In this article we look into a simple 220V mains PWM controlled fan or light regulator circuit which does not require a microcontroller or costly triac drivers for the intended operations.

Capacitive Phase Chopping

All Ordinary types fan regulator and dimmers which rely on capacitive phase chopping technology have one drawback in common, these generate a lot of RF noise and require bulky inductors for controlling them partially.

Furthermore, the switching or the phase chopping being done using ordinary capacitor diac technology lack accuracy and sharpness.

The proposed mains transformerless PWM controlled fan regulator circuit designed by me is free from all such possible issues normally accompanied with traditional fan or light dimmers since it uses an advanced CMOS IC based circuit and an accurate zero crossing detector stage.

No MCUs Used

The best thing about this circuit is that it does not require microcontrollers and programming, and also a triac driver has been eliminated making the circuit extremely easy to build even for the new hobbyists.

I have explained the configuration in detail, which is rather too straightforward:

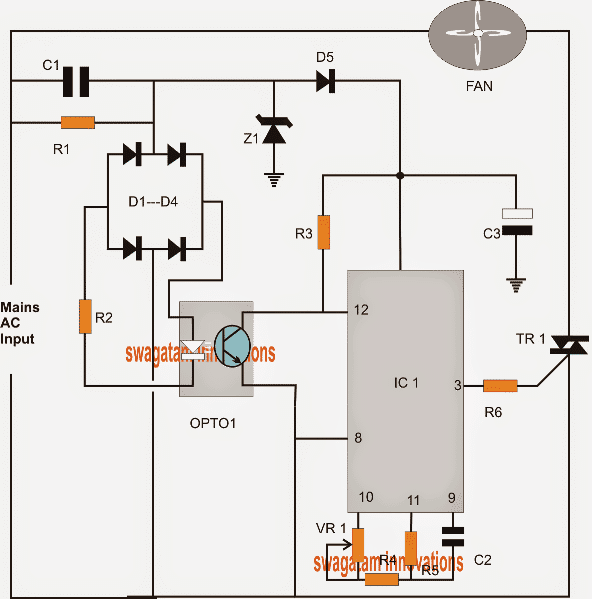

Referring to the circuit, IC1 which is a 4060 timer chip is configured to produce a delayed positive pulse for the triac each time the phase crosses the zero line of its phase angle.

The entire circuit is powered from an ordinary capacitive power supply using C1, D5, Z1 and C3.

IC1 is configured in its standard form for generating a delayed switch ON or a high every time its pin12 goes through a reset action.

Zero Crossing Switching for the Triac

The dimming action or the phase control action is achieved by making the triac to conduct after a predetermined delay each time a zero crossing is detected.

If this delay is short, it means the triac gets an opportunity to conduct for a greater amount of time for the phase angles, causing the connected fan to spin faster or the light to shine to brighter.

As this delay is increased, the triac is forced to conduct for proportionately shorter durations across the phase angles producing a proportionate amount of reduction over the speed or the brightness of the connected fan or the light respectively.

The zero crossing operation is simply enforced by using an ordinary opto coupler, as can be witnessed in the given diagram.

The bridge D1---D4 transforms the alternating phase angle into equivalent 100 Hz positive pulses.

The LEd and the transistor inside the opto coupler responds to these positive 100Hz pulses and stays switched ON only for so long as the pulses are 0.8V above the zero mark and switches OFF instantly as the pulses reach the zero crossing point.

While the opto transistor is in the conducting phase, the IC pin12 is held at ground level allowing a delay or a predetermined negativestarting pulse for the triac gate.

However at the zero crossing levels the opto switches OFF, resetting the pin12 of the IC such that the IC pin3 restarts a fresh or a new delay for the triac to respond for that particular phase angle.

PWM Phase Control

The length or the pulse width of this delay pulse can be varied by suitably adjusting VR1 which also becomes the speed control knob for the discussed PWM controlled fan regulator circuit.

VR1 and C2 must be selected such that the maximum delay produced by these should not exceed the 1/100 = 0.01 second timing in order to ensure a linearly incrementing 0 to full calibration over the given control knob.

The above could be implemented by some trial error or by using the standard formula for IC 4060.

For the above you may also experiment the other outputs of the IC.

Circuit Diagram

Construction and Connection

Power Supply Section

C1 (Capacitor):

Connect one terminal of the high-voltage capacitor (e.g., 0.33uF, 400V) to one of the AC mains input wires.

