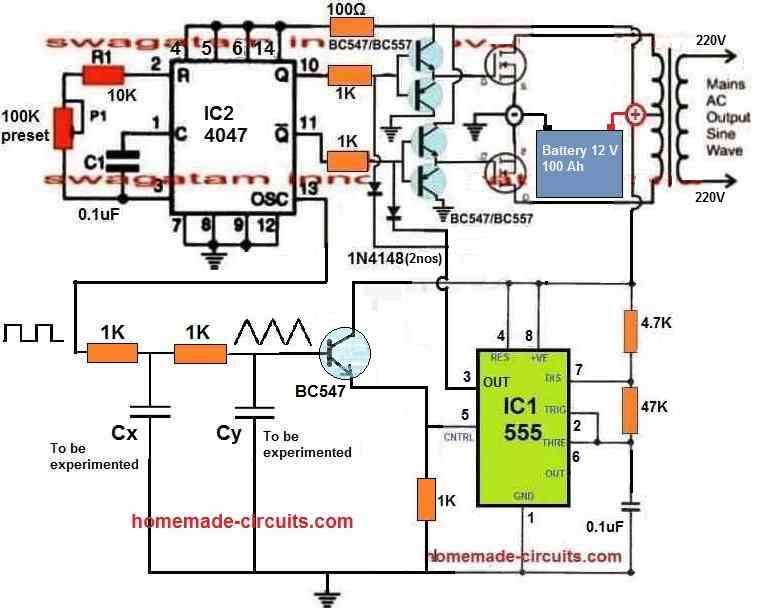

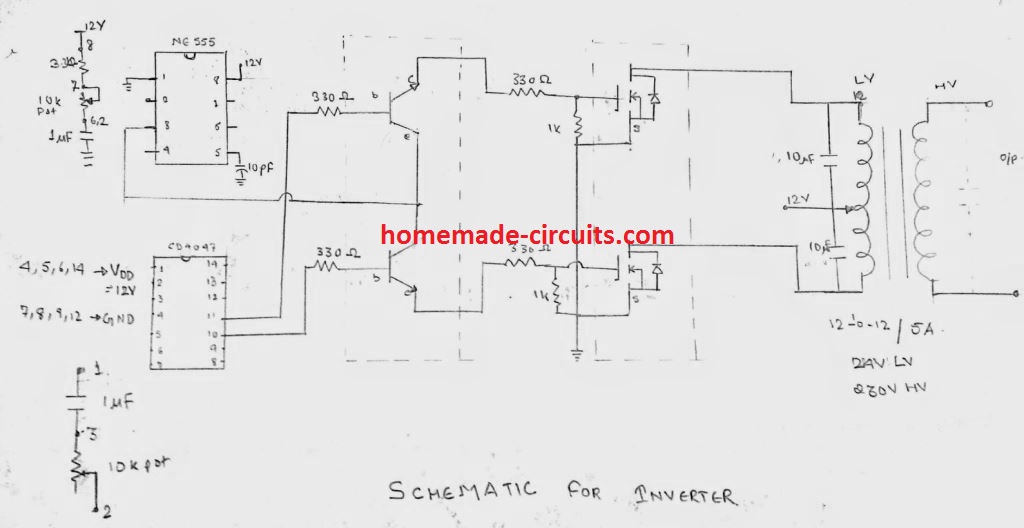

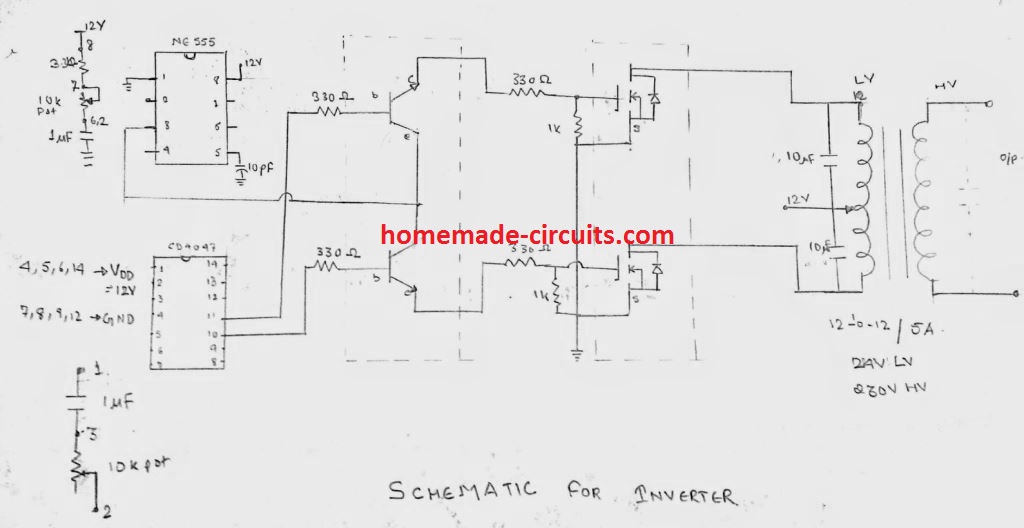

A very effective pure sine wave inverter circuit can be made using the IC 4047 and a couple IC 555 together with a few other passive components. I have explained the details below.

The Circuit Concept

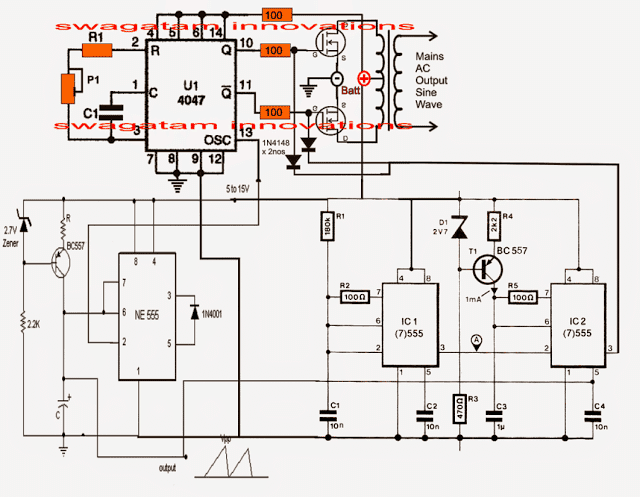

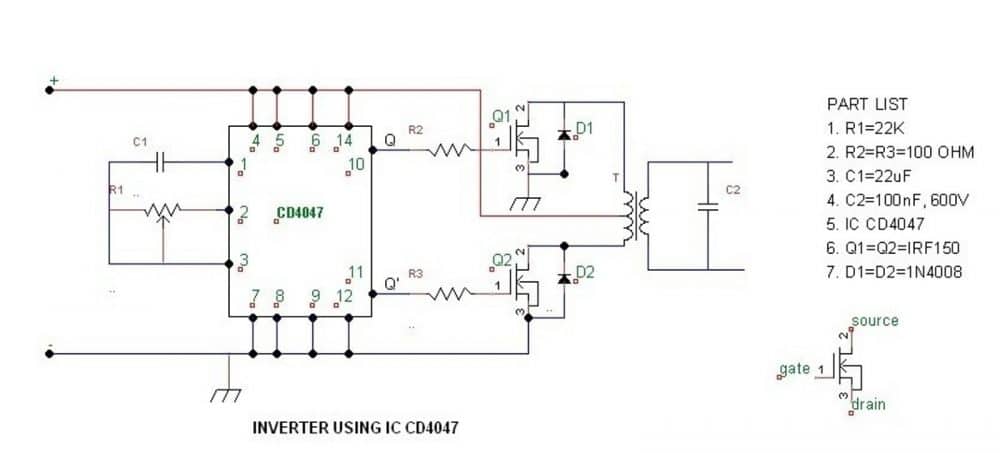

In the previous post I explained the main specifications and datasheet of the IC 4047 where I have explained how the IC could be configured into a simple inverter circuit without involving any external oscillator circuit.

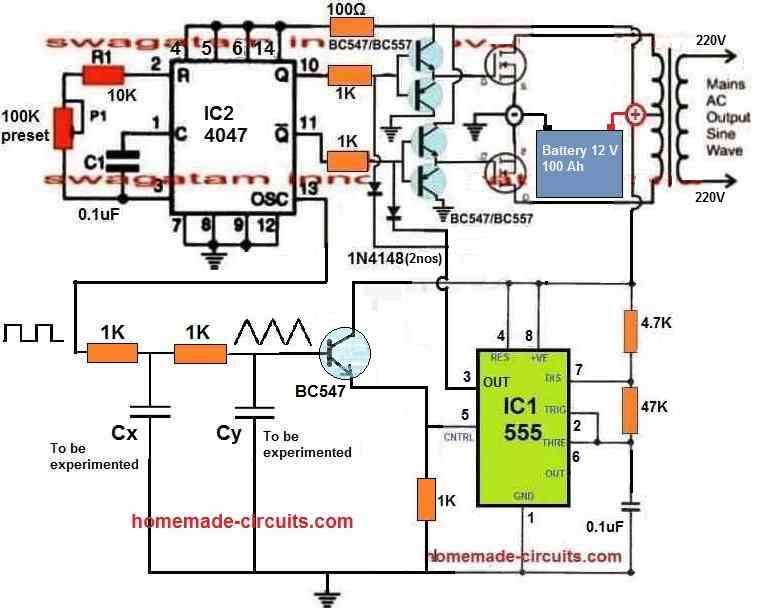

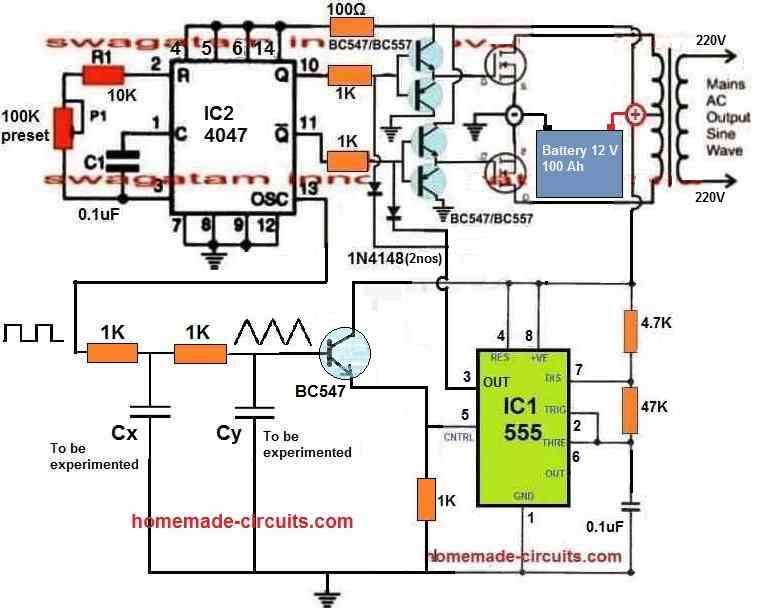

In this article we carry on the design a little ahead and learn how it can be enhanced into a pure sine wave inverter circuit using a couple of additional ICs 555 along with the existing IC 4047.

The IC 4047 section remains basically the same and is configured in its normal free running multivibrator mode with its output extended with the mosfet/transformer stage for the required 12V to the AC mains conversion.

How the IC 4047 Functions

The IC 4047 generates the usual square waves to the connected mosfets creating a mains output at the secondary of the transformer which is also in the form of square wave AC.

The integration of the two 555 IC to the above stage completely transforms the output into a pure sine wave AC. The following explanation reveals the secret behind the IC555 functioning for the above.

