instead of a continuous signal? If not, what about another IC such as a 74164 or a 74595? Thanks!

Hi Norman, yes that’s a good idea.

You can implement this simply by adding a 1uF capacitor and a 100 ohm resistor in series between the 4017 output and the transistor base.

The 1N4148 must be removed in this situation.

Try to make the capacitor value smaller, as far as possible.

The zeners are not working. I tried using a single transistor and two transistors and two reed ralays. None of them works. The only way it works is if I skip every other 4017 output.

The system runs off of 5v. Should the zeners be forward or backward? The black bar away from the 4148 or toward the 4148. I tried it with a 3,3v zener since the circuit runs on 5v.

For 5V, you can try 3.3V zener diodes.

The black bar of the zener diode should meet the black bar of the 1N4148 diode.

Hi Swagatam,

I am working on a CD4017 circuit and need some help. The circuit uses a TTP223 touch module to advance the 4017 through its 10 outputs. All 4017 outputs are equipped with 1N4148 protection diodes. Outputs 3 2 4 7 10 1 5 6 9 all trigger a BC547 to trigger a FLM038A doorbell module. Each time the FLM038A is triggered, it advances and plays a different sound or melody. Output 11 of the 4017 is used to trigger a 555 one shot that triggers a piezo siren circuit. I have found that I have to skip outputs 2 7 1 6 11 because the BC547 is continuously triggered if all 4017 outputs are connected. I tried using two separate output rails with two separate transistors. That doesn’t work either. Only one of the output rails triggers the FLM038A. Both the transistors are parallel connected to the FLM038A pins. Could you please suggest a remedy for my problem. I can email a circuit schematic if you need that. Thanks!

Hi Norman,

It is happening because there’s no deadtime between the 4017 IC outputs, which means the transition between the two outputs is seamless without any breaks.

To induce a deadtime you can try adding a 6V or 9V zener diode in series with the 1N4148 diodes and check if that helps to break the transition between the pinouts?

Let me know how it goes?

Good explaination how a 4017 ic works

Hi Swagatam, is it possible to use the 4017 as a one shot counter and at the end of the sequence the pin to remain “High”

I have found your site to be very interesting.

Thank you

Thank you Yeboyeah, 4017 cannot be used as a one shot counter. To make this happen you will need an additional 555 astable or an oscillator circuit with a push button latching facility.

Thank you for your prompt reply, much appreciated.

Would I not need a 555 as a monostable, triggered from the last output of the 4017?

Thank you

The 4017 requires a pulsed input at its pin#14 so an astable would be required to supply the pulses to the 4017 pin#14 in order to create a sequential output from the 4017 outputs.

The last output pin which is pin#11 can be latched or freezed by connecting it with the pin13 of the IC.

Hi I learned about the 4017b as a kid a number of years ago and I think this is the clearest description maybe of any cmos circuit I have ever read so thank you for sharing it in such plain language, it’s been a huge help for beginners in this really awesome line of cmos ic’s.

I have a project/idea I’m working on and I’d like to drive relays or perhaps transistors or I suppose both may be needed for using the 4017’s outputs to switch various audio line level signals. At 20mA I don’t think there is a relay that would function at such low current, my guess is that it would starve the circuit or worse so I wanted to ask your opinion on how I should go about it. My idea was outputs to bases of transistors which would switch by collectors to relay coils but there may be a smarter way to accomplish this ? I’m pretty new to transistors so any help would be hugely appreciated. Again thanks so much.

Thank you Stonelion, I am glad you found the post useful.

Yes transistor relay drivers is the common method for switching a load across a 4017 outputs, however if your load current is small then tiny relays can be employed. These relays are typically rated at 10 mA so these can be directly connected with the outputs of the 4017 IC.

Hi,

Great explanation of this IC.

But I am a bit of a newbee and the 4017 doesn’t want to do what I tell it to.

Here’s is what I did.

I connected 8 and 15 to negative of a CR2032 cell. 16 to the positive.

Then 3 to via a LED to negative of another CR2032.

I use 14 to create positive pulses from the last CR2032.

I expect the LED to flash every 10 contacts of 14. But it doesn’t. What am I doing wrong?

I want to use this for my treadmill to create a ANT+ signal via my Garmin bike-sensor.

This sensor has a magnet switch which reacts to the passing of a magnet on a bike-wheel.

Eventually I want this sensor, the magnet switch, to create the pulses for 14.

But, as it seems, I am far away from that point.

Hi, thanks for liking the above post.

Did you connect all the negatives of the CR2032 in common with the negative of the IC?.

Meaning, the negative side of all the cells must join with pin#8, pin#15 and pin#13 of the IC.

Make sure pin#13 is also connected to the ground line.

Ok, now I have only 1 cr2032 connected.

Negative to 8, 13,15, 3

Positive to 16

I use a wire to 14 to connect pulses to CR2032 positive.

