In this article I have explained how to build an automatic battery charger circuit using dump capacitor concept for self detecting and charging a multiple set of batteries. The idea was requested by Mr. Michael.

Circuit Objectives and Requirements

- My name is Michael and live in Belgium.

- I found your site thru google during my search of a battery trickle charger.

- I've checked all 99 battery chargers but couldn't find one that maintains multiple batteries.

- I'm still looking for a good circuit, therefore I hope maybe you can help me out.

- At home we have a variety of lead acid batteries and during the winter most of them get neglected.

- Resulting in spring, a check which battery made it and which one didn't.

- Problem is the variety of batteries I'm a biker, my brothers has a small excavator and tractor, we have 2 vans with 2 caravans and we ( I, mother, sister, 2 brothers and there girlfriends) all have a car.

- So you see a WIDE variety of batteries, in the past I've bought a smart 7stage charger but it is impossible to take care of all batteries using only one charger.

- So I ask if you could design a circuit for me.

- With the following specs:

- Maintain at least 5 or more batteries simultaneously.

- Checks voltage if low dumps a capacitor into the battery.

- Able to handle capacities as low as 3 Ah up to 200Ah.

- Safe to operate 24/7 with no user input.

- Some of the things I've given some thought:

- With the use of a cap dump, there's no need for a heavy mains transformer, because the load for transformer is under control.

- A selectable capacitor depending on the capacity of the battery.

- A problem for me was to find something that could activate multiple outputs on a time base(using a lm311 to sense the voltage, a 555 to dump using mosfet).

- An indicator of some sort, which will indicate which battery needed the most dumps or immediate dumps, and locate bad batteries.

- If you believe I've made some errors, or my requirements are impossible please let me now.

- If you could implement extra features or safety features, I didn't think of do not hesitate to add or modify:)

- I'm a student getting a bachelor in Electro Mechanics, I'm a electronic enthusiast, have a room full of components and parts to play with.

- But I lack the designer skills for building circuits for my needs.

- I hope to have drawn your interest in this problem and hope you find the time to design something for me.

- Maybe this circuit could become number hundred on your site!

- Also great job with your site and hope al the best for you!

The Design

The discussed circuit concept for automatically charging multiple batteries using dump capacitor can be fundamentally divided into 3 stages:

- opamp comparator detector stage

- IC 555 ON/OFF interval generator

- dump capacitor circuit stage

The opamp stages are configured to maintain a continuous sensing of battery charge level, and correspondingly execute the cutoff /restoration of the charging process across the batteries attached with their relevant inputs. The charging process is carried out through capacitor dump system.

Let's undersatnd the various stgaes elaborately:

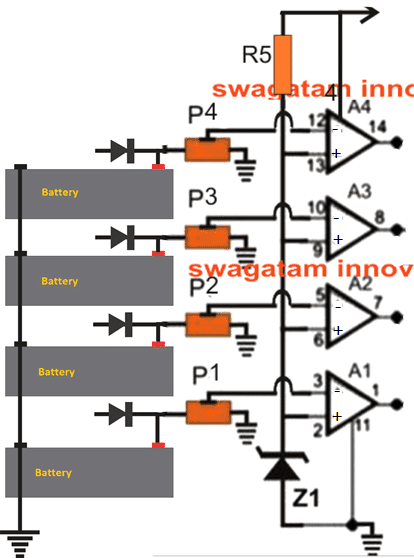

Self Regulating 4 Battery Opamp Charger Circuit

The first stage within this design is the opamp battery over charge detector circuit, the schematic of this stage can be seen below:

Parts List:

opamps: LM324

presets:10K

zener 6V/0.5 watt

R5 = 10K

diodes = 6A4 or as per the charging specs

We will consider only 4 batteries here, and therefore use 4 opamps for the respective over charge cut offs. A1 to A4 opamps are taken from the quad opamp IC LM324, each configured as compartaors to detect the attached corresponding battery over charge levels.

As can be seen in the diagram the non-inverting inputs of each of the opamps is configured with the relevant battery positives for enabling the required sensing of the battery voltages.

The positives of the individual batteries are connected with the capacitor dump output, which I will elucidate in the later part of the article.

The inverting (-) pins of the opamps are designated to a fixed reference level through a single common zener diode.

The presets attached with the (+) or the non-inverting inputs of the opamps and are used for setting up the precise full-charge trip points with respect to the corresponding (-) pin zener reference levels.

The presets are set such that when the relevant battery voltage reaches the full charge level, the proportionate value at the pin(+) of the opamp just goes above the (-) pin zener reference level.