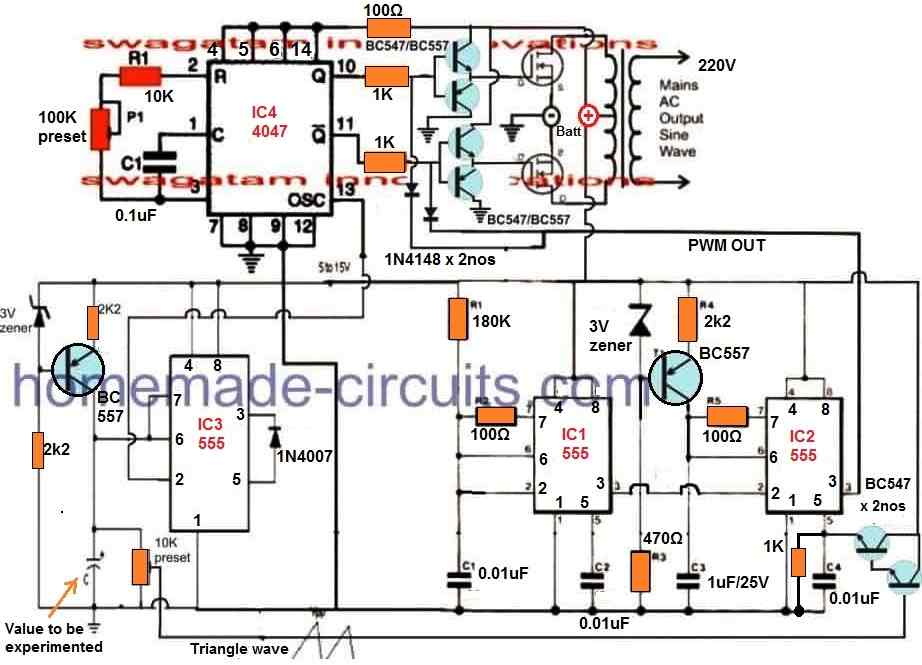

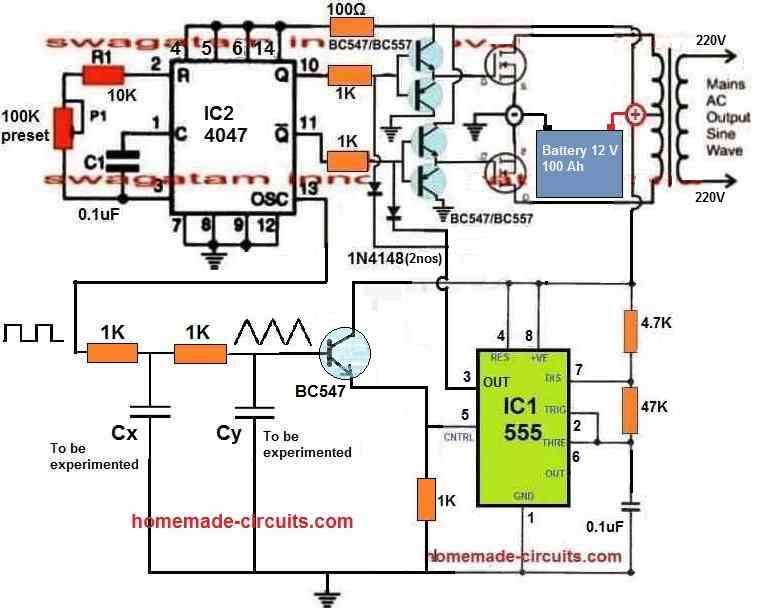

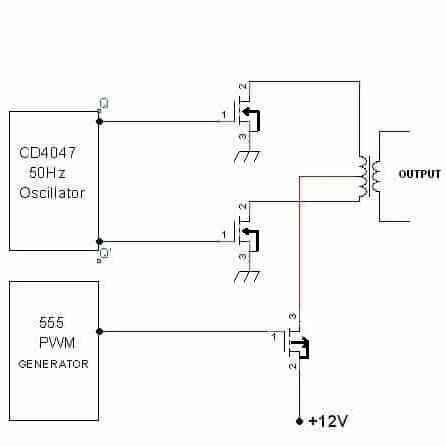

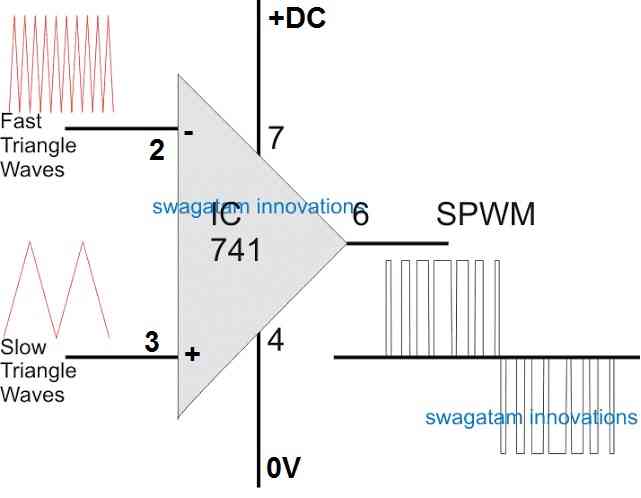

Referring to the below shown IC 4047 pure sine wave inverer circuit (designed by me), we can see two identical IC 555 stages, wherein the left section functions as a current controlled sawtooth generator while the right hand side section as a current controlled PWM generator.

The triggering of both the 555 ICs are derived from the oscillator output readily available across pin#13 of IC 4047. This frequency would be 100Hz if the inverter is intended for 50Hz operations, and 120Hz for 60Hz applications.

Using IC 555 for the PWM Generation

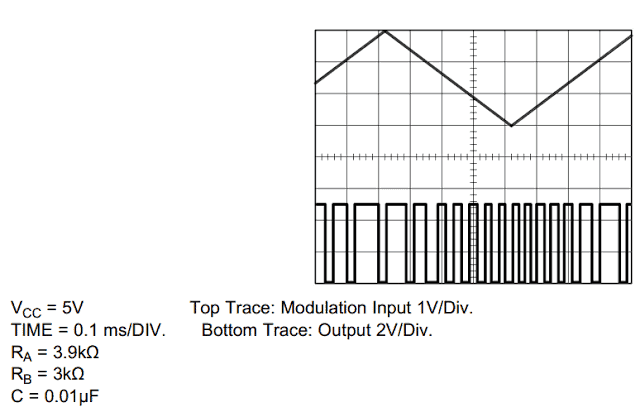

The left 555 section generates a constant sawtooth wave across its capacitor which is fed to the modulating input of the IC2 555 where this sawtooth signal is compared with the high frequency signal from pin3 of IC1 555 creating the required pure sine wave equivalent PWM at pin#3 of 555 IC2.

The above PWM is directly applied to the gates of the mosfets. so that the square pulses here generated through pin10/11 of IC4047 gets chopped and "carved" as per the applied PWMs.

The resulting output to the transformer also causes a pure sine wave to be stepped up at the mains AC secondary output of the transformer.

The formula for calculating R1, C1 is given in this article which also tells us about the pinout details of the IC 4047

For the NE555 stage C may be selected near 1uF and R as 1K.

Assumed output waveform

More info on how to use IC 555 for generating PWM

An RMS adjustment could be added to the above design by introducing a pot voltage divider network across pin5 and the triangle source input, as shown below, the design also includes buffer transistors for improving mosfet behavior

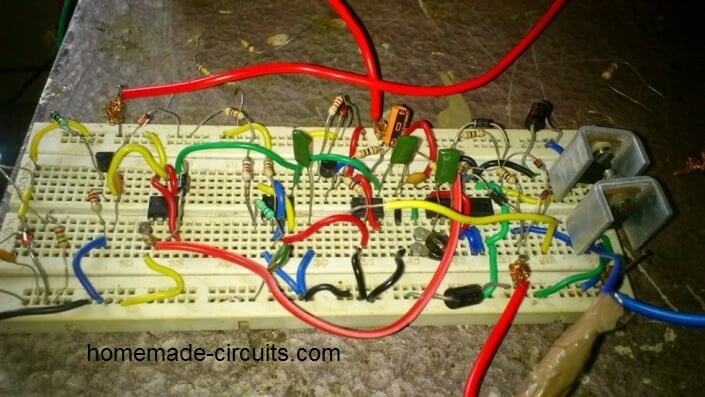

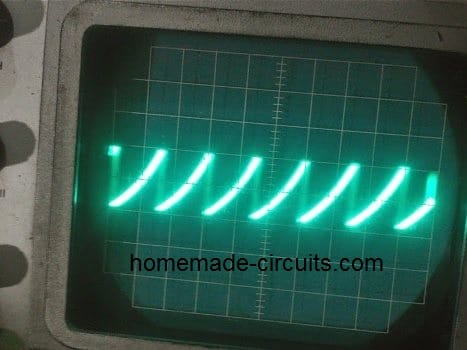

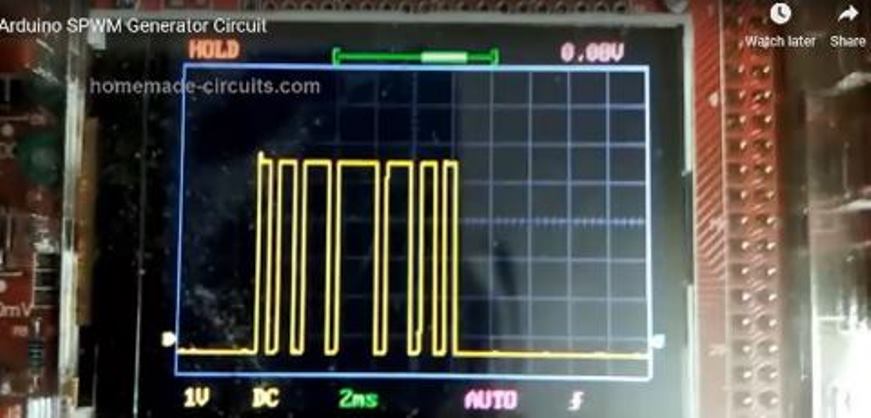

The above pure sine wave inverter design was successfully tested by Mr. Arun Dev, who is one of the avid readers of this blog and an intense electronic hobbyist. The following images sent by him prove his efforts for the same.

More Feedback

Inspiring response received from Mr. Arun regarding the above IC 4047 inverter results:

After completing this circuit, the result was amazing. I got full wattage by the 100 W bulb. Couldn't believe my eyes.

The only difference i had made in this design was replacing the 180 K in the second 555 with a 220 K pot to adjust the frequencies accurately.

This time the result was fruitful in all respects... On adjusting the pot, i could get a non disturbing non flickering full wattage glow in the bulb, also the 230/15 V transformer connected as the load gave a frequency in between 50 and 60 ( say 52 Hz ).

The pot was adjusted gently to get a high frequency ( say 2 Khz ) output from pin#3 of second ic 555. The CD4047 section better calibrated to get 52 Hz at the two output terminals....

Also I am facing a simple problem. I have used IRF3205 mosfets at the output stage. I forgot to connect the safety diodes across the drain terminals of each mosfets...

So when I had tried connecting an another load ( say table fan ) in parallel to the given load ( 100 W bulb ), the glow of the bulb also the speed of the fan was reduced a little and one of the MOSFET was blown due to the absence of the diode.

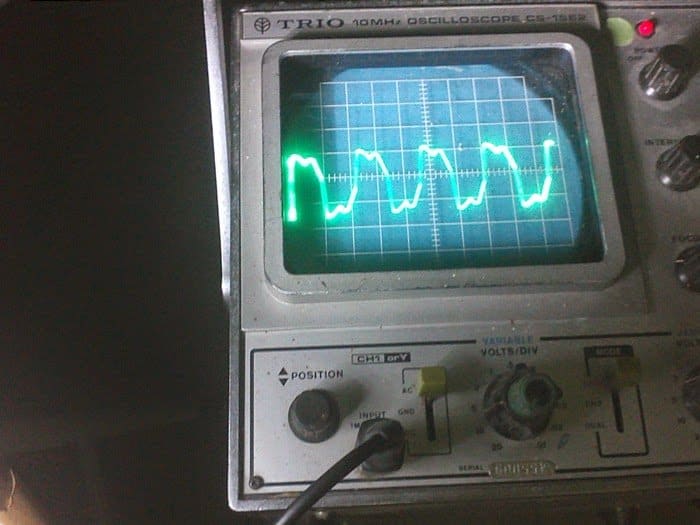

The above 4047 sine wave inverter circuit was also tried successfully by Mr. Daniel Adusie (biannz), who is a regular visitor of this blog, and a hardworking electronic enthusiast. Here are the images sent by him verifying the results:

Sawtooth Waveform Oscilloscope Output

Illuminating a 100 Watt Test Bulb

The following images show the modified waveforms at the output of the transformer as captured by Mr. Daniel Adusie after connecting a 0.22uF/400V capacitor and a suitable load.

The waveforms are somewhat trapezoidal and are far better than a square wave which clearly shows the impressive effects of the PWM processing created by the IC555 stages.

The waveforms could be probably even further smoothened by adding an inductor along with the capacitor.

Showing an near Sinewave Oscilloscope Trace after PWM Filtration

Interesting feedback received from Mr. Johnson Isaac who is one of the dedicated readers of this blog:

Good day

In your post, Pure Sine Wave Inverter using 4047, in the second I.c stage (ic.1) you used 100 ohms resistor in between pin 7 and 6.,

Is that correct? I use to think an astable multivibrator using 555 pin configuration should have the 100 ohms between pin 7 and 6. Also, the 180k variable between pin 8(+) and pin 7. Pls check the pin connection and correct me pls. Because it oscillate sometimes and it doesn't sometimes also. Thanks,

Isaac Johnson

Solving the Circuit Issue:

In my opinion, for a better response you can try connecting an additional 1k resistor across the 100 ohm outer end and pin6/2 of IC1

Johnson:

Thank you very much for your response. I actually constructed the inverter you gave in your blog and it worked.

Though I don't have an oscilloscope to observe the output waveform BUT I bet readers its a good one cos it operated a fluorescent tube lamp in which any modified or pwm inverter can't power on.

See the picture sir. But my challenge now is when I add load, the output flickers sometimes. But am happy its a sine wave.

Video Test Waveform

Simplifying the above Concept

The above explained IC 4047 pure sine wave inverter can be actually simplified greatly by eliminating two IC 555 configurations from the design.

The basic idea is to produce a synchronized sine PWM output for chopping the MOSFET switching so that this SPWM waveform is replicated at the output of the transformer and is transformed into a pure sine waveform. The complete circuit diagram can be seen in the following diagram:

In this simplified design, we yet again exploit the pin#13 square wave output from the IC 4047 and convert it into triangle waves. This triangle wave is then used to modulate the PWM output of a IC 555 astable to create the required synchronized SPWM for chopping the MOSFET gates.

The capacitors Cx and Cy will need to be experimented a bit to create a proper triangle waves from the RC network output.

Remember, you will need an oscilloscope to check and confirm the various waveform discussed in the above diagram.

Calculating the Cx and Cy Values for the Square wave to Sine wave Converter stage using RC Integrator

A 100 Hz frequency from pin#13 of the IC can only generate a crude sine wave using the shown double passive RC integrator circuit. We can make things easier by choosing the cutoff frequency fc to be pretty close to the fundamental frequency of the square wave which is fo and that happens to be 100 Hz. By doing this, we can reduce the higher harmonics a bit while still keeping that fundamental frequency intact. However if you want to get a decent sine wave, then remember we need to make sure that the input frequency is at least 300 Hz.

