When an inverter with square wave AC output is modified to generate a crude sinewave AC output, it is called a modified sine wave inverter.

The following article presents 7 interesting modified sine wave inverter designs with exhaustive descriptions regarding its construction procedure, circuit diagram, waveform output and detailed parts lists. The designs are intended for learning and building experimental projects by engineers and students.

Here I have explained different varieties of modified designs ranging from a modest 100 watt to a massive 3 Kva power output model.

How Modified Inverters Work

Folks who are new to electronics may get a bit confused regarding the difference between a square wave and a modified square wave inverter. It may be understood through the following brief explanation:

As we all know an inverter will always generate an alternating current (AC) similar to our domestic AC line voltage so that it can replace it during power failures. An AC in simple words is basically a rise and fall of voltage of a particular magnitude.

However, ideally this AC is supposed to as close as possible to a sinewave as shown below:

Basic Difference between Sine waveform and Square Waveform

This rise and fall of voltage happens at a particular rate i.e. at a particular number of times per second, known as its frequency. So for example a 50 Hz AC means 50 cycles or 50 ups and downs of a particular voltage in one second.

In a sine wave AC as found in our normal domestic mains outlet the above rise and fall of voltage is in the form of a sinusoidal curve, i.e. its pattern gradually varies with time and thus is not sudden or abrupt. Such smooth transitions in the AC waveform becomes very suitable and a recommended type of supply for the many common electronic gadgets like TVs , music systems , Refrigerators, motors etc.

However, in a square wave pattern the voltage ups and downs are instant and sudden. Such immediate rise and fall of potential creates sharp spikes at the edges of each wave and thus becomes very undesirable and unsuitable for sophisticated electronic equipment. Therefore it is always dangerous to operate them through a Square weave inverter supply.

Modified Waveform

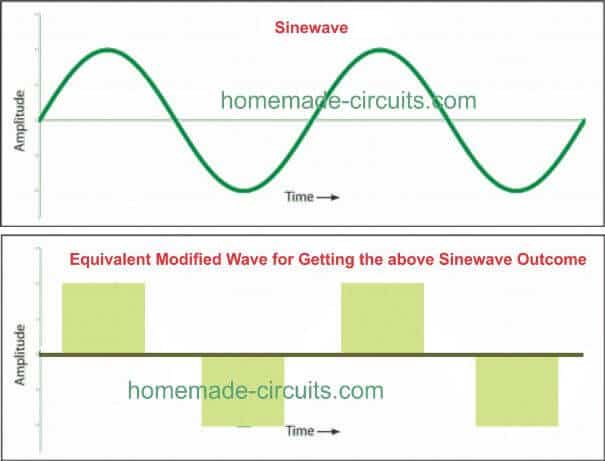

In a modified square wave design as shown above, the square waveform shape basically remains the same but the size of each section of the wave-form is appropriately dimensioned so that its average value matches closely to an AC waveform’s average value.

As you can see there's a proportionate amount of gap or null areas between each square blocks, these gaps ultimately help to shape up these square waves into sinewave like output (albeit crudely).

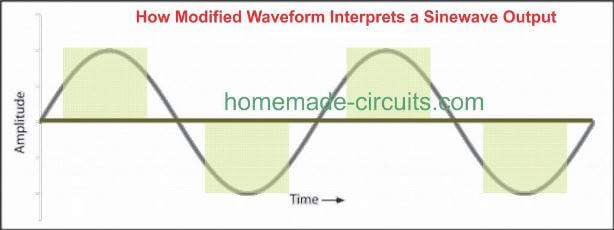

And what is responsible for adjusting these dimensioned square waves into sinewave like features? Well, it is the inherent characteristic of the transformer's magnetic induction which effectively carve the "dead time" transitions between the square wave blocks into a sinewave looking waves, as shown below:

In all the 7 designs I have explained below we try to implement this theory and ensure that the RMS value of the square waves are appropriate controlled by chopping the 330V peaks into 220V modified RMS. The same can be applied for 120V AC by chopping down the 160 peaks.

How to Calculate through Easy Formulas

If you are interested to know how to calculate the above modified waveform so that it results in an almost ideal replication of a sinewave, then please refer to the following post for the complete tutorial:

Calculate Modified Square Wave RMS Sine Equivalent Value

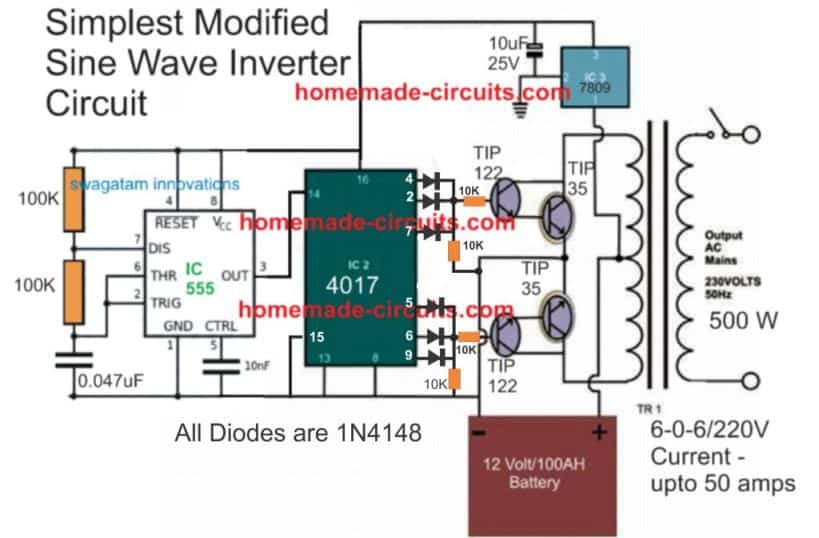

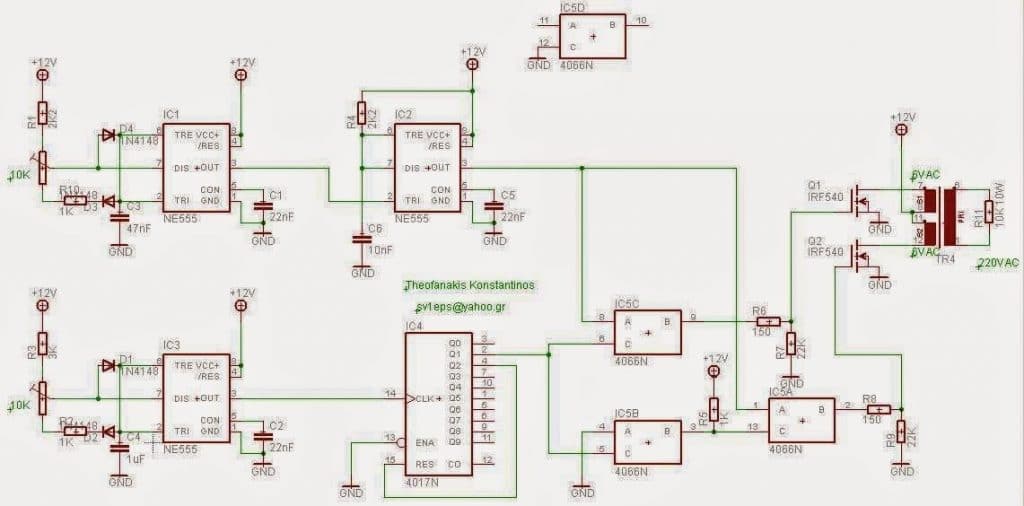

Design#1: Using IC 4017

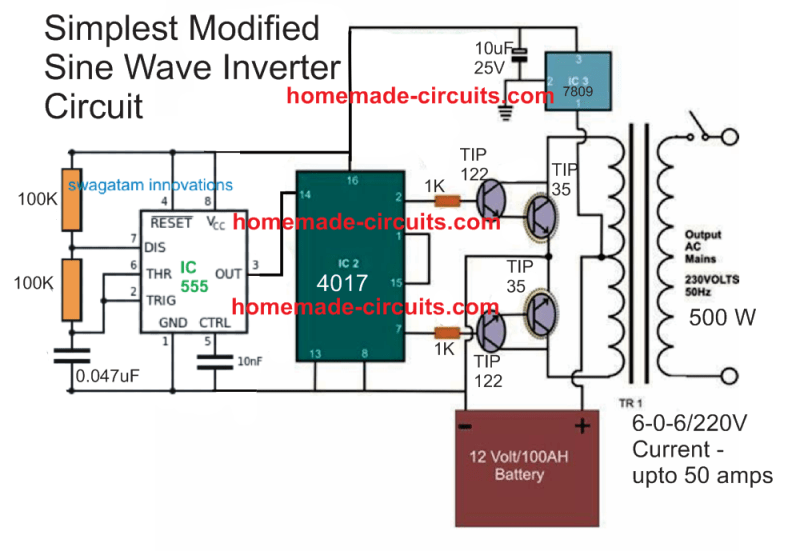

Let's investigate the first modified inverter design which is rather simple and uses a single IC 4017 for processing the required modified waveform.

If you are looking for an easy to build modified sine wave power inverter circuit, then perhaps the following concept will interest you. It looks astonishingly simple and low cost with an output that’s to a very extent is comparable with other more sophisticated sine wave counterparts.

We know that when a clock input is applied to its pin #14, the IC produces a shifting cycle logic high pulses through its 10 output pins.

Looking at the circuit diagram we find that the pin outs of the IC are terminated to supply the base of the output transistors such that they conduct after every alternate output pulse from the IC.

This happens simply because the bases of the transistors are connected alternately to the IC pin outs and the intermediate pin-out connections are just eliminated or kept open.

The transformer windings which are connected to the transistor’s collector respond to the alternate transistor switching and produce a stepped up AC at its output having a waveform exactly as shown in the diagram.

The output of this Modified sine wave power inverter is although not quite comparable to the output of a pure sine wave inverter but definitely will be far better than that of an ordinary square wave inverter. Moreover the idea is very easy and cheap to build.

