In this article I have explained how to make a multilevel (5 step) cascaded inverter circuit using a very simple concept developed by me. I have explained more regarding the details.

The Circuit Concept

In this website so far I have developed, designed and introduced many sine wave inverter circuits using straightforward concepts and ordinary components such as IC 555, which happen to be more result oriented instead of being complex and full of theoretical jumbles.

I have explained how simply a high power audio amplifier can be converted into a pure sine wave inverter, and I have also covered comprehensively regarding sine wave inveters using SPWM concepts

We have also learned through this website regarding how to convert any square inverter into a pure sine wave inverter design.

Assessing the above sine wave inverter circuits using sine equivalent PWMs, we understand that the waveform of SPWMs do not directly match or coincide with an actual sinusoidal waveform, rather these execute the sine wave effect or results by interpreting the RMS value of the actual sine wave AC.

Although SPWM can be considered an effective way of replicating and implementing a reasonably pure sine wave, the fact that it does not simulate or coincide with a real sine wave makes the concept a little unsophisticated, especially if compared to a 5 Level cascaded sine wave inverter concept.

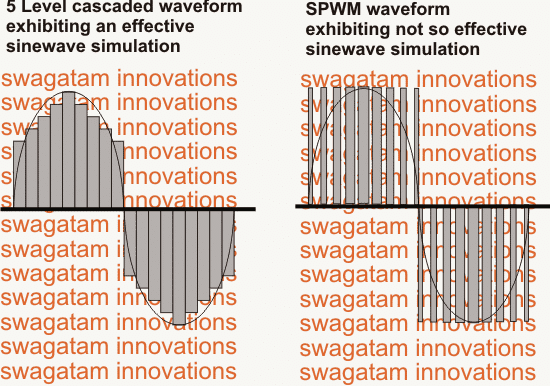

We can compare and analyze the two types of sine wave simulation concepts by referring to the following images:

Multilevel Cascaded Waveform Image

We can clearly see that the multilevel 5 step cascaded concept produces a more obvious and effective simulation of a real sine wave than the SPWM concept which relies solely on matching the RMS value with the original sine wave magnitude.

Designing a conventional 5 Level Cascaded sine wave Inverter can be quite complex, but the concept which is explained here makes the implementation easier and employs ordinary components.

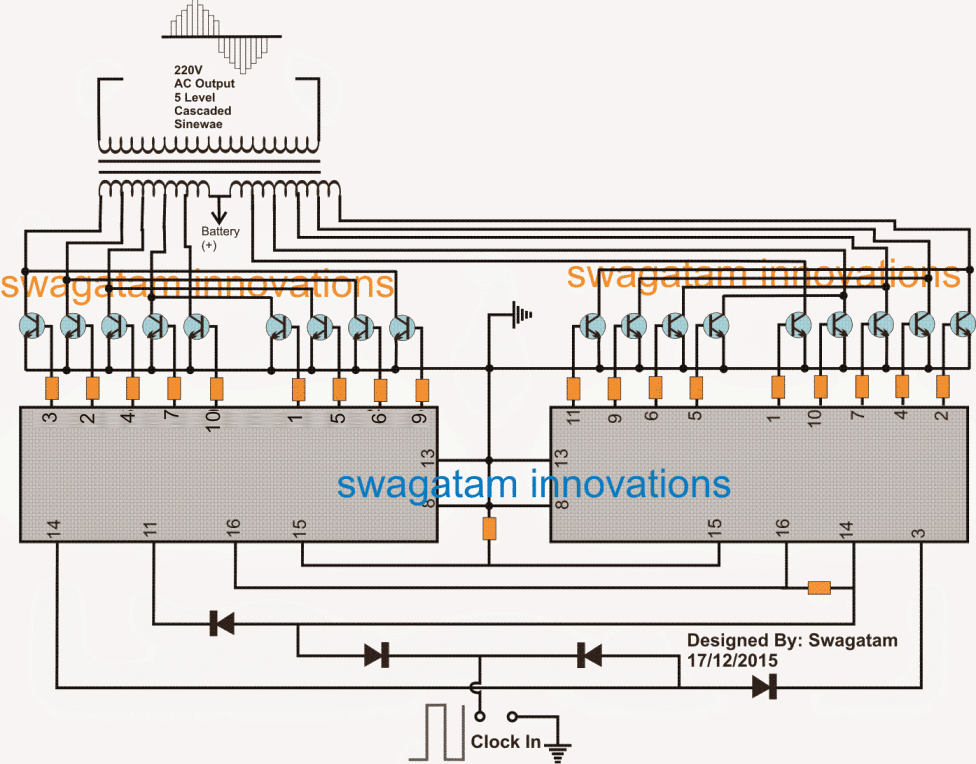

Circuit Diagram

NOTE: Please add a 1uF/25 capacitor across pin#15 and pin#16 lines of the ICs, otherwise the sequencing will not initiate.