Formula:

The RC time constant relationship is:

fc = 1 / (2 * π * R * C)

R * C = 1 / (2 * π * fc)

For fc = 100 Hz:

R * C = 1 / (2 * π * 100) = 1592 * 10-6 seconds

Choosing Component Values:

First Stage (R1, Cx):

Choose R1 = 10 kOhms:

Cx = 1592 * 10-6 / (10 * 103) = 159.2 nF

Second Stage (R2, Cy):

Similarly, for the second stage:

R2 * Cy = 1592 * 10-6 seconds

Choose R2 = 10 k Ohms:

Cy = 1592 * 10-6 / (10 * 103) = 159.2 nF

Final Values for a Crude Sine Wave:

- R1 = 10 kOhms

- Cx = 159 nF (rounded to the nearest standard value)

- R2 = 10 kOhms

- Cy = 159 nF

Expected Output:

With these values our circuit will do a moderate job of cutting down those harmonics, and what we will end up with is a rough sine wave that has quite a bit of distortion. If you want to get things just right, you can tweak the values of the resistors or capacitors a little bit to fine-tune that waveform.

Another Simpler Looking Options

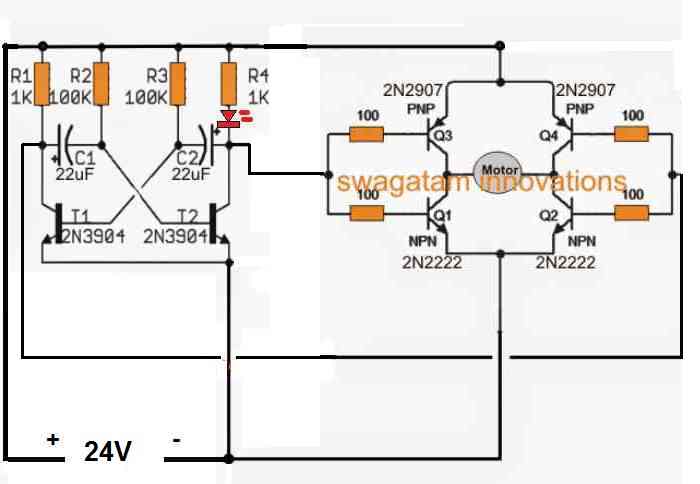

The following concept discuses a rather simpler method of modifying an ordinary square wave inverter using IC 4047 into a sine wave inverter through PWM technology. The idea was requested by Mr. Philip

Technical Specifications

I hope that i am not going to be a bother, but I need some advice with a PWM-controlled modified sine wave inverter I am designing so I want to seek your expert opinion.

This simple design is tentative, I haven't implemented it yet but I would like you to take a look at it and tell me what you think.

Also I want you to help answer some questions which I have not been able to find answers to.

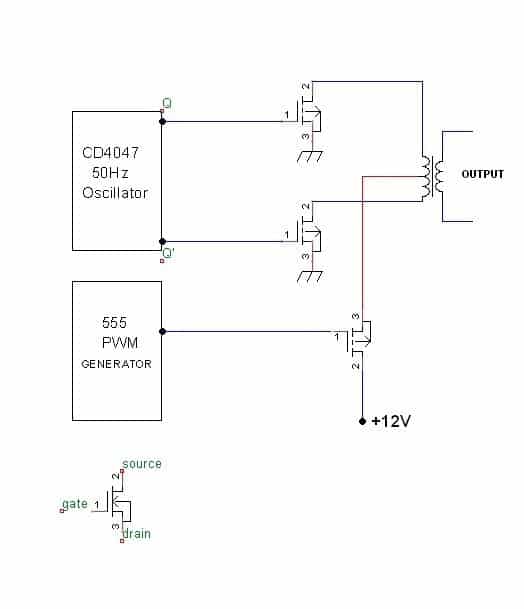

I have taken the liberty of attaching an image of a quasi-block diagram of my tentative design for your consideration.

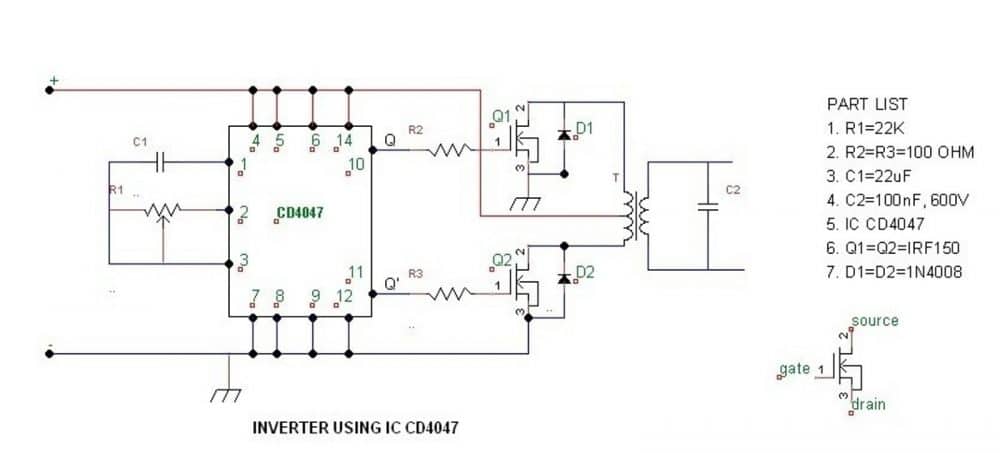

Please help me out. In the diagram, the IC CD4047 in the inverter is responsible for generating square wave pulses at 50Hz which will be used to alternately switch on MOSFETS Q1 and Q2.

The PWM circuit will be based on IC NE555 and its output will be applied to the gate of Q3 so that Q3 will provide the PWM. Besides this, I have two questions.

First, can I use square waves for the PWM pulses? Second, what is the relationship between PWM frequency and supply frequency? What PWM frequency should I use for a 50Hz inverter output?

I hope that this design is feasible, I think it is feasible, but I want your expert opinion before I commit scarce resources to implement the design.

Looking forward to hearing from you sir!

Sincerely, Philip

Solving the Circuit Request

The configuration shown in the second figure above would work only if the center tap mosfet drain/source pins are swapped and N-channel mosfets are used for the 4047 inverter oscillator output, as shown below:

The PWM section should be built as I have explained in this article:

The PWM transforms the flat square waves into a modified square wave by chopping them into smaller calculated sections such that the overall RMS of the waveform becomes as close as possible to an actual sine counterpart, yet maintaining the peak level equal to the actual square wave input. The concept may be learned in details here:

However the above transformation does not help to eliminate the harmonics.

The PWM frequency will be always in the form of chopped square waves.

The PWM frequency is immaterial and may be of any high value, preferably in kHz.

How to Add Feedback Voltage Control to a 4047 IC Inverter

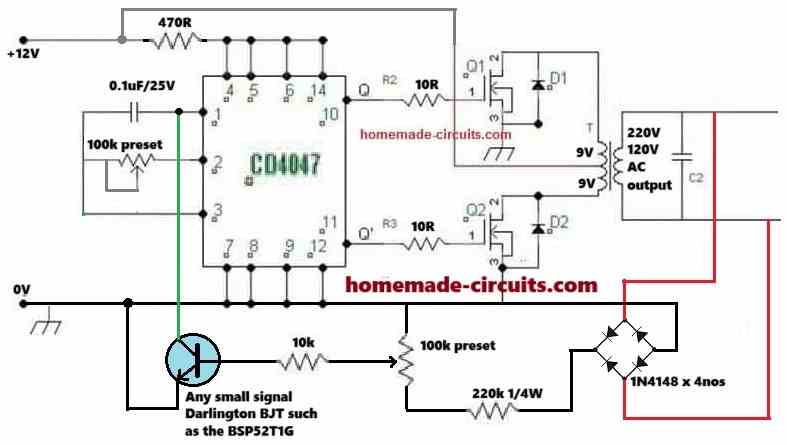

In this section we will discuss how to add an automatic feedback voltage control to a 4047 IC based inverter circuit.

If you don't want to read the whole explanation, you can watch the following video instead:

This type of feedback network is intended to ensure that the AC output voltage from the inverter never exceeds a predetermined safe value. For example, using this automatic feedback control, a 220 Volt inverter circuit output could be restricted to maximum 230V AC level, which may be safe for most 220 Volts appliances.

For a 120 Volt inverter system, this feedback network could be adjusted to restrict the output AC to a maximum of 115 Volts AC, which may be safe for most 110 Volt appliances.

How the Feedback Circuit Works

Now let's understand how the simple feedback network is designed to work, by referring to the following circuit diagram:

The mains AC voltage from the inverter transformer secondary is first converted to a DC voltage using a bridge rectifier.

This bridge rectifier is built using 4 numbers of 1N4148 diodes.

The DC 220 Volts output from the bridge rectifier is applied to an adjustable voltage divider network built using a 220 k resistor and a 100 k preset or trimpot.

The 100 k preset is carefully adjusted such that its central wiper terminal generates around 1.2 volts in response to an input AC voltage which is considered high, and needs to be restricted.

Let's say, the input AC needs to be restricted at around 270 Volts, then the 100 k preset may be adjusted so that its wiper terminal generates a proportional DC voltage level of 1.2 Volts.

We select a 1.2 Volt output because this is the equivalent DC level required to just switch ON the attached BJT device.

That means, whenever the inverter output AC voltage tries to exceed the 270 Volts mark, it causes the BJT to turn ON and become conductive.

When the BJT conducts, it starts grounding the CT pin of the IC 4047.

Since the RC network associated with the CT and the RT pinouts of the IC determines the output frequency and PWM, the grounding of the CT pin instantly causes the output PWM and frequency to nullify, which in turn causes the output AC voltage to dip.

When this happens, the feedback voltage to the BJT also drops proportionately until the BJT is turned off. In this situation the IC output PWM is restored back to its previous form, and if the output voltage continues to rise, it yet again activates the BJT via the feedback network, and this feedback on off cycle keeps repeating rapidly, ensuring that the output AC is not able to rise above the set threshold, which is 270 volts in our example.

This concludes our feedback control circuit explanation, now let's try to understand how this feedback circuit can be setup prior to integrating it with the inverter circuit.

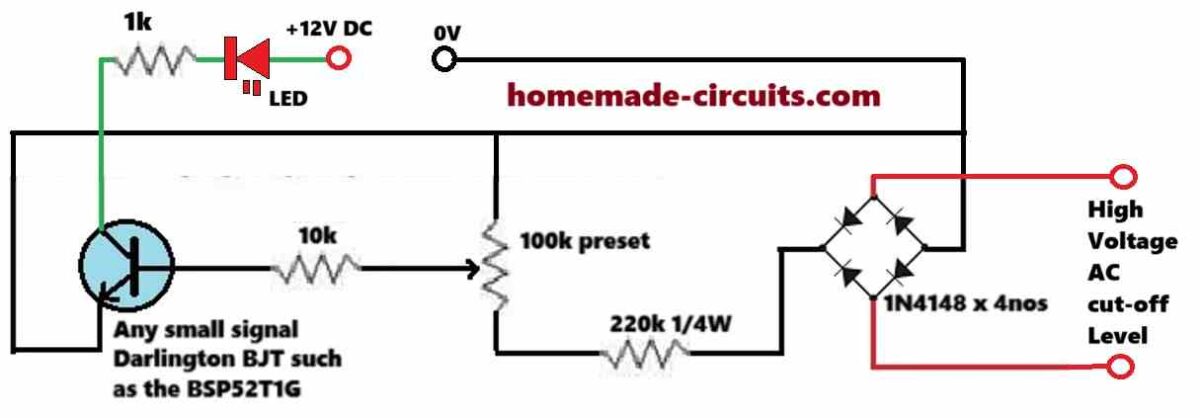

How to Setup

The next diagram below shows the isolated feedback circuit, which can be set up by implementing the following steps, before interfacing it with your inverter circuit:

Initially keep the 100k preset's wiper arm fully towards the ground side of the DC supply.

Now, switch ON the 12 DC supply and then switch ON the AC supply to the bridge rectifier whose voltage level is around the desired high cut-off limit.

Next, slowly adjust the preset using a well insulated screw driver, until the LED just begins to illuminate.

To confirm the results, try varying the input AC voltage around the cut-off threshold and watch the LED turn on and off at the thresholds. Although the cut-off may not be too sharp, yet it will do the job of the intended output voltage control of the inverter quite well.

That's it! This simple procedure should be enough to complete the setting up of the feedback circuit.

After this, make sure to seal the preset adjustment with some super glue.

So, this concludes our explanation on a feedback circuit for the 4047 inverter.

Pseudo-sinusoidal IC 4047 Inverter Circuit

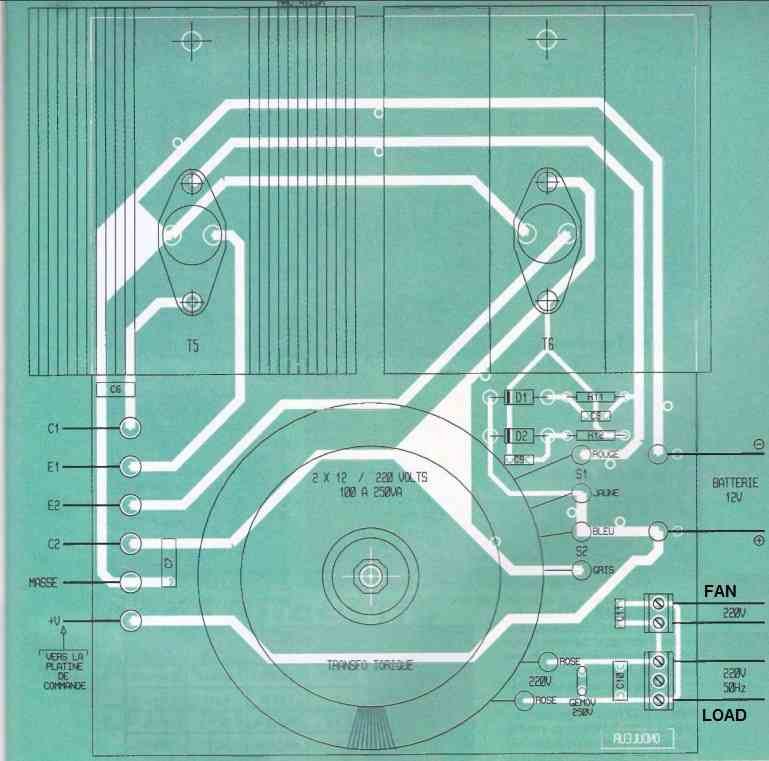

From a continuous source, battery, or vehicle alternator, it is possible to produce a 50 Hz voltage/pseudo-sinusoidal waveform, using this simple IC 4047 inverter circuit. The design is capable of operating many low-power devices that require a voltage of 220 V AC, typically supplied by the AC mains grid distribution network. The power of this module depends largely on the chosen transformer and, above all, on the continuous source's ability to supply the circuit without failure.