On 3 there is a LED connected so I can see the result of my pulses.

I also had a LED connected to 1 to see if the counting works.

Most of the times the lights start blinking fast without needing a pulse.

After about 5 seconds they stop blinking..

Just one time the LEDs reacted to my pulses.

I can’t replicate it. So i must be doing something wrong.

3V is the minimum limit of the IC 4017, and anything under 3V will cause the IC to work abnormally.

So I would recommend you to use a proper 5 V or 12V supply for testing your circuit.

If you are using a CR2032, you can use two of them in series to make the supply above 5 V.

Thanks for all your help but I am about to give up.

I tried 3V, 6V, 9V (3 CR2032 in series).

The blinking has stopped but it seems to count at random.

I tried another 4017BE with the same results, I tried Q0 for another count sequence.

The LED blinks at contact. When pulsing sometimes it stays on until the next pulse, fully shining, somethings it is shining just a little, sometimes a flash. The count is really not consistent. It may be 4 or 7 or 11.

The only thing my setup differs from your scheme is the capacitor. I don’t have one at hand so I can not solder that in.

I am running out of options.

4017 IC is a very straightforward IC and should start responding correctly immediately without faltering, I am not sure why you are having problems with this simple procedure?

I think your positive clocks at pin#14 is not proper. Try connecting a 1uF capacitor or some other value capacitor between pin#14 and ground, and I hope you already have a resistor between pin#14 and ground. So a capacitor and a resistor across pin#14 and ground should ensure proper clocking of pin#14 and proper sequencing across the output pinouts.

The above capacitor very crucial.

Hello Swagatam,

I apricate your explanation of the 4017 IC. I have created a wire continuity checker using the the 555 and 4017 . The 4017 outputs drive a LM358 circuit that checks installed wires at 1 ohm or less. Currently I send Pin 11 (output 9) to Pin 15 to reset the counter. My issue is that I will be using this tester to for multiple combinations of cables with several of them under 9 wires. So I would like to find a way for the counter to go back to Pin 3 with less than 9 wires. Is there a way through dip switches or something else to make it reset based on a variable number of inputs? Thank You.

Thank you Ed, you can probably use a rotary switch to select and set the desired reset output from the IC. The following images provide more information regarding the subject.

https://www.homemade-circuits.com/wp-content/uploads/2022/12/rotary-switch.jpg

https://www.homemade-circuits.com/wp-content/uploads/2022/01/Rotary-switch-11-position.jpg

Thank you Swagatam for the response. I did find find a schematic using a rotary switch after I emailed you. I think that will work well for my application. However, you added the 1M resistor on the ground side which I did not see on the other schematic. Being a newbie, my assumption is that is used to pull down the voltage on the selected output. That is very helpful to know. Thank you again.

You are welcome Ed!

The 1M is for pi#15, to make sure this pin never stays floating even for a second while the rotary switch is being moved. All inputs of CMOS IC must be terminated to a ground or positive potential as preferred, by default, to ensure proper working of the IC.

Thank you Swagatam that makes sense. Yesterday I incorporated the switch into the circuits and was testing it only on three of the nine. I was having issues with it working correctly. On the continuity tester circuits, there is an electrolytic capacitor on the power to the LM358. Once I removed them, the switch worked as needed. My guess is that the capacitor was causing pin15 to “float” as you stated.

Thanks for the update Ed, you may be right, however the exact reason could be confirmed only after checking the schematic visually.

Thank you again Swagatam for all your help. I have the rotary switch in the circuit and fully functional. My last addition to the circuit would be to add a momentary switch to reset the IC on demand. Since the 4017 is being driven by a 555, sometimes after power is turned on it does not start with the first output. This will be used as a cable tester and it may confuse an operator not familiar with how the circuit works if when powered on it does not start at output Q0. So I would include a switch as a manual reset. Thank you.

That’s great Ed! Glad it is working now. For ensuring that the 4017 always starts from the first pinout (pin#3) whenever power is switched ON, you just have to add a capacitor between the positive line and the pin#15. The capacitor can be any small value such as a 0.22uF or 0.47uF etc.

However, for this to work, the 4017 outputs associated with pin#15 must be connected through a high value resistor such as 10K

Hi Swagatam,

I added a .47 uF as you suggested and it works great. That is a much better option that using a rocker switch. I apricate all your help and education.

Thank you Ed, I’m glad it worked. It is a standard auto resetting method employed in all CMOS ICs which has a reset pin.

Hi, superb explanation! How do I set up to toggle between 2 led’s and all off before resetting?

Thank you and glad you found it useful.

You just have to disconnect pin#15 from the ground and connect it with the pinout which comes just after the last LED pinout.

For example if you want to toggle between two LEDs, you will connect the first LED to pin#3 and second one to pin#2, and then to make sure the sequence keeps returning back to the first LED you will need to connect the pin#15 with pin#4, which comes right after pin#2 (second LED).