WARNING: PLEASE CONNECT PROTECTION DIODES ACROSS THE COLLECTOR EMITTER OF THE TIP35 TRANSISTOR (CATHODE TO COLLECTOR, ANODE TO EMITTER)

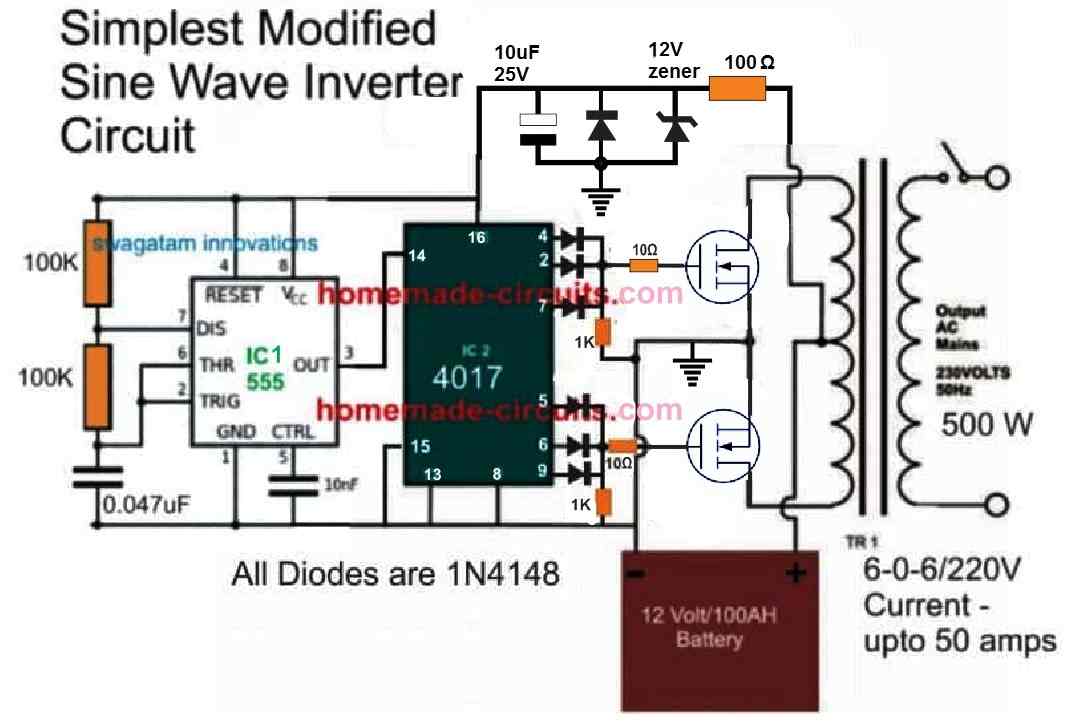

UPDATE: As per the Calculations presented in the this article, the IC 4017 output pins could be ideally configured for achieving an impressive looking modified sinewave inverter.

The modified image can be witnessed below:

WARNING: PLEASE CONNECT PROTECTION DIODES ACROSS THE COLLECTOR EMITTER OF THE TIP35 TRANSISTOR (CATHODE TO COLLECTOR, ANODE TO EMITTER)

A MOSFET version of the above design can be witnessed in the following diagram. Using MOSFETs IRF3205 can allow the inverter to handle above 400 watts.

Video Demo:

Minimum Specifications

- Input: 12V from Lead Acid Battery, for example 12V 7Ah battery

- Output: 220V or 120V depending on transformer rating

- Waveform : Modified sinewave

Feedback from one of the dedicated viewers of this blog, Ms Sarah

Hello Swagatam,

This is what I obtained from the output of IC2 post resistors R4 and R5. As I earlier said I expected to have a bipolar wave. One in positive and the other in negative . to simulate an ac wave cycle. I hope this picture will help. I need a way forward please.

Thanks

My Reply:

Hello Sarah,

The IC outputs will not show bipolar waves since the signals from these outputs are intended for identical N type transistors and from a single supply....it's the transformer which is responsible for creating the bipolar wave at its output since it's configured with a push-pull topology using a center tap ....so what you are seeing across R4 and R5 are correct waveform. Please check the waveform at the output of the transformer for verifying the bipolar nature of the waveform.

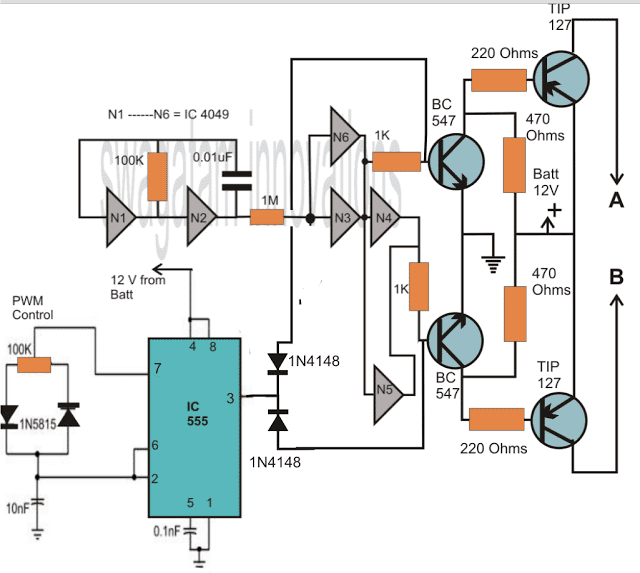

Design#2: Using NOT Gates

This second in the list is a unique modified sine wave inverter concept also designed me. The entire unit along with the oscillator stage and the output stage can be easily built by any electronic enthusiast at home. The present designed will be easily able to support 500 VA of output load.

Let's try to understand the circuit functioning in details:

The Oscillator Stage:

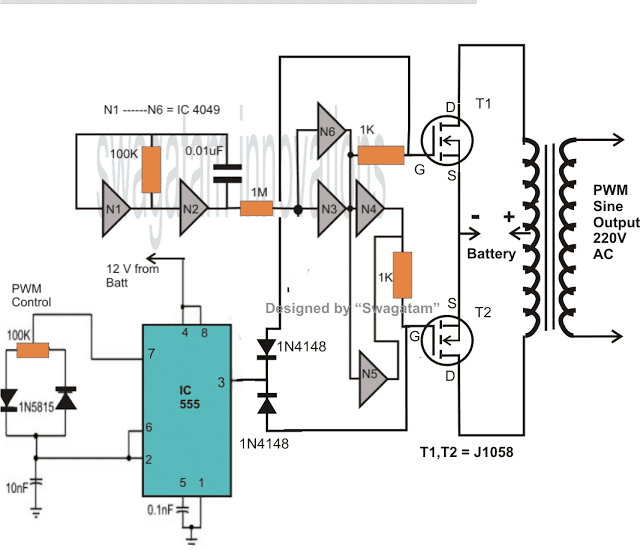

Looking at the circuit diagram above, we see a clever circuit design comprising both, the oscillator as well as the PWM optimization feature included.

Here, the gates N1 and N2 are wired up as an oscillator, which primarily generates perfectly uniform square wave pulses at its output. The frequency is set by adjusting values of the associated 100K and the 0.01 uF capacitor. In this design it is fixed at the rate of around 50 Hz. The values can be altered appropriately for getting a 60 Hz output.

The output from the oscillator is fed to the buffer stage consisting of four parallel and alternately arranged NOT gates. The buffers are used for sustaining perfect pulses and for avoiding degradation.

The output from the buffer is applied to the driver stages, where the two high-power darlington transistors take the responsibility of amplifying the received pulses, so that it can be finally fed to the output stage of this 500 VA inverter design.

Until this point the frequency is just an ordinary square wave. However the introduction of the IC 555 stage entirely changes the scenario.

The IC 555 and its associated components are configured as a simple PWM generator. The mark-space ratio of the PWM can be discretely adjusted with the help of the pot 100K.

The PWM output is integrated to the output of the oscillator stage via a diode. This arrangement makes sure that the generated square wave pulses are broken into pieces or chopped as per the setting of the PWM pulses.

This helps in reducing the total RMS value of the square wave pulses and optimize them as close as possible to a sine wave RMS value.

The pulses generated at the bases of the driver transistors are thus perfectly modified to resemble sine wave forms technically.

The Output Stage:

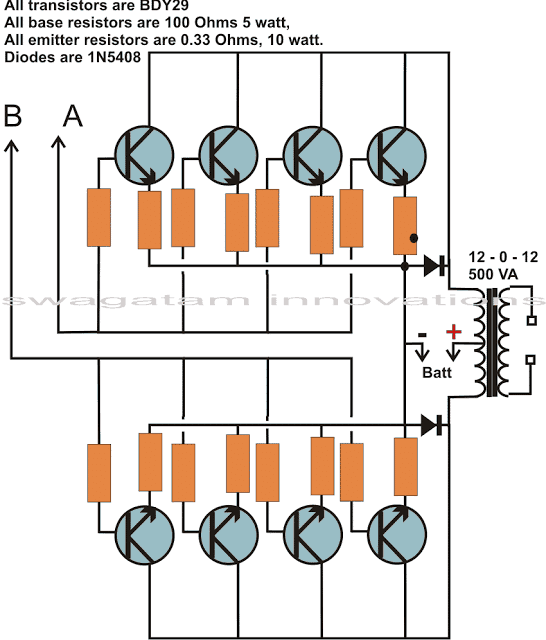

The output stage is quite straight forward in its design. The two winding of the transformer are configured to the two individual channels, consisting of banks of power transistors.

The power transistors at both the limbs are arranged in parallel to increase the overall current through the winding so as to produce the desired 500 watts of power.

However to restrict thermal runaway situations with the parallel connections, the transistors are connected with a low value, high wattage wire wound resistor at their emitters. This inhibits any single transistor from getting over loaded and fall into the above situation.

The bases of the assembly are integrated to the driver stage discussed in the previous section.

