A very simple low battery cut-off and overload protection circuit has been explained here.

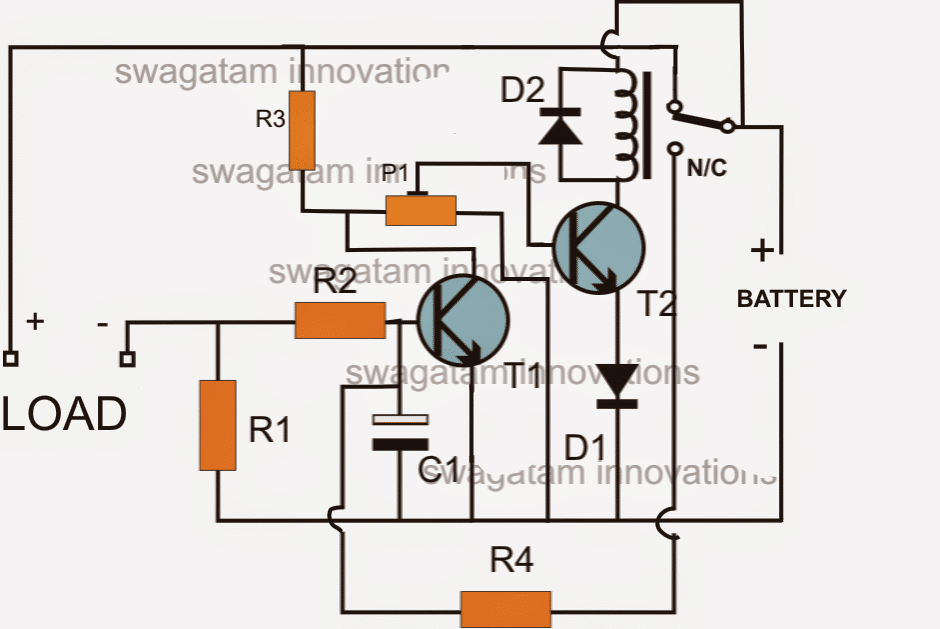

The figure shows a very simple circuit set up which performs the function of an overload sensor and also as an under voltage detector.

In both the cases the circuit trips the relay for protecting the output under the above conditions.

How it Works

Transistor T1 is wired as a current sensor, where the resistor R1 forms the current to voltage converter.

The battery voltage has to pass through R1 before reaching the load at the output and therefore the current passing through it is proportionately transformed into voltage across it.

This voltage when crosses the 0.6V mark, triggers T1 into conduction.

The conduction of T1 grounds the base of T2 which gets immediately switched Off. The relay is also consequently switched OFF and so is the load.

T1 thus takes care of the over load and short circuit conditions.

Transistor T2 has been introduced for responding to T1's actions and also for detecting low voltage conditions.

When the battery voltage falls beyond a certain low voltage threshold, the base current of T2 becomes sufficiently low such that it's no longer able to hold the relay into conduction and switches it OFF and also the load.

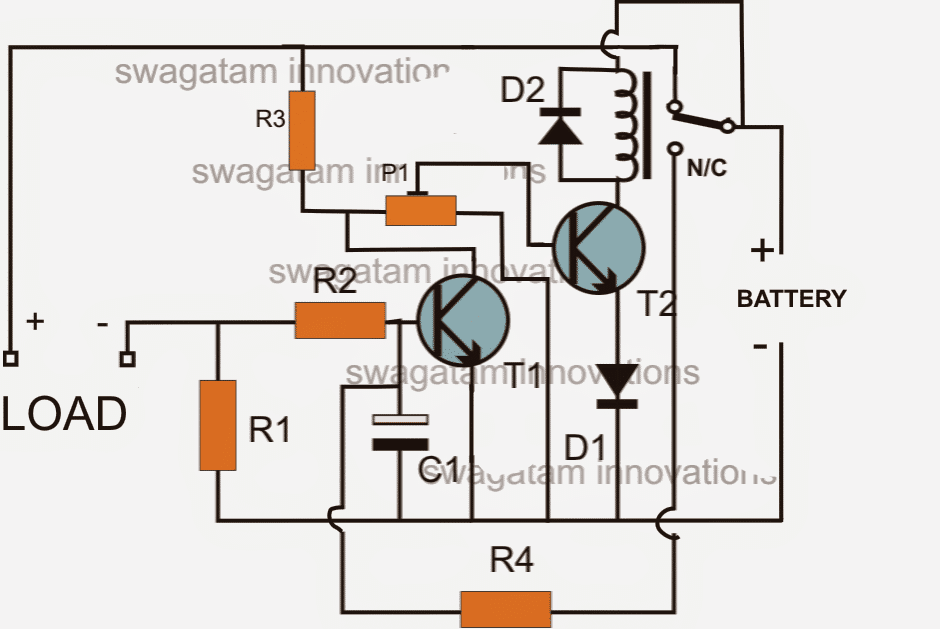

The"LOAD" terminals in the above diagram is supposed to be connected with the inverter +/- supply terminals.

