In the previous post I explained a piezo transducer element and learned how to use it with electronic circuits. In this article we will see how a piezo tranducer can be driven or operated using a simple circuit.

As discussed earlier a piezo transducer basically requires a frequency to vibrate and reproduce the required sound.

This property makes these devices typically suitable for buzzer related applications and in warning alarm devices.

So does this mean that if we apply a frequency across the terminals of a piezo transducer, it will start generating the intended sound outputs?

Partially this may be correct but might not be as easy as that.

Basic Working

A thin circular slice of ceramic piezoelectric material placed on a metal diaphragm serves as the fundamental constituent for all forms piezo transducers.

The manufacturer's selection determines the type of ceramic that is utilized. Titanate zirconate and barium titanate are two common substances.

The metal diaphragm is most often composed of brass or stainless steel and has a thickness of less than 0.5mm. Its thin shape guarantees that the metal diaphragm could be quickly activated into a condition of resonant mechanical vibration.

When an AC voltage is passed over the piezoelectric material's electrodes, the body expands and contracts in time with the voltage.

Consequently, sound waves are produced as a result of the metal diaphragm bending in harmony with the ceramic substance.

For best efficiency, keep in mind that the mechanical resonant frequency of the element must coincide with the driving voltage frequency.

Structural Characteristics

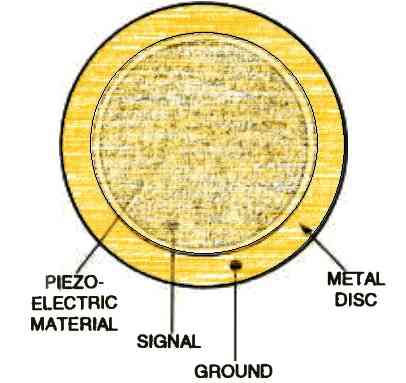

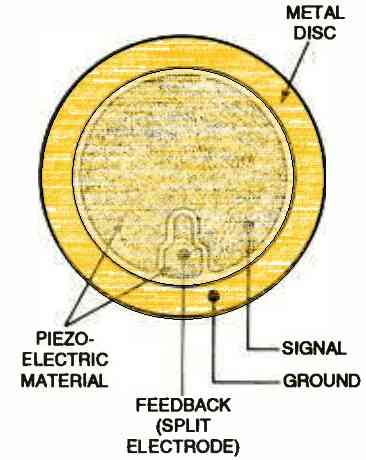

Two main forms of piezoelectric elements are available: two terminal and three terminal. The physical distinctions between the two forms of elements are depicted in the figure below.

In a two terminal type of piezo transducer, the metal diaphragm works like one electrode, while the piezo element serves as the second electrode. An AC signal is applies across these two electrodes to operate a piezo transducer.

The piezoelectric element in the three-terminal type has a split electrode. When an AC signal is supplied to the primary electrodes, a phase-shifted signal is produced between the split electrode and the metal electrode.

The oscillator/driver circuit is provided feedback from the phase-shifted signal in order to make it resonate at the element's intrinsic frequency.

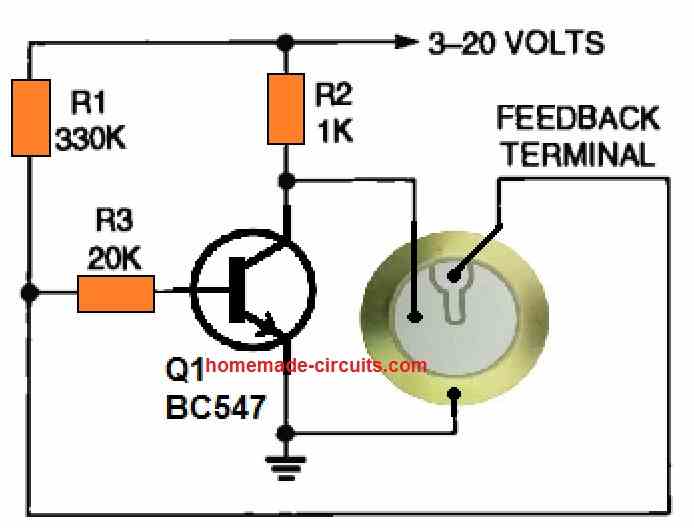

Piezo Driver using a Single Transistor

A basic "self-drive" piezo driver circuit is shown in the following figure.

In this oscillator, the inductor and capacitor that typically make up a Hartley circuit have been replaced by a piezoelectric device.

The image provides common component values. The working voltage and resonant frequency can vary from 3 to 20 volts and 2 to 6 kHz, respectively, depending on the specific element and transistor utilized.

How to Operate a Piezo with Maximum Sound

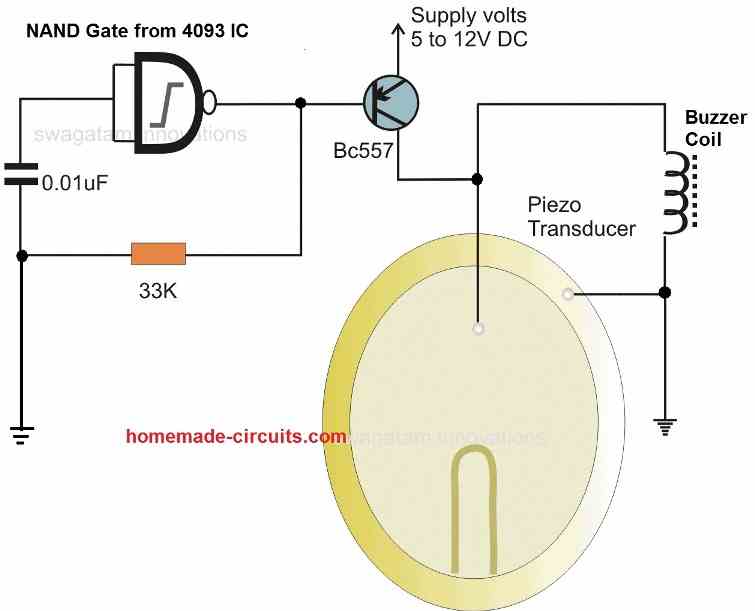

The applied frequency will be required to be amplified very sharply or strongly before it can actually produce the intended effects in the piezo.

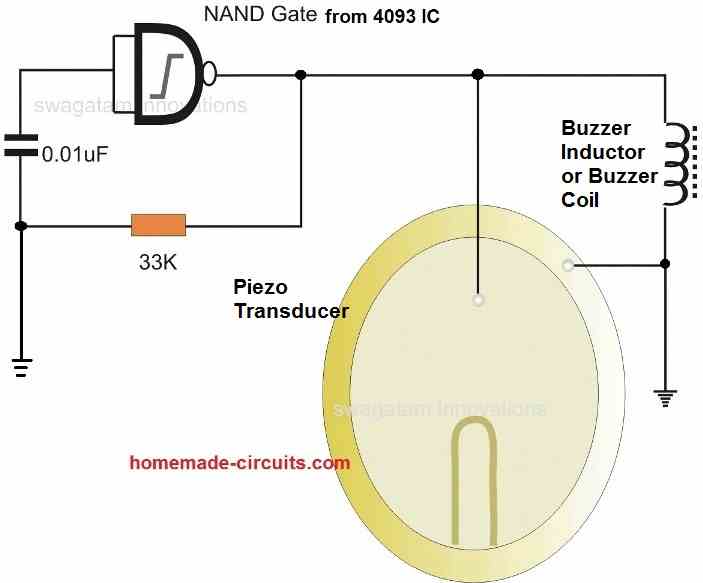

However the amplification procedure is not by using conventional amplifying circuits as used in systems incorporating speakers, but rather it is simply implemented through an inexpensive inductor.

The low power frequency which may be available from a relevant circuit or an IC is first amplified using a transistor, and further more the transistor output is pumped up using an inductor. The use of a inductor becomes the most crucial stage for driving a piezo electric transducer.

The used inductor might not be critical with its value, but the value should as high as possible, the higher the sharper the reproduction from the piezo.

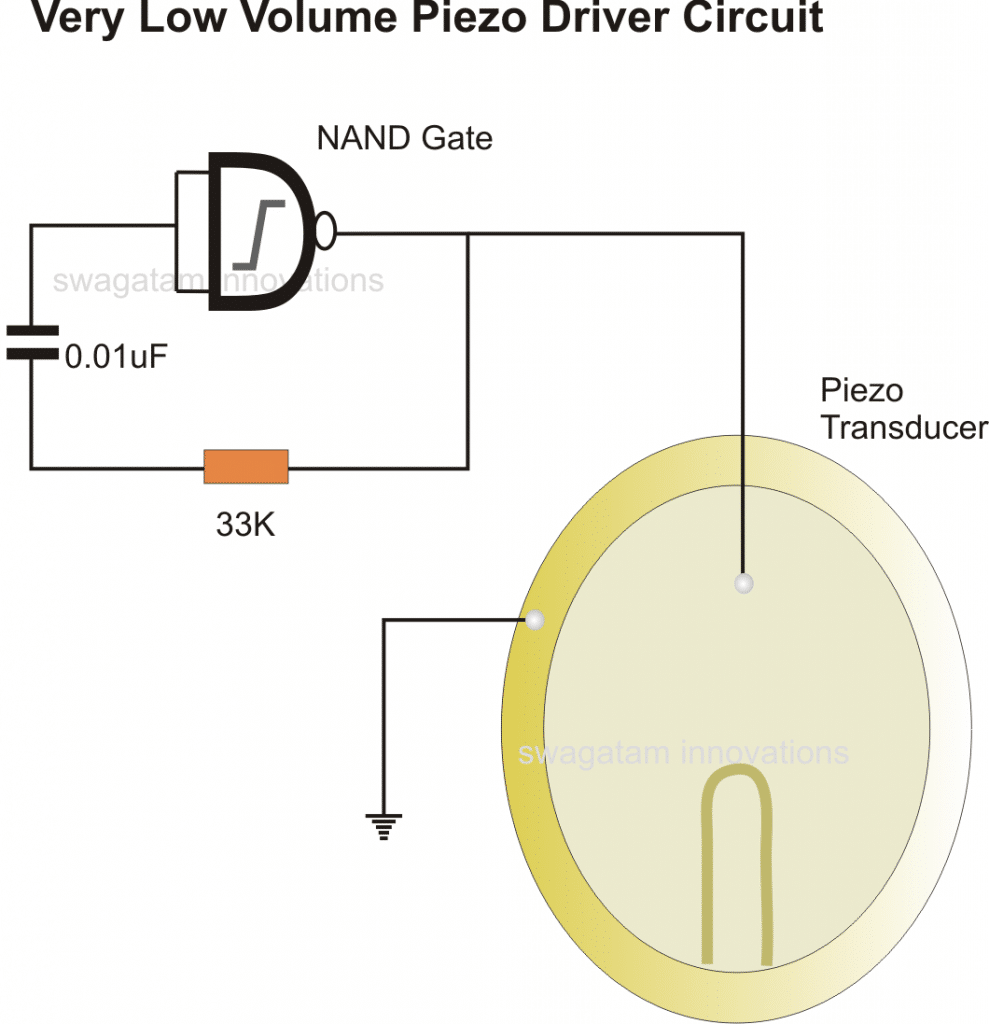

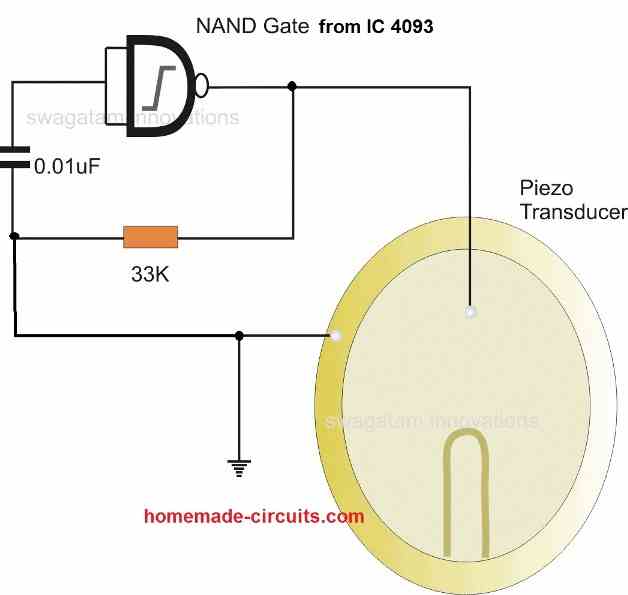

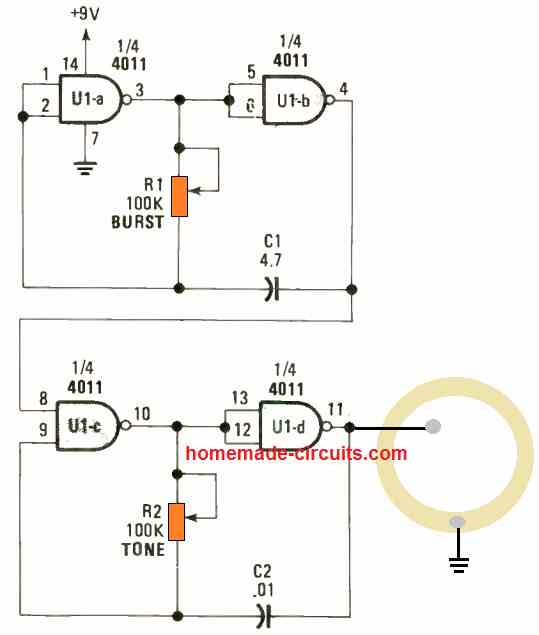

A simple piezo transducer driver circuit or a simple piezo alarm circuit is shown in the following circuit using a NAND gate.

Powerful Piezo Alarm Circuit