Referring to the image above, we can see how simply the 5 level cascaded inverter concept can be practically implemented using just a muti-tap transformer, a couple of 4017 ICs and 18 power BJTs, which could be easily replaced with mosfets if required.

Here a couple of 4017 ICs which are Johnson's 10 stage counter divider chips, are cascaded to produce a sequentially running or chasing logic highs across the shown pinouts of the ICs.

Circuit Operation

These sequentially running logic are used for triggering the connected power BJTs in the same sequence which in turn switch the transformer winding in an order which causes the transformer to produce a cascaded kind of sine equivalent waveform.

The transformer forms the heart of the circuit and employs a specially wounded primary with 11 taps. These taps are simply extracted uniformly from a single long calculated winding.

The BJTs associated with one of the ICs switch one of the halves of the transformer through 5 taps enabling the generation of 5 level steps, constituting one half cycle of the AC waveform, while the BJTs associated with the other ICs does the identical function to shape up the lower half AC cycle in the form of 5 level cascaded waveform.

The ICs are run by clock signals applied to the indicated position in the circuit, which could be acquired from any standard 555 IC astable circuit.

The first 5 sets of the BJTs build up the 5 levels of the waveform, the remaining 4 BJTs switch the same in reverse order to complete the cascaded waveform having a total of 9 skyscrapers.

These skyscrapers are formed by producing an ascending and descending voltage levels by the switching of the corresponding winding of the transformer which are rated at the relevant voltage levels

For example, winding #1 could be rated at 150V with respect to the center tap, the winding #2 at 200V, winding #3 at 230V, winding #4 at 270V and winding #5 at 330V, so when these are switched sequentially by the set of the shown 5 BJTs, we get the first 5 levels of the waveform, next when these winding are switched in reverse by the following 4 BJTs it creates the descending 4 level waveforms, thus completing the upper half cycle of the 220V AC.

The same is repeated by the other 9 BJTs associated with the other 4017 IC giving rise to the lower half of the 5 level cascaded AC, which completes one complete AC waveform of the required 220V AC output.

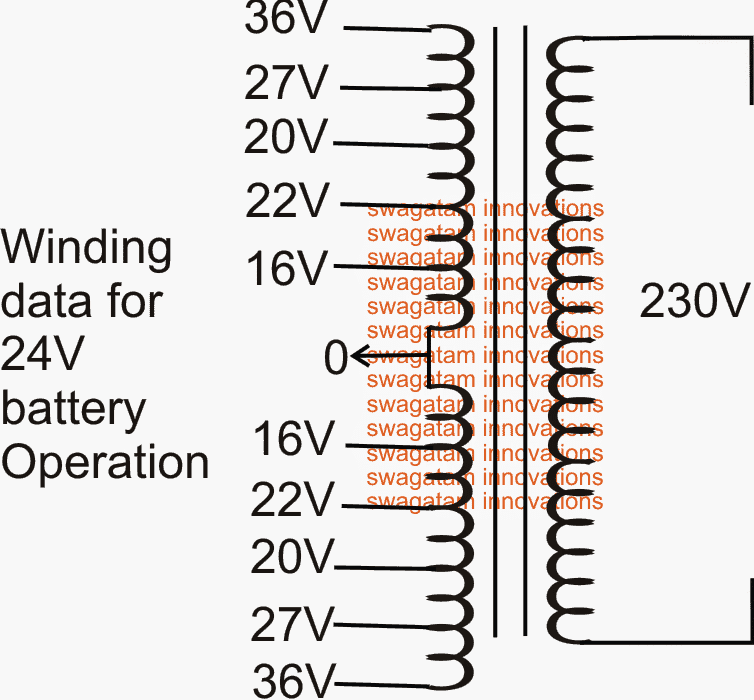

Transformer Winding Details:

As may be witnessed in the above diagram, the transformer is an ordinary iron core type, made by winding the primary and the secondary with turns corresponding to the indicated voltage taps.

When connected with the corresponding BJTs these winding can be expected to induce a 5 level or a total of 9 level of cascaded waveform wherein the first 36V winding would correspond and induce a 150V, the 27V would induce an equivalent of 200V, while the 20V, 27V, 36V would be responsible of producing 230V, 270V and 330V across the secondary winding in the proposed cascaded format.

The set of taps on the lower side of the primary would carry out the switching to complete 4 ascending levels of the waveform.

An identical procedure would be repeated by the 9 BJTs associated with the complementary 4017 IC for building the negative half cycle of the AC...the negative is rendered due to the opposite orientation of the transformer winding with respect to the center tap.

