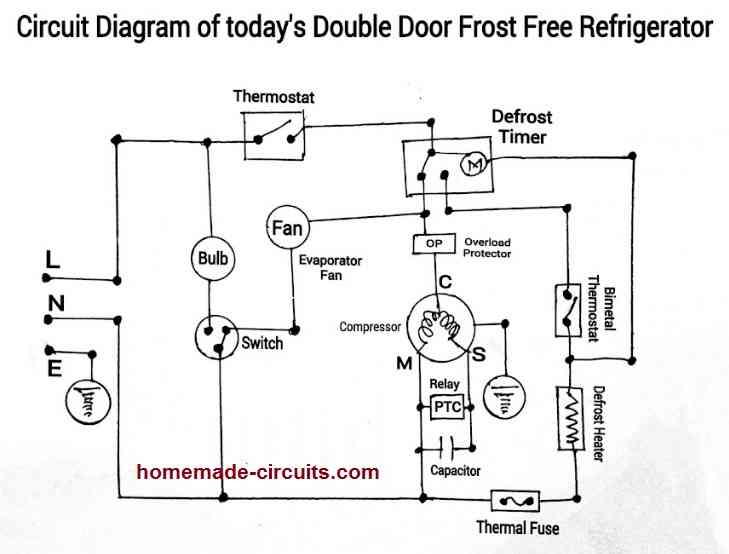

Existing frost free double door refrigerators function with the help of defrost timer and defrost heater for automatic defrosting. The objective of my circuit is to convert the existing refrigerator to one, without freezer (freezerless)

Written and Submitted By: Subramanian. C.N.

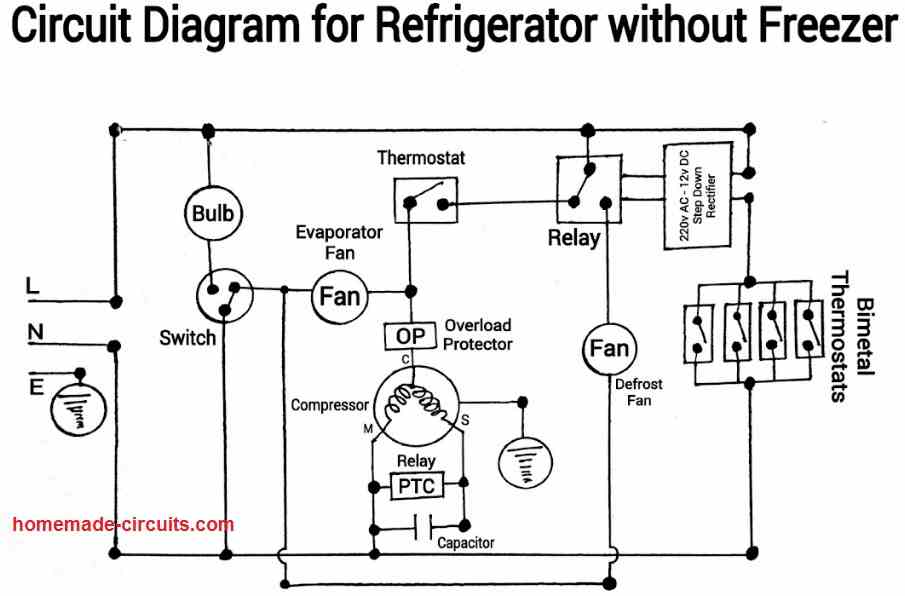

My circuit modifies the existing circuit of my refrigerator, by replacing the existing defrost heater with a DEFROST fan (additional) which helps to defrost the ice accumulated on the evaporator.

Also, my circuit replaces the defrost timer with a relay, which switches when the temperature goes below, in the same way a defrost timer works.

The relay gets operated by the same bimetal thermostat inside the refrigerator. Also, my design seals all the holes in the back of the freezer except one, to make the freezer a fridge, permanently.

Working principle of my circuit

Since the back of the freezer contains only one hole to let in cold air by the EVAPORATOR fan provided by the manufacturer, the freezer would function as fridge normally.

When the temperature drops below a certified amount, the bimetal thermostat will switch the relay to stop the compressor and EVAPORATOR fan, by switching on the DEFROST fan provided by my design at the back of the freezer.

When the temperature increases, the bimetal thermostat would switch on the compressor and EVAPORATOR fan, by switching the DEFROST fan off. Thermal fuse is not needed for my circuit, since it doesn’t employ defrost heater.

However, my circuit requires additional fan for defrosting. The fan employed by the manufacturer shouldn’t be used for defrosting because, if used, it would run non stop, throughout the life of the refrigerator. This circuit will serve its best, if the refrigerator is single door.

But, to be effective, the existing single door refrigerator should shift the evaporator coils on the freezer to its back, like that of a frost free double door refrigerator.

This idea can’t be new, since there already exists bottle coolers without freezers. My idea is just to convert the existing refrigerators with freezer into freezerless ones.