The battery is connected across the center tap and the ground of the transformer and also to the relevant points in the circuit.

Switching ON power immediately starts the inverter, providing rich modified sine wave AC at its output, ready to be used with any load upto 500 VA.

The component details are supplied in the diagram itself.

The above design can also be modified into a 500 watt PWM controlled mosfet sine wave inverter by replacing the driver transistors simply by a few mosfets. The design shown below would provide about 150 watts of power, for obtaining 500 watts, more number of mosfets may be required to be connected in parallel with the existing two mosfets.

Design#3: using a 4093 IC for the Modified Results

The PWM controlled modified sine wave inverter circuit presented below is our 3rd contender, it uses just a single 4093 for the specified functions.

The IC consists of four NAND gates, out of which two are wired up as oscillators while the remaining two as buffers.

The oscillators are integrated in such a way that the high frequency from one of the oscillators interacts with the output of the other, generating chopped square waves whose RMS value can be well optimized to match the regular sine waveforms.Inverter designs are not always easy to understand or build, especially so when it's as complex as modified sine wave types. However the concept discussed here utilizes just a single IC 4093 for handling all the required complications. I have explained how simple it is to build.

Parts you will Ned to Build this 200 Watt Inverter Circuit

All Resistors are 1/4 watt, 5 %, unless otherwise specified.

- R1 = 1 M for 50 Hz and 830 K for 60 Hz

- R2 = 1 K,

- R3 = 1 M,

- R4 = 1 K,

- R5, R8, R9 = 470 Ohms,

- R6, R7 = 100 Ohms, 5 Watt,

- VR 1 = 100 K,

- C1, C2 = 0.022 uF, Ceramic Disc,

- C3 = 0.1, disc ceramic

- T1, T4 = TIP 122

- T3, T2 = BDY 29,

- N1, N2, N3, N4 = IC 4093,

- D1, D1, D4, D5 = 1N4007,

- D3, D2 = 1N5408,

- Transformer = 12 -0 – 12 volts, current from 2 to 20 Amps as desired, output voltage can be 120 or 230 volts as per country specifications.

- Battery = 12 volts, typically a 32 AH type, as used in cars is recommended.

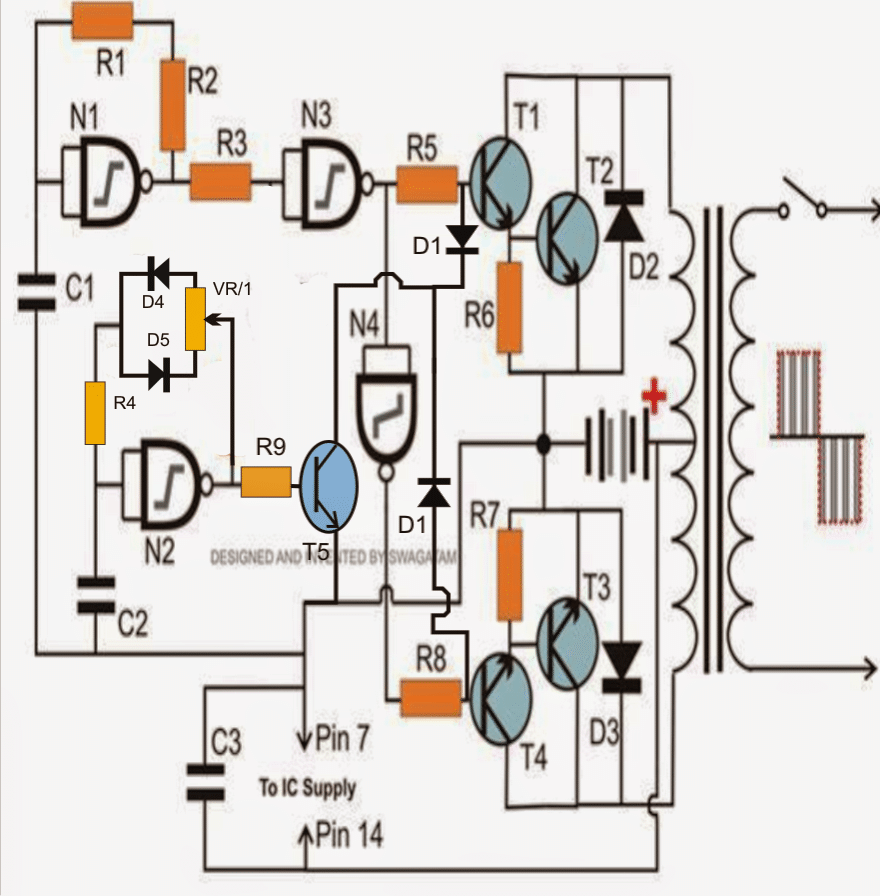

Circuit Operation

The proposed design of a 200 watt modified sine wave inverter obtains its modified output by discretely “cutting” the basic square wave pulses into smaller sections of rectangular pulses. The function resembles to a PWM control, commonly associated with IC 555.

However, here the duty cycles cannot be varied separately and is kept equal throughout the available variation range. The limitation does not affect the PWM function by much, since here we are only concerned in keeping the RMS value of the output close to its sine wave counter, which is executed satisfactory through the existing configuration.

Referring to the circuit diagram, we can see that the entire electronics hovers around a single active part – the IC 4093.

It consists of four individual NAND Schmitt gates, all of them have been engaged for the required functions.

N1 along with R1, R2 and C1 forms a classic CMOS Schmitt trgger type of oscillator where the gate is typically configured as an inverter or a NOT gate.

The pulses generated from this oscillator stage are square waves which forms the basic driving pulses of the circuit. N3 and N4 are wired up as buffers and are used for driving the output devices in tandem.

However these are ordinary square wave pulses and do not constitute the modified version of the system.

We can easily use the above pulses solely for driving our inverter, but the result would be an ordinary square wave inverter, not suitable for operating sophisticated electronic gadgets.

The reason behind this is that, square waves may differ greatly from the sine waveforms, especially as far as their RMS values are concerned.

Therefore, the idea is to modify the generated square waveforms so that its RMS value closely matches with a sine waveform. To do this we need to dimension the individual square waveforms through some external intervention.

The section comprising N2, along with the other associated parts C2, R4 and VR1, forms another similar oscillator like N1. However this oscillator produces higher frequencies which are tall rectangular shaped.

The rectangular output from N2 is fed to the basic input source of N3. The positive trains of pulses have no effect on the source input pulses due to the presence of D1 which blocks the positive outputs from N2.

However, the negative pulses are allowed by D1 and these effectively sink the relevant sections of the basic source frequency, creating kind of rectangular notches in them at regular intervals depending upon the frequency of the oscillator set by VR1.

These notches or rather the rectangular pulses from N2 can be optimized as desired by adjusting VR1.

The above operation cuts the basic square wave from N1 into discrete narrow sections, lowering the average RMS of the waveforms. It is advised that the setting is done with the help of a RMS meter.

The output devices switch the relevant transformer windings in response to these dimensioned pulses and produce corresponding high voltage switched waveforms at the output winding.

The result is a voltage which is quite equivalent to a sine wave quality and is safe for operating all types of household electrical equipment.

The inverter power may be increased from 200 watts to 500 watts or as desired simply by adding more numbers of T1, T2, R5, R6 and T3, T4, R7, R8 in parallel over the relevant points.

Salient Features of the Inverter

The circuit is truly efficient and moreover it is a modified sine wave version which makes it outstanding in its own respect.

The circuit utilizes very ordinary, easy to procure types of components and is also very cheap to build.

The modifying process of the square waves into sine waves can be done by varying a single potentiometer or rather a preset, which makes the operations pretty simple.

The concept is very basic yet offers high power outputs which may be optimized as per ones own needs just by adding a few more number of output devices in parallel and by replacing the battery and the transformer with the relevant sizes.

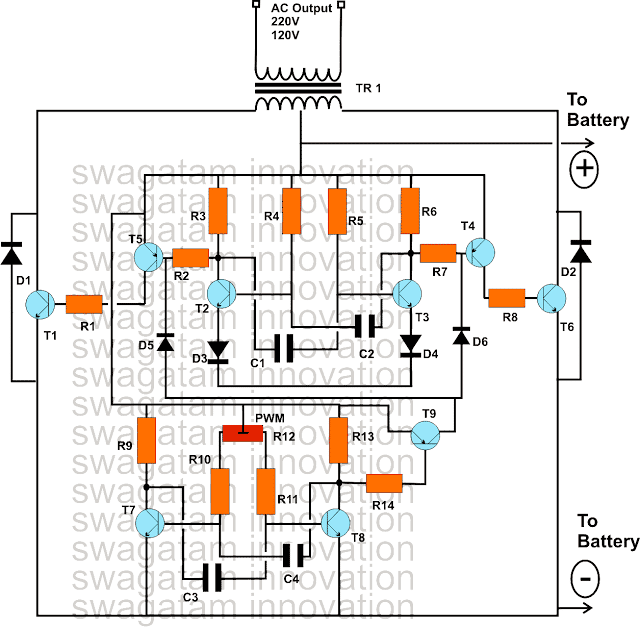

Design#4: Fully Transistor Based Modified Sinewave

A very interesting circuit of a modified sine wave inverter is discussed in this article which incorporates just ordinary transistors for the proposed implementations.

The use of transistors typically makes the circuit easier to understand and more friendly with the new electronic enthusiasts. The inclusion of a PWM control in the circuit makes the design very efficient and desirable as far as operations of sophisticated appliances are concerned at the inverter output.The circuit diagram shows how the entire circuit is laid down. We can clearly see that only transistors have been involved and yet the circuit can be made to produce well-dimensioned PWM controlled waveform for generating the required modified sinew waveforms or rather modified square waves to be more precise.

The whole concept may be understood by studying the circuit with the help of the following points:

Astable as the Oscillators

Basically we can witness two identical stages which are wired up in the standard astable multivibrator configuration.

Being astable in nature the configurations are specifically intended for generating free running pulses or square wave at their respective outputs.