The above situation instantly turns the opamp's output from its initial 0V to a high logic equal to the supply voltage level.

This high at the opamp output triggers an IC 555 atable circuit so that the IC 555 is enabled to produce a periodic ON/OFF intervals over the attached capacitor dump circuit...the following discussion have explained us the proceedings:

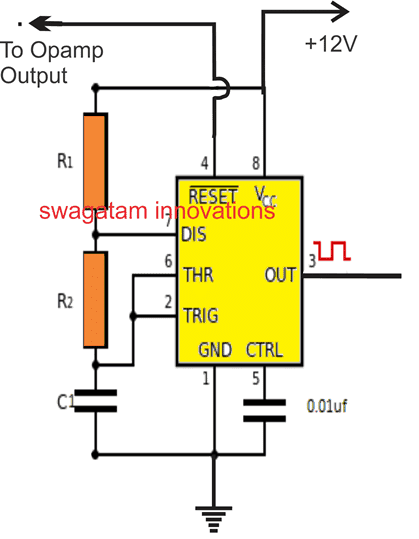

IC 555 Astable for Generating periodic ON/OFF

The following schematic shows the IC 555 stage configured as an astable for the intended periodic ON/OFF switching generation for the subsequent capacitor dump circuit.

Parts List

IC = IC 555

R2 = 22K

R1, C2 = calculate to get the desired charge dump cycle rate

As shown in the above diagram, pin#4 which is the reset pinout of the IC 555 is connected with the output of the relevant opamp stage.

Each of the opamps will have its own separate IC 555 stages along with the capacitor dump circuit stage.

While the battery is in the charging process and the opamp output is held at zero, the IC 555 astable stays disabled, however the moment the relevant attached battery gets fully charged, and the concerned opamp output turns positive, the connected the IC 555 astable becomes activated, which causes its output pin#3 to generate a periodic ON/OFF cycles.

The pin#3 of the IC 555 is configured with its own individual capacitor dump circuit, which responds to the ON/OFF cycles from the IC 555 stage and begins the process of charging and dumping a capacitor across the relevant battery.

To understand how this dump capacitor behaves in response to the IC 555 ON/OFF cycles we may have to go through the following section of the article:

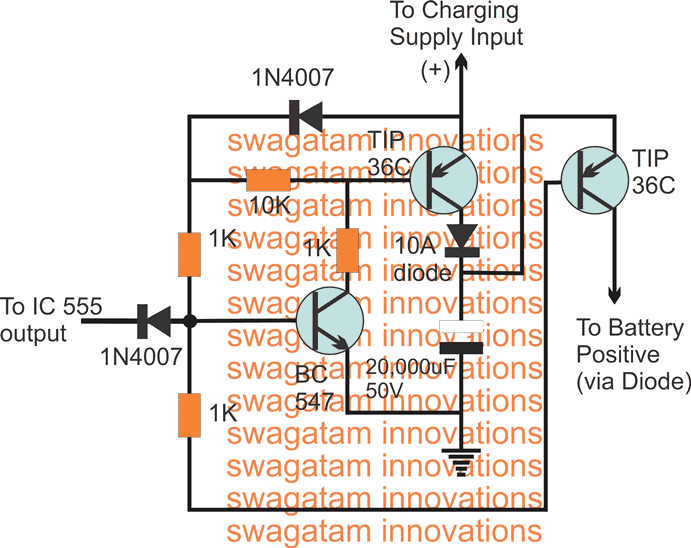

Capacitor Dump Charger Circuit:

As per the request the battery is required to be charged through a capacitor dump circuit, and I came up with the following circuit, I hope it would do the job as per the expectations:

The circuit functioning of the above shown capacitor dump charger circuit can be learned following explanation:

- As long as IC 555 stays in the disabled state, the BC547 is allowed to get the required biasing through its base 1K resistor, which in turn keeps the associated TIP36 transistor in the ON position.

- This situation allows the high value collector capacitor to get charged to its maximum allowable limit. In this position the capacitor is armed in the charged stand-by position.

- The moment IC 555 stage gets activated and begins its ON OFF cycle, the OFF periods of the cycle switches OFF BC547/TIP36 pair, and switches ON the extreme left side TIP36, which instantly closes and dumps the charge from the capacitor into the associated battery positive.

- The next ON cycle from the IC 555 reverts the situation into the previous conditions and charges the 20,000uF capacitor, and yet again, with the next subsequent OFF cycle the capacitor is allowed to dump its charge via the relevant TIP36 transistor.