Pros and Cons of my circuit:

Pros:

1. Since it employs DEFROST fan in place of defrost heater, it saves energy (electrical).

2. Since it employs DEFROST fan in place of defrost heater, the compressor run time is minimised, since the DEFROST fan (provided by my circuit) would provide cooling to the refrigerator, longer. Defrost heater just increases compressor run time by defrosting the ice on the evaporator coil, quicker.

3. This modified circuit would require only half of the energy, consumed by the original circuit of the manufacturer.

4. Since the compressor run time is minimized, it extends the life of the compressor.

5. My circuit reduces maintenance of the refrigerator since it is simple without defrost heater, without defrost timer and without thermal fuse.

Cons:

1. My circuit can’t provide a freezer. This circuit is only suited for refrigerators without freezer similar to commercial bottle coolers.

A single door manual defrost refrigerator is the best energy efficient of all, because, the frost on the freezer provides cooling to the refrigerator through convection at all times, even during defrosting, without additional energy consuming components and complicated circuits.

But, the only problem is that its freezer can’t serve its purpose during defrosting operation, the main reason why frost free refrigerators came to fill this gap, though it makes everyone feel that the frost free refrigerators exist, to relieve us from the hassle of manual defrosting (also an admissible additional feature).

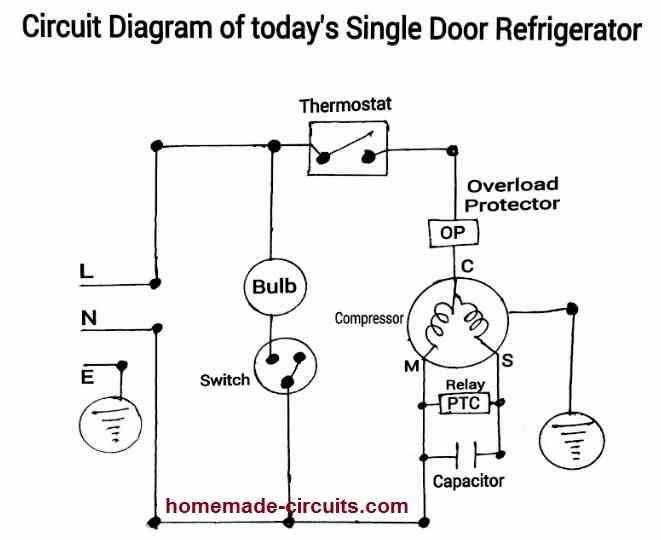

The double door frost free refrigerator’s thermostat, function the same way as is in a single door manual defrost refrigerator, but, lacks the manual defrosting switch, since defrosting is automated with the help of a bimetal thermostat, defrost heater and defrost timer.

If we remove these additional automatic defrosting components and keep the back of the freezer open permanently, then we can manually defrost the refrigerator, by switching it (refrigerator) off. Energy consumption is notably more in a double door refrigerator, just because of its high energy consuming defrost heater.

Also, since the accumulated frost gets destroyed by the heater during the defrost cycle, it (the frost) is not used by the refrigerator effectively.

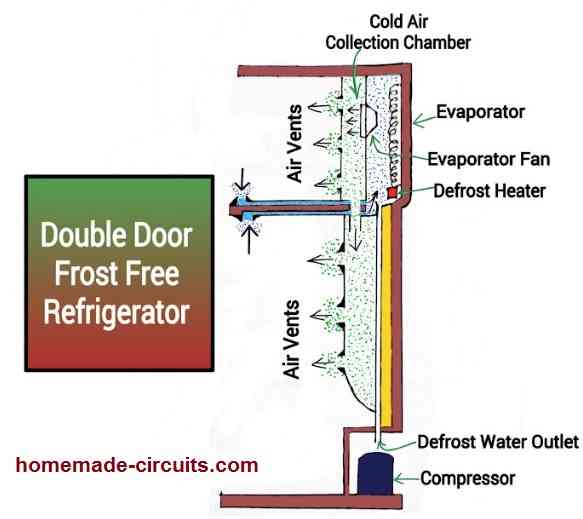

In a frost free refrigerator, evaporator fan is provided, just because, cooling by convection can’t be effective, since the evaporator coil is hidden and the small vents provided at the internal back of the refrigerator can’t provide enough cooling by convection effectively.

A frost free refrigerator can provide ice (edible) at all times (even during defrost cycle) only if the frost on the evaporator coils gets destroyed quickly, the reason why the heater is employed.

If the defrosting is done slowly, like that in a single door refrigerator, the ice (edible) would melt with the accumulated frost on the evaporator coils (during defrost cycle), making its freezer useless (during defrost cycle).

An idea without a purpose is useless. The main purposes behind my idea are as follows:

1. Not every consumer needs freezers. A simple example would be, the bottle coolers. A refrigerator without freezer would look neat and clean for those who don’t need freezers. Anything that looks good, feels good.

2. To increase refrigerator’s shelf space by removing its freezer permanently.

3. To automate defrosting in a simple economic way which saves energy with a simple circuit.

4. To relieve consumers from the hassle of manual defrosting using a simple circuit which brings down costs.

My idea is to use the frost provided by the evaporator coils efficiently, without wasting by liquidating it by a heater to save energy. But, to be honest, this is in no way better than a manual defrost refrigerator. Above all, my idea is useless for those who need freezers.