However the upper AMV stage is positioned for generating the normal 50 Hz (or 60 Hz) square waves which are used for operating the transformer and for the required inverter actions, in order to get the desired AC mains power at the output.

Therefore there’s nothing too serious or interesting about the upper stage, typically it consists a central AMV stage consisting of T2, T3, next comes the driver stage consisting of the transistors T4, T5 and finally the receiving output stages consisting of the T1 and T6.

How the Output Stage Works

The output stage drives the transformer via the battery power for the desired inverter actions.

The above stage is only responsible for carrying out the generation of the square wave pulses that’s imperatively required for the intended normal inverting actions.

The PWM Chopper AMV Stage

The circuit at the lower half is the section which actually does the sine wave modifications by switching the upper AMV according to its PWM settings.

Precisely, the upper AMV stage’s pulse shape is controlled by the lower AMV circuit and it implements the square wave modification by chopping the basic square inverter square waves from the upper AMV into discrete sections.

The above chopping or dimensioning is executed and defined by the setting of the preset R12.

R12 is used for adjusting the mark space ratio of the pulses generated by the lower AMV.

According to these PWM pulses, the basic square wave from the upper AMV is chopped into sections and the average RMS value of the generated waveform is optimized as close as possible to a standard sine waveform.

The remaining explanation regarding the circuit is pretty ordinary and may be done by following the standard practice that’s normally employed while building invertes, or for that matter, my other related article may be referred for acquiring the relevant information.

Parts List

- R1, R8 = 15 Ohms, 10 WATTS,

- R2, R7 = 330 OHMS, 1 WATT,

- R3, R6, R9, R13, R14 = 470 OHMS ½ WATTS,

- R4, R5 = 39K

- R10, R11 = 10K,

- R12 = 10K PRESET,

- C1-----C4 = 0.33Uf,

- D1, D2 =1N5402,

- D3, D4 = 1N40007

- T2, T3, T7, T8= 8050,

- T9 = 8550

- T5, T4 = TIP 127

- T1, T6 = BDY29

- TRANSFORMER = 12-0-12V, 20 AMP.

- T1, T6, T5, T4 SHOULD BE MOUNTED OVER SUITABLE HEATSINK.

- BATTERY = 12V, 30AH

Design#5: Digital Modified Inverter Circuit

This 5th design of a classic modified inverter is yet another design developed by me, although it's a modified sine wave, it can also be referred as a digital sine wave inverter circuit.

The concept is again inspired from a mosfet based powerful audio amplifier design.

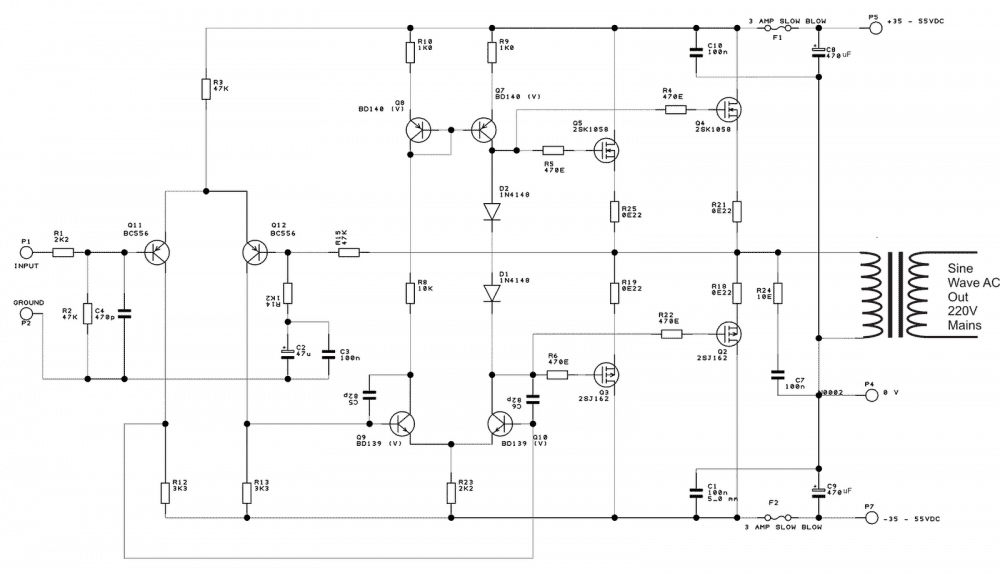

Looking at the main power amp design we can see that basically it's a 250 watt powerful audio amp, modified for an inverter application.

All the stages involved are actually for enabling a frequency response of 20 to 100kHz, though here we won't need such high degree of frequency response, I didn't eliminate any of the stages as it wouldn't do any harm to the circuit.

The first stage consisting of the BC556 transistors is the differential amplifier stage, next comes the well balanced driver stage consisting of the BD140/BD139 transistors and finally it's the output stage which is made up of the powerful mosfets.

The output from the mosfets are connected to a power transformer for the required inverter operations.

This completes the power amp stage, however this stage requires a well dimensioned input, rather a PWM input which would ultimately help to create the proposed digital sine wave inverter circuit design.

The Oscillator Stage

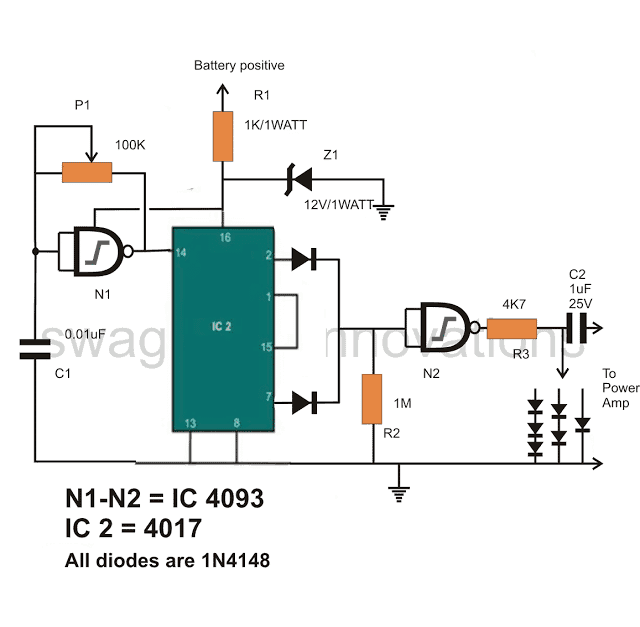

The next CIRCUIT DIAGRAM shows a simple oscillator stage which has been suitable optimized for providing adjustable PWM controlled outputs.

The IC 4017 becomes the main part of the circuit and generates square waves which very closely matches the RMS value of a standard AC signal.

However for precise adjustments, the output from the IC 4017 has been provided with discrete voltage adjustment level facility using a a few 1N4148 diodes.

One of the diodes at the output may be selected for reducing the amplitude of the output signal which would ultimately help in adjusting the RMS level of the transformer output.

The clock frequency which must be adjusted to 50Hz or 60Hz as per the requirements is generated by a single gate from the IC 4093.

P1 can be set for producing the above required frequency.

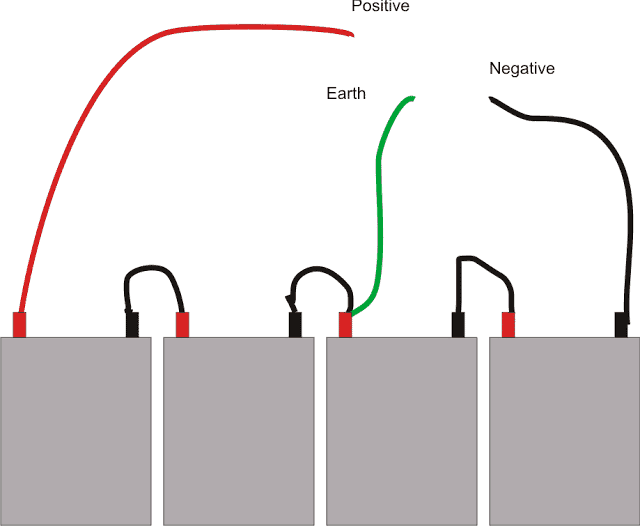

For getting a 48-0-48volts, use 4 nos. 24V/2AH batteries in series, as shown in the last figure.

Power Inverter Circuit

Sine Wave Equivalent Oscillator Circuit

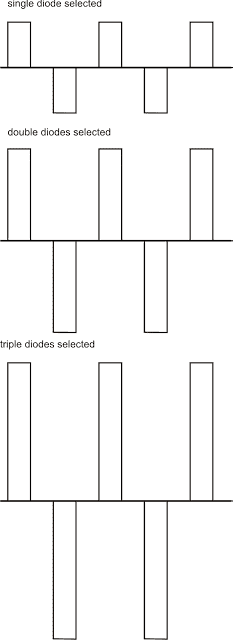

The figure below shows various waveforms outputs as per the selection of the number of diodes at the output of the oscillator stage, the waveforms may have different relevant RMS values, which must be carefully selected for feding the power inverter circuit.

If you have any problems understanding the above circuits, please feel free to comment and inquire.