Update:

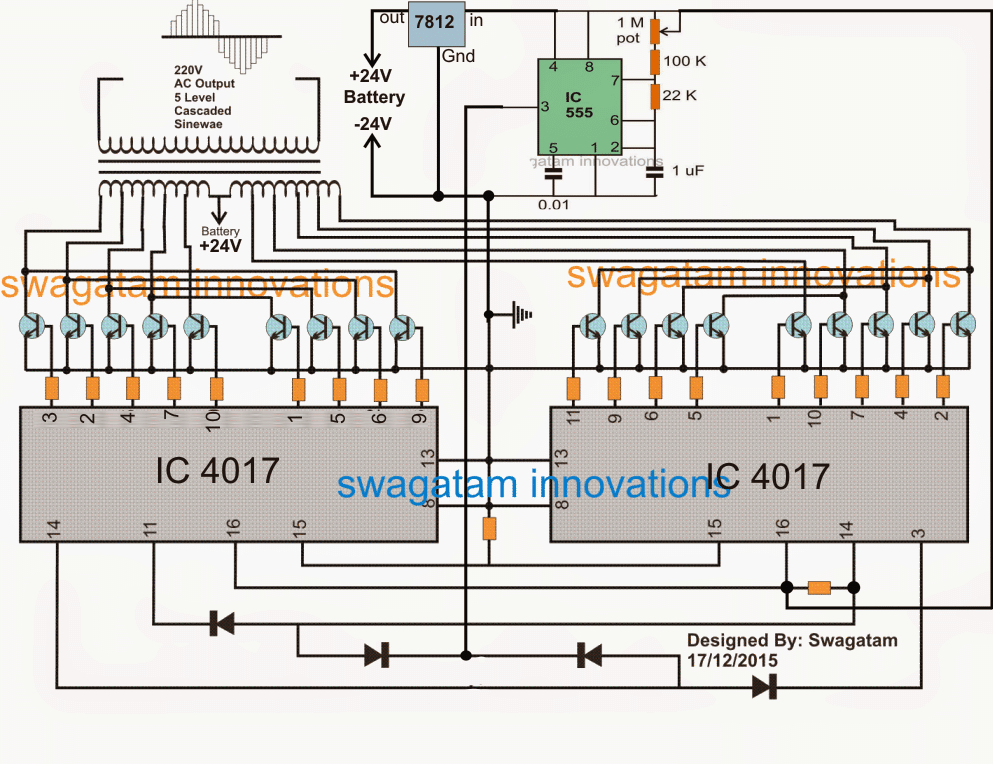

Complete circuit diagram of the discussed multi-level sinewave inverter circuit

NOTE: Please add a 1uF/25 capacitor across pin#15 and pin#16 lines of the ICs, otherwise the sequencing will not initiate.

The 1M pot associated with the 555 circuit will need to be adjusted for setting up a 50Hz or a 60Hz frequency for the inverter as per the country specs of the user.

Parts List

All unspecified resistors are 10k, 1/4 watt

All diodes are 1N4148

All BJTs are TIP142

ICs are 4017

Notes for the Multilevel 5 Step Cascaded Sine Wave Inverter Circuit:

The testing and verification of the above design was successfully conducted by Mr. Sherwin Baptista, who is one of the keen followers of the website.

1. We decide the input supply to the inverter---24V @ 18Ah @ 432Wh

2. There will be an issue of NOISE generated in the whole process of building this inverter. To crack the issue of noise generated and amplified very easily;

A. We decide to filter the output signal of IC555 the moment it is produced at pin 3, by doing so a cleaner square wave can be obtained.

B. We decide to use FERRITE BEADS at the respective outputs of IC4017 to enhance filtering before the signal is sent to the amplifier transistors.

C. We decide to use TWO TRANSFORMERS and enhance filtering between both of them in the circuit.

3. The Oscillator Stage Data:

This proposed stage is the main stage of the inverter circuit. It produces the required pulses at a given frequency for the transformer to operate. It consists of IC555, IC4017 and Amplifier Power Transistors.

A. IC555:

This is an easy to use low power timer chip and has plenty of variety of projects that can be done using it. In this inverter project we configure it in astable mode to generate square waves. Here we set the frequency at 450Hz by adjusting the 1 megaohm potentiometer and confirming the output with a frequency meter.

B. IC4017:

This is a Jhonson's 10 stage counter divider logic chip which is very famous in sequential/running LED flasher/chaser circuits. Here it is smartly configured to be used in an inverter application. We provide this 450Hz generated by IC555 to the inputs of IC4017. This IC does the job of breaking the input frequency into 9 parts with each resulting in a 50Hz output.

Now the output pins of both 4017's are having a clock signal of 50Hz continuously running forward and backward.

C. The Amplifier Power Transistors:

These are the High Power Transistors which pull the battery power into the transformer windings with accordance to the signal fed into them. Since the output currents of the 4017s are too low, we cannot directly feed them into the transformer. Therefore we need some kind of amplifier which will convert the low current signals from the 4017s into high current signals which then can be passed onto the transformer for further operation.

