A self-powered generator is a perpetual electrical device designed to infinitely run and produce a continuous electrical output which is usually larger in magnitude than the input supply through which it's running.

Who wouldn't like to see a self-powered motor generator running at home and powering the desired appliances non-stop, absolutely free of cost. We discuss the details of a few such circuits in this article.

A free energy enthusiast from South Africa who doesn’t want to reveal his name has generously shared the details of his solid state self-powered generator for all the interested free energy researchers.

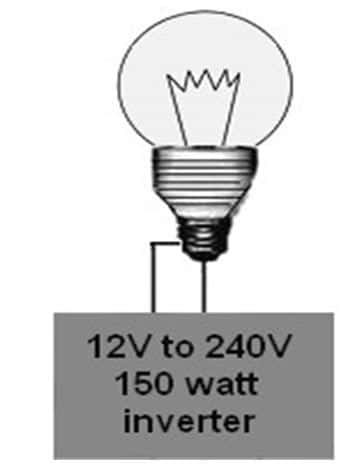

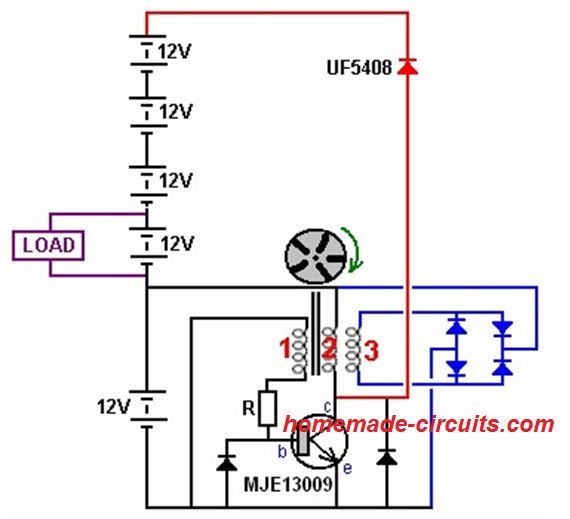

When the system is used with an inverter circuit, the output from the generator is around 40 watts.

The system can be implemented through a few different configurations.

The first version discussed here is able to charge three 12 battery's together and also sustain the generator for a permanent perpetual operation (until of course the batteries lose their charging/discharging strength)

The proposed self-powered generator is designed to work day and night providing continuous electrical output, quite like our solar panel units.

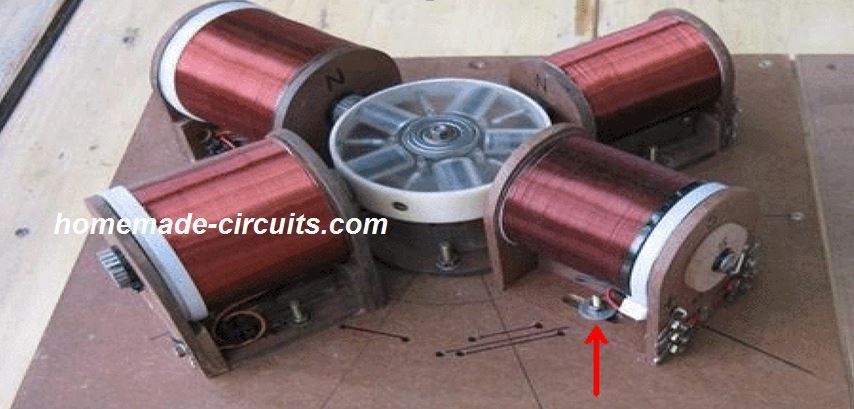

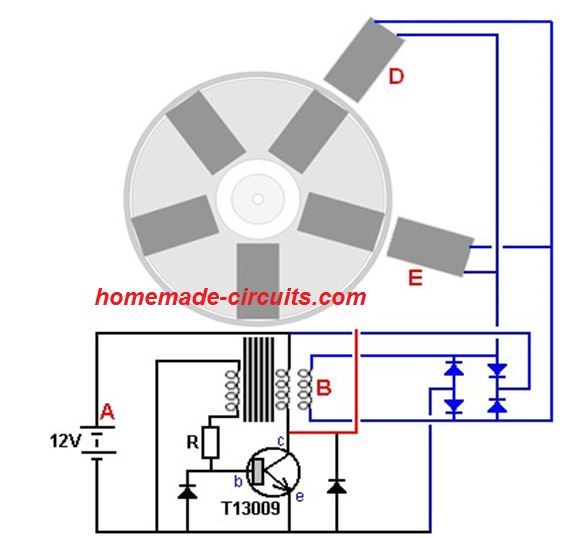

The initial unit was constructed using 4 coils as the stator and a central rotor having a 5 magnets embedded around its circumference as depicted below:

The shown red arrow tells us regarding the adjustable gap between the rotor and the coils which can be changed by loosening the nut and then moving the coil assembly near or away from the stator magnets for the desired optimized outputs. The gap can be anywhere between 1mm to 10 mm.