Design#6: using only 3 IC 555

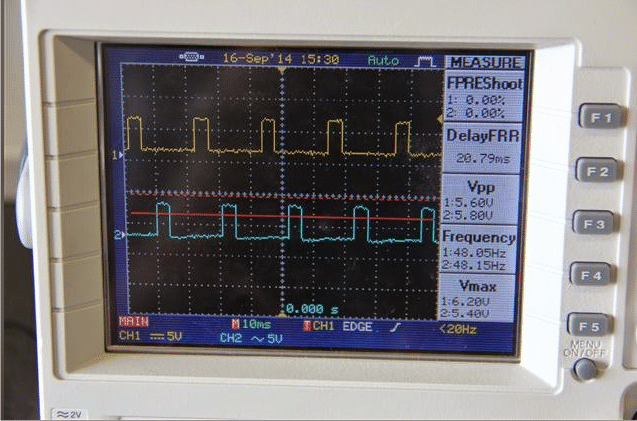

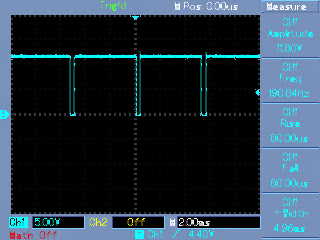

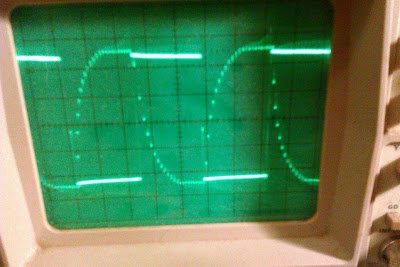

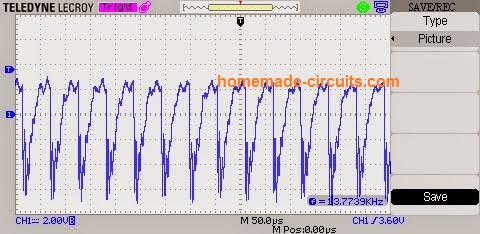

The following section discusses the 6th best modified sine wave inverter circuit with waveform images, confirming the credibility of the design. The concept was designed by me, the waveform being confirmed and submitted by Mr. Robin Peter.

The discussed concept was designed and presented in a few of my previously published posts: 300 watt sine wave inverter circuit, and 556 inverter circuit however since the waveform were not confirmed by me the relevant circuits weren't completely foolproof.Now it's been tested, and waveform verified by Mr. Robin Peter, the procedure revealed one hidden flaw in the design which has been hopefully sorted out here.

Let's go through the following email conversation between me and Mr. Robin Peter.

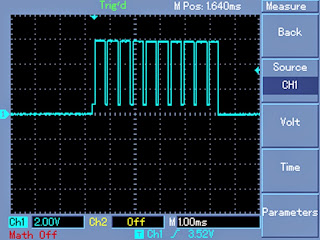

I built the simpler modified sine wave alternative version IC555's,with no transistor. I changed some of the values of the resistors and caps and did not use[D1 2v7,BC557,R3 470ohm]

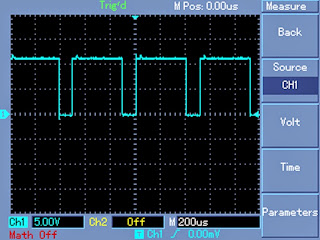

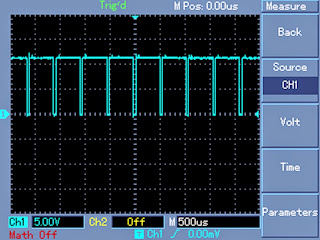

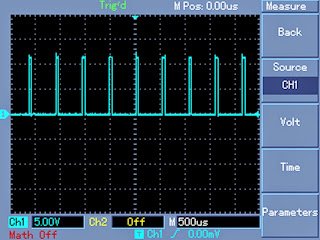

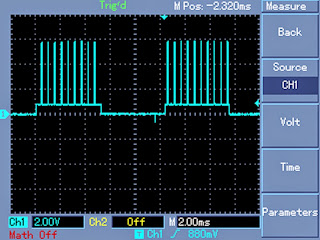

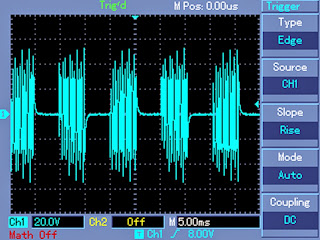

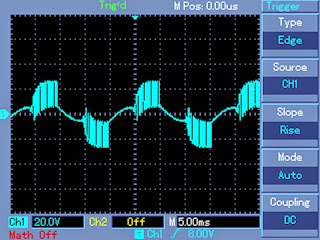

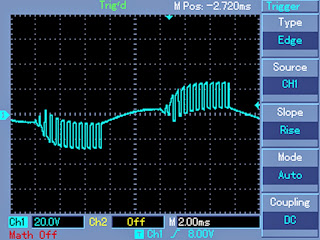

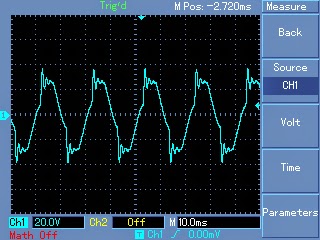

I joined Pin2&7 of IC 4017 together to get the required waveform. IC1 produces the 200hz 90% duty cycle pulses(1 image), which clock IC2 (2-images) and therefore IC3(2 images, min duty cycle & max D/C)Are these the expected results, My concern is that it is a modified sine where you can vary the

RMS,not a pure sine

Regards

Robin

Hi Robin,

Your modified sine wave circuit diagram looks correct but the waveform isn't, I think we'll need to use a separate oscillator stage for clocking the 4017 with frequency fixed at 200Hz, and increase the frequency of the topmost 555 IC to many kHz, then check the waveform.Regards.

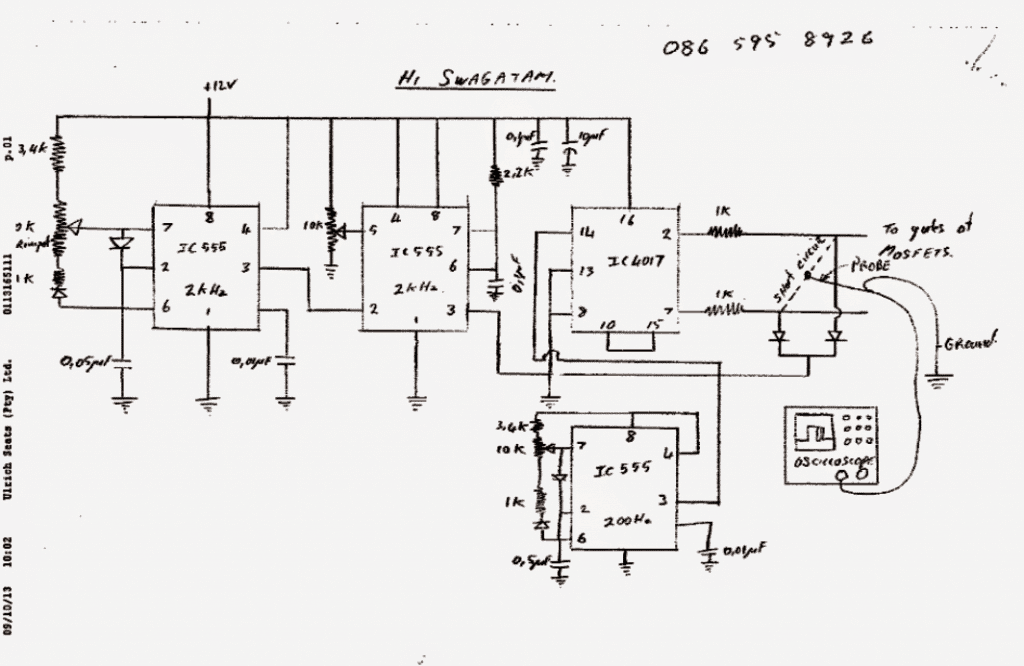

Hi Swagatam

I have attached a new circuit schematic with the changes you suggested along with the resultant wave forms.What do you think of the PWM waveform,the pulses don't seem to go all the way down to ground

level.

Regards

Hi Robin,

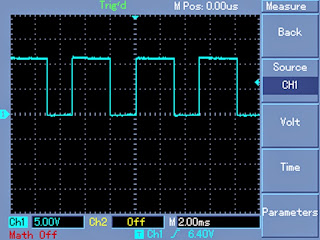

That's great, exactly what i was expecting, so it means a separate astable for the middle IC 555 must be employed for the intended results....by the way did you vary the RMS preset and check the waveforms, please do update by doing so.

So now it looks much better and you can go ahead with the inverter design by connecting the mosfets.

....it's not reaching the ground due to the diode 0.6V drop, I assume....Thanks very much

Actually a much easier circuit with similar results as above can be built as discussed in this post:https://www.homemade-circuits.com/2013/04/how-to-modify-square-wave-inverter-into.html

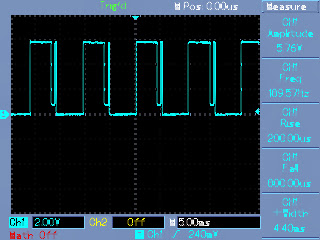

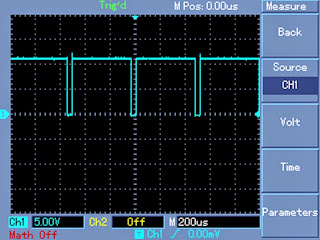

More Updates from Mr. Robin

Hi Swagatam

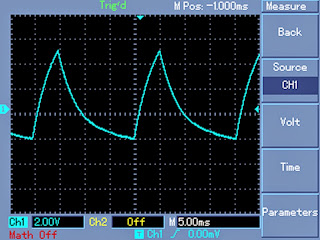

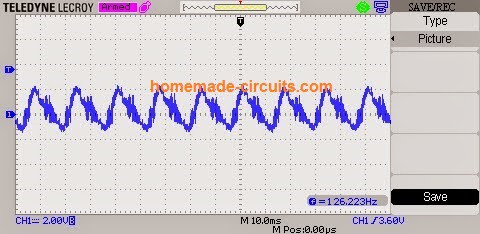

I varied the RMS preset and here are the attached waveforms.I would like to ask you what amplitude of triangle wave can you apply to pin 5,and how would you synchronise it so that when pin 2 or 7 go + the peak is in the middle

regards Robin

Here's some better modified sine waveform, maybe the guy's will understand them easier. It's up to you whether you publish them.

By the way i took a 10uf cap from pin2 to 10k resistor to .47uf cap to ground.And the triangular wave looked like this(attatched).Not too triangular,7v p-p.