Working Principle of the circuit

Being able to power a device on the 220 V AC network when no mains AC power is available can be very convenient. We particularly think of campers, caravanners, fishermen, and motorists.

Although this simple setup does not provide a 100% clean sinusoidal wave, it can still satisfy many undemanding devices such as incandescent or fluorescent lighting, soldering irons, small motors, etc.

The power can reach up to 250 VA if the continuous source is strong enough and an adequate toroidal power transformer is chosen.

The power transistors are rated for 30 A, provided that a substantial heatsink is used.

We even suggest adding a small fan directly connected to the 220V output, which will prevent it from operating without a load.

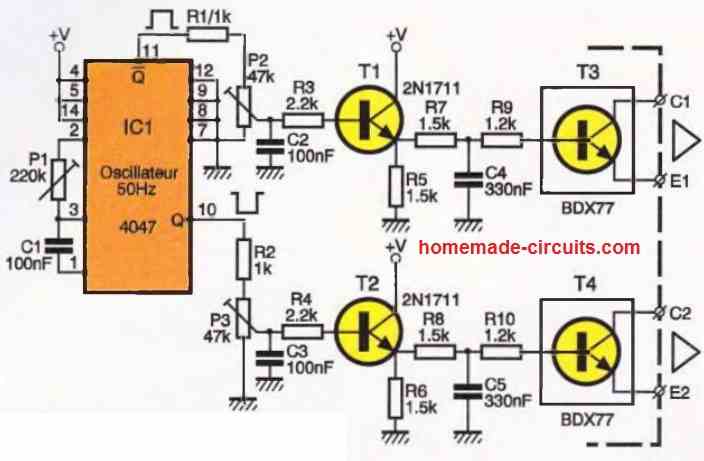

Analysis of the Circuit Diagram

To obtain an alternating voltage from a DC source, the simplest solution is to use an inverted transformer: the low-voltage secondary winding has a center tap.

It is then sufficient to alternately supply power to the two windings to produce a symmetrical, but non-sinusoidal, variable voltage on the primary side if the low-voltage secondary winding is driven by a rectangular signal with steep edges.

Two complementary and opposite signals are required, and the CMOS integrated circuit with the reference 4047 is used to generate them, capable of either building an astable or monostable flip-flop.

The proposed diagram is shown in the figure below.

Of course, we will operate our circuit as an astable generator, ensuring a precise frequency of 50 Hz. This task is entrusted to components C1 and P1. Some pins of the IC1 circuit are connected to the ground or the positive supply, depending on our needs.

For more information, you will find an explanation in the appendix about the multiple possibilities of this practical little integrated circuit.

The symmetrical square voltages available at pins Q and Qdash (corresponding to terminals 10 and 11 of the circuit) are routed through resistors R1 and R2 to an adjustable element. Its role is to balance the amplitude of the two signals and facilitate the adjustment of the control module.

Note that the duty cycle will be exactly 50% by design. The sliders of elements P2 and P3 control the base of a 2N1711 transistor, which is responsible for driving the downstream power semiconductors.

Components R7, R9, C4, as well as R8, R16, and C5, form a coarse filter capable of smoothing out the signal angles to some extent.

This will allow us to create a "pseudo-sinusoidal" signal that will control the intermediate transistors T3 and T4 mounted on the small control board.

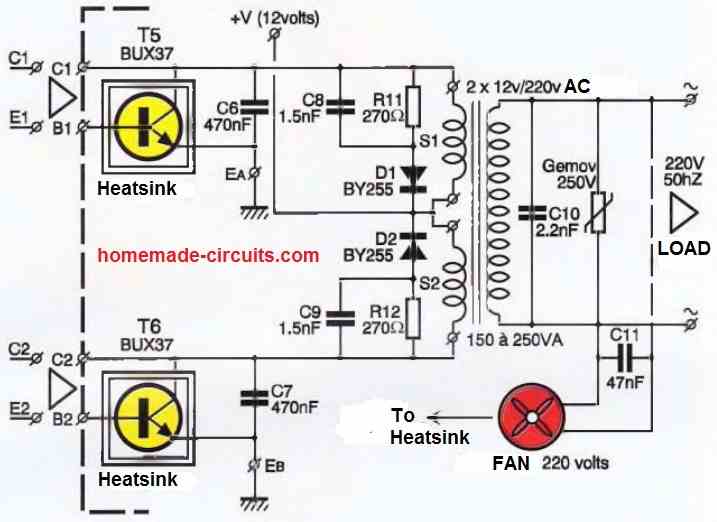

The BDX 77 models are rated for an emitter-collector voltage of 80V and a maximum peak current of 8A. They are delivered in a TO-220 package and will benefit from a heatsink.

The secondary windings of the transformer do have a common point connected to the positive pole of the power supply.

The other end of the coils will receive the ground through the power transistors T5 and T6, a model not much larger than the famous 2N3055 but with a maximum peak current of around 30A in this case.

It is the NPN bipolar model with the reference BUX 39.

Diodes D1 and D2 absorb the unavoidable breakdown current produced at each interruption of the inductive element, which is the transformer.

The primary of the transformer, a toroidal model in this case, delivers a 50 Hz AC voltage.

The component labeled Gemov (or varistor) is placed between the output pins to clamp excessive voltage surges that may occur.

Two wires can also be tapped from the output to operate a fan directly powered by 220V, which will provide airflow to cool the transistor-heatsink assembly.

It is important to ensure that the voltage of the continuous source does not drop too much or be completely depleted in the case of a lead-acid battery.

It goes without saying that the input DC current can reach considerable values if, for example, a power of 200VA is desired. It would be prudent to include a robust series fuse, similar to those found in a household installation.

Construction

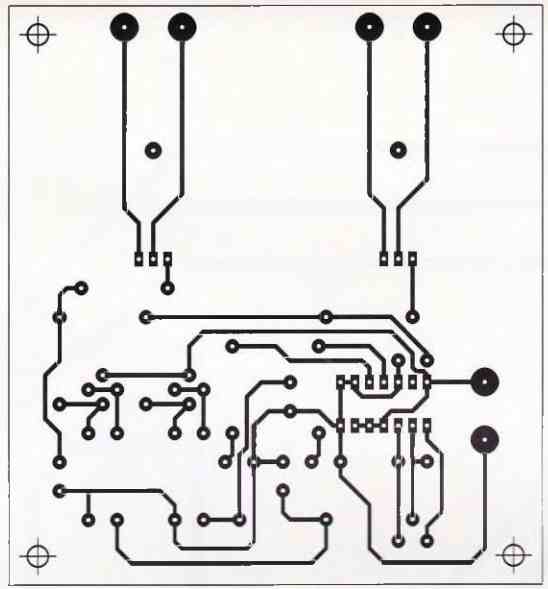

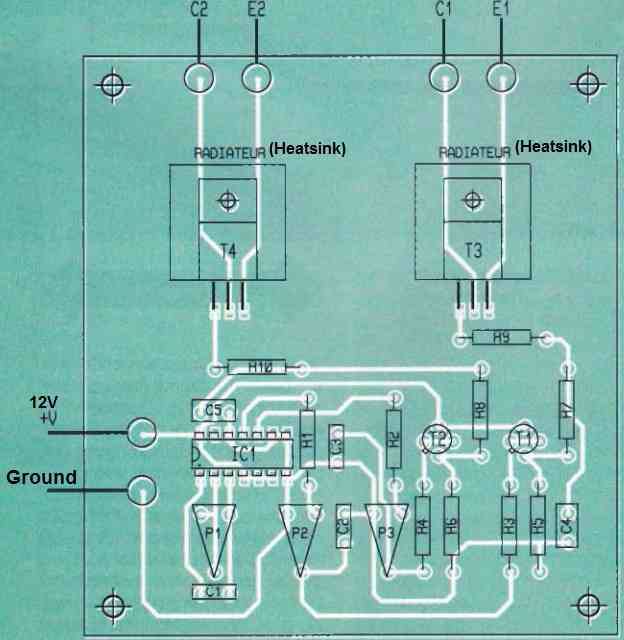

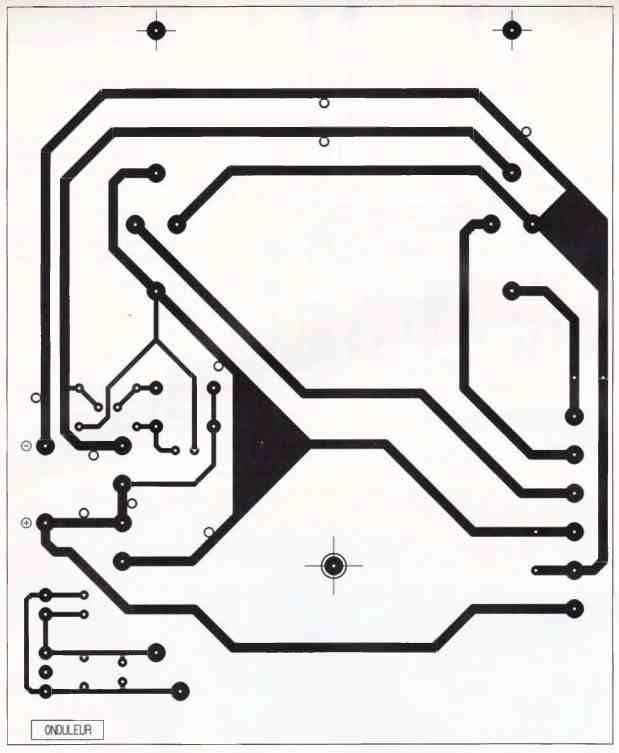

The creation of two printed circuit boards is necessary: the first one, shown in the figure below, is designed for the components described in the control module.

The layout is not very dense, but it is still recommended to use pre-sensitized copper-clad boards for reproduction.

After etching and rinsing, various drillings are carried out. Care must be taken to carefully mount transistors T3 and T4 on a small heatsink, which is directly attached to the epoxy board.

From this board, six wires will go to the significantly larger power module, and the track layout at a 1:1 scale can be found in the figure below.

It should be noted that certain tracks on this simple IC 4047 inverter circuit board will carry high currents and require special treatment. We recommend soldering bare copper lengths, with a section of approximately 1.5 mm2, directly onto these tracks.

For example, electrician's copper wire with the insulation removed can be used. Care should also be taken to ensure all connections between the two boards, and in particular, to avoid reversing the wires.

The transformer has six wires, with the two thinnest wires corresponding to the primary, and therefore our 220V output.

It is important to properly identify the other windings before soldering them permanently. This assembly can be housed in a sturdy, adequately ventilated metal enclosure.

How to Setup

We leave it to you to complete this final step for this simple IC 4047 inverter circuit. After a thorough check, the frequency can be adjusted to 50 Hz under no-load conditions using the adjustable preset P1, if you have an oscilloscope or frequency meter.

Otherwise, simply set this element to the midpoint position. The other two adjustable components are set to obtain a symmetrical signal in amplitude.

Initial tests can be performed using a simple socket where different power lamps can be connected. For resistive or slightly inductive loads, there should be no serious issues.

Proceed with caution when testing devices that typically require a true sinusoidal voltage.

" rel="ugc">

Good day sir, thanks for your articles.

I have been trying to tweak various values of CX, cy ranging from pf to nf but the waveform was still sawtooth, please is there anything to do to improve the quality.

However, the inverter was able to power what ordinary modified square wave inverter could not power.

Thanks sir, I appreciate.

Good day Seun,

In the shown RC passive integrator circuit, the voltage across CX should be a sawtooth and the voltage across CY should be transformed to sine wave. It is a standard RC integrator circuit and should produce the intended results.

You must try try adjusting the resistors also.

Or you can try calculating the parameters using any online software, or online formulas and check the results.

Ok sir, thanks for the enlightenments. please what values and parameters to use, I couldn’t get any online calculator to use, please assist Me

Seun, I have updated the calculations in the above article for the Cx, Cy values, please check it out….

Thanks for your input. please what is the effect of crude sine wave and it’s meaning. is there anyway to enhance it?

It is not too crucial, even with crude sine at pin#5 of the IC 555, the inverter output will produce a decent sine wave provided it is appropriately filtered through capacitors at the output. You can use 3uF/400V PPC capacitors at the inverter output.

Thanks sir for your guide, I noticed the frequency generator produced 1.4Khz with R1 4,7k and R2 47k at the 555 timer does it have any implication?

Seun, 1.4kHz is high for an iron core transformer, it should not be more than 300 Hz, so please adjust the capacitor value accordingly.

The duty cycle will control the output voltage.

Thanks for the 4047 inverter design, it produced a good sine inverter, but I have issues build the trafo, please which transformer design for the input voltage for 12v design because of voltage drop.

Thanks Seun,

The transformer center tap voltage should be equal to the average voltage that you measure at the output of the PWM 555IC

I want to make a 24v inverter design, I used a voltage regulator for the circuit but I don’t know if to use 12-0-12 or 15-0-15 trafo, please kindly guide Me.