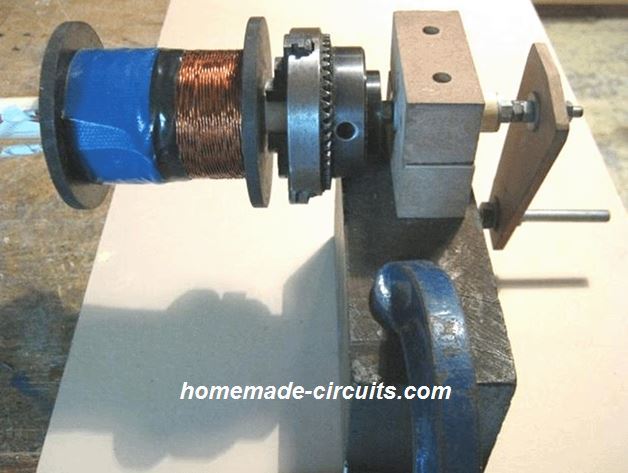

The rotor assembly and mechanism should be extremely accurate with its alignment and ease of rotation, and therefore must be built using precision machines such as a lathe machine.

The material used for this can be clear acrylic, and the assembly must include 5 sets of 9 magnets fixed inside cylindrical pipe like cavities as shown in the figure.

The top opening of these 5 cylindrical drums are secured with plastic rings extracted from the same cylindrical pipes, to ensure that the magnets stay fixed tightly in their respective positions inside cylindrical cavities.

Very shortly, the 4 coils had been enhanced to 5 in which the newly added coil had three independent windings. The designs will be understood gradually as we run through the various circuit diagrams and explain how the generator works. The first basic circuit diagram can be witnessed below

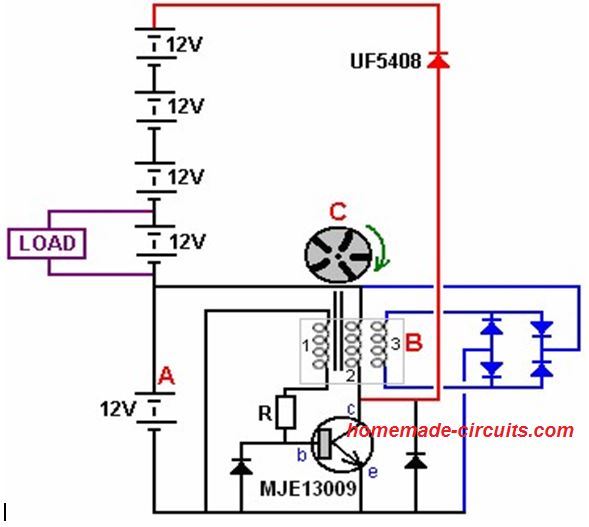

The battery designated as “A” energizes the circuit. A rotor “C”, made up of 5 magnets is manually moved pushed such that one of the magnets moves close to the coils.

The coils set “B” includes 3 independent windings over a single central core and the magnet going past these three coils generates a tiny current inside them.

The current in coil number “1” runs through the resistor “R” and into the base of the transistor, forcing it to switch on. The energy moving through the transistor coil “2” enables it to turn into a magnet which shoves the rotor disc “C” on its path, initiating a spinning motion on the rotor.

This rotation simultaneously induces a current winding “3” which is rectified through the blue diodes and transferred back to charge battery “A”, replenishing nearly all of the current drawn from that battery.

As soon as the magnet inside rotor “C” moves away from the coils, the transistor switches off, restoring its collector voltage in a short time close to the +12 Volt supply line.

This depletes coil “2” of current. Because of the manner the coils are positioned, it pulls the collector voltage upwards to around 200 volts and above.

However this does not happen because the output is connected to series five batteries which drop the rsising voltage according to their total rating.

The batteries have a series voltage of approximately 60 volts (which explains why a strong, fast-switching, high-voltage MJE13009 transistor has been incorporated.

As the collector voltage goes by the voltage of the series battery bank, the red diode commences turning ON, releasing the stored electricity in the coil into the battery bank. That current pulse moves through all 5 batteries, charging every one of them. Casually speaking, this constitutes the self powered generator design.

In the prototype, the load used for long-term, tireless testing was a 12 volt 150-watt inverter illuminating a 40-watt mains lamp:

The simple design demonstrated above was further improved by the inclusion of a couple of more pick-up coils:

Coils “B”, “D” and “E” are all activated simultaneously by 3 individual magnets. The electric power generated in all of the three coils is handed down to the 4 blue diodes to manufacture a DC power which is applied to charge battery “A”, which powers the circuit.

The supplemental input to the drive battery a result of the inclusion of 2 extra drive coils to the stator, enables the machine to run solidly in the form of a self-powered machine, sustaining the battery "A"voltage infinitely.

The sole moving portion of this system is the rotor which is 110 mm in diameter and is a 25 mm thick acrylic disc installed on a ball-bearing mechanism, salvaged from your discarded computer hard disc drive. The set up appears like this:

In the images, the disc appears to be hollow however in reality it is solid, crystal clear plastic material. Holes are drilled on the disc is across five equally spread out locations throughout the circumference, meaning, with 72 degree separations.

The 5 primary openings drilled on the disc are for holding the magnets which are in groups of nine circular ferrite magnets. Each of these are 20 mm in diameter and 3 mm in height, creating stacks of magnets with a total height of 27 mm long and diameter of 20 mm. These stacks of magnets are placed in such a way that their North poles project outwards.