- This charging and dumping operation is carried out continuously until the corresponding battery becomes fully charged, forcing the opamp to turn OFF itself and the whole proceedings.

All the opamps work in the similar manner, by sensing the attached battery condition and self starting the above explained procedures.

This concludes the explanation regarding the proposed automatic multiple battery charger using capacitor dump charging, if you have any questions or doubts, do not hesitate to communicate through comments...

Hello again, What charging supply voltage do you think should be used for the dump circuit when charging a 12v battery? I know you’re limited by the 50v cap voltage. The higher the voltage, the more joules could be pushed into the battery. The TIP36C can handle quite a bit, but the energy can be pretty high.

Thanks again,

Ken

Hi Kenneth, the current capacity of the capacitor depends on its uF value, higher the uF value higher will be the current delivering capacity. If this capacity is much lower compared to the battery’s Ah value then the voltage won’t matter and could be of any level (within the capacitor’s maximum limit).

Energy depends on the uF value of the cap

Hi Swagatam, Make sure I am understanding the battery voltage set point. If I want the battery charged voltage to be 15v, I would use a 15v zener diode. If I wanted to make that set point variable, I could use a 30v zener, then a pot as a voltage divider to get a 0-30v variable set point.

Thanks, Ken

Hi Kenneth, the zener value is not critical, the preset adjusts the cut off point according to the zener value, but the zener value must be lower than the battery voltage.

Super Capacitor Chargers.

Do you have a diagram of a supercap charger?

I’m trying to charge a 6pack 2.7 v 120F super capacitor.Any Help would be appreciated. I’m trying to charge it with a 12v motor generator it will not except the output of the Gen. Ivan charge it with a battery charger and a 110/12v power supply ,but not with the MGen, Can you help me.

Jim

Hi, if the voltage of the super capacitor is 2.7 V then you must make sure that the 12 V from the motor is appropriately reduced to the 2.7 V level. You can do it through a buck converter, after rectifying the motor through a bridge diode network

Could you use the same sort of setup injunction with multiple alternators to develop a system to maintain power

sir i wanted to know the batteries are interconnected in a battery back so the charge flows through all the battery for 4S and 2P.

how to have a voltage check circuit for a individual battery in a battery pack??

Ashutosh, yes the cells are connected in series inside a battery pack….since they are tightly sealed, there’s no way to check individual battery conditions.

I have a battery pack for an older (2003) hybrid Civic, with twenty 6.5 Amp Hr. battery sticks. I would like to charge and cycle them safely, 3, 4, or more at the same time. As the circuits for DIY stuff get expensive quickly, I saw this circuit using dump capacitors and thought it could be adapted cheaply to NiMH type batteries. The battery sticks are out of the car, and will be out of the pack.. Do you think this is a worthy direction to go?

Many thanks!

Battery charger circuits are not expensive at all, in fact the dump capacitor circuit can be more expensive than a standard charger. You can make the following circuit and implement it for your purpose:

The resistors will need to be calculated as per your battery Ah specs, and the preset R2 will need to be set such that the output voltage is slightly lower than the full charge limit of the battery

Good day sir. I must say that you a good and an experienced teacher in this field. I want to learn electronics, starting from how to read schematic diagrams to how to build projects with them but I have no one that can show me the kindness in that part.

Thanks Alexandar, learning electronics can be a long process which may require a lot of patience, understanding and practical experimentation. If you have specific questions you can ask here, I will try to guide you as far as possible.

I love all these and want to learn them. I wish I could be taught the basics of electronics by you. From your responses so far your audience I can tell that you are really a good and an experienced teacher indeed. Once, I wanted to charge a capacitor that could be used as a power bank for my mobile phone but, I ended up dropping the idea because, I do not know how to go about it.

Thank you very much, however a charged capacitor cannot be used for charging a cellphone, you will need a battery bank for that.

Hi sir Swagatam!

Thank you for your generosity and your time! I am going to do this.

You are welcome Luimem, wish you all the best!

Hi sir, I just wanna say a very big thank you for being there for those of us who are inspired to be like you sir, God bless you abundantly.

Thanks Joseph, I appreciate your thoughts.

Hi Mr. Swagatam, Thank you for answering me. Do I have permission to make the PCBs of your schematics that I would like to try? please.

I would like your help too:

-I have a small electronic module “5015 # Bistable relay card” (I am the third replacement), because of its low power.

-You will be able to design a small electronic circuit, using mosfet perhaps, which would be able to pass a current of 1A to 30A.

-This circuit would be this way

order by the small bistable module: “www.ebay.fr/itm/5015-Carte-relais-bistable-5-12v-ideal-modelisme-/171298469945?var=” I thank you in advance for your generosity.