I will investigate the 4047 option

cheers Robin

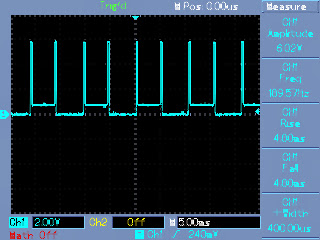

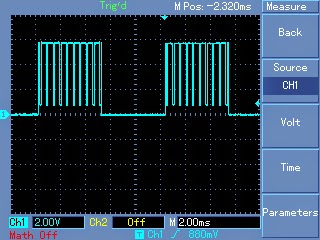

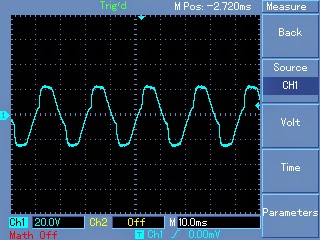

Output Waveform across Transformer Mains Output (220V)The following images show the various waveform images taken from across the output mains winding of the transformer.

Courtesy - Robin Peter

No PWM, no Load

No PWM, with load

With PWM, without load

With PWM, with load

The above image magnified

The above waveform images looked somewhat distorted and not quite like sinewaves. Adding a 0.45uF/400V capacitor across the output drastically improved the results, as can be witnessed from the following images.

Without load, with PWM ON, capacitor 0.45uF/400v added

With PWM, with load, and with an output capacitor, this looks very much like an authentic sinewaveform.

All the above verification and testing were conducted by Mr. Robin Peters.

More Reports from Mr. Robin

Ok,I did some more testing and experimenting last night and found that if I increase the batt voltage to 24v the sinewave did not distort when I increased the duty/cycle.( ok,I've regained my confidence)I added that 2200uf cap between c/tapp and ground but that made no difference to the output waveform.

I noticed a few things that were taking place,as I increased the D/C the trafo makes a noisy humming sound(as if a relay is vibrating back and forth very quickly),The IRFZ44N's get hot very quickly even with no loadWhen I remove the cap there seems to be less stress on the system.The humming noise is not so bad and the Z44n's don't get so hot.[of course no sinewave}

The cap is across the output of the trafo not in series with one leg. I took (3 different windings) round inductors{I think they are toriodal} out of a switch-mode power supply.The result was no improvement in the output wave(no change),

The trafo output voltage also dropped.

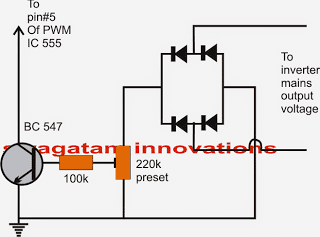

Adding an automatic load correction feature to the above modified sine wave inverter circuit idea:

The above shown simple ad-on circuit can be used for enabling automatic voltage correction of the inverter output.

The fed voltage across the bridge is rectified and applied to the base of the NPN transistor. The preset is adjusted such that at no load the output voltage gets settled at the specified normal level.

To be more precise, initially the above preset should be kept at the ground level so that the transistor says switched OFF.

Next, the 10k RMS preset at pin#5 of the PWM 555 IC should be adjusted to generate around 300V at the transformer output.

Finally, the load correction 220K preset should be realigned to bring down the voltage to may be around 230V mark.

Done! Hopefully the above adjustments would be enough for setting up the circuit for the intended automatic load corrections.

The final design might look like this:

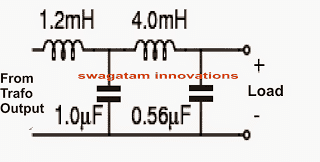

Filter Circuit

The following filter circuit can be employed at the output of the above inveter for controlling Harmonics and for enhancing a cleaner sinewave output

More Inputs:

The above design was studied and further improved by Mr Theofanakis, who is also an avid reader of this blog.

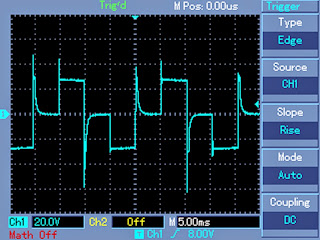

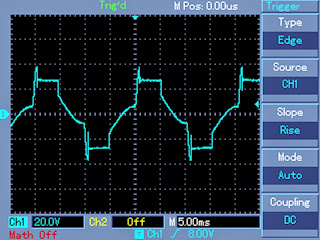

The oscilloscope trace depicts the modified waveform of the inverter across the 10k resistor connected at the mains output of the transformer.

The above modified inverter design by Theofanakis inverter was tested and approved by one of the avid followers of this blog, Mr. Odon. The following test images by Odon confirm the sinewave nature of the above inverter circuit.

Design#7: Heavy Duty 3Kva Modified Inverter Design

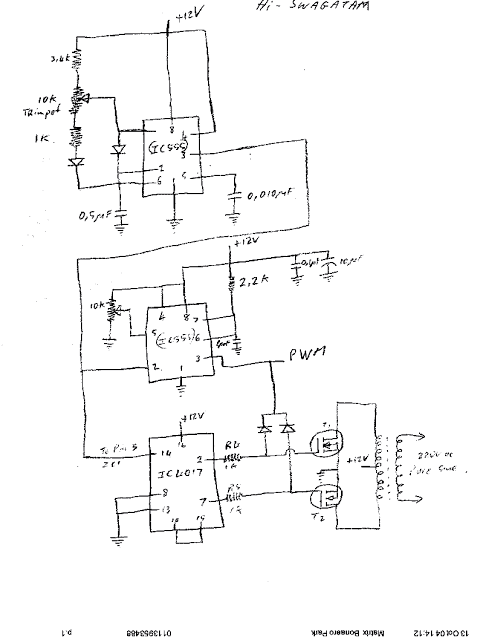

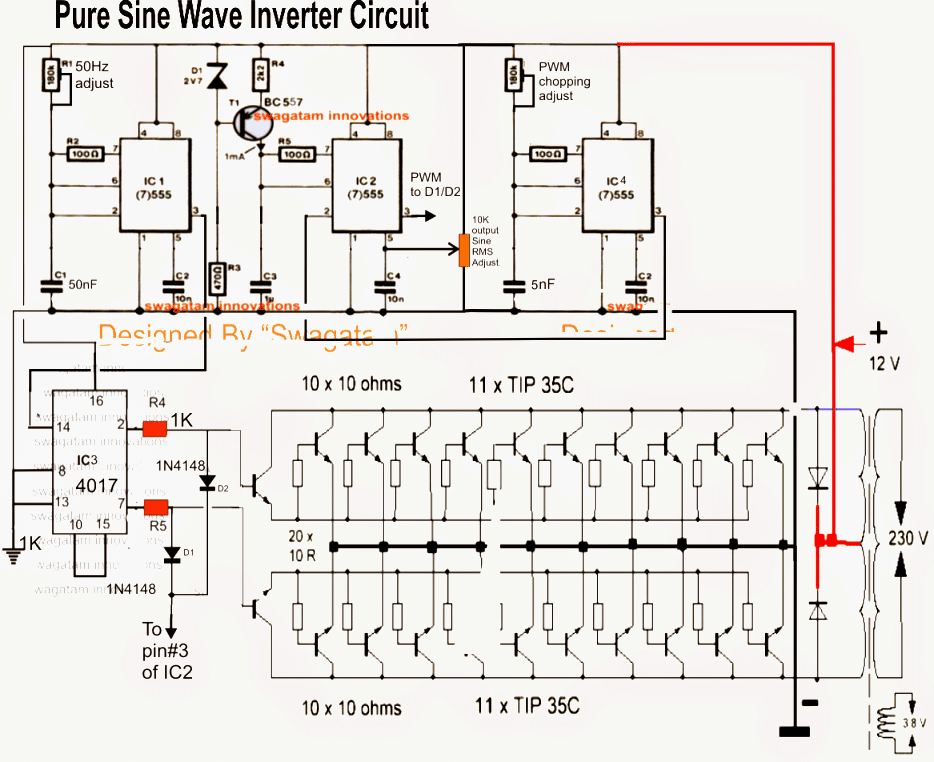

The below explained content investigates a 3kva sine wave inverter circuit prototype made by Mr. Marcelin using only BJTs instead of the conventional mosfets. The PWM control circuit was designed by me.

In one of my previous posts I have explained a 555 pure sine wave equivalent inverter circuit, which was collectively designed by Mr.Marcelin and me.

How the Circuit was Built

In this design I have used strong cables to sustain the high currents, I used sections of 70 mm2, or more smaller sections in parallel. 3 KVA transformer is actually as solid weighs 35 kg. Dimensions and volume is not a drawback for me. Photos attached to the transformer and installation in progress.

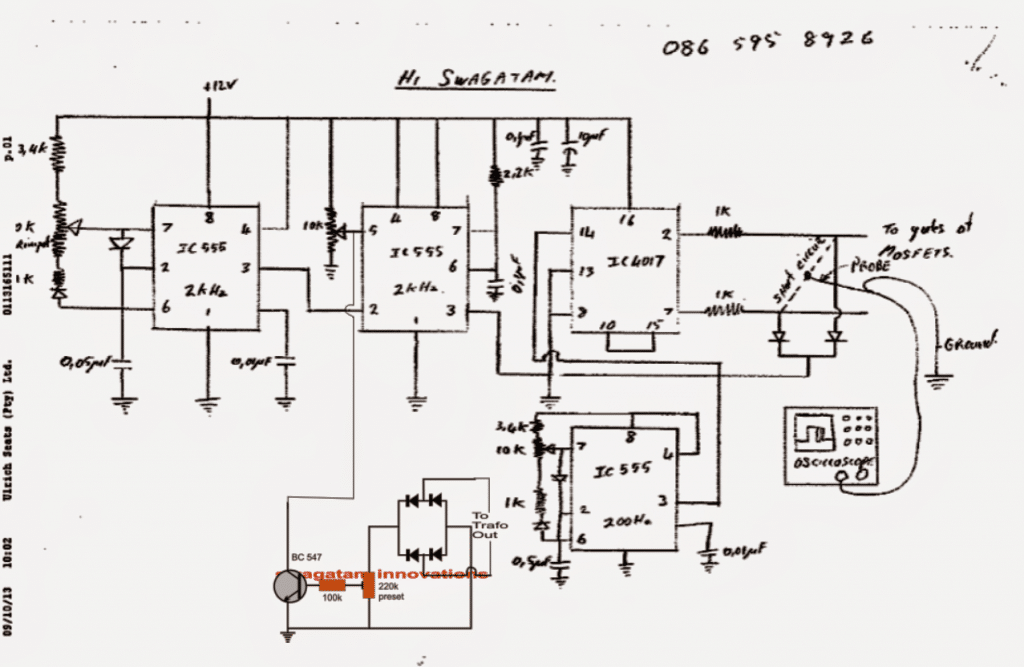

The following assembly nearing completion, based on the 555 (SA 555) and CD 4017

On my first try, with mosfets, earlier this year, I used IRL 1404 which Vdss is 40 volts. In my opinion insufficient voltage. It would be better to use mosfets with a Vdss at least equal to or greater than 250 volts.