These transistors would get hot during operation and would necessarily need heatsinking.

One could use a separate heatsinks for each transistor, hence it should be ensured that the

heatsinks do not touch each other.

OR

One could use a single long piece of heatsink to fit all the transistors on it. Then one should

thermally and electrically isolate each transistor's center tab from touching the heatsink in

order to avoid them from getting shorted. This can be done by using Mica Isolation Kit.

4. Next comes the First Stage Transformer:

A. Here we employ the Multi-tapped Primary to a Two Wire Secondary transformer. Next we find the volts per tap to prepare the primary voltage.

---STEP 1---

We take into consideration the Input DC Voltage that is 24V. We divide this with 1.4142 and find its AC RMS equivalent which is 16.97V~

We round the above RMS figure which results in 17V~

---STEP 2---

Next we divide RMS 17V~ by 5(since we need five tap voltages) and we get RMS 3.4V~

We take the final RMS figure by 3.5V~ and multiplying it by 5 gives us 17.5V~ as a round figure.

In final we found the Volts Per Tap which is RMS 3.5V~

B. We decide to keep the Secondary voltage to RMS 12V~ i.e., 0-12V is because we can obtain a higher amperage output at 12V~

C. So we have the transformer rating as below:

Multi-tapped Primary: 17.5---14---10.5---7---3.5---0---3.5---7---10.5---14---17.5V @ 600W/1000VA

Secondary: 0---12V @ 600W/1000VA.

We got this transformer wound by a local transformer dealer.

5. Now follows the main LC Circuit:

An LC circuit being known as a filter device has robust applications in power converter circuits.

Being used in an inverter application it is generally required for breaking down the sharp peaks

of any generated waveform and helps convert it into a smoother waveform.

Here at the secondary section of the above transformer being 0---12V, we expect a multilevel

square cascaded waveform at the output. So we employ a 5 Stage LC Circuit to get a SINEWAVE equivalent waveform.

The data for the LC Circuit is as below:

A) All Inductors should be a 500uH(microhenry) 50A rated IRON CORE EI LAMINATED.

B) All Capacitors should be a 1uF 250V NONPOLAR type.

Note that we stress on the 5 stage LC circuit and not just one or two stages such that we can get a much cleaner waveform at the output with lesser harmonic distortion.

6. Now comes the Second and Final Stage Transformer:

This transformer is responsible for converting the output from the LC network i.e., RMS 12V~ to 230V~

This transformer would be rated as below:

Primary: 0---12V @ 600W/1000VA

Secondary: 230V @ 600W/1000VA.

Here, NO additional LC network would be required at the final 230V output for more filtering since we already filtered every stage of each processed output at the beginning.

The OUTPUT will now be a SINEWAVE.

A GOOD thing is that there is absolutely NO NOISE at the final output of this inverter and

sophisticated gadgets can be operated.

But one thing to be kept in mind by the person operating the inverter is NOT TO OVERLOAD THE INVERTER and keep the power loads of sophisticated gadgets being operated in limits.

A few corrections to be made in the circuit diagram are given as under:

1. The IC7812 regulator should have bypass capacitors connected. It should be mounted on a

HEATSINK since it would get warm during operation.

2. The IC555 timer should follow a series resistance before it's signal passes forward to diodes.

The value of resistance should be 100E. IC gets hot if the resistor is not connected.

In Conclusion we have 3 proposed filter stages:

1. The signal generated by IC555 at pin 3 is filtered to ground and then passed on to resistor

and then to the diodes.

2. As the running signals exit the relevant pins of IC4017, we connected ferrite beads before

passing signal to resistor.

3. The final filter stage is employed between both transformers

How I Calculated the Transformer Winding

I would want to share something with you today.

When it came to winding iron core, i knew nothing about rewinding specifications since i found out a lot of parameters and calculations go into them.

So for the above article i gave the basic specs to the trafo winder person and he just asked me:

a) The input and output voltage; tapping if necessary,

b) The input and output current,

c) The total power,

d) Do you need external clamping fixture bolted to the trafo?

e) Do you want a fuse connected internally in the transformer 220V side?

f) Do you want wires connected to the trafo OR simply keep the enameled wire on the outside with added heatsink material?

g) Do you want the core to be grounded with an external wire connected?

h) Do you want the IRON CORE to be protected; varnished and painted with black oxide?

Finally he assured me of a complete safety test for the transformer being a made-to-order type once ready and it will take a span of 5 days to get completed till a part payment is provided.

The part payment were (on an approx.) one fourth of the total proposed cost dictated by the winder person.

My answers to the above questions are:

NOTE: To avoid wiring confusions, i assume trafo is made for one purpose: STEP DOWN TRANSFORMER where primary is high voltage side and secondary is low voltage side.

a) 0-220V primary input, 2-wires.