After the magnets are mounted, the rotor is put inside a plastic pipe strip in order to secure the magnets tightly in place while the disc spins speedily. The plastic pipe is clamped with the rotor with the aid of five mounting bolts with countersunk heads.

The coil bobbins are 80 mm long with 72 mm end diameter. The middle spindle of every coil is constructed of a 20 mm long plastic pipe having an outer and an inner diameter of 16 mm. providing a wall density of 2 mm.

After the coil winding is completed, this inner diameter becomes full with a number of welding rods with their welding coating taken out. These are subsequently enveloped in polyester resin, but a solid bar of soft iron can also become a excellent alternative:

The 3 wire strands that constitute coils “1”, “2” and “3” are 0.7 mm in diameter wire and are wrapped with each other before it's wound on the bobbin “B”. This method of a bifilar winding creates a lot heavier composite wire bundle which can be simple coil over a spool effectively. The winder shown above works with a chuck to hold the coil core for enabling the winding, nevertheless any kind of basic winder can also be used.

The designer carried out the wire twisting by extending the 3 strands of wire, each originating from a independent 500 gram bundle reel.

The three strands are tightly held at each end with the wires pressing one another at each end having three metres space between the clamps. After that, the wires are fixed at the center and 80 turns ascribed to the midsection. This allows 80 turns for every single of the two 1.5 metre spans positioned between clamps.

The twisted or the wrapped wire set is curled on a temporary reel to maintain it neat because this twisting will have to be duplicated 46 more occasions since all the contents of the wire reels will be required for this one composite coil:

The next 3 meters of the three wires are then clamped and 80 turns wound to the middle position, but on this occassion the turns are placed in the opposite direction. Even now exactly the same 80 turns are implemented, but if the previous winding had been ‘clockwise’ then this winding is flipped ‘counter-clockwise’.

This particular modification in the coil directions provides a completed range of twisted wires in which the twist direction becomes opposite every 1.5 meters over the whole length. This is how the commercially manufactured Litz wire is set up.

This specific great looking twisted wires sets are now employed for winding the coils. A hole is drilled in one spool flange, exactly near the middle tube and core, and the start of the wire is inserted through it. The wire is next bent forcefully at 90 degrees and applied round the spool shaft to begin the winding of the coil.

The winding of the wire bundle is executed with great care next to each other across the entire spool shaft and you will see 51 no of winding around each layer and the following layer is wound straight over the top of this very first layer, going back again towards the start. Make certain that the turns of this second layer rests precisely over the top of the winding underneath them.

This can be uncomplicated because the wire pack is thick enough for allowing the placement quite simple. In case you like, you can try wrapping one thick white paper around the first layer, to make the second layer distinct as it is turned around. You will need 18 of such layers to finish the coil, that will ultimately weigh 1.5 kilograms and the finished assembly might looks something as shown below:

This finished coil at this point consists of 3 independent coils tightly wrapped to each other and this set up is intended to create an fantastic magnetic induction across the other two coils, whenever one of the coils is energized with a supply voltage.

This winding currently includes coils 1,2 and 3 of the circuit diagram. You don't need to to keep worrying about tagging the ends of each strand of wire as you can easily identify them using an ordinary Ohmmeter by checking the continuity across the specific wire ends.

Coil 1 can be used as the triggering coil that will switch the transistor ON during the right periods. Coil 2 could be the drive coil that is energized by the transistor, and Coil 3 could be the one of the first output coils:

Coils 4 and 5 are straightforward spring like coils that are connected parallel with the drive coil 2. They help to boost the drive and therefore are important. Coil 4 carries a DC resistance of 19 ohms and coil 5 resistance can be around 13 ohms.

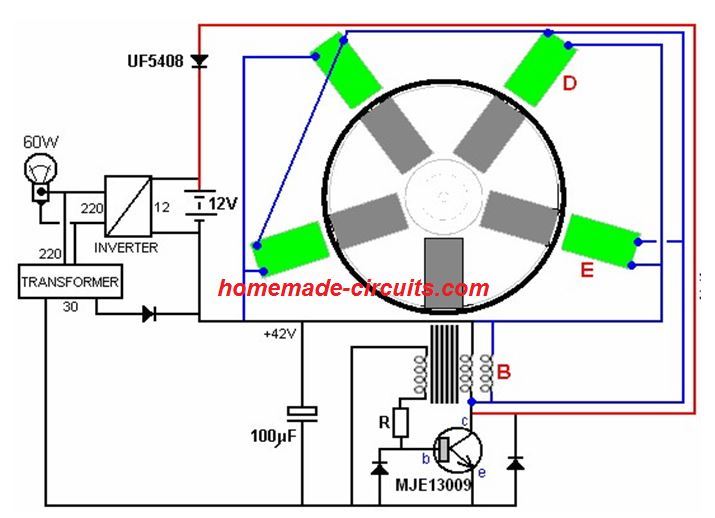

However, research is ongoing currently to figure out the most effective coil arrangement for this generator and possibly further coils could be the identical to the first coil, coil “B” and all three coils are attached in the very same manner and the driving winding on each coil operated through the a single highly rated and, fast switching transistor. The present set up looks like this:

You may ignore the shown gantries since these were included only for examining different ways of activating the transistor.

Currently, coils 6 and 7 (22 ohms each) work as additional output coils attached in parallel with output coil 3 which is built with 3 strands each and with a resistance of 4.2 ohms. These could be air-core or with a solid iron core.