This implies that the battery current from the right side has to pass through R1 before reaching the inverter, enabling the sensing circuit around R1 to sense a possible over current or overload situation.

CORRECTION:

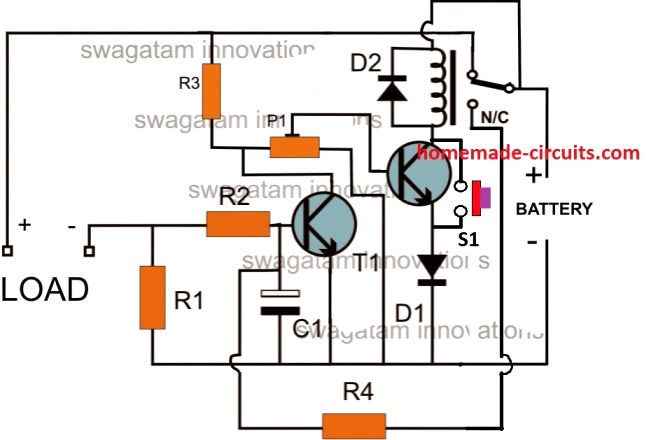

The above shown circuit will not initiate unless the relay is actuated manually through a push switch as shown below:

Parts List

- R1 = 0.6/Trip Current

- R2 = 100 Ohms,

- R3 =10k

- R4 = 100K,

- P1 = 10K PRESET

- C1 = 100uF/25V

- T1, T2 = BC547,

- Diodes = 1N4148

- Relay = As per the specs of the requirement.

Formulas and Calculations

Low Battery Cut-off Threshold

The low battery sensing is handled by R3 and P1 which forms a potential divider to set the base voltage of the relay driver transistor (T2). When the battery voltage drops below a set threshold the voltage at the base of T2 falls below Vbe (0.6V–0.7V) turning OFF the relay and disconnecting the load.

Formula for Threshold Voltage:

Vth = Vbat * (P1 / (P1 + R3))

- Where:

- Vth = Base threshold voltage (0.6V–0.7V)

- Vbat = Battery voltage

- P1 = Adjustable potentiometer resistance

- R3 = Fixed resistor

To calculate the battery voltage cut-off level:

Rearrange for Vbat:

Vbat = Vth * (P1 + R3) / P1

Overload/Overcurrent Sensing

Overcurrent protection is implemented using R1 which is placed between the base and emitter of transistor T1.

As the load current increases, the voltage drop across R1 rises. When the voltage across R1 reaches the Vbe of T1 (typically 0.6V–0.7V) T1 starts conducting and shunts the base current of T2 turning it OFF.

Formula for Overcurrent Trip Current:

Itrip = Vbe / R1

- Where:

- Itrip = Overcurrent trip current

- Vbe = Base-emitter threshold voltage of T1 (0.6V–0.7V)

- R1 = Resistor sensing the overcurrent

Base Current Limiting Resistor (R2)

Resistor R2 (optional) limits the base current for T1 to prevent excessive current through its base-emitter junction.

Formula for Base Resistor (if used):

R2 = (Vbat - Vbe) / Ib

- Where:

- Ib = Required base current for T1

- Vbat = Battery voltage

- Vbe = Base-emitter voltage of T1

For small signal transistors (e.g., BC547) Ib can be estimated as Iload / hFE where hFE is the DC current gain.

Inverter Overload Cut-OFF using Opamp

In the above paragraphs I have explained a very simple concept of inverter overload cut-off using only transistors.

However a cut off system using only transistors cannot be very accurate and sharp.

In order to get a precision inverter overload and short circuit cut off circuit the use of an opamp based design becomes imperative.