You can try 12-0-12V first, and check the results…

Thanks sir, can a range of trafo rating from12-0-12v to 18-0-18v work for 24v inverter system? please what is the effect in this variation.

Seun, a 12-0-12v to 18-0-18v trafo will produce a very high output voltage if the inverter is a standard square wave type, but if it is a sine wave PWM concept, then a 12-0-12V should work fine with a 24V battery.

sir, I am encountering a big challenge, As I complete this setup, I discovered that the 555 circuit is being damaged and the 12v regulator after working for 30minutes, please what could be the problem?

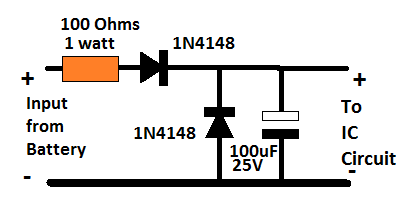

Hi Seun, please try connecting a 0.1uF and a 100uF capacitor, right across the pin#8 and pin#1 of the IC 555, and also connect a 12V zener diode across the same pinouts, and check the response…

Hello sir, the 555 timer is still getting burnt, please what could be the cause and what can I do?

Hello Seun,

Supply the pin4 and 8 of the 555 IC through this circuit, and check the response:

Also make sure to connect 1N4007 diodes between the center tap and the outer taps of the transformer.

" rel="ugc">

good day sir, I really appreciate your support here. you are doing a good job. please can this method of feedback be used with sg3525 inverter? I have tried using the FB pin but it’s not working.

Hi Hillary, please see the following diagram and see how the pin#1 of the IC SG3525 is configured:

" rel="ugc">

This takes care of the feedback control in the SG3525 circuit.

hello sir, how are you?

i want to ask on feedback point

can i use BC547 as a BJT device

or not?

Hello Sayed, yes BC547 can be used…

Hi Swagatam,

I sent you some more pics of what I was seeing at the 4047 and the 555 timer under different conditions. Please take a look at them and let me know what you can tell me about pics. I don’t know whatelse to try or what the problem could be with the 555 not producing PWM signals. I’ve replaced both chips multiple times and get the same results. I seem to come up with different cap and resister values for the 555 timer that are drastically different than what your schematic shows. Any ideas and/or pics that you can give me would be extremely helpful.

Thank you.

John

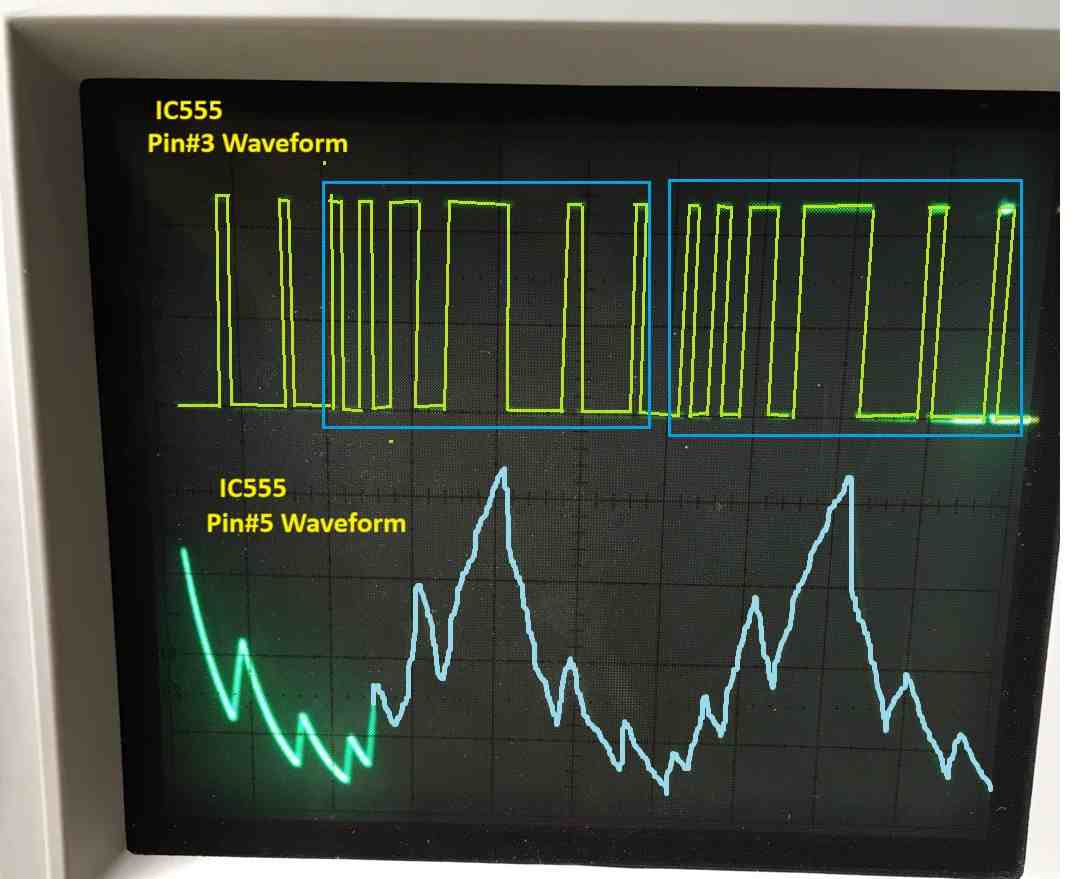

Hi John,

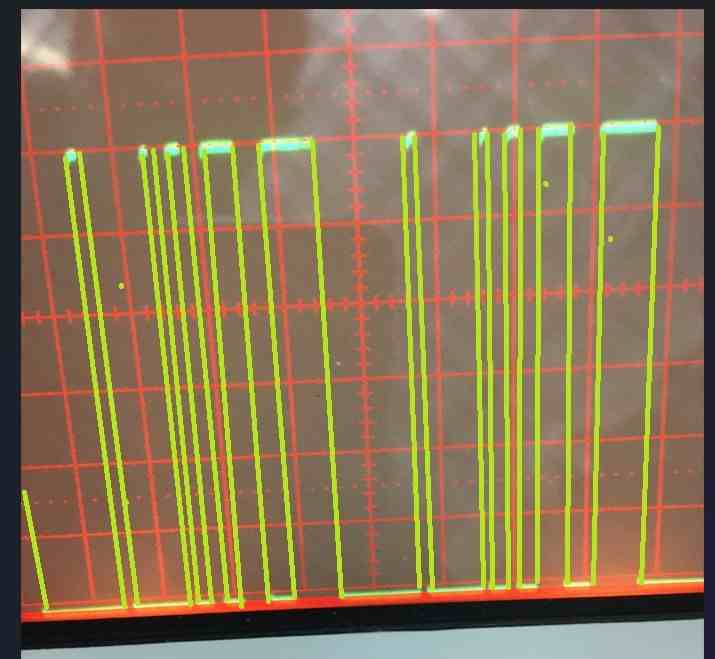

I checked the oscilloscope traces that you are getting, and when i joined the horizontal traces with corresponding vertical lines, I could clearly see the SPWM being generated at pin#3 of IC 555.

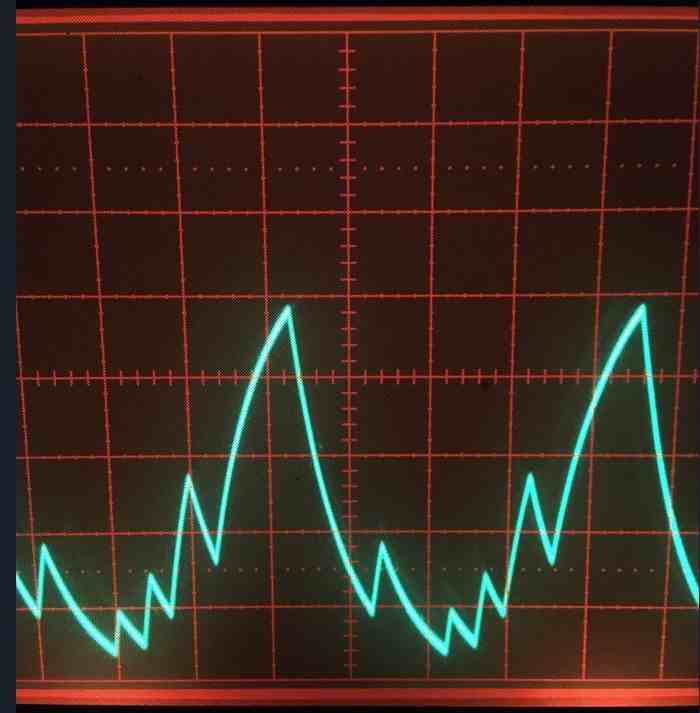

However, your triangle waves are not good, which may cause the SPWMs to be inconsistent.

Please investigate why the pin#2 triangle waves of your IC 555 are not good.

Initially try by removing everything from pin#5 of the IC.

The following are your scope images after I connected the horizontal traces with corresponding vertical lines.

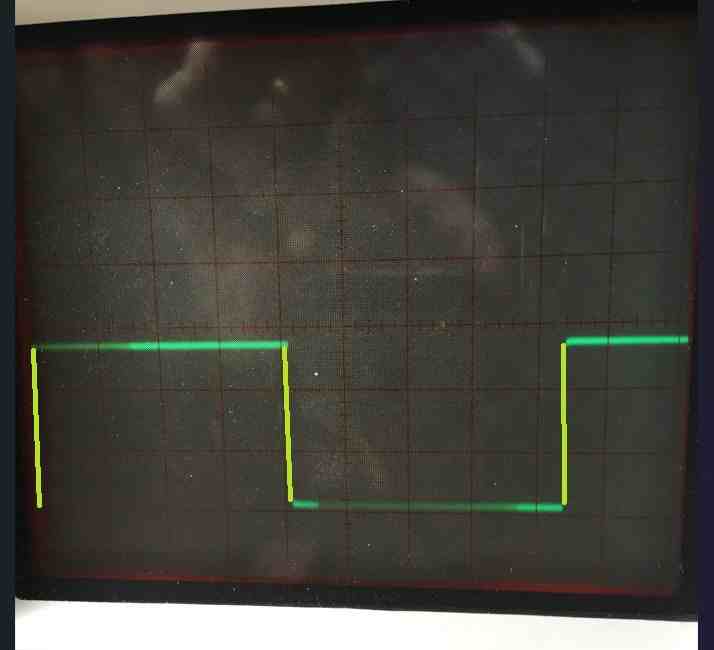

Pin#13 square wave image:

" rel="ugc">

IC 555 Pin#2 Triangle wave image:

" rel="ugc">

IC 555 pin#3 SPWM image:

" rel="ugc">

Hi Swagatam,

I sent you more pictures for your evaluation and response. My scope does not show the vertial part of the traces for whatever reason, but let me know what you think.

Thank you

John

Hi John,

The SPWM looks somewhat good but not the ideal one.

Since the pin#5 triangle waveform is not smooth, rather very bumpy, it is causing the SPWMs to be unsymmetrical.

Could you please try adding a 0.1uF or 0.22uF or an appropriate capacitor across the pin#5 1k resistor and check whether the triangle waveform improves or not? You are very close to getting a perfect SPWM at pin#3 of the IC 555.

Here’s the waveform that you are currently getting.

" rel="ugc">

Hi Swagatam,

I tried the caps across the 1k resister at pin 5 of the 555 timer without any effect. I sent you some more scope pics and some more questions. Still don’t know what to do to correct this and appreciate your help.

Thank you

John

Hi John,

Even with the existing SPWM you might succeed to get a sine wave output, although not very symmetrical.

However, the question is why the triangle waves are getting spiked as soon as they are connected with the pin#5 of the IC 555. That’s strange and must not happen.

When I check the internal configuration of the IC 555, I find that the pin#5 is just connected to an opamp input and a potential divider.

Potential dividers and opamp input cannot themselves induce spikes on pin#5, so it is difficult to understand why you are getting those spikes on the triangle waves.

You can try adding a 100uF or a 1000uF capacitor directly across Vcc and ground pinouts of the IC 555 and check if the spikes disappear or not.

If not then you might have to simply replace the IC 555 SPWM converter with an opamp circuit, as shown below:

" rel="ugc">

Hi Swagatam,

I’ve struggled to get anything resembling a PWM out of the 555, until I drastically changed the resistor values. The resister value between pins 6 and 7 is 80K and the resister between pin 7 and 8 is 4.3K. I also changed the cap from pin 2 to Gnd to .015uF. Then it appears that I’m getting a PWM at pin 3 of the 555. I was going to send you some scope shots but was not sure if I could do that via comments. Let me know how to send scope shots.

In a previous message you told me to connect this up without a transformer and measure the rms value to determine the transformer ratio. I was trying to do this, but I’m using bench supplies of 12V in place of a battery. But this output stage is connected directly across the 12 volts and so draws more current than I can source. If I use a battery for the output stage it appears that it will just short out the battery drawing max current until something breaks? Now the rest of circuitry (555/4047) is connected to a different supply. Is it important that all of the circuitry is connected to a common 12v source (power supply) to control the overall current? Or can you explain how the current through the output FETs is controlled?

Thank you for all of your help

Thanks John,

I appreciate your efforts.

While measuring the average output voltage from the IC 4047, you do not need any transformer, and since no transformer is connected to the MOSFET drains, the drains are open, so the MOSFETs should not draw any current from the power supply or the battery.

The grounds of the two power supplies must be connected in common, otherwise the MOSFETs might fail to work.

Current through the MOSFETs will depend on the load current specifications across the secondary side.

To enable a current control you will need an external circuit which will initiate a grounding on the CT pin of the 4047 whenever an overload is detected.

Thank you Swagatam,

I appreciate all of your help!

I will continue to work on this an see what I can find out.