Connect the other terminal to one of the input terminals of the bridge rectifier (D1–D4).

D1–D4 (Bridge Rectifier):

Arrange the diodes to form a bridge rectifier.

Connect one AC terminal of the bridge rectifier to C1, and the other AC terminal to the other AC mains input wire.

The positive output of the bridge rectifier goes to the zener diode (Z1) and the circuit's DC supply.

The negative output serves as the ground, for the circuit.

Z1 (Zener Diode):

Connect the cathode of the zener diode (marked end), to the positive output of the bridge rectifier.

Connect the anode to ground.

This zener regulates the DC voltage for the control circuit, (typically 12V).

R1 and R2 (Resistors):

R1 connects in series with C1 to limit the current from the AC mains.

R2 connects between the positive DC supply, and the optocouplers input LED (inside OPTO1) to limit the current through the LED.

Oscillator Setup with the 4060 IC

The 4060 IC is used to generate a timing signal. Follow these steps to configure the oscillator:

Pin Connections:

Pin 16 (Vcc): Connect to the positive DC supply (regulated by Z1).

Pin 8 (GND): Connect to the ground.

Pin 12 (Oscillator Output): This pin outputs the oscillating frequency and is used as the input to the TRIAC/MOSFET gate.

Resistors (R3 and R6) and Capacitor (C2):

Connect R3 between Pin 10 and Pin 11 (oscillator timing pins).

Connect R6 between Pin 11 and Pin 9 (oscillator input pin).

Connect C2 between Pin 9 and ground.

These components set the frequency of the oscillator.

Formula for frequency (f):

f = 1 / (2.2 * R3 * C2)R3 = Timing resistor between Pins 10 and 11.

C2 = Timing capacitor between Pin 9 and ground.

Adjust R6 (or replace it with a variable resistor/VR1) to fine-tune the frequency.

Reset Pin (Pin 12):

Leave this unconnected if not needed, or connect to ground via a small resistor to avoid floating.

Oscillator Output (Pin 3 or another Q Output):

Choose an appropriate Q output pin (e.g., Pin 3 or others like Q4, Q5) to deliver the timing signal to the gate/base of the TRIAC/MOSFET (TR1).

The selected Q pin depends on the desired frequency division factor.

Output Switching Section

TR1 (Switching Device - TRIAC/MOSFET):

Connect the gate/base of TR1 to the oscillator output pin (e.g., Pin 3 of IC 4060) through R3.

Connect one terminal (MT1/source) to the AC mains neutral and the other terminal (MT2/drain) to one end of the fan.

D5 (Freewheeling Diode):

Place D5 across the fan terminals as a protection mechanism.

Fan Load

Connect the fan in series with the TRIAC/MOSFET.

- One terminal of the fan connects to the AC live wire.

- The other terminal connects to MT2 (or drain) of TR1.

Ensure that the fans current and voltage ratings match the circuit's capacity.

Adjusting the Fan Speed

Frequency Tuning:

The fan speed is indirectly proportional to the frequency of the oscillator.

Adjust R6 or replace it with a potentiometer (VR1) to control the oscillator frequency, which alters the effective power delivered to the fan.

A lower frequency allows the TRIAC/MOSFET to remain "on" for a longer time, increasing the fan speed.

Zener Diode Protection:

Use a zener diode across the fan terminals to clamp voltage spikes.

Formulas and Calculations

Oscillator Frequency:

f = 1 / (2.2 * R3 * C2)R3 and C2 define the base frequency.

Effective Power Delivered to the Fan:

P = V * I * Duty CycleAdjusting the oscillator frequency indirectly controls the duty cycle and, consequently, the power.

Capacitor Selection for Timing (C2):

C2 = 1 / (2.2 * f * R3)Assembly Notes

4060 IC Socket:

Use an IC socket for mounting the IC, because as this makes it easier to replace in case of failure.

PCB Layout:

Place the timing components (R3, R6, C2) close to the 4060 IC to reduce the noise.

Testing:

Before connecting the fan use an oscilloscope to verify the frequency at the oscillator output pin.

Adjust R6/VR1 and, observe the changes in frequency.