Also you have to make sure that the IC always resets and starts with pin#3 whenever the power is initially switched ON.

For this make sure to connect pin#15 with pin#4 through a 10K or 100K resistor, and connect a 1uF capacitor between pin#15 and the positive supply line.

Wow, lightning reply…..Superb! Been trying to find a way to jump between 2 LED’s and OFF with one toggle button. Simple I thought…. Nah, not till I found this site.

Will this touch ic work as a switch signal along with (any) 4017?

Many thanks.

I am glad to help! You do not need any external circuits for the touch activation. It can be simply done using a couple of transistors attached to pin#14 of the 4017 IC.

You can try the second circuit from the following article:

https://www.homemade-circuits.com/simple-touch-sensor-switch-circuit/

Hi,

There seems to be a relationship of pin 16 voltage to reset and clock voltages. For example, If I run the chip at 12v, it seems to take 12v to reset it. Also, the clock pulses must be 12v. No sites make this very important announcement.

Hi, these are logic ICs so just 5V is enough to reset the circuit. even if the supply Vcc is 12V, according to me.

I am just learning. I would like to understand the gates you show when connecting two or more IC 4017’s. Are they just 3 pin connectors?

Hi,

I am working with a 4017s connected to the FET outputs of a PLC, and then voltage divided at the board down to nominal voltages. However, I recently encountered malfunctions of the counters and the only thing I can find is that pin 15 isn’t completely clean. Has about 150millivolts(from the PLC) My question is… at how many millivolts(+) on pin 15… will failure begin.

Thank you so much,

Hi, the 4017 IC being a CMOS IC and pin#15 being one of its inputs, it can start malfunctioning (partial resetting) at around 1V or 2V, however I don’t think a mV on pin#15 can reset the IC or cause it to malfunction. You can try adding a 1uF capacitor from pin#15 to ground and see if that helps.

Thank you for this advice!

Mr Swagatam, I am building the sequencer circuit using cascaded 4017s. I only need 13 Leds to sequence. From reading the above comments I can see that you must do something with the unused outputs. Could you clarify that for me? Thank you and happy New Year!

Hello Bob,

Thank you Robert,

you can probably try the following concept, and in the lower 4017 IC connect D4 end to pin#1 of the IC instead of Pin#3. Hope this helps!

https://www.homemade-circuits.com/wp-content/uploads/2011/12/182BLED2BLight2BChaser2BCircuit2BDigram252C2BImage-1.png

Thank you very much!

Bonjour Monsieur,

Pouvez-vous me dire combien je peux mettre de led en parallèle (20 mA) sur chaque sortie du CD 4017 ?

Afin de ne pas le bruler. Bien merci pour votre réponse

Hello Jean,

you cannot use 20mA LEDs in parallel, because IC 4017 can produce only around 20 mA current across its output pins. If you put two LEDs in parallel, the light will be slightly dim.

However you can put 4 in series with high brightness if the supply input is 12V

Bonjour et merci d’avoir été très réactif a me répondre j’ai oublié de vous dire que je voudrai utiliser seulement 4 sorties avec 4 led en parallèle et surtout que chaque circuit doit clignoter rapidement,

donc dans ces conditions pourriez – vous être plus tolérant ?

You can use 4 LEDs across 4 outputs of the IC, with single LED on each output with individual resistors. But you cannot use 4 LEDs in parallel on each output.

Hi,

Senior Citizen here. I am making a lighthouse with 6 sequential LED’s.

I used your “IC 4017 Working Simulation”. The LED’s sequence in order, however there is a PAUSE after the 6th LED goes out before the 1st LED begins. How can I make it be a Continuous Sequence whereby it keeps going (which is what I need for my lighthouse. I am not sure how old your messages are and not sure if you are still monitoring them. In the event you are, could you please advise what I can do to eliminate the pause? Thank You, Richard (Massachusetts)

Hi,

I guess you have used only 6 channels instead of all the 10 channels as shown in the diagram. If you don’t want to use all the 10 channels, rather want to use a lesser number of channels, then you must connect the pin which is next to the last channel with pin#15.

This will ensure continuous sequencing of the LEDs without any pause.

Meaning, if your last LED which is the 6th LED is connected with pin#1 of the IC, then the next pin#5 which follows, must be connected with pin#15.

But remember, for the above connections, the pin#15 must be first disconnected from the ground line and then connected with pin#5.

I hope you understood the procedure.

Mr Swagatam,

Please tell me how can I use pin 13 to catch negative signal clock.

What changes must be made?

Thank you

Hello Hakim, According to me, you connect pin#14 to ground, disconnect the pin#13 from ground and connect a 10K from pin#13 to positive. After this with each ground signal applied to pin#13 will cause the output to sequence from one pin to the next.