The other question that I had was if I could attach pics somewhere so that I could show what I was seeing. Is there a way of getting pics to you?

Thanks

John

No problem John,

You can send me the pics on my email ID:

homemadecircuits

@gmail.com

Hi Swagatam,

I was wondering if you got my pictures that I sent to you on the 7th via email? I seem to be stuck with this project until I get some input to tell me what stage of the circuit is not working properly.

Thank You for all of your help

John

Hi John,

I checked my emails and the spam boxes, I could not find any email from you.

Or you can upload the diagram to any free online image hosting site and provide the link to me here, I will check it out.

Ok I received your email, the PWM waveforms from the IC 555 are not clear.

Are you getting proper triangle waves across the 1K resistor at pin5 of the IC 555??

If you feed a triangle wave om pin5 of the IC 555 (across the 1k resistor) you should be able to get a proper SPWM at pin3 of the IC.

Hi Swagatam,

I forwarded the email that I sent before with the pics. Please let me know if you get it. I sent it to [email protected], I hope this is correct.

Thank You

John

Thank you John,

I saw the scope images that you sent. The triangle wave looks good but I could not understand any of the other images since the PWM waveforms are undistinguishable.

Are the triangle waves taken across the 1k at pin#5 of the IC 555? If yes, in that case you should be able to get a correspondingly varying SPWM at pin#3 of the IC. I am sure about this, provided the IC 555 is good.

Also can you please take the waveform image at pin#13 of IC 4047, that will prove your scope is producing the square wave pillars correctly or not. Does each pillar of the square wave appear separately and fully or are they produced as dashes only, we can confirm this at pin#13.

I guess you are working with this circuit:

" rel="ugc">

Hi Swagatam,

I have a few more questions;

1. What are transiters are used in the output stage to drive the transformer and where can I get the heatsink hardware?

2. What would be a good diode to put across the drain of the output FETs?

3. You told me a good transformer to start with would be a 9-0-9 5A. does that mean the primary has one winding with a center tap or …? Does the “9” represent turns ratio 9:1 in reference to the secondary. Also can you a step-down for a step-up interchangeably?

Thank you for responding when you have time.

Hi John,

1) The BJJTs can be BC547/BC557 pair, and the MOSFETs can be IRF540.

2) The diode can be a 1N5408.

3) 9-0-9 refers to 9V – 0V – 9v, which represents two winding with a center tap and would produce 9+9 = 18V if a 220V was applied from the 220V side of the transformer. Conversely, if this 9-0-9V side was switched by an inverter, it would generate a 220V from the 220V side of the transformer.

Yes, a step down transformer can be used to work like a step up transformer for an inverter.

Hi Swagatam,

Thank you for answering my questions, I’m sure many of them are fairly elementary to you.

I have just a few more and I hope to start acquiring the parts.

1. At this time I only want to generate 110V @60Hz. Is there a transformer that has a 9-0-9 on the primary and the secondary with a center tap to get both 220V and 110V? If so what would the nomenclature be?

2. For the simplified design you gave me, can you suggest starting values for the Cx/Cy caps?

Thank you again for your help.

Hi John,

The transformer that you are referring to can be termed as 9-0-9V / 5 amps / 110-0-110V.

However, please do not buy the transformer as yet, because the transformer primary winding voltage will depend on the average SPWM DC voltage value from the IC 555. You will have to first check this SPWM value and then buy the transformer accordingly.

You will strictly need an oscilloscope for testing and confirming the waveform. https://www.homemade-circuits.com/dso138-best-small-oscilloscope-for-electronic-hobbyists/

For Cy and Cx you can try 0.1uF initially and tweak them until you get a perfect triangle wave at 120 Hz, (60 Hz x 2 at pin#13 of 4047 IC)

Hi Swagatam,

I do have a scope (Tek 475) and plan on using a power supply for the 12V source. I have ordered some of the parts and am waiting for their arrival. How would you suggest I check the SPWM levels without the transformer. Can I leave the output transistor collectors open and measure the peak-to-peak voltage on each of the collectors, or do I need to have some kind of load in place of the transformer primary windings?

Hi John,

You can check the average DC voltage across the base of the bc547 transistors and the ground line, meaning connect the positive probe of the meter on the base of transistors, and connect the black probe on the ground line of the battery. No load is required because we only want to check the average dc produced by the spwm chopping. You can confirm the same across the gates/sources of the mosfets also. The drains of the mosfets can remain open while testing the above…

Hi Swagatam, I’ve been looking at this site for awhile and find that it has answered more of my questions than any other site I’ve looked at. I’ve been trying to determine where to get all of the components and hardware to start. The transformer is one of the main items that I’m having trouble finding. Do you have any suggestions where I might get this transformer? Also if anyone has some scope shots of the output of the different stages that would be helpful.

Thank you for all of your hard work that you have put into this website.

John

Thank you John, Glad you liked the site.

You can get all the parts from any online electronic spare part shop. There are many shops online that you can find.

You can even get the transformer from an appropriate online store. For experimentation you can start with a 9-0-9V 5 Amp transformer.

You will also need an oscilloscope to test and confirm the waveform across the various stages. I would recommend you to buy the following scope which is small, cheap and versatile:

https://www.homemade-circuits.com/dso138-best-small-oscilloscope-for-electronic-hobbyists/

For the circuit diagram, I think the following one is the easiest to build:

" rel="ugc">

Greetings Swagatam. Please receive my irrevocable appreciations and highest regards!

Thank you so much Ohonkpo.

Good day sir. Great work i must say. Please i have a question, where do i connect my oscilloscope probes to an inverter to measure the frequency?

Daniel, the best place is at the secondary or the 220V side of the transformer. However make sure to use a resistive divider so that the 220V is scaled down to a proportionate 5 V AC for the oscilloscope.

Good day Sir.

I’ve carried out tests on the inverter circuit.

I used 12v DC supply.

I didn’t connect the transformer.

I kept the IN4148 diodes disconnected from pin 3 of IC 2.

Here are the results I got:

Pin 10 & 11 of CD 4047 = 51.65Hz square wave

Pin 13 of CD 4047 = 104.2Hz square wave

Frequency across capacitor “C” = 104.2Hz square wave, and not triangle wave

Frequency across the wiper of 10k pot = 104.2Hz square wave, and not triangle wave

Pin 3 of IC2 is giving DC signal(horizontal straight line) with 157mV Vpp

Pin 3 of IC1 does not give any frequency, has 157mV Vpp

Pin 5 of IC 2 gives square wave with 3.76Vpp

IC1 is slightly warm

Please Sir, what could be the possible causes?

Hello Victor,

Your 4047 results are correct, but the IC 555 results are not correct.

The waveform across the timing capacitor C of a 555 will be always a triangle wave, because the capacitor is slowly charging and discharging which will cause a triangle wave across it. Are you using an oscilloscope to check the waveform?

IC1 pin3 must produce a square wave with a frequency above 100 Hz or 200 Hz, because it is a basic astable circuit.

So please correct the two issues. you must get a triangle wave across C.

and you must get a square wave frequency from pin3 of IC1

Yes sir. I used oscilloscope to carry out the test. I’ve tried testing again. Am still getting the same from 555 ICs.

Pls sir, what should I do?

I am thinking of testing the 555 IC with a test jig to know if it’s working well.

Pls sir, help me with a test jig for 555 IC

Victor, You will have to check and confirm the stages separately. If your IC1 stage is not generating a frequency then somethings wrong in that circuit, because all these circuits are well tested.

The IC3 stage is square wave to triangle wave converter circuit, which should convert the square wave from IC 4047 pin13 into triangle wave across the capacitor C.

Isolate all these stages and test the results separately.

If you still have problems, I will try to make the stages simpler for you.

Ok sir, thank you sir.

I would really appreciate making the stages simpler because I don’t know how to go about isolating the stages to test them separately.

Thank you very much Sir

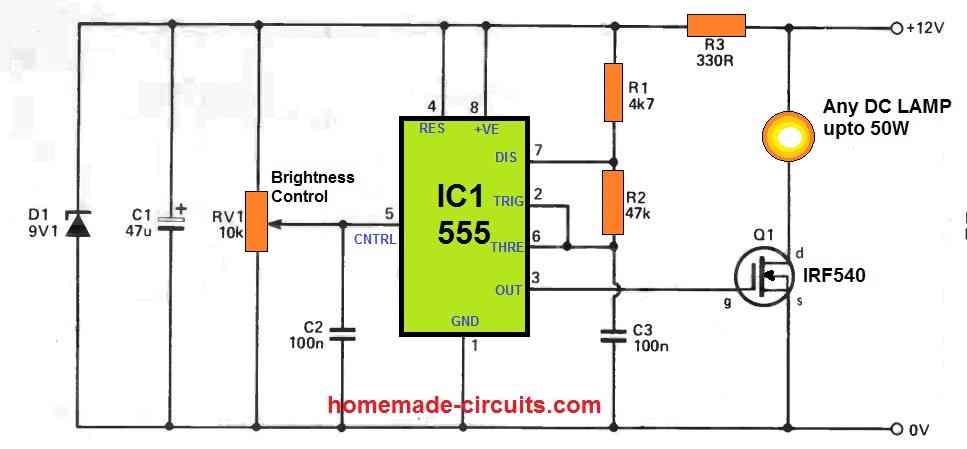

OK, then first try building and confirming the following simple circuit. This concept shows how applying a varying voltage at pin#5 of a 555 astable produces a variable PWM at its pin#3. You can eliminate the mosfet and the bulb and R3.

" rel="ugc">

Good day Sir,

Please sir, help me with voltage divider circuit to convert the 220Vac from the transformer output to 5Vac so that the oscilloscope can handle.

Thank you

Victor,

you can take the help of the following page to calculate the values:

https://www.homemade-circuits.com/voltage-divider-calculator-software-potential-divider-calculator/

Thank you sir for the calculator.

Please Sir, I don’t really get the e24 and e96 series.

1. Which series is carbon and metal films resistors with 5% tolerance. Like the 220k, 10k 5% tolerance?

2. Also, am confused about the resistor scale(ohm).

Which scale is 220k, 10k , 100k etc ?

Thank you very much for your reply

Victor, you can read the following article regarding E24 resistor. You can select E24 in the calculator.

https://asenergi.com/pdf/resistors/standard-resistor-values-e24.pdf

For the scale range select the value which provides both the resistors in kilo ohms

i saw one of the UPS..the inverter section they have used Lm339 ic and ne555 and the transfomer is not center tapped,,its single…with mosfet z44..sir if you have such circuit or similar…help me..the ups bord was not clear

Hi Brian, I don’t have this circuit right now with me, If I find it I will surely let you know.

Is there any circuit available for 20w 24 volts dc to 24 volts ac inverter. can you help me about it?

I will try to design it for you….

Thanksgiving

Here’s the circuit you wanted:

" rel="ugc">

SIR, CAN WE PRODUCE 220 V 150 W (SINUSOIDAL) OUTPUT WITH THIS CIRCUIT.

PLEASE EXPLAIN…

Hi Amit, yes that’s possible, but you can build this circuit only if you are well versed with electronics and inverter concepts. If you want an easier circuit then you can try the following sine wave inverter circuit:

Arduino Pure Sine Wave Inverter Circuit with Full Program Code

Is there any circuit available for 150W 220V inverter other than arduino.

Or please suggest what should I change in this circuit to achieve it.

You can try the second or the third schematic from the following article:

https://www.homemade-circuits.com/modified-sine-wave-inverter-circuit-2/

Dear sir,

Once I have connected the battery, the circuit has burned. Can I connect 12V 45Ah car battery directly to the circuit without other components. Please help me sir.

Hi Hasai,

This circuit is a complicated circuit. It can be built successfully only if you understand each and every section of the circuit correctly and then implement it step-wise, using multimeters and oscilloscope. If you build it without understanding the stages and if you construct the whole circuit at once then surely the circuit may have a chance of burning due to a fault.

You will have to build and check each stage separately with an oscilloscope then slowly integrate each stage with one another. And before this you must first grasp and understand the working of all the stage perfectly.

Good day Sir.

It’s my pleasure to come across your website. I really appreciate your great work on electronics, and your offer of help on electronic circuit related problems.

As an electrical/electronics student/technician, I picked up interest of building this pure sine wave inverter circuit you designed (the second circuit from top with RMS adjustment), and I’ve viewed some comments.

Pls Sir, I would like you to help me with dis points:

1. I’ve built the entire circuit, where should I disconnect or section out to carry out stage by stage tests/checking on frequencies, waveforms and voltages before powering the entire circuit?

2. What points/pins should I check for the required frequencies & waveforms?

Pls sir include the required frequencies and waveforms at the points/pins

3. Will there be problem if the transformer is of higher capacity, while the battery and load are perfectly matched?

For instance, using 300VA transformer with 12V 7AH battery for a 12W load

4. I’ve used 7805 voltage regulator to supply CD4047 IC. I connected 100 ohms resistor to the IN pin of the regulator.

Then, I removed the 100 ohms resistor connected to the supply pins of CD4047 and connected the OUT and GND pins of the regulator to supply the CD4047 through a 10V/100uf capacitor.

Please sir, is it OKAY like that?

Pls Correct me if it’s not OK

5. In one of your replies to comments, you said for iron core transformer, each SPWM cycle should have 4 pillars. I don’t really understand d pillars.

Pls sir, what should be the actual PWM frequency that ensures there are 4 pillars in each cycle?

6. Generally, What is the maximum output wattage that can be achieved with 12V DC inverter system using a transformer?

6. Can the pure sine wave inverter circuit be powered to carry out test/checking on frequencies, waveforms and voltages without connecting the transformer?

7. Without connecting the transformer, can it be confirmed that the output AC waveform and frequency to be induced in the second side is sine wave and 50hz frequency by checking the waveform and frequency of the pulsating DC from the 3 wires to d primary side of the transformer?