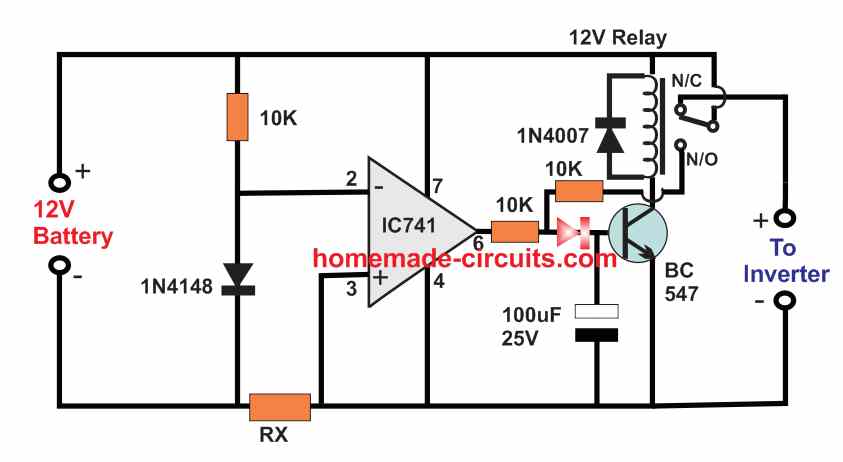

The following diagram shows a simple battery overload controller circuit using a single opamp 741 and a relay driver stage.

How it Works

The opamp is configured as a simple comparator circuit. he inverting input of the opamp is clamped at a fixed 0.6 V using a 1N4148 diode.

The non-inverting input of the op amp is connected with the negative line of the circuit through a over-current sensor resistor Rx.

Due to inverter overload or short circuit or over current conditions, a voltage drop develops across the resistor Rx which can exceed the 0.6V as per the calculated value of the RX, and cause the non-inverting input of the opamp potential to go higher then its inverter 0.6V potential.

This causes the op amp output to turn high activating the transistors and tripping the relay.

When power is first switched ON, and assuming the inverter is working normally without an overload, the voltage developed across RX is minimal, which keeps the pin3 potential of the opamp the opamp lower than the pin2 potential.

This allows the output of the opamp to be low ensuring that the transistor is switched OFF, and relay contacts stays at the N/C point.

Due to this the 12V is able to reach the inverter and operate it normally.

However, as soon as an overload or over current happens at the inverter side, a large amount of current passes through the RX resistor, causing a voltage drop to develop across pin3 of the IC.

When this voltage drop exceeds the 0.6V reference level of the pin2 of the IC, the output of the op amp goes high, causing the transistor to switch ON and trigger the relay.

The relay contacts now shift from N/C to N/O switching of power to the inverter and thereby averting the short circuit or overload conditions.

The N/O contact can be seen attached with the base of the relay driver transistor, which ensures that as soon as the an overload is detected the relay contact quickly latches the transistor, switching the power permanently off for the inverter.

The power can be restored only by disconnecting the 12 V battery input, but before that it must be ensured that the short circuit or the over load condition is appropriately removed from the inverter side.

Formulas and Calculations

Key Parameters

- RX: Current sensing resistor (ohms)

- Vref: Reference voltage at the inverting input (-) of IC741

- Itrip: Overcurrent trip current (amperes)

- Vdrop: Voltage drop across RX at trip current

Formulas

Voltage Drop Across RX:

Vdrop = Itrip * RX

- Where:

- Itrip = Overcurrent trip point (A)

- RX = Current sensing resistor (ohms)

Reference Voltage (Vref):

The voltage at the non-inverting input (+) of IC741 is set using a resistor divider or Zener diode (if used). For proper cutoff:

Vref ≈ Vdrop

Choosing RX (Sensing Resistor):

To calculate the value of RX for a given trip current:

RX = Vref / Itrip

- Where:

- Vref = Reference voltage (V)

- Itrip = Desired trip current (A)

Power Dissipation in RX:

The sensing resistor RX must handle the power dissipated during operation.

We will Use:

P = Itrip2 * RX

- Where:

- P = Power dissipation in RX (W)

Choose RX with a power rating higher than P for safe operation.

Example Calculation

Let’s assume:

Itrip = 10A (trip current)

Vref = 0.7V (reference voltage determined by the op-amp threshold)

Step 1: Calculate RX

RX = Vref / Itrip = 0.7 / 10 = 0.07 ohms

Step 2: Power Dissipation in RX

P = Itrip2 * RX = 102 * 0.07 = 7W

Choose a 0.07-ohm 10W resistor for RX to ensure safe operation.