Hi Luimem, yes you can make PCBs for the shown schematics.

If you want to use a MOSFeT instead of a relay, you can do it by connecting the MOFET in the following manner:

1) connect the gate directly to the input signal, which must be around 12V DC.

2) Connect the source directly with the negative of the supply power.

3) Connect the LOAD between the positive of the suply and the drain of the MOSFET.

The MOSFET can be an N-channel MOSFET such as IRF540

Hi

Mr. Swagatam, I would like to test your capacitor charger circuit and as I do not know how to make artwork, could you please do it. Thank you for your generosity.

Hi Luimem, I am sorry, designing PCB may not be possible due to lack of time!

Hi mister Swagatam, I send you a big thank you for your advice and your drawings. Great to you and to your generosity I could concretize my little electronic circuits! It works wonders! You are a gift from heaven! Thank you !!!! May God bless you and fill you with long days. THANK YOU

You are welcome Luimem, I am glad my circuits are helping you. God bless you too!

Hello, sir, thank you for the attention and the time you have given my first message! Hoping to be a little clearer in my explanations this time. Can you help me to design an electronic circuit, battery charger having for power source, 12v / 13amps direct current. This circuit will have to be able to:

-to supply at its output a voltage of 14v with a current of 1 ampere max.

– to read the voltage of the battery to be charged and to be able to cut the load at 13.6v.

– to track between three batteries and to detect which one needs to be charged.

Thank you in advance.

Hello Luimem, for converting 12V to 14V you will need a boost converter, which you can find plenty on the net.

If you want to cut the battery at 13.6V then instead of 14V you can limit the output to 13.6V, and no cut off will be required in such case, because at 13.6V your battery will never get over charged so no need to cut off.

Tracking will not be required at 13.6V, simply connect the 3 batteries in parallel to the charger through separate current limiters using LM338, that’s all.

for LED tracking you can try this: https://www.homemade-circuits.com/3-step-dc-voltage-level-monitor/

Hi Luimem, I mistakenly read 13.6V as the battery cut off.

For load cut off you can try “4 led circuit” from this post:

https://www.homemade-circuits.com/how-to-make-current-controlled-12-volt/

Good morning, mr Swagatam, thank you for your generosity and for your website. I am an electronics enthusiast who unfortunately does not have the knowledge for the creation of electronic circuits. Could you help me for a circuit with two batteries of 12v / 13ah(number 1 and number 2) would be able to charge the number 2 through your capacitor dump circuit?, while the number 1 would feed this same circuit and another consumer (1ah)? With for example a NE555 which would switch a mosfet or a bistable relay to switch from one battery to the other. Thank you in advance. Hoping not to have been too confused in my explanations.

Thanks Luimem, sorry I could not properly understand the sequence. If possible please explain it step wise, if possible I’ll try to help!

sir i have 12v 2A transformer and i want bust it to be 12v 5A or 10A. Is there any way to make it?

sorry, no that may not be possible!

Hello

I am a noob in regards to this but would like to try an make a suggestion.

Due to the cost of the cap, can a common cap for all batteries be used an the transistor be triggered by the sensing circuit? This way we can cut the cost of this project allot.

Hello, the capacitor used is a standard or common electrolytic capacitor, it is not a super-cap or any other special type.

The capacitor must be switched ON/OFF in order to create the dump/charge effect, if it’s directly connected with the opamp output the dump/charge action will not happen and the circuit will not function as it is designed to function.

Good Day Sir,

can this charger charge a li-ion battery? and do you have a balancing charging circuit for multiple li-ion battery? pls can you provide me a link sir..

thank you very much sir..

Paul

Hi Paul, yes it can be used for charging any type of battery, just make sure to charge the capacitor with the right amount of current, depending on the battery type.

for Li-ion use the full “1C” current which may be equal to the batt’s AH rating, to charge the capacitor.

a balance charger must be used only if the batts are connected in series, you can refer to the following article:

https://www.homemade-circuits.com/lipo-battery-balance-charger-circuit/

good day, sirthanks for your valuable information

please help me i want a schematic for battery charger 110vdc (9 battery 12v 70ah)

You are welcome radwen, you can modify the following concept for your specific application

cordially

sorry i forgot to provide the link, here it is:

https://www.homemade-circuits.com/high-voltage-360v-battery-charger/

hi

Thanks for quick reply sir

I have finished the 127V DC power supply (battery charger) project, but the problem is that when I connect to the batteries the voltage rises above 157V DC and the current goes up 7-8A. Knowing that I did an experiment with a fully charged battery at the factory (total voltage 9 batteries 115V DC

Hi Radwene, which circuit did you use for the auto cut off?