8. For using headlamp bulb in series with battery positive, if the circuit connections are 100% Ok, will the bulb still light?

9. For capacitor C(value to be experimented), should the valued be selected 1uF and below or 1uF and above?

Thank you Victor,

Here are the answers:

1) Keep the diodes disconnected from the base/gate of the 4047 MOSFETs or the BJTs.

2) Check the frequency at pin13, it should be 100 Hz, and it should 50 Hz across pin10 and pin11. The waveform across the capacitor “C” must be a triangle wave. Pin3 of IC 555 will produce SPWMs or sine PWM with a frequency depending on the values of R1/C1 of IC1 555. This frequency will decide the number of pillars within each SPWM waveform.

3) Higher transformer power rating will have no problems.

4) You must use 7812 and not 7805 otherwise the MOSFETs might not conduct well. Capacitor across the 4047 supply terminals is OK.

5) If you see the image of a PWM waveform you will find they are made up of pillars or vertical blocks, or skyscrapers.

6) Maximum practicable power from a 12V inverter is 200 watts. Checking and testing the various waveform is possible without connecting a transformer.

7) They can be checked but ultimate confirmation can be achieved only after connecting a transformer.

8) If the circuit connections are OK, the bulb will not light up.

9) You can try with 1uF and check the triangle waves. Keep checking with different values until you get reasonably good triangle waves across “C”.

Thank you very much Sir for the answers.

Please sir,

1. Using 7812 voltage regulator now to supply the CD4047 IC, will the 100 ohms resistor on the supply pins of the CD4047 still be there or should be removed?

2. I also used one 7805 voltage regulator to supply the three 555 ICs.

please sir, Is it Ok or I should change to 7812 regulator as well?

3. How do I connect the oscilloscope probes to the three wires pulsating DC (fed to primary side of transfo) to check the waveform and frequency?

Thank you for your response, Sir.

Victor,

1) 100 Ohm should still be included even if a 7812 is used. Make sure to add a 100uF capacitor right across the 4047 supply pins and also a 12V zener diode paralel across the supply pins, this zener diode is for enabling the passage of reverse voltage spikes.

2) use 7812 or all the ICs, 7805 is not required anywhere.

3) Connect the ground probe to the drain of the MOSFET and the positive probe to the battery positive.

Okay Sir,

Thank you very much Sir.

Please, do I have to also connect 12v zener diode across 100uf capacitor supplying the three 555 ICs from 7812 regulator as you have mentioned in the case of CD4047 above?

2. Please sir, am also confused about this point: explain for me, please

Will the zener diode across cd4047 not function as voltage regulator also?

Cos from the 12v supply from the battery and the 100 ohms resistor in series with the battery positive, the voltage reaching the zener diode is less than its zener voltage(12v), meaning the zener diode will not conduct.

Thank you sir

The zener diode is not for 12V regulation, it is to make sure that if any reverse spike is present it can be shorted through the zener safeguarding the IC. You can replace the zener with a 1N4148 diode also.

Thank you very much Sir

Hello, I also made this project.

However, it does not work because the triangular wave that modulates pin 5 of the ‘SPWM’ generator is not centered on the square wave signal produced by IC4047. This can be seen thanks to the 2-channel oscilloscope.

How is it possible to center the 50 Hz. triangular wave of the first timer 555 and make the sawtooth crest fall in the middle of the square wave produced by IC4047 ?

It is synchronized with 4047 square wave signal. Please see pin#13 of IC 4047 which goes to the pin#2 of IC 555

Ing,,,, I can’t find the 3v Zener diodes,,, they only have 2.7V,,,4,7V…5.6V….8.2V….9.1V Ect

for sale, which could be replaced,, ,?

you can try 2.7 V zener, should work.

Dear sir,

Here, should we need to use 6V Fullwave (6Vx2) Transformer or 12V

Fullwave (12Vx2) Transformer. Please help me sir.

Hi Hasai, for a basic 4047 IC square wave inverter if the battery is 12V then the transformer should be 12-0-12V and if the battery is 6V the transformer should be 6-0-6V.

However since this is an SPWM based circuit, even with a 12V battery the transformer should be 6-0-6V or at least 9-0-9V.

The best way to confirm is to check the average DC at the gate of any one of the MOSFETs….that will be the value of the half primary winding of the transformer.

Ok sir. Is it enough 2 Ampere transformer?

If a 12V transformer is used then 2 amp rating will provide you with 12 x 2 = 24 watt output, which will be practically only 20 watts.

Thank you so much for your quick replies and great help sir.

I have a someone problem to clarify. Can you please explain, why we not need filter part here. How we satisfy filtering requirements in this circuit.

Hi Hasai,

For filtering the SPWM into a pure sinewave you just have to connect a 3uF/400V capacitor across the output wires of the transformer. The filter cannot be connected on the DC side of the circuit, that will not work.

Sir, is it ok we use 1mF capacitor for first test, will it blow out if it’s not Ok.

Hello Rncp, where do you want to use 1uF

Ok sir. Then can you please explain the reason for connecting the midpoint of the transistor to the positive of the battery? I can’t understand it. Why can’t we use a normal transformer?

It works in this way: The mosfets are configured to switch alternately using the oscillator frequency input. This in turn causes each half winding of the transformer to switch alternately using the battery 12V. When this happens the current from the transformer primary is induced into the secondary and stepped up to generate the 220V AC

Thank you so much sir

Dear sir,

Can you please explain,

1. what is the waveform of 3 rd pin of third 555.

2. should we connect midpoint of the primary winding of the transformer to the positive of batery. Then what type of transformer should we choice for it.(Center taped?)

1) The waveform at pin#3 of IC2 will be sine wave PWM.

2) Yes, the entire line which connects the center tap of the transformer must be connected with the positive of the battery.

Transformer should be a center tap transformer.

Dear sir,

Can you please explain How to connect midle point of primary winding in transformer to the positive of battery.

Hello Hasai,

You must connect it exactly as shown in the diagram.

Dear sir,

Where should we connect the negative side of the DC battery?

Carefully check all the lines which are shown with a ground or earth symbol. All those lines should be connected with the battery negative.

ok sir. Thank you so much

mr pleese 100w inweter circuit ferrit core trans former+

Hi, sorry, I don’t have a 100 watt ferrite core inverter design with me.

Dear sir,

1. what is the component P1 in circuit 1.

2. What is the component marked by the (+) which is in orange color near the transformer?

Please help me, sir.

Hasai,

P1 is a preset to adjust the output frequency of the inverter at 50 Hz or 60 Hz.

The orange colored + indicates the positive the battery. Battery positive should be connected at this point.

Dear sir,

What is the function of NE555 in the first circuit? Please explain

Hasai, all the 555 ICs are configured to generate sine wave PWM for chopping the 4047 50 Hz frequency

Dear Sir,

Please sir, I forgot to get clarified about the point:.

“The configuration shown in the second figure would work but only if the center tap PWM mosfet is replaced with a p-channel mosfet.”

I don’t understand it cos am using IRF3205, which is N channel, in the second circuit that has RMS adjustment.

Hi Godfrey, The “second circuit” is referred to the second last diagram, not the second circuit from top. I have updated the specific last section of the article, you can check it out.

Okay sir, I really appreciate your great and prompt replies. Thank you.

I am about carrying out some tests/checking for the Voltages, Frequencies and Waveforms on the circuit for 50Hz operation of the circuit.

I have supplied the ICs with 5V from LM7805 regulator

Please sir, I need your help on the following points:

1. What should be the required PWM frequency and voltage at pin 3 of IC2?

2. Which pot is used to adjust the PWM frequency?

3. The triangle wave of IC3 is at which pin? And what should be the required frequency and voltage at that pin?

4. What should be the required frequencies and voltages at pin 2 and 5 of IC2?

5. Which component/pot is used to adjust the Frequencies at pin 2 and 5 of IC2?

6. What should be the required voltage at pin 3 of IC2?

7. Is it OK to still add the 100 ohms resistor after LM7805 to the supply pins of cd4047?

8. What should be the required voltage at the gate of the mosfet?

9. What should be the required voltage at pin 10, 11 and 13 of CD4047?

10. Apart from the drain pins and batt +Ve to the 6-0-6V side of the transformer, which is AC. Are the above tests/checking to be set DC? That’s connecting black meter probe to the ground of the circuit and red probe to the points to be checked?

11. In situation where small portable oscilloscope can’t handle 220vac of the transformer output, can 50Hz frequency and Sine wave check on the 6-0-6V input to the transformer be judged as what the transformer is outputting on the 220V side?

12. Is it necessary to connect a capacitor, for smoothing purpose, across a 12V input supply to the inverter circuit, even when using 12V battery? If so, what value can be used?

13. The capacitor C ( i.e value to be

experimented), is the value to be chosen below 1uf or above 1uf?

I would be glad for your help.

Thank you

Godfrey, here are the answers:

1) If you are using an iron core transformer, the SPWM frequency at the pin#3 of IC2 should be 200 Hz, or in other words the PWMs should have 4 blocks or 4 pillars on each cycle.

2) The value of the capacitor C of IC3 and the associated 10K preset decides how the PWM pillars vary its thickness. It does not decide the frequency, I was wrong in the previous comments.

3) The adjusted triangle wave can be measured across the preset output, and the non-adjusted triangle wave can be measured across the capacitor C. The frequency will be same as the frequency generated at pin#13 of 4047.

4) The frequency at pin#2 of IC2 needs to be adjusted by adjusting the value of the R1 180K resistor or C1. This resistor actually also decides the SPWM frequency. You will have to play with the 180k value to finally adjust the SPWM frequency so that it has around 4 to 5 pillars in them. pin#5 receives the triangle waves whose amplitude can be adjusted with the IC3 10k preset.

5) The 180 K and the C1 values decides the frequency at pin#2 of IC2.

6) The voltage at pin#3 of IC2 is a SPWM varying voltage which will have an average value depending upon how the 180K and the 10k preset are set.

7) Use a 7812 Ic and a 22 ohm resistor, along with a capacitor, and a zener diode protections across the supply pin of the 4047.

8) The peak voltage at the mosfets gate will be 12V, and the average voltage will be 6V without the SPWM added.

9) All these will ahve peak voltage equal to the supply voltage of the IC, average voltage will be according to the frequency outputs of the pins

More answers will be provided in the next comment.

10) All the points on the transformer primary side are either DC or pulsating DC, they are not AC. AC is only at the secondary side of the transformer. You will ahve to measure all the battery side connections with respect to the black probe connected to the ground line.

11) To measure the output side 220V create a voltage divider using a 220K/10k resistor or something like that which will convert the 220V AC sine frequency into 5V AC sine frequency and then you can comfortably measure the secondary side sine wave.

Remember mains AC from inverter is dangerous and lethal, you are doing all these testing at your own risk.

12) It is always good to add a high value capacitor across the battery terminals to absorb voltage spikes.

13) You can start with 1uF and check how it responds, and then you can use other values to verify that the SPWM pillars are distributed uniformly across each cycle of the AC.

Thank you very much sir for your time and effort in providing the answers.

Please sir, am very very confused about point 10, that “all the points on the transformer primary side are either DC or pulsating DC.”

Because I learnt that transformer works on AC only. That is, applying an alternating voltage to one side usually the primary, then an induced voltage by electromagnetic induction appears at the secondary side.

Please sir, I want to get clarified if iron core inverter transformers don’t have the same working principle as ordinary iron core transformers?

Thank you sir

Godfrey, transformer works using pulsed DC and AC both. Pulsed DC means any DC which switches ON/OFF alternately. AC is a supply which changes its polarity from + to – and then – to + alternately, this is not mandatory for a transformer to work. The mosfets are switching DC across each half winding of the transformer, they are not switching AC. But the center tap winding are configured with each mosfet in such a way that when both the winding are switched alternately, it causes an AC to generate across the secondary. Each of the mosfet is creating pulsed DC on the primary side of the transformer which is causing an AC to develop on the secondary side of the transformer.

Okay sir. I have got the principle now.

Thank you

No problem Godfrey!

I think you can get a ready made triangle wave across timing capacitor of 4047 IC, and you can use this triangle wave to feed the pin#5 of the IC2, in this way you can eliminate the IC3 completely.

Dear Sir,

Thank you for updating the second circuit.

Please sir, the capacitor c across 10k preset (i.e “Value to be experimented”)

1. I have already used 1uf/50V, please sir is it within the values to be used?

2. Please sir, how does the value used affect the performance of the circuit?

As in, why the value need to be experimented.

Thank you sir

Thank you Godfrey,

The capacitor C determines how many pillars each SPWM cycle will have from pin#3 of IC2. If you are using an iron core transformer then you must make sure the number of pillars in each SPWM cycle does not exceed 4nos otherwise the transformer might heat up. You must have an oscilloscope to check how many pillars in each SPWM cycle you are getting for the selected capacitor.

Okay sir. Thank you so much.

Please sir, I’ve googled to know what is pillar in SPWM, I can’t find answer..

Please sir, what’s pillar?

Thank you

Hi Godfrey, By “pillars” I meant to indicate the number of blocks in a PWM cycle. You can see it in the following example image:

" rel="ugc">

Okay sir, thank you.

Please sir, to get you very well.

Using the image u sent, how many cycles are there in that PWM?

2. Then, Each of the pwm cycle contains how many pillars?

Thank you sir

The number of blocks is not a fixed number, higher the number of blocks, cleaner will be the sinewave and vice versa. But higher number of blocks would also cause the frequency of the PWM to increase, adversely affecting the working of an iron core transformer. Therefore you have to limit and optimize the number of blocks in such a way that you get a reasonably good sinewave and the transformer also remains cooler.