When tested it revealed that the air core variant performs just a bit better than with an iron core. Each of these two coils are consist of 4000 turns wound on 22 mm diameter spools using 0.7 mm (AWG # 21 or swg 22) super enameled copper wire. All the coils have the same specs for the wire.

Using this coil set up, the prototype could run non-stop for around 21 days, preserving the drive battery at 12.7 volts constantly. After 21 days, the system had been stopped for some modifications and tested again using a completely new arrangement.

In the construction demonstrated above, the current moving from the drive battery into the circuit is actually 70 milliamps, which at 12.7 volts produces an input power of 0.89 watts. The output power is approximately near 40 watts, confirming a COP of 45.

This is excluding the three additional 12V batteries which are additionally being charged simultaneously. The results indeed appear to be extremely impressive for the proposed circuit.

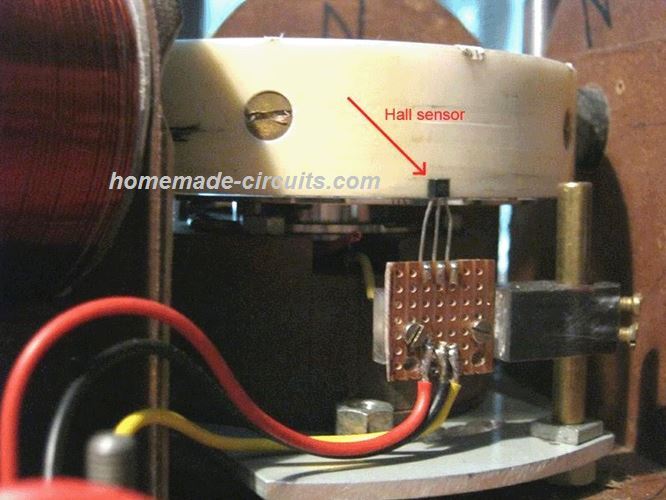

The drive method had been employed so many times by John Bedini, that the creator opted to experiment with John’s approach of optimization for highest efficiency. Even so, he found that eventually a Hall-effect semiconductor specifically aligned correctly with a magnet offers the most effective outcomes.

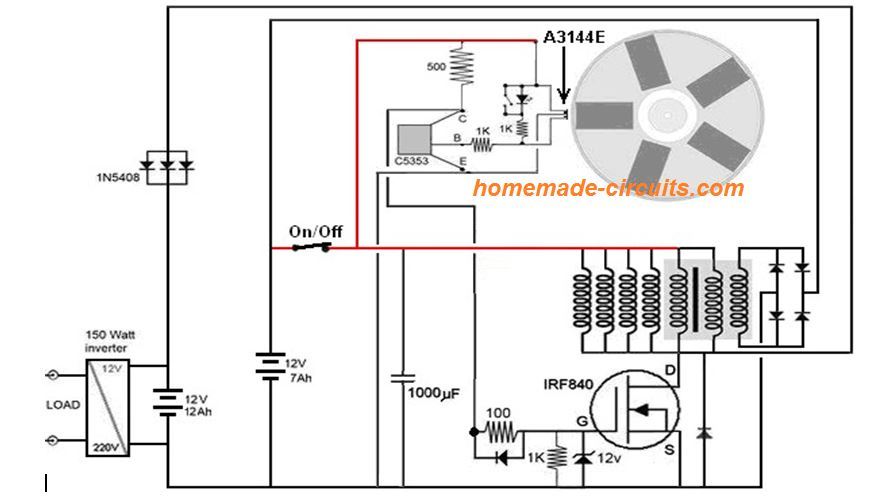

More research goes on and the power output has at this point attained 60 watts. This looks truly amazing for such a tiny system, particularly when you see it includes no realistic input. For this next step we reduce the battery to just one. The set up can be seen below:

Within this set up, coil “B” is also applied with the pulses by the transistor, and the output from the coils around the rotor is now channelized to the output inverter.

Here the drive battery is removed and is replaced with a low-power 30V transformer and diode. This is in turn operated from the inverter output. Giving a slight rotational thrust to the rotor produces ample charge on the capacitor to enable the system cranking without any battery. The output power for this present set up can be seen going up to 60 watts which is an awesome 50% enhancement.

The 3 12 volt batteries are also taken off, and the circuit can easily run using just one single battery. Continuous power output from a solitary battery that by no means requires for an external recharging appears to be a great achievement.

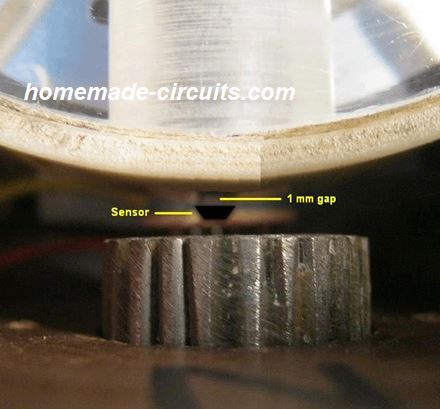

The next improvement is through a circuit that incorporates a Hall-effect sensor and an FET. The Hall-effect sensor is arranged precisely in line with the magnets. Meaning , the sensor is placed in between one of the coils and the rotor magnet. We have a 1 mm clearance between the sensor and the rotor. The following image shows how exactly it needs to be done:

Another view from top when the coil is in the right position:

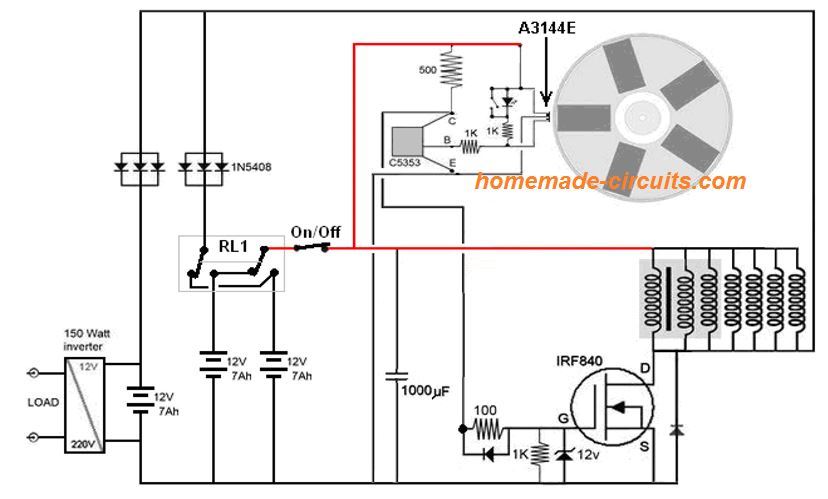

This circuit showed an immense 150 watt of nonstop output using three 12-volt batteries. The first battery helps to power the circuit while the second gets recharged via three diodes hooked up in parallel to increase the current transmission for the battery which is being charged.

The DPDT changeover switch “RL1” swaps the battery connections every couple of minutes with the help of the circuit displayed below. This operation allows both the batteries to remain fully charged all the time.

The recharging current as well runs through a second set of three parallel diodes recharging the third 12-volt battery. This 3rd battery operates the inverter through which the intended load is run. The test load used for this set up was a 100-watt bulb and a 50-watt fan.

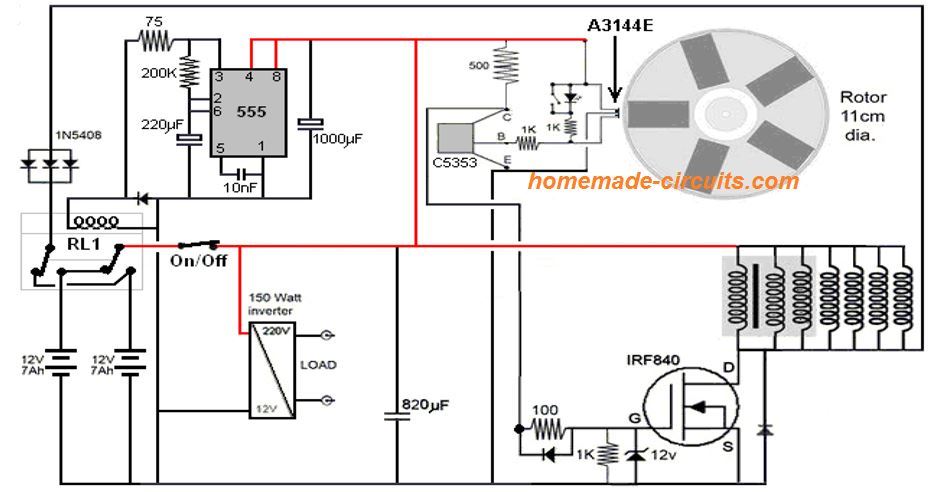

The Hall-effect sensor switches an NPN transistor nevertheless virtually any fast-switching transistor for instance a BC109 or a 2N2222 BJT will work extremely well. You will realize that all of the coils are at this point being operated by the IRF840 FET. The relay employed for the switching is a latching type as indicated in this design:

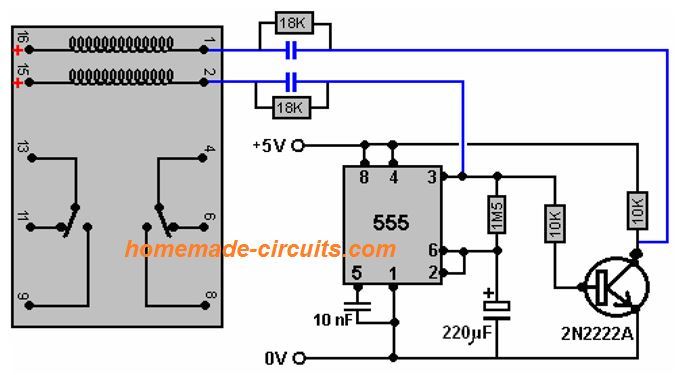

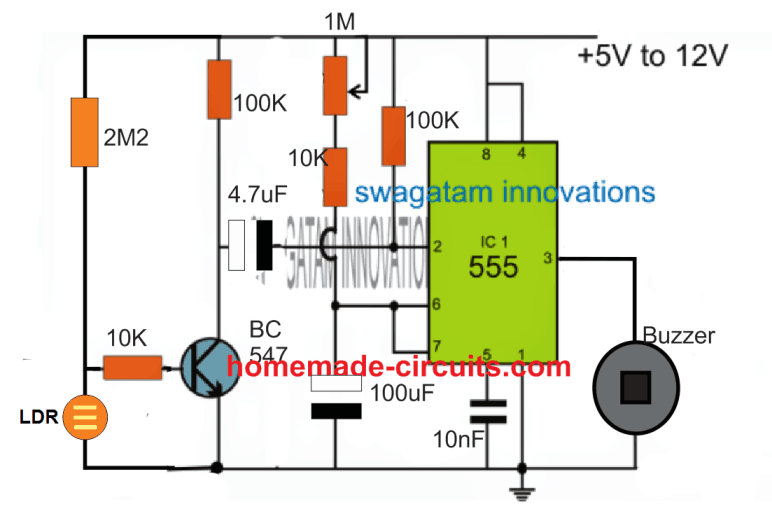

And it is powered by a low current IC555N timer as shown below:

The blue capacitors are selected to toggle the specific actual relay which is used in the circuit. These briefly allow the relay to be ON and OFF every five minutes or so. The 18K resistors over the capacitors are positioned to discharge off the capacitor throughout the five minutes when the timer is in the OFF state.

However, if you do not want to have this switching between the batteries, you can simply set it up in the following manner:

In this arrangement,, the battery powering the inverter connected with the load is specified with higher capacity. Although the creator utilized a couple of 7 Ah batteries, any common 12-volt 12 Amp-Hour scooter battery may be used.

Basically one of the coils is employed to deliver current to the output battery and the one leftover coil, which may be the part of the three-strand main coil. This is accustomed to provide supply voltage directly to the drive battery.

The diode 1N5408 is rated to handle 100-volt 3-amp. The diodes without any value can be any diode such as 1N4148 diode. The coils ends joined to the IRF840 FET transistor are physically installed near the circumference of the rotor.

One can find 5 such coils. The ones which are grey in color reveal that the extreme right three coils consist of the separate strands of the main 3-wire composite coil already duscussed in our earlier circuits.

While we saw the use of the three-strand twisted wire coil for the Bedini-style switching incorporated for both drive and output purposes, it was ultimately found unnecessary to incorporate this type of coil.

Consequently, an ordinary helical type wound coil made up of 1500 grams of 0.71 mm diameter enameled copper wire was found to be equally effective. Further experimentation and research helped to develop the following circuit which worked even better than the previous versions:

In this improved design we find the use of a 12-volt non-latching relay. The relay is rated to consume around 100 milliamps at 12 volts.

Inserting a 75 ohm or a 100 ohm series resistor in series with the relay coil helps to bring down the consumption to 60 milliamps.

This is consumed only for half the time during its operation periods because it remains non-operational while its contacts are in the N/C position. Just like the previous versions, this system too powers itself indefinitely without any concerns.

Feedback From one of the dedicated readers of this blog, Mr. Thamal Indica

Dear Swagatam Sir,

Thanks so much for your reply and I am grateful to you for encouraging me. When you made that request to me I had already fixed some more 4 coils for my small Bedini Motor in order to make it more and more efficient. But I could not create the Bedini Circuits with Transistors for that 4 coils as I could not purchase the euipments .

But still my Bedini Motor is running with the previous 4 coils even if there is a small drag from the ferrite cores of the newly attached other four coils as these coils do not do anything but they are just sitting around my small magnet rotor. But my Motor is still able to charge the 12V 7A battery when I drive it with 3.7 batteries.

At your request , I have attached herewith a video clip of my bedini motor and I advise you to watch it till the end as at the beginning the voltmeter shows the Charge battery has a 13.6 V and after starting the motor it rises up to 13.7V and after some 3 or 4 minutes it rises up to 13.8V .

I used 3.7V small batteries to drive my small Bedini Motor and this proves the efficiency of the Bedini Motor well. In my Motor, 1 coil is a Bifilar coil and other 3 coils are triggered by the same trigger of that Bifilar coil and these three coils boost the energy of the motor by giving out some more coil spikes while speeding up the magnet rotor. . That is the secret of my Small Bedini Motor as I connected the coils in the parallel mode.

I am sure when I use the other 4 coils with bedini Circuits my Motor will work more efficiently and the magnet rotor will be spinning in a tremendous speed.

I will send you another video clip when I finish creating the Bedini Circuits .

Best Regards !

Thamal Indika

Practical Test Results

Very good effort. Thanks for lighting the way. feed back soon after real work begins here. my passion has found refuge here.

at the moment, I have a 12v car battery connected to a 1500w DC to AC inverter with a trickle charger plugged into it and attached to the battery. I can run a 110v/12v cooler, the trickle charger, and charge 2 cell phones and never go below 12.4 volts on the inverter or the battery when I test battery

post voltage.

actually no batteries shouldn’t be required to self run all you need is a generator that provides electric while it runs the generator itself then have a speed controller to speed it up and it the generator and the coils has to run at same rpms or it will not work I came up with this idea in 5 minutes mentally

i have a problem, i want to have the knowledge to build a sysytem where i can generate enough current to supply power to my drill, power saw, and light bulb. what do i start out with, please help.

You must first try the above circuits on smaller loads and check the response, if it works then gradually you can upgrade the system for powering higher wattage loads.