And did you regulate the power supply output to 127V? If you regulate it then the voltage will never rise to 157V

hi swagatam concerning the cut off system I use your proposal based on aop 741 and relay

the test that I perform without connecting the cut off, I just feed the battery bank and I check the measurements

Radwen, the source input supply should be regulated at precisely 127V, otherwise the batteries may get damaged

hi swagatam already my power supply is not regulated

Do you have a way how the regulated 127 vdc

cordially

Radwen, what is the source of the voltage, is it from a transformer?

Good morning, mr Swagatam

yes I have a transformer P: 230 S: 120/130V AC 2000VA with a large model bridge rectifier solely

Thanks Radwen, in that case a circuit can be built with a triac to cut off the primary voltage whenever the secondary voltage tries to go beyond 127V, through a feedback link

hi

I replaced a transformer that gives 100 volts and added a capacitor 400 VDC 2200uF. Of course, after the diode bridge, the method was successful. The system operates from 110 VDC and CUT OFF when it reaches 129 VDC with a current of 0.6 amps.

What do you think

cordially

Glad you could solve it, but the auto cut off system will also cut off the supply for the earlier 156 V transformer….. so the cut off system will work for both the situations

good day,

I have no problem with the cut off system and for stabilization I used an auotransformer (servomotor) to guarantee stabilization at the primary

Thank you my friend, you served us well

No problem, wish you all the best!

hi swagatam.can u help me make an automatic battery charger with adjustable voltage and current, charging and full charge indicator,and can charge lead acid 6v and 12v batteries.these are my components:transformer 220ac,12 amps.12-0,capacitor 4700uf,16v electrolytic,diode 1n5400.looking forward.thnx.

Hi, Michael here,

Many thanks for the design and the quick response, I’ve got a few questions and suggestions;

On the first image I see a diode attached to positive terminal of the battery what is its purpose?

Also by using the pots P1 to P4 it would be best to use high resistive pots, maybe even split them up with fixed resistors .

Is there a way to prohibit multiple dumping of the different caps? In a way like:

Batt1 ok no dump; Batt2 nok dump; Batt3 ok no dump; Batt4 ok no dump; repeat cycle;1234, 12…

I believe it would be the easiest way to alter the duty-cycle of the 555 to be sure de caps are fully charged before dumping?

An extra sensing circuit to control the voltage of the caps would make the circuit to complicated?

Sincerely

Michael

Hi Michael, here are answers to your questions:

1) The diode ends (anodes) will connect with respective dump capacitor outputs or the collector of the right side TIP36 transistors.

you can use a high value resistance pots, but the value is not relevant because the opamp inputs have a high impedance, and it is the ratio across the pot slider arm that actually matters not the value…still a high value can be good as it will help reduce power drain across the pots.

same cap is not used for all the batteries….each battery is supposed to have a separate dump capacitor stage, linked with the diode of the battery positive, so each dump capacitor stage will work separately for their allocated batteries.

therefore each battery will be sensed separately and charged separately.

The IC 555 will be immediately switched OFF and rendered inactive as soon as the relevant battery is found to be charged, therefore capacitor dump cannot happen if the battery is fully charged.

By the way even if the the capacitor was allowed to dump, it will not be able to pass its charge into the battery if the battery is fully charged, the capacitor will have to retain the charge inside itself, because the battery will not accept anything extra.

Hi good day mr swagatam.. let me ask you.. please help me about this.. I have a power transformer which is have output of 33v and 36amps, input 220 v. I want this to be an inverter to provide a current to my household, can you please provide me a circuit and the solar pv to be used? Please please please

Hi Mark,

Please provide the following information which will help me to advise correctly:

1) Is it a center tap trafo or a 2 wire trafo?

2) what type of output do you require, a square wave, modified square wave or a sine wave?

Also note that for a 36Amp full current operation you may require a 200 AH battery.

Hi Swagatam,

guten morgen.eine sehr schöne schaltung und nicht kompliziert oder mit mikroprocessor.

viele grüße

walter

Danke Walter, ich bin froh, dass es dir gefallen hat …

sir can I charge 6 volts 4 amp lead acid battery directly to the secondary windings of 9v 200ma trafo? because if I put a rectifier to the trafo it lower the voltage to just 5v

Jindro, that can be very dangerous for the battery….you can use a minimum single diode as shown in the following concept:

https://www.homemade-circuits.com/make-battery-charger-circuit-in-15/