17.5---14---10.5---7---3.5---0---3.5---7---10.5---14---17.5V secondary multi-tapped output, 11-wires.

b) The primary input current: 4.55A at 220V The output current: 28.6 Amps on multi-tapped secondary @ end to end voltage 35V…..where calculation is concerned.

I told him i need 5 amps at 220V(230. max) i.e., primary input and 32 amps at 35V i.e., multi-tapped secondary output.

c) I initially told him 1000VA but based on volt times amp calculation and rounding off decimal figures, the power went to 1120VA +/-10%. He provided me with a safety tolerance value for the 220V side.

d) Yes. I do need for easy fixture onto metal cabinet.

e) No. I told him i will place one externally for easy access of it when it accidentally blows off.

f) I told him to keep the enameled wire on the outside for the multi-tapped secondary side being appropriately heatsinked for safety and on the primary side i requested wires to be connected.

g) Yes. I need the core to be earthed for safety reasons. Therefore please attach an external wire.

h) Yes. I requested him to provide the necessary protection for the core stampings.

These were the interaction between me and him for the proposed made-to-order type transformer.

UPDATE:

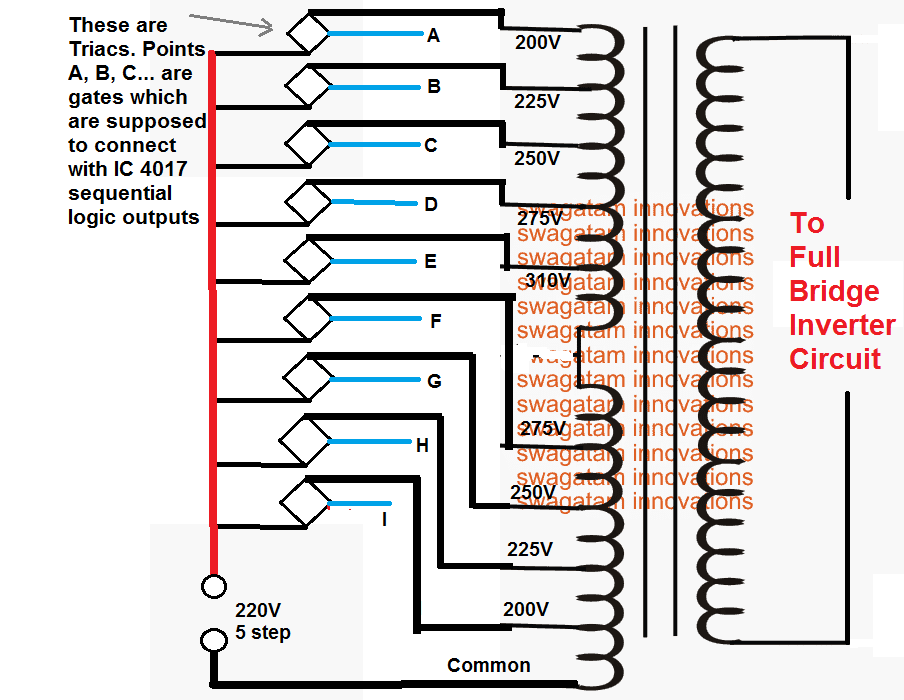

In the above 5 step cascaded design we implemented the 5 step chopping across the DC side of the transformer, which appears to be a bit inefficient. It's because the switching could result in a significant amount of power lost through back EMF from the transformer, and this will need the transformer to be enormously big.

A better idea could be to oscillate the DC side with a 50 Hz or 60 Hz full bridge inverter, and switch the secondary AC side with our 9 step sequential IC 4017 outputs using triacs, as shown below. This idea would reduce spikes and transients and enable the inverter to have a smoother and efficient execution of the 5 step sine waveform. The triacs will be less vulnerable to the switching, compared to the transistors at the DC side.

Do you happen to have the oscilloscope waveforms for this DIY inverter?

Thanks,

Will

Sorry, presently we do not have the oscilloscope image of the waveform.

I am interested in a circuit that doesn’t use a transformer if possible but I will use it if needed. I need to use a 12vdc or 24vdc input and I need to acquire a 130vdc at 18a on the output side. I have looked through the web site to find something like that but unable to locate a circuit to fit my needs. I prefer to obtain my goal as soon as possible. Can you help.

I don’t think an inverter can be built without a transformer….that doesn’t seem feasible.

Creo que les falta algo muy importante ….. y son las fechas de las preguntas y respuestas ….. por lo anterior si es posible un inversor sin transformador de nucleo de hierro .

Hello Baptista I will appreciate if you will send me the LC filter stage circuit diagram you used. My email: uchennanze218@gmail.com

I have mentioned the details of the LC filter circuit in the article itself. Make sure you use EI laminated iron core type inductors only.