In this new installation, I foresee two diodes on the transformer windings.

There will also be a fan for cooling.

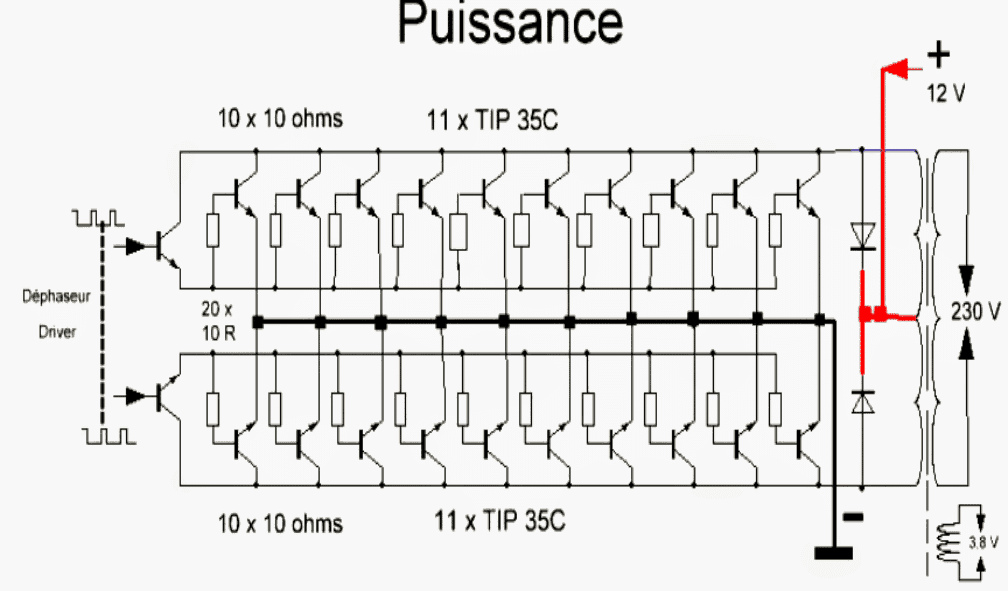

TIP 35 will be mounted by 10 in each branch, like this:

Complete Prototype Images

Finalized 3 KVA Inverter Circuit

The final circuit design of the 3 kva modified sine wave inverter should look like this:

Parts List

All resistors are 1/4 watt 5%, unless specified.

- 100 Ohms - 2nos (value can be between 100 ohm and 1K)

- 1K - 2nos

- 470 ohms - 1no (can be any value upto 1K)

- 2K2 - 1nos (slightly higher value will also work)

- 180K preset - 2nos (any value between 200K and 330K will work)

- 10K preset - 1no (please 1k preset instead for better outcome)

- 10 Ohm 5 watt - 29nos

Capacitors

- 10nF - 2nos

- 5nF - 1no

- 50nF - 1no

- 1uF/25V - 1no

Semiconductors

- 2.7V zener diode - 1no (upto 4.7V can be used)

- 1N4148 - 2nos

- 6A4 diode - 2nos (near transformer)

- IC NE555 - 3 nos

- IC 4017 - 1no

- TIP142 - 2nos

- TIP35C - 20 nos

- Transformer 9-0-9V 350 amps or 48-0-48V / 60 amps

- Battery 12V / 3000 Ah, or 48V 600 Ah

If 48V supply is used then make sure to regulate it to 12V for the IC stages, and supply the 48V only to center tap of the transformer.

How to Safeguard the Transistors

Note: In order to safeguard the transistors from a thermal runaway, mount the individual channels over common heatsinks, meaning use a long single finned heatsink for the upper transistor array, and another similar single common heatsink for the lower transistor array.

Mica isolation would be fortunately not required since the collectors are joined together, and the body being the collector would get effectively connected through the heatsink itself. This would actually save a lot of hard work.

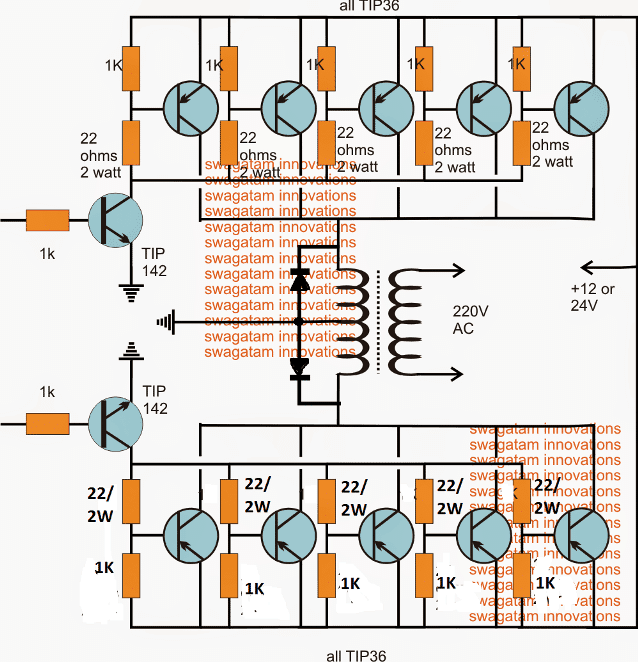

In order to obtain maximum power efficiency, the following output stage is recommended by me, and must be employed with the above explained PWM and 4017 stages.

Circuit Diagram

Note: Mount all the upper TIP36 over a larger finned common heatsink, DO NOT use mica isolator while implementing this.

The same must be done with the lower TIP36 arrays.

But make sure these two heatsinks never touch each other.

The TIP142 transistors must be mounted on separate individual large finned hearsinks.

Sir could you please suggest three modifications in this circuit as said below

1). to suppress the noise produced by the transfomer due to high harmonics

2). An automatic overload protector

3). Low battery cut off feature

Arun, I would suggest that you should first complete the basic circuit of an inverter having 100 watt output, once you succeed then we can proceed with the other additional features.

Sir should an electrolytic capaicitor be put at the output or a non electrolytic capaitor.

i noticed that when i put an electrolytic capacitor at the output it gets hot quickly.

It should be a non-polar strictly….use a metallized polyester capacitor for perfect results.

hello Mr Swagatam I am sort of busy at the moment so I am not able to do any more test on the circuit. Have u got any more update from Mr Robins or Michael on their side . As soon as I can I will post a report

Alex, no further updates received, however the situation looks quite convincing now and there's hardly any doubt regarding the circuit except the issue of using a ferrite cored trafo

Hi Swagatam

I would like to wish everybody a prosperous and happy new year,I really have been following the progress on these inverters and if I can help in any way I will,be assured,up untill now I realize I"ve got a lot of studying to do,With the guidance and expertise of our friend Swagatam I'm sure we can achieve what we want

Best wishes to everyone

Robin.

Hi Robin,

Wish you too a merry Christmas and a Happy New Year from all here.

We all very much appreciate your valuable inputs to this blog and will keep cooperating with you whenever you need us.

Thanks and best wishes.

Hello swagatam, I use 2pairs of IRF3205 mosfet, how can I connect the PWM accross the 4 mosfet gate.

use separate resistors on each gate of the mosfets, and connect separate diodes on each gate, then terminate the common diode cathodes with the PWM source

Hello swgatam, I got an idea. Can we set our 555IC to 200Hz, 25% duty cycle to make the wave resemble a PWM?

Hi ifeanyi, yes it can be done, the circuit has a wide option one can play with.

Hello, do u have any inverter design using feritte transformers?

you can the try the design given in this article:

https://www.homemade-circuits.com/2013/09/half-bridge-mosfet-driver-ic-irs21531d.html

thank u for ur caution yes I have like a 1meg in series with the signal line of the probe now I know u have similar wave form so tomorrow I will test it on the inverter and see the response and post it here because this is one of the most important circuits online and hard to find.

Hello Michael I tested the analyser today but dont know if its something with my probe or thats so it works. When i plug a small transformer into my house power outlet The wave form I get well somewhat looks like a sine wave its clean but some of the lines are croocked not straight is it that way urs show not able to post it here that others can see because not sure how to view the format it is saved in just want to clear this up but it works Thank u

hello Mr Swagatam I am putting together a proble to use on the pc scope Mr Michaeil recomended so I will be able to give u a better report on the project. Thank u for ur help to us

The frequency will influence the voltage so I think you cannot change the frequency once it has been decided in the design.

The cdi circuit gives an idea regarding making a basic inverter ferrite trafo which can be studied and modified further through trial and error, however taking a professional help could be even better.

yes the formula would hold good even for a ferrite trafo.