For the diagrams shown in the above article, the number of pwm cycles will be equivalent to the frequency at pin13 of the 4047 IC, and number of pillars or blocks will depend on the triangle wave amplitude, generated by the IC3

Thank you so much sir

My pleasure!

Dear Sir,

Please sir, I have finished building the second circuit that has RMS adjustment.

Please sir, I want to know the terminals I have check with Frequency meter and Oscilloscope to get the expected frequencies and waveforms for 50Hz operation of the inverter.

Thank you sir!

Hi Godfrey,

Initially do not connect the IC2 555 pin3 output with the transistors of the inverter. First check the inverter without this connection. Confirm the 50 Hz frequency at the inverter output with 220V. Check this with a load bulb

Once confirmed, next check the triangle waves at pin#5 of IC2 555, and also check whether pin#3 is generating the required sine wave PWM or not….

Once confirmed only then integrate the pin3 output of IC2 555 with the inverter transistors.

Okay sir, thank you so much.

Please sir confirm this additional things I have done if they are OK before I power the circuit:

1. I have connected IN5404 diode across the S/D of each mosfet.

2. I have connected 1k resistor across Gate/Source of each mosfet.

3. I have connected 100ohms resistor across the emitters of bc547/557 and the gate of each mosfet(gate resistor).

4. I have used 7805 ic to power only cd4047 ic and another 7805 to power only the three 555 ICs while the rest circuit remains the way u designed.

5. I used a 100uf/25v cap for the IN pins of the 7805 ICs and 100uf/10v cap each for the OUT pins of the 7805 ic

Please sir, are all the above OK?

Or any change needed for the capacitor values and so on?

Then, I saw in one of your replies to comments advising the person to connect a 12v car headlight in series with the battery positive to tackle some heating issues. Please sir, is there need for me to also do so?

Thank you very much sir.

Godfrey, yes all those points are prefect and can be applied to the second schematic! A series headlamp initially ensures that if something is not correct in the circuit then nothing will burn, instead the bulb will illuminate and prevent anything from burning. If you are 100% sure that nothing is wrong in your circuit then the bulb is not required.

There’s one thing that seems to be missing in the schematics, it is a 1K resistor across C4. Please add a 1K resistor across C4

Dear Sir

Please sir, I have connected a diode to S/D of the mosfet for Avalanche protection.

Please sir, can I add Gate/Source Resistor for another protection?

Yes you can add a 1K resistor across gate/source of each mosfet for more efficiency.

Dear Sir,

Please sir, if I wish to power the ICs with 5v, can I use one 7805 voltage regulator to power the three 555 ICs?

Hi Godfrey, yes that’s fine, you can do it.

Thank you very much sir

You are welcome Godfrey.

Dear Sir,

I have seen HA17555 ic in market,

pls sir, is it the same as CMOS 7555 ic?

2. I wish to replace the 180k resistor with 220k preset in case of necessity for frequency setting, but 500k preset is handy for now.

Please sir, can I used the 500k preset?

Dear Godfrey,

It seems both the ICs are the same. HA17555 is a CMOS version of IC 555

You can use 500k resistor instead of 180K

Thank you sir

Dear Sir,

Please am trying to build the second design that has RMS adjustment and buffer transistors.

1. Is the circuit diagram/components Okay or new any modification/update is done?

2. What should be the frequency at pin 10, 11 and 13 of CD4047 IC for 50Hz operation of the inverter?

3. What are the fixed values of C1 and R1+P1 for CD4047 for 50Hz operation of the inverter?

Thank you very much sir for response

Dear Godfrey,

yes the circuit components are OK. Just make sure to add a 12V zener diode across the supply pins of the 4047 IC, and also add a 100uF/25V capacitor across the supply pins.

The frequency at pin 10, 11 should be 50 Hz, at pin13 it should be 100 Hz, but all these should be confirmed with respect to the output AC frequency.

The C1, R1+P1 will need to be set by checking the frequency at the output of the transformer. initially you can take C1 as 0.1uF, R1 as 22K, and P1 as 100k preset.

Okay sir,

Please sir, is the zener diode to be connected in reverse bias as voltage regulator? That is, the anode to the GND of the Cd4047 and cathode to the Vdd of the cd4047?

Yes that’s correct.

Hi Mr Swag, nice job here

I just stumbled across this website and wanted to let you knowhow much I anticipate studying it. It will most likely take a while but I am sure you will hear from me down the road. If you’re an amateur radio enthusiast, you probably saw the call in my email address but I no longer hold that call. I exchanged it for W4PFC. I have been tinkering with electronics since the early 50’s and can hardly wait to get familiar with your web site. I have some hefty projects in mind.

Sincerely,

Rich Ferguson

Flagstaff, AZ

Thank you for your kind feedback, appreciate your interest!

Mr Seagate, my problem here is how to connect inverter with battery charger and auto switch. Please help out with simple circuit diagrams showing these connections. Thanks for the usual responds.

Stephen, please refer to the following article, and customize your design accordingly:

https://www.homemade-circuits.com/how-to-make-mini-homemade/

Dear sir,

Please sir, I can’t find the 1uF non polarized capacitor (C3 at the bottom right of the circuit) in the market.

Please sir, what other value can I use or can I replace it with 1uF 50V electrolytic capacitor?

Godfrey, you can use polarized cap also, since the negative terminal is directly connected to the ground line…

Okay sir, thank you!

Dear sir,

Please sir, for the polarized capacitor C which is connected across the 10k preset in the second circuit,

Can I use 1uF 50V electrolytic cap. Or

a lower value (say 0.33uf or 0.47uf)?

Thank you

Yes you can use 1uF or lower values will also do….

Dear sir,

Please sir, for a 600VA transformer, if the max output power of a transformer is 360W.

In a situation where a 12V, 30Ah battery for delivering 360W for one hour is not handy

Please sir,

1. Can I use a 12V, 25Ah battery to deliver 100W to run a load of 100W for 3 hours?

2. Can I use the IRF3205 mosfet in the pure sine wave inverter with RMS adjustment for the 12V, 25Ah battery to run the 100W load for 3 hours?

3. To calculate the inverter supply current in order to know the protection diode to use across S/D pins of the mosfet, please sir, will it be 100watt / 220V inverter supply voltage = 0.45A if am using the 12V, 25Ah battery?

Hello Godfrey,

1) you can 25 Ah battery for running a 60 watt load, not a 100 watt. You must discharge the battery at a maximum 15% of the Ah value

2) You can use IRF3205

3) protection diodes can be rated at 5 amps which is the recommended discharge rate of the battery, or the operating current for the inverter with a 25 Ah battery

Okay sir, thank you for your reply!

Please sir, to get you very well about the 15% max discharge.

1. Do you mean that, though the 12V, 25Ah can deliver a Max power of 100W for 3 hours, it must not be used to run a 100W load even for a very short time, say 5 minutes?

2. Please sir, in a general view, what is the recommended discharge rate or the max percentage discharge for a battery with respect to its Ah value?

3. Please sir, how do you calculate the 5 Amps discharge rate of the battery and the operating current of the inverter?

Godfrey, there are no fixed parameters in electronics, all parameters are relative and approximate values.

A lead acid battery must be charged or discharged at around 10 to 15% of its Ah rating to prevent cell deterioration. Therefore for a 25 Ah, the maximum discharge current should be around 4 amps, and not 5 amps.

So if yo multiply 4 amps with 12 V, gives 48 watts, so that’s the maximum load recommended for your inverter.

Now Ah = 25, and considering A = 4 amps

we have

h = 25 / A

h = 25 / 4 = 6 approximately, which is 6 hours back up time in ideal situation, practically it may be just 3 to 4 hours due to many hidden losses.

Okay sir, thank you very much

Dear sir,

Please sir,

1. From the theoretical 6 hours, what is the formula to calculate the actual time the battery should be discharged practically?

2. Please sir, If the current rating of my system is between 1.12A to 1.44A, can I use 1A diode like IN4007 for the avalanche protection?

3. Please sir, will increase in the resistance of the 10K preset from 5K upward increase the RMS output voltage of the inverter to the rated value or decrease it?

Hello Godfrey,

1) Please read the article Lead Acid Battery Charging

2) Yes, that will do

3) Moving the slider towards the capacitor positive will increase the RMS and moving it toward the ground will decrease the RMS

Dear sir, please sir can I use IRF3205 MOSFETS for the pure sine wave inverter circuit with RMS adjustment?

yes you can use it….

Thank you sir

Dear sir,

Please I have a 10A ups transformer having four wires(black, blue, green and yellow) on the primary side and two fat wires on the secondary side.

When I applied 220V across the black and blue wires, I got 14V from the secondary.

Please sir I want to know if I can disassemble and centre tap the secondary to be 7-0-7v , and then use it for the above pure sine wave inverter circuit you designed?

Hello Godfrey, you can do that, just pull out a center tap from the middle of the 14V winding….and then you can use it for making any center tap transformer based inverter

Dear sir, thank you for all your tutorials on pure sine wave inverter circuit. I really appreciate it.

I wished to have been done building, testing and confirming your great design and work on this inverter circuit diagram by this weekend, but just one part of the components is keeping me. I have searched through many electronic part shops in my area. I can’t find the a TRANSFORMER with the 10A current rating you recommended for me. The highest current rating seen in all the shops is 2A.

I saw 240/15-0-15v, 2A transformer (iron laminated):

1. Please sir can this transformer be disassembled and rewound based on specifications to output 9-0-9v, 10A you recommended for me to use for 60W inverter circuit?

2. I have also seen a UPS transformer during my search for 9-0-9v, 10A transformer.

The UPS transformer has four wires on the low voltage winding and two wires on the high voltage winding.

Please sir can the UPS transformer be useful for the inverter circuit in question?

3. I would really love to design and build my own inverter transformer, please sir I would appreciate my help on how to design and build the transformer and the materials I need to use.

Although I have read your post on “how to design your own inverter transformer”, I am not getting it well. Please sir throw my light.

Thank you for your time.

Hi Godfrey, yes you can rewind the transformer for higher current if the space between the core allow the accommodation for the winding.

2) transformers are all similar with their working principles, so UPS transformer will also work.

3) Transformer designing should be done only with the recommended formulas, so you will have to follow the mentioned formulas in the article, there’s no other easy method.

Alternatively, you can also refer to the following article for more info:

How Transformers Work

Thank you very much sir!

Please sir concerning the UPS transformer, the one I have has four small wires on one winding (i.e black, blue, green and yellow wires),

and two fat wires on the other winding(i.e blue and red wires).

I didn’t know which winding is primary and which is secondary.

So I downloaded two videos on YouTube about the transformer.

From the two videos, i learnt that the winding with four wires is taken to be the primary, and was supplied with 230v mains. The black wire from the four wires was the COMMON. So from the voltmeter that was connected across the two fat wires(as the secondary), when 230v was applied across black and blue, the voltmeter read 14v; black and green = 5v; black

and yellow = 7v.

1. Please sir my question is how can I use this transformer with the above pure sine wave inverter circuit you designed? How will I connect the transformer to the circuit?

Thank you sir.

Godfrey, the transformer ratings cannot by assumed by guessing, you must check it practically by feeding the 220V on the primary side and then checking the corresponding voltages on the secondary. If the voltage matches the specifications provided in the above sinewave inverter circuit only then you can use it, otherwise not.

Alright sir. Thanks very much sir for your time!

So there’s no 22k resistor in the circuit, please sir any need for protection diode for the MOSFET?

You are welcome Godfrey, yes there’s no 22k in the diagram, you can add external protection diodes across S/D pins of the MOSFETs for increased safety

Okay sir, thank you very much.

Let me go about with the design.

Dear sir,

1. Please sir can I mount the two IRF540 MOSFETs on one heat sink? Or if the two mosfets are not to be mounted on one heat sink, can I use heat sink insulator pad or use two heat sinks separately at once?

2. Please sir what protection diode can I connect across the S/D pins of the mosfets? And also which terminal of the diode (cathode/anode) is connected to the D pin and the S pin of the mosfets?

Thank you sir!

Hello Godfrey,

1) yes you can mount two MOSFETs on a common heatsink, preferably you can use heatsink insulator with them.

2) You can use a diode with current rating equal to the current rating of the inverter, cathode will go towards the positive supply line, and anode towards the negative supply line.

Okay sir, thank you sir!

But am confused somewhere: I don’t know how to get the current rating of an inverter. Please sir help me with the formula for calculating the current rating of an inverter.

Thank you

Please divide wattage of the inverter with its voltage

Dear sir, I would like to sieze this opportunity to thank you for your time and the great offer of help you have made tutoring electronic engineering lovers in circuit designs. I really appreciate it.

Please sir I would like to build the pure sine wave inverter circuit using IC 4047.

I want to go for your second circuit diagram which has RMS adjustment and buffer transistors for improving mosfet behavior.

Please sir I have some questions I want to get clarified about the circuit.

Q1. In your post on IC 4047 data, you said R1, P1 and C1 determine the oscillator frequency of the IC and the output at pin 10 11 and 13. Please sir, what value of R1 and C1 should be used and what resistance value should P1 be set to in order to get 50Hz source frequency from the inverter?

Because I haven’t seen the formula for calculating R1 and C1 in this article and also frequency meter is not handy with me for now.

Q2. Please sir what is wattage of the resistors used in the inverter circuit?

Q3. Please sir, the 10K preset, is it for RMS adjustment? Is the RMS adjustment responsible for output voltage of the transformer inverter? And also what resistance value should it be set to?

Q4. Please sir, the 10nF and 1uF capacitors, can I use ceramic or polyester type? Again, what is the voltage of the capacitors? Also what is the voltage of the capacitor C = 1uF at NE555 stage?

Q5. Please sir, do I need to work with these formulas in order to ensure good performance of the inverter?

f = 1/8.8RC at pin#10 and pin#11

f = 1/4.4RC at pin#13. of IC 4047