These will need to be made-to-order type and may not be available ready-made.

Initially you can try 100uH : The inductor value, and 50A : The rated coil current.

You will need to build five of them to have maximum filtering to a close sine wave.

Sir Swagatam, please can you give me the circuit diagram of the 5 stage LC filter circuit that should be connected to this inverter? My email address uchennanze218@gmail.com

Thanks

Hi Dominic, sorry I do not have a 5 stage LC filter circuit at this moment.

Just to confirm with you that when transformers are designed taking for example 100 VA 220V primary and 0–12 V secondary(two wire), upon test measuring the current of the secondary side gives us 8.33 A (can go up to 8.5 or 10 A if properly rated with accuracy)on a short circuit……IS THAT RIGHT? please clarify.

But in this proposed article i had to build a multi-tapped transformer with the rating 1000 VA 220 V primary to 17.5—14—10.5—7—3.5—0—3.5—7—10.5—14—17.5 V secondary.

My question:

1. Does it mean that on end to end i.e., 35 V secondary i will get 28.57 A (may go up to 30 A where accuracy and rounding off is concerned) on a SHORT CIRCUIT? please clarify.

2. If we draw a smaller voltage from the transformer for a different application i.e., taking for example the smallest voltage available being 3.5 V from the output are we still able to get the HIGH CURRENT being 28.57 A at those taps ? please clarify.

3. When converting from a higher voltage to a lower voltage using a transformer, IS THE POWER CHANGED? please clarify.

What i mean to say is that the power flowing in the primary winding is the same as the power flowing in the secondary winding.

Hi Sherwin,

The current will be the same across all the winding as per its rating. So the smallest winding and the longest winding all will have identical current delivering capacity in them.

Power will be always equal across the primary and secondary. For example for a 12/5 amp/220V transformer, the power will be 12 x 5 = 60 watt on one side and 220V x 270 mA = 60 watt on the other side.

Dear Mr. Swagatam,

I have updated the details of the LC circuit, this time it was smartly configured to be operated on the 220V side of the transformer…..I hope you have noticed it…..in my previous comment in the article.

I used 3 stages for the LC circuit.

Point: The LC filtering were far easier on the 220V side of the transformer since it involved much lesser current there.

Thank you Dear Sherwin,

All your efforts are truly commendable.

It would be great if you could complement these with some pictures or a video clip for the interest of the viewers.

Dear Sir Swagatam,

I have succeeded with the conversion part of stepped sine wave to pure sine wave conversion. I used one transformer in the circuit (primary multi-tapped 11 wires and secondary 2 wire) as i described earlier.

I have placed the filter on the secondary side 220v this time and the results were:

1. Such that the LC filter were much happier, there were less strain on the LC stages to filter out the waveform at 220V.

2. For the LC circuit, i used a 2A step down transformer for the ‘L’ and 1.25uF 440V oil based capacitor for the ‘C’.

Being ‘C’ remaining charged at mains voltage after the inverter shut off, i shunted a 220K resistor across the caps at every stage. I made three such stages and then used lamp and speaker to find out the hum.

3. To be sure how the sine hum is i connected lamp+speaker directly on mains and listened carefully. I memorized the hum.

Next, i placed the lamp+speaker directly on the final stage of the LC circuit and the hum were somewhat similar. Now i’m quiet relaxed at the moment.

4. I connected a 75 watt ceiling fan to the final LC stage. The fan ran smoothly without any hum at the proposed speed set on the regulator.

I also tested the fan on a ceramic based wire-wound resistance step type regulator to see for any audible humming but there were no hum.

I also tried a 40W tubelight with copper ballast and it worked normally without any humming.

5. I can call it a near sine wave output since inductive loads are being able to operate without humming on the final stage of the LC circuit.

NOW, FINAL SUCCESS is gained by me.

Hello Mr. Swagatam,

Wishing you and your family a very HAPPY NEW YEAR 2019!!!

The inclusion of noise reduction components in the above circuit is eventually necessary, without which there are constant humming from the transformer section when assembled and operated.

I tested the above circuit without inductors and ferrite beads, doing so caused me to bear humming from the transformer, i connected a Ceiling Fan Load to the inverter circuit and that eventually started humming in the process of the inverter in operation.

To avoid all noise issues what i did was:

1. At the very first moment when I built the circuit, I brought all the components and I eventually purchased ferrite beads from the market without fail.

2. On the output pins of both ICs 9 + 9 sequentially, PWM IC555 pin 3 out and 7812 regulator output i placed the ferrite beads before the series resistor as the signal came out of the proposed ICs, in total they sum up to 20 of them.

So on all these paths of the circuit noise is completely suppressed.

For the transformer, i bought it from the market made to order (thinking in a step down configuration to avoid confusions), i prepared the schematic : PRIMARY—2 wire and SECONDARY—5+1+5 meaning 5 taps + common tap + 5 taps—total 11 wires.