Parts List

R1, R5 = 1M

R2, R3, R4 R6 = 10K

VR1, C2 = SEE TEXT

OPTO = 4N35 OR ANY STANDARD

C1 = 0.22uF/400v

C3 = 100uF/25V

D1---D5 = 1N4007

Z1 = 12V

IC1 = 4060

TRIAC = BT136

Waveform Simulation

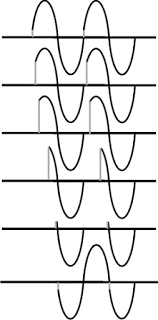

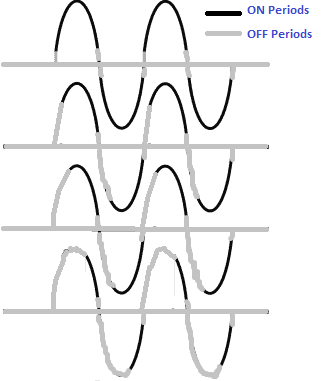

The delay waveform image below shows how the phase for the fan may be delayed at every zero crossing, for the various settings of VR1 and C2.

Smart PWM Fan Regulator Using IC 555

Almost all light/fan regulator circuits make use of a silicon-controlled rectifier (triac or SCR).

These devices are switched with a predetermined phase angle which subsequently stays in the conduction mode until the following zero crossing of the mains AC cycle.

This process looks easy, however simultaneously it presents difficulties while controlling smaller loads or which are inductive in nature causing hysteresis and flickering.

The reason of these issues depend on the truth that due to smaller load wattage the current delivered to the devices is inadequate to sustain their conduction.

Therefore a region of the control characteristic is not thoroughly implemented. The outcome further deteriorates for the loads that are inductive.

How the Circuit Works

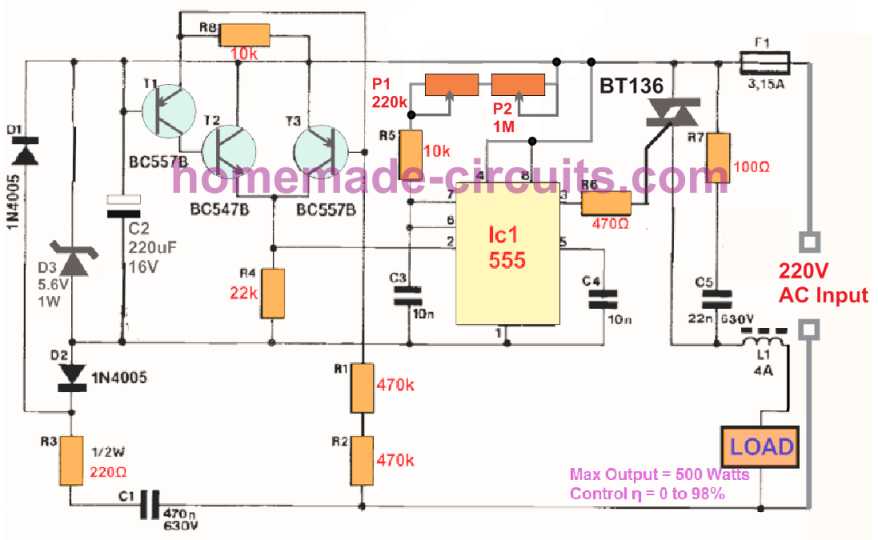

The proposed AC 220V PWM regulator circuit using IC 555 gives you a simple solution by supplying the triac with a constant gate current, to ensure that loads as nominal as 1 watt is also controlled smoothly.

To have the circuit as compact and straightforward as it can be, we utilize the popular timer IC 555.

The output of the IC 555, which can be typically triggered high, is activated low through a negative potential input.

This negative supply is made available from the stage comprising C1-R3, rectifier D1 -D2, along with stabilizer section D3-C2. BJTs T1 to T3 deliver a initializing pulse on the trigger input pin#2 of the 555 for each of the zero crossings of the mains AC input.

During a PWM period, as decided by the adjustment of P1 and P2, the output of the IC 555 is usually high, and we, therefore, have practically zero voltage difference across pins 3 and pin 8, i.e. the triac remains switched off.

As soon as the set interval is elapsed, pin 3 becomes low and the triac is activated.

For the rest of the half AC cycle, a gate current keeps running, which allows the the triac to continue to conduct.

The lowest point where, let's say, a light bulb need not just illuminate, is determined by carefully adjusting the pot P1. Filter R7 C5 L1 supplies the necessary decoupling for the triac.

As a final point, remember that the absolute maximum power that could be governed by this IC 555 based smart regulator switch should not exceed 600 watts.