Freezerless Refrigerator

My circuit keeps the automatic defrosting intact, even after the removal of defrost heater. In my circuit, the compressor and the evaporator fan is OFF, when the thermostat is OFF.

When the temperature increases, the thermostat switches ON the evaporator fan and compressor like a manual defrost single door refrigerator.

When the frost increases on the evaporator, the bimetal thermostat switches ON, to stop the compressor and the evaporator fan and starts the defrost fan with the help of a relay, irrespective of whether the temperature control thermostat is ON/OFF. My circuit uses 4 bimetal thermostats in parallel to maximise defrosting.

The four bimetal thermostats finds its place on the four corners of the evaporator coil. Even if one bimetal thermostat is ON, the line is ON for defrosting.

Since the defrosting is done by a fan instead of a heater, defrost duration increases. All the accumulated frost is used efficiently by the defrost fan to cool the refrigerator longer, when the compressor is off, to save energy.

My circuit diagram employs a reciprocating compressor. Changes can be made to my circuit diagram, for a refrigerator that employs an inverter compressor.

But, my circuit becomes meaningful only if a reciprocating compressor is employed, because, today’s inverter compressors are not as powerful as reciprocating compressors, in relevance to cooling effectiveness.

I admit that reciprocating compressors consume more current to start, but, only for a very short span (spark) of time (to start the compressor).

Inverter compressors work on DC which requires rectifier boards making the circuits of refrigerators complicated which might require maintenance (sometimes, frequently) later. Good for the manufacturers but, bad for consumers.

To implement my circuit, the body of today’s frost free refrigerator requires some structural changes for effective cooling and energy savings. In my design the structural changes to the body of the refrigerator gains importance than the circuit itself.

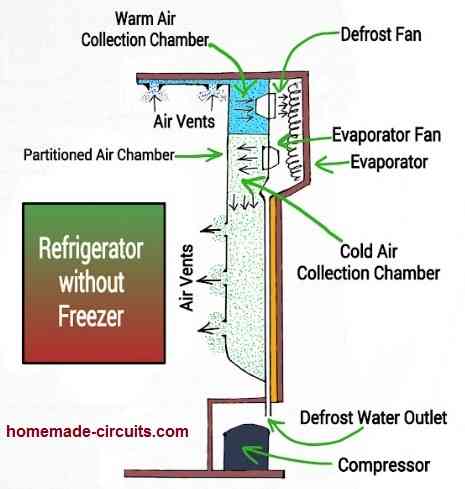

The body of today’s frost free refrigerator with freezer and the pattern of air flow is illustrated by the diagram below.

For a frost free freezerless refrigerator, two doors aren’t necessary. The efficiency and effectiveness lies in the pattern and control of air flow and the placement of fans as shown in the diagram below. Please note that the air collection chamber is divided and is independent of one another.

In my design, vents aren’t provided on the back (interior) near the evaporator coil to avoid freezing inside the refrigerator. For those who needs to convert their existing frost free refrigerators to ones without freezers, they need to make the necessary alterations to their refrigerator’s structure.

Doubts may arise as to whether my circuit requires today’s cooling potential of compressor and evaporator, since my design involves refrigeration WITHOUT a FREEZER.

Suppose, if the cooling potential is reduced, the refrigerator would become an closed air conditioned container, making cooling duration longer and cold retention shorter, which would increase compressor run time.

Hence, if the cooling potential of today’s compressor and evaporator coils aren’t compromised, the compressor run time would be reduced considerably without affecting cooling effectiveness.

In both the cases the total energy consumed will be the same just like the difference between 110v and 220v power supply. But, if the same compressor (the one which used today) is used, its (compressor) life span increases, since its wear and tear decreases due to decrease in run time.

I admit that there are also frost free refrigerators without defrost timers and without bimetal thermostats. Here the defrosting is automated by electronic thermostats accompanied by a special purpose circuit and a defrost heater. Now, we can find single door refrigerators with auto defrost technology.

But, it works the same way like a manual defrost refrigerator, just my automating its thermostat function (by removing its manual defrost switch) to deliver defrosting without our interference.

The main reason why I needed to convert my frost free refrigerator to a freezer-less refrigerator is to increase its shelf space and to save energy by removing its defrost heater.

To conclude, a manual frost free refrigerator is THE best of all energy efficient refrigerators, since my circuit also uses additional defrost fan, existing evaporator fan and additional components which adds to the refrigerator’s cost and energy consumption. Also, it lacks freezer. My idea is just another variant, which may accompany today’s variants of refrigerators.

Single speed, AC reciprocating/rotary compressors are always better than variable speed DC invertor compressors. The difference is nothing like the differences between AC of Nikola Tesla and DC of Thomas Alva Edison.

Wrapping Up

Hope my circuit might help some. Above all, I should THANK YOU VERY MUCH for giving me the space and opportunity to share my ideas with you and with all the readers of your website.