Hi

Above the 100K resistor connected across the A3144E there is a LED and switch, is the switch manually operated and what is its purpose.

Regards

Peter G Dawe.

Hi,

yes, the switch can be operated manually for disabling the LED function.

there is a simpler way to to make a perpetual generator a car alternator motor, an ac motor with a shaft on each generator and also the motor it can be a ac motor found In saws or table saws, some wire 16 gauge solid core wire 2 pulley wheels a fan belt the proper size, a piece of plywood 2 feet by 3 or 4 feet width and length, ac power the alternator, dc power the generator, screws, nuts and bolts, washers, wire, solder, soldering gun, drill bits, drill, drill bits screwdriver ends, PILLIPS, ROBSON, and SLOT, wire cutters and pliers, HEXIGON SET, a multigauge volt meter, to test for ac or dc, the pulley the bigger the pulley the slower the wheels turns the faster or slower the generator and alternator runs, you can get most of the parts from a junk yard, when you have every thing working connect it to the your junction box. give the fanbelt a few spins you might need a 12 volt battery, make sure all the wires are hooked up properly.it should power the whole house, think about to make sure everything is right. you may need a motor Instead of a generator. if you have any inquiries text me Garth shalom shalom

Do you have any schematics for a generator/power supply?

“A free energy enthusiast from South Africa who doesn’t want to reveal his name” … No, I bet he doesn’t! Perpetual energy generators are a myth – they break the established laws of thermodynamics; anyone who claims to have built such a machine – however, sophisticated it may appear – is a charlatan. If such machines really existed, do you think we’d still be drilling for fossil fuels, and polluting the air with greenhouse gases?

Here is one of those ‘myths’ to which you refer: Power Multiplier Device, last resize (I hope)-overunity.com

True, no generator will run forever, only as long as the universe supplies power, be it from an understood source or not. When that power is coming from a source that is not currently understood they may be labeled “perpetual motion” and then scorned as being fraudulent and in violation of our thermodynamic laws.

I suggest that we don’t yet understand all there is to know about energy in our complex universe.

Here is an open sourced, gravity driven, continuous motion, free energy generator:

Go to Overunity.com, then to ‘gravity powered devices’, then to October 24, 2015.

This is Power Multiplier Device, last resize (I hope)-overunity.com Russ Lee

Have you tested for longevity? Do we have literature on magnetic depletion?

Could battery A be replaced with capacitor?

Hello dear Mr. Swagatam,

Thank you for the usefull info on this site.

I’d like to ask you if a car alternator 14V, 200Amps. with added magnets on the rotor and eliminating its diodes would work as a 3 phase generator and will generate around 400V , 3kW? If so how many magnets should I fix and in which intervals?

Can you please advise me?

Kind regards

Hi Milan, sorry, I have no idea whether a car alternator can be enhanced to generate 400 V by connecting magnets on it.

Maybe replace the stator windings in your alternator with about 25 times as many turns ( with much thinner wire) as the original automotive alternator to get that 400 volts.

but don’t expect 60 Hz frequency output, more in the range of 400 Hz which will vary as your engine changes rpm.

Good site you have here.. It’s hard to find quality writing like yours nowadays. I really appreciate individuals like you! Take care!!

Good day Sir

I am an engineering student 5th year From Cameroon, my end of year project is on self powered generator, going through the right up , my mind was really opened.

I will love to be in contact with you for more direction, I am From Cameroon university of Douala

Hi Wirba,

I wish you all the best with this project, however my knowledge of self powered generators is not good, so I am not sure if I would be able to provide you with any useful suggestions.

Why are these being made on a commercial basis instead of the very noisy gas generators.

Is there some information about the timeline of the hall sensor? Meaning how is the percentage between open and close state? How many rpm does this setup turn? That would help in comparing with an own implementation.

Thank you

Sorry, I do not have these information with me at this moment.

Hi Mr Swagatam,

Congratulations on this fantastic work.

I will give it a try and see what I can obtain with it at the end.

However, I am trying to identify a part in the last diagram and I cannot figure out what it is.

From the A3144E the top pins and between one of the 1K resistors, seems to go through something that looks like a diode and it is paralleled with a Switch.

Is that an optocoupler, or just a simple diode and a reed relay?

Best regards

Thank you Marian, I appreciate your interest in this concept!

That’s an LED according to me since I can see two small arrow like marking just beside the device, so it has to be an LED.

Swagata this not about the posting you wrote above, but please read this. I am a US Army Vietnam Veteran living on a fixed income. I retired in 1976 and at that time retirement pay was only 50% of our basic monthly pay. Now I’m 82 and the light company is eating me up with bills of over $ 300.00 every month. My question is there a way to build a small self contained 110v and a 220v generator without an outside power supply. When I looked at your diagrams I had no idea what you were talking about. If you could sent me a list of what I will need to get along where to get the items, it will very much appreciate it. I know next to nothing about what I’m trying to build and badly need advise. Thank you for reading this. God Bless you and yours. Avery

God Bless and please stay safe to and your family. Avery

Thank you Sir, for posting your comment.

The above circuit is actually about a concept that promises to charge a connected battery without using any external source. The circuit compensates the load usage and additionally keeps the battery fully charged all the time….which means the concept promises a perpetual operation, until of course the battery degrades.