Hello Michael,

You can take the help of the following circuit which is actually a CDI circuit, however it can be referred to as a classic mini Ferrite core inverter.

https://www.homemade-circuits.com/2013/10/universal-multi-spark-enhanced-cdi.html

ferrite transformers are always smaller and much efficient than iron core counterparts. however their calculations could be entirely from the iron core types so first you will need to find out the exact dimensions, turns, thickness etc for getting the right trafo with the right specs.

Hello Michael I am so sorry I did not see your reply I though u had forgotten me. This is so help full now I know someone else has the same problem with the 1khz frequency at the output like I have and a cap accross has corrected it. I will try pin 2 and 3 but should we still connect pin 10 to pin 15. I really thank u foor telling me about the visual analyser. I will do the changes and post it here so everyone can know the progress. Happy too know of your sucess with yours so have u built the voltage correction section as yet to see how well it works because this is crusial in an inverter. we really thank Mr Swagatam for helping us. Looking forwart to hear from u.

yes the trafo will have a ferrite core, however now the dimension will become too small compared to the iron core trafo………wires will be always copper wires.

here's one example of a compact ferrite cored inverer, although here the application is intended as a CDI unit, the concept is of an inverter:

https://www.homemade-circuits.com/2013/10/universal-multi-spark-enhanced-cdi.html

I still await ur help to move on and make this project be a success

yes LC filters are always recommended for such applications….so it could be the right approach.

voltage drop is one big drawback in such arrangements, you may refer to the following example and see how an LC filter is employed at the outputs of this simple square wave inverter circuit:

4.bp.blogspot.com/-khKat0UA8Jw/UITpCnNd7yI/AAAAAAAAA_A/8x-KAD2aHLE/s1600/simplest60%20Hz%20Inverter%20circuit%20diagram.jpg

I don't think the number of blocks have anything to do with the quality of the sine wave, it's the RMS optimization and harmonic filtration that are connected with sine wave performance.

ferrite material can handle high frequencies with great efficiency without generating heat, whereas iron stamping are specified for lower frequencies only, that's why i doubt that higher PWMs could reduce the efficiency of the inverer if an iron core trafo is used.

Hello Michael, I have just tried to introduce the concept of optimizing a flat square wave into a modified sine wave. We say modified sine because we optimize and match it's RMS with an conventional sine wave RMS.

The IC 555 becomes the simplest and the cheapest option for implementing this and that's exactly what I have tried to explained in the above and in many of my previous articles.

The harmonics are the only issue here which can be taken care of by employing suitable L/C filters at the output of the trafo.

We should keep the chopping blocks to some lower number, may be to 3 or 4 this will prevent the trafo from getting hot.

Alternatively we could go for ferrite trafos and increase the number of PWM blocks to as many numbers as possible and check the results.

The PWM blocks can be tweaked by increasing or decreasing the input frequency.

thank u my friend if u look in the post n dec 3 I have written again thank u for ur help

3524 will never produce pure sine wave PWMs, unless treated with external circuits as done above.

The circuit discussed above is a full fledged pure sine wave equivalent inverter circuit,,,, the external capacitor is only helping to the carve out the harmonics and to shape up the modified pure sine waves into conventional pure sine wave that we are more familiar with.

ok Mr Swagatam and Michael I have seen your great discoverys and success so what do i do now to move from where I am stuck. Congratulations Michael it seems u are well on your way to the final product great I await ur reply

yes that's right

Thanks Michael,

Useful update, thanks very much…the fets will start becoming hot once you use the actual power trafo with optimum load at the output.

Anyway i think you have a wonderful job without involving the 555ICs and only with opamps.

thank you Michaei I am using pin 2 and 7 as output now so I await the result of the questiond between u and MR Swagatam to continue because that is my problem now with the voltage being low when I connect the pwm, Thank u

….hence the name pulse width modulation

Michael, the PWMs will not influence the count of the blocks rather the thickness of the blocks, meaning with 10k slider shifted toward ground will decrease the thickness of the blocks and vice versa keeping the number of blocks always the same.

The above will read in the form of proportionately varying voltage when measured with a voltmeter.

the PWM output should show a voltage between minimum 0 and max near to 2/3rd supply volts when the 10k preset is varied from ground to positive.

If this is not happening means your PWM circuit is not working or is faulty.

remove the pwm and then check the output freq, if it reads 50hz would mean your circuit is correct and the 1kHz after pwm connection is simply a misinterpretation or inability of your meter.

Actually a scope is strictly recommended for such projects.

Hello Mr Swagatam I am up again with the inverter and ready to test again. without pwm i am getting very high volts which is normal with the pwm diodes connected i get 104v but as I said before the gate voltage falls I adjust pot 10k to the positive as u said above in a post but this only brings it up to about .9v and the output frequency at the transformer is about 1khz and not 50hz as it was before without pwm. I am designing 120v system please help us here Sir

Thank u Mr Swagatam for ur reply I will try to do the adjustment and try again because we are determin to get it to work. We all appreciate the work that Mr Robin Maechaeil Majumdar and many others are doing to make it a success.As soon as I get more fets I will power up again Sir and let u know the results

250V or 280V trafos could be difficult to get in the market.

1) keep the 10k preset toward the ground and make sure the PWM output the IC shows near 0V in the voltmeter.

2) wider pwm blocks will force the mosfet to conduct more which in turn will allow more votlage/current into the trafo

I have updated the latests from Mr. Robin.

hello Alex,

it could have burnt due to excessive current….increasing voltage increases current too….you should have increased the voltage by keeping the PWM to lowest point.

hello Mr Swagatam I did not get to do more testing because i raise the voltage to 24v and imidiatly the output fet burst into flames so I have to go and try again. At 12v it was ok. Mr Robin is having quite similar heating so please help us here Sir. Thank u

inductor won't help the cause according to the latest reports from Mr. Robin.

yes that's right

yes pwm may give rise to heat in the trafo, so better to first filter out the high frequency content and carve the waveform into a decent looking sine equivalent, it could be done using a LC filter, not an RC.

yes, it can be tried. but RC will not do…you can try only with a high value Cap…may be 2200uF across center tap and ground.

1) step down trafo is not required because current is immaterial here.

2) a filter cap can be added at the base/ground of the transistor for better response

Hello Mr Swagatam thank u Sir I understand your explanation quite well about the pwm chopping up the wave form into smaller sections . The thing I am asking u is if it is normal for the gate voltage to drop from about 4v down to .08v when pwm is applied to the gates this is what i need u to answer Sir . Thank u. I think this is one of ur busy blogs because it is very informative and looks promising. I await ur reply

the gate voltage will depend on the space width of the PWM, if you have increased it to an extent which corresponds to zero voltage then the gate voltage would also drop to zero….adjust the 10k preset toward the positive for reducing the space width and for increasing the gate voltage.

Hello Alex, the 4017 output is responsible for triggering the mosfets with the intended 50 Hz frequency…one mosfet turned ON 50 times per second to produce the upper half cycle….the same for the other mosfet which creates the lower half cyces 50 times per second.

If your 4017 IC gets the required 100Hz pulse at its pin#14 hen this function will execute correctly and the output will show 50Hz.

When the diodes are introduced at the gates of the msfets, the PWMs cut the above 50Hz cycles at the mosfets gates into fine segments such that the average output RMS gets optimized at the rated voltage (220V here). this is controlled by Increasing or decreasing the space ratio of the PWMs.

I hope this clears your doubts…

the waveform shown by Mr Robin Peter above operations distinctly evident.

In systems that have no load correction, the maximum voltage is set for the optimal level (example 220V), means from here the voltage will only go down when its loaded, it can stay stable but surely cannot rise at any cost.

whereas in our system, the max voltage is set for 400V or more and is optimized at 220V according to the load conditions by the correction circuitry, in the above example it's done by automatically adjusting the voltage at pin#5 of the relevant 555 IC.

hello Mr Swagatam today i made a change on the circuit i put a 2.2uf cap accross the transformer out and I got back the 50hz when I check before it was actually giving me about 1089khz at the AC volts out but with the cap i am getting a difference. Dont know if this is a right approach.another thing I should youI notice when i connect the diodes is I see the gate voltage falling from about 4v to .08 is this normal. well reaching so far i dont know what kind of waveform i am getting now because I dont have a scope. Any other word from Mr Robin or Miacael about their progress. I await ur usual support Sir

thank u Mr Swagatam I read the blog and now i understand the function u made it so simple . So the 10k would be to adjust the pulse width at the gates of the fet. so I think this will adjust the output voltage at the secondary of the transformer Sir. please correct me if I am wrong.With regards to the 2khz what i am saying is at the output of the transformer when I connect the diodes the frequency changes to 2khz instead of 50hz so I wanted to know what was wrong here because u said I should still be getting 50hz only chopped at smaller pieces please help me here sir thank you

hello Alex, you can go through the following for understanding the role of the mentioned 555 IC and the 10K preset:

https://www.homemade-circuits.com/2012/12/how-to-use-ic-555-for-generating-pwm.html

The 2khz is the PWM for optimizing the RMS only, and will not change the 50Hz cycleit will only chop the individual pulses of the 50Hz….so the output frequency will remain = 50Hz.

hello Mr Swagatam thank u for your usual support to us . I know that the transformer should be about 6-0-6 for 12v supply but my transformer is just 10-0-10 the voltage is not a problem to me now because I know the transformer ratio. What I wanted u to do was to explain what is the purpose of the middle 555 and the use of the 10k at pin 5. The other problem with me getting 2khz at the output of the transformer is this a case that I need a filter now to get rid of the 2khz frequency now so as to see the 50hz usable frequency. This is where I need u to clarify for us and we appreciate ur support to us all. Thank u sir and I await ur answer

yes, he got over 500V with a 12-0-12V trafo using a 26V batt

it will display the average voltage for the negative and positive half cycles, irrespective of AC or DC, so it's fine to use it according to me.

Yes, forcing a higher voltage into the low voltage winding will force equivalent higher voltage across the output winding than the actual rating.

we are not interested to run the trafo at this forced voltage as it will heat up the trafo, it's here where the PWM comes into play for adjusting the output to the optimal 220V level.