The transformer was huge about 4 kgs and the trafo winder asked me for what are you going to use it, be careful and don’t use it for illegal purpose, it is high current and it can harm a human being so use carefully.

I agreed with this fact. It was finally rated for a 1000VA.

It was a well laminated EI structure bolted with nut and screws for a firm layout.

CONCLUSION:

AS YOU KNOW that previously i used TWO TRANSFORMERS in the proposed design and enhanced filtering between both transformers to acquire near sine wave on the output……..i succeeded in the design,

BUT i once for all decided to order a single transformer rated for 1 KVA in the circuit design.

NOW i’ll have to change the LC FILTER parameters since i will be dealing on the 220v primary side and will UPDATE YOU as i progress.

Regards,

SHERWIN BAPTISTA

Hi Sherwin, A Very Happy 2019 to you also!

As usual you have provided some very useful information and I appreciate it very much.

Actually the above idea could be improved a lot by a smart innovation. Instead of switching the 12V side we can switch the 220V side through SCRs or SSRs, and switch the 12V side through a basic full bridge inverter circuit.

So basically we switch the 12V side with 50Hz frequency, and then divide this 50Hz into 5 steps at the 220V side through SSRs.

The advantage of this would be very low loss and higher efficiency.

Please keep up the good work and keep posting your valuable opinions and suggestions.

how many volt transformer for inverter?

Dear Sir,

Where the LC circuit is concerned, i didn't use any software nor calculator rather figured out the combination by mind itself, basically we have two components:

A. The Inductor

B. The Capacitor

Here we select one component with a high value and the other with a much lower value.

Keeping the capacitor value high got me understood that more current were consumed from the inverter for every UF it had. I tried this on one of my previous made inverters and found out that the capacitor value cannot be kept high upto a certain limit. This was with regard to filtering the UPS output.

Also on my COMPUTER UPS 600VA model, the ceiling fan that i powered made irritating noise, but after connecting a 1.25uF capacitor, all noise diminished but the noticeable hum remained.

Then i also tried increasing the capacitor value to 2.5 and 5uF by combining capacitors on the UPS output, they behaved in the same manner and what i got in final was no noise but only hum present.

All this was only after keeping an ammeter connected on the DC side of the UPS and i found out that connecting higher value capacitors consumes more current from the battery.

My UPS never tripped after connecting several caps on the output, but the results were same.

I came up to a conclusion;

"Capacitor only removes NOISE but keeps the HUM intact".

"Capacitor value should be kept as low as possible when filtering inverter output".

What remains is the inductor,

here its value can be kept as high as possible since its always a series connected component. But the resistance for the wire used at a given inductance say 100uH should not exceed 0.001 ohms meaning a thick guage wire should be used for winding and the core should preferably be an EI IRON CORE laminated type.

The inductor is the component going to break down the harmonics in the generated stepped waveform and since being a 5 step inverter, we have attached a 5 stage LC circuit to further enhance the output to a clean sinewave.

Here, sensitive and sophisticated gadgets can be operated without problems.

The final conclusion with the inductor is that;

"It removes the HUM and filters out the waveform making it close to a smooth sine wave and its value(UH) can be kept as high as possible".

The basic LC filter for this inverter design;

Whatever the value(UH) of inductor used one should connect 100 times less the value of capacitor to satisfy one stage of the filter circuit.

The capacitors used for this filter should be preferably a 400V AC cylindrical type rated to work on mains voltage.

Thanks

That's great Sherwin, the practical outcome is more important than calculations, if you are able to achieve a best possible output as per the requirement, that's good enough.

Could you please provide a schematic in my email for the same, I will publish it as a new article, and also compensate you accordingly.

By the way the SPWM article which you required is published below:

https://www.homemade-circuits.com/2017/07/spwm-inverter-circuit-using-ic-555.html

Okay, i just thought that the 4020 might help, but no issues.

Actually i were asking for a second alternative only because i seen it having more outputs than the 4017 that's why i were asking you.

Anyway there are no issues with the 5 level inverter as long as the LC circuit has helped me get the SINE WAVE output.

I have cracked the data of transformer, clamping circuit and LC circuit and will send it to you soon.

THANKS

yes, 4017 has the highest number of outputs (10) to date…I hope somebody manufactures a similar IC with 20 or 30 outputs…

wish you all the best, keep up the good work

Dear Sir,

After getting success in making the Multilevel 5-Step Inverter circuit, i now wish to prepare a higher level inverter i.e., 7 or more step using the IC4020 binary counter.

Please if this is possible my request to you is to help me with the same.

Keeping the LC circuit intact i am getting a stable SINE WAVE output which i added in the previous circuit. This also takes much more space and i'm prepared to make that.

I will send you the updates as i prepare the circuit…..

Just give me a GO……..THANKS!!!

