The post comprehensively discusses the construction procedure of a 1 watt LED lamp using SMD LEDs such as 3528 smd LEDs or 2214 SMD LEDs. I have explained the details.

1 Watt LED vs 3528 smd LEDs or 2214 SMD LEDs

Today 1 watt LEDs are very popular and these are utilized in most LED lamp applications. Although these are extremely efficient in terms of light intensity levels and current consumption, these high watt LEDs require a formidable heatsink in order to keep them functioning correctly and optimally.

Without a heatsink, 1 watt LEDs can become completely useless as it would mean an immediate damage to the devices due to over heating and thermal runaway.

Moreover these LEDs require special aluminum base PCBs for the assembly, which in turn requires an external aluminum heatsink for added cooling.

All these compulsions make these LED modules fairly difficult to assemble and apply for hobbyists or any interested new electronic enthusiast.

However with the advent of many smaller SMD LED variants which range right from 20mA to 60mA, making 1 watt LEd equivalents with matching illumination and reliability is now a child's play, and since these smaller variants do not require heatsink for functioning makes them extremely desirable and feasible for the many newcomers in the field who may be avidly intrigued and interested to play with, and make their own LED light projects for their homes, and boast the same among their friends.

Making a 1 watt LED using 3528 smd LEDs or 2214 SMD LEDs

A 1 watt LED equivalent lamp can be quite easily made by incorporating a many 20mA or 50mA smaller LEDs and configuring these together with a suitable supply voltage.

In fact any high watt equivalent LED can be made by using these smaller low current LEDs as desired, therefore it's possible to make a 3 watt, or a 5 watt or even higher rated LED using the smaller counterparts such as the 3528 LEDs or the 2214 LEDs.

The advantage of using smaller LEDs for generating an equivalent illumination comparable to the 1 watt, 3 watt or 5 watt can be summarized as given below:

Advantages using SMD LEDs

Low current LEDs can be operated without the need of a heatsink, and over any ordinary PCB. The use of special, expensive aluminum base PCBs can thus be avoided with these LEDs.

Low current LEDs become compatible with transformerless capacitive power supply units, and therefore SMPS operation can be eliminated.

With a capacitive power supply in use, the need of a current control becomes immaterial because the input capacitor itself acts like an effective current controller and alone is able to restrict current to the calculated levels.

A high watt LED made by using low amp LED may have the capability of producing more illumination compared to a single identically rated high watt LED.

Due to the above comforts, such high watt equivalents can be easily built even by the noobs or people who are relatively new in the field of electronics.

Disadvantages of SMD LEDs

The only disadvantage is the involved size of such modules which could be slightly bigger area wise, and also the assembly could be slightly time consuming.

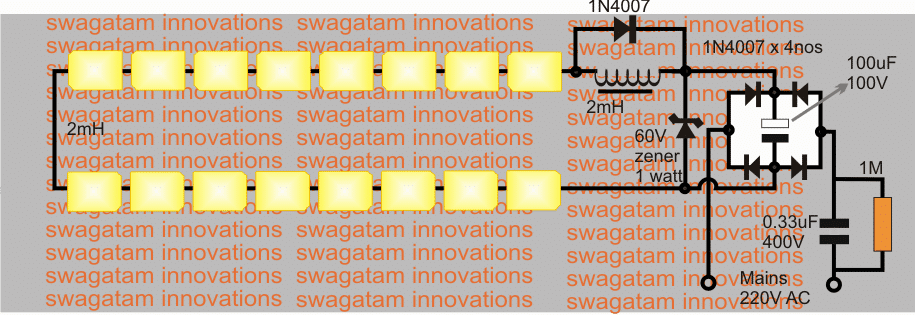

The following diagram shows an example 1 watt LED lamp circuit made by using 16nos of 2214 (20mA) SMD LEDs and a suitably rated transformerless power supply.

Circuit Diagram

Warning: the following circuit is not isolated from the AC mains, and prone to electric shocks. Therefore make sure that you are extremely careful while handling this circuit in an uncovered and powered condition.

All the 20mA LEDs can be seen connected in series with a compact transformerless power supply.

A 20mH inductor can also be seen, this is included to arrest the initial switch ON surge, the zener diode provides an extra protection from any possible voltage fluctuations.

One may also include an NTC thermistor at the input for providing even greater protection to the LEDs from surge currents.