Since the above concept is not tested by me, I cannot suggest this to you.

Instead, it is probably better to go for a diesel generator, which are quite cheaply available online.

Alternatively you can install solar panels and inverters and exploit the off-grid power source.

Hope this helps!

Good used solar panels can be found for 75% to 90% off the new cost but still deliver over 85% of their new power. I haven’t found batteries or inverters cheap, though.

I would like to see the schematic of Mr. Indika’s test unit as shown in the video, please….

Hi Swagatam,

I’ve always been impressed with these valuable skills, I wonder if you like to enter a discussion to create a small working generator that could be used to power a mobile phone and laptop in the third world?

Hi Melvin, If time permits I will surely build one of the above discussed units and report my experience here about the same.

Could you clarify the winding of the litz coil.

Thanks for the collection of interesting concepts and articles. Very inspiring!

With regards to the 555 timing chip, please confirm that pin 7 is to be unconnected.

Regards,

Lou

Thank you, it seems pin#7 is intentionally omitted in the 555 circuits presented in the above article….

I have a question the resistor in the original sketch with the mje13009 has no value driving the base can you elaborate what that value is

It will need to be set with some calculations, depending on the required load current or the battery current.

R = (supply – o.6) hFE / load current

Please help me achieve 12 DC volts generator using DC motor, coil, and few components (capacitor, rectifiers etc). I’m carrying out my post graduate construction. I will be grateful to have a direction to achieve this self running technology. Thank you.

I love Nikola Tesla! One of a kind. The greatest inventor in history.

Dear Mr. Swagatam, how can you believe that the circuit can pull 40W out of nothing, indefinitely ?

In the most optimistic case the magnets will be exhausted, so the circuit will stop working.

Dear Arnoldo, Neodymium magnets may take very long to lose their strength, so by he time they gets weaker, a lot of free energy could be collected in the batteries. And afterwards these weakened magnets can be replaced with new magnets.

So, the energy is not “free”.

You should know they meant free energy as in “does not need outside energy” like gasoline or any other fuel. Also, neodymium magnets are fairly inexpensive. It may not generate as much electricity to equal the electrical bill, but you will definitely make a profit.

Hi! Good day.

I’m just wondering, cause i saw in youtube some energy generator using round ferrite magnet. Is it really true that it can supply electricity?

Thank you,

Antonio

Hi, most of them are fake. Only the ones which are built using many magnets and coils may have some truth.

Hello Swag,

thanks for your wonderful circuits and tutorials, i will love to build this circuit. do you advice me to go ahead. if so please i will like to get the final design you used to build the prototype in the video. is it also possible to power load in the house simultaneously while it charges the battery.

Thanks

Hello zaka, I am sorry, I can’t guarantee the results for the above concepts since I have not yet checked them myself.

Do you any video,,regarding this article?

And if you have..

Kindly send me a link in my email.. Thanks.

You can find it at the bottom of the post…

Ok, thanks

Sorry for the work. But my doubt in this!

https://drive.google.com/file/d/1oB6LJU2pOJgHTL7jyN14MRT69F1oaOXD/view?usp=sharing on page eight of this link, red figure

Good afternoon. Sorry for the work, but what I ask you to explain to me is this recommendation to follow, how to put the monestavel at each exit.

See the following recommendation:

If experimentation shows that your particular circuit construction works best with increasing frequency of clock pulses, and this results

In each transistor triggering coil requiring a period of drive voltage longer than the length of a division clock period by N, then this can be solved by

using a monostable at each output, as shown by the shaded portions of this diagram:

You can use this circuit for the monostable:

" rel="ugc">

remove the 2M2 and the LDR, and connect the 10K end of the BC547 with the 4017 output. You will need 10 such circuits for the 10 outputs of the IC 4017. You will also need a relay to be connected across pin#3 and ground of the IC. The relay contacts can then be wired with the coils.

Boa noite. sobre este link: https://drive.google.com/file/d/1oB6LJU2pOJgHTL7jyN14MRT69F1oaOXD/view?usp=sharing ,página oito

figura vermelha, não estou entendendo a explicação, como colocar monoestável em cada saida, você pode explicar melhor? obrigado.

For the IC 4017 connect its pin15 with ground, and use the outputs from pin3 to pin11 to connect the MOSFeT and the coils.

And what’s the type and dimensions of the magnets used?

Hello Mr Swagatam, pls what’s the name of the magnets used here?

And what’s the length of wire used in the winding that drove the magnets into sustainable motion? I mean the wire connected with collector of the driving transistor

Hello Victory, all the details are given in the article, or you can also find it in the download link at the bottom of the article.

Boa noite. Na página oito no link a seguir,o que quer dizer a figura em vermelho,sobre o 4017? obrigado.veja o link: https://drive.google.com/file/d/1oB6LJU2pOJgHTL7jyN14MRT69F1oaOXD/view?usp=sharing

Coil driver stages 1,2,3,4

Boa noite,como vai? Se colocar neodímio, precisa de trocar os resistores da base do transistor, ou tem mais mudanças a ser feita? obrigado.

Sorry I have not yet tested it, so not sure about it. For more info you can refer to this article:

https://drive.google.com/file/d/1oB6LJU2pOJgHTL7jyN14MRT69F1oaOXD/view?usp=sharing