Regards

Dear Sherwin,

for 7 step you will require an IC which may have higher number of sequential outputs than 4017, so far we do not have any such ICs, IC 4020 has even less no of outputs than what 4017 has…so according to me it looks difficult. moreover a 5 step may be quite sufficient for getting a good sinewave output

please send me the filter related updates, as as soon as you finish preparing the details

I forgot to mention,

I have correctly calculated the LC filter circuit and now it takes extra space in my inverter and makes it more bulky.

But i don't mind this since at the output i'm getting a proper sine wave and there is no hum from operating inductive loads.

Finally completed this project.

Thanks

That's great Sherwin, I think you should quickly submit the details to me so that I publish it as a new article.

I'll make sure you are compensated for the article appropriately.

Dear Sir Swagatam,

Now that this project has become successful to me, i'm able to power sophisticated and sensitive gadgets properly from this inverter circuit.

Indeed you have really cracked a simple way of making this step inverter using ordinary components.

I'm greatly thankful to you for providing such an easy circuit.

Thanks.

Thank you Sherwin, I appreciate your efforts a lot, you are indeed one of the valuable readers of this website who builds my projects by deeply understanding the project concept.

Appreciate it a lot, keep up good work.

Dear Sir Swagatam,

I have sucessfully built and tested this multilevel inverter circuit….It works….

Thanks

That's great Sherwin, your keen effort is very much appreciated.

I have received the details of the experiment in my Gmail ID sent by you from G+, and I will soon publish it in this website.

If possible send me your Bank details to my following email, I will make the necessary compensation for the sent write up.

hitman2008

@

live.in

Also Each reading on the transformer in the drawing are they in repect to the 0v tap.

for example if im to test for 36v is it between the last tap and the center tap?

I plan to use 12v so if thats the case would I be able to wrap it 9v, 12v, 15v, 19v, 22v.

the outer tap values are with respect to the center tap, not from end to end

I cant believe this is the first time seeing this post I have built basically all your inverters except this one, did you by chance get any time to test it or have anyone tested it and given you a feed back?

Also do you believe this would be the inverter you have with the closest to puresinwave using a scope to look at the wave?

I have not tested it, but the circuit concept looks pretty straightforward and according to me it should work as stated.

the output will be sinewave effortlessly, although my other designs using PWM will also create pure sinewave if the output filter is optimally calculated

sir can i use FET instead of BJT?

yes you can use…

i don't have an oscilloscope sir.. thank you.

sir at what frequency should the ic 555 set to be able to get a 50hz at the output of the inverter? and at its configuration what's its output power?

..output power will depend on transformer wattage and the battery AH rating, the transistor must be rated accordingly…

sir at what frequency should the 555 ic to be set to be able to take a 50hz frequency at the output of the inverter. i don't an oscilloscope. thank you.

Jay, it should be 9 x 50 = 450 Hz

Hello sir thanks for the reply , there is what noticed on the tranformer detail , the taps are 16,22,20,27,36 , that put tap 3 at lower than tap 2, my questions are (1) was that a mistake? If yes the correct should be 16,20,22,27,36 (2)the voltage between the taps are not even is that ok? (3) I want to achive it with 12 volts 500 watts , so I tend to device the figures in 2 to achive that, there by getting 8,10,11,13.5,18. Is that correct?(4) I want to incorporate the "No load detection" circuit , my question is , after deactivating because of no load , will the circuit be able to detect added load and reactivate or will I need to reset to use it? I look farword to your king reply , best wishes

Thanks Usa,

yes the 20V tap after the 22V seems to be done by mistake, so please correct it appropriately.

Any trafo tap configuration can be used, provided it has a center tap and an identical sets of incrementing winding taps across the two halves.

the no load feature can be added by some suitable circuitry which will need to be figured out…it will be a real time control no resetting would be required.

Hello sir please sujest the power of the transformer for this project , how much power can I achieve with out modifying it?

hello Usa, the transformer will depend on your requirement specs and the load…..you can upgrade it to any level by suitably matching it with the power devices and the battery output specs.

I was thinking of using the old faithful 3055's and winding the coil toroid style. i would make use of current amp bd139/140 buffer between the 4017's and the 3055's.

I think an NPN/PNP buffer is advisable for mosfets, but for the above design a Darlington stage will work better, using BD139 and 2N3055 as pairs…… you may refer to the following example:

https://www.homemade-circuits.com/2014/11/48-v-inverter-circuit.html

im really liking what i see here., but was curious.

is there any chance of a fully blown example of different transformer designs that are compatible with this project and also possibly. a complete diagram. I worked out what needs to be done. but a full diagram would be really cool

I have updated the complete circuit diagram at the bottom of the article, please check it out.

The shown transformer is the recommended one, although it can be upgraded as per other battery voltages by changing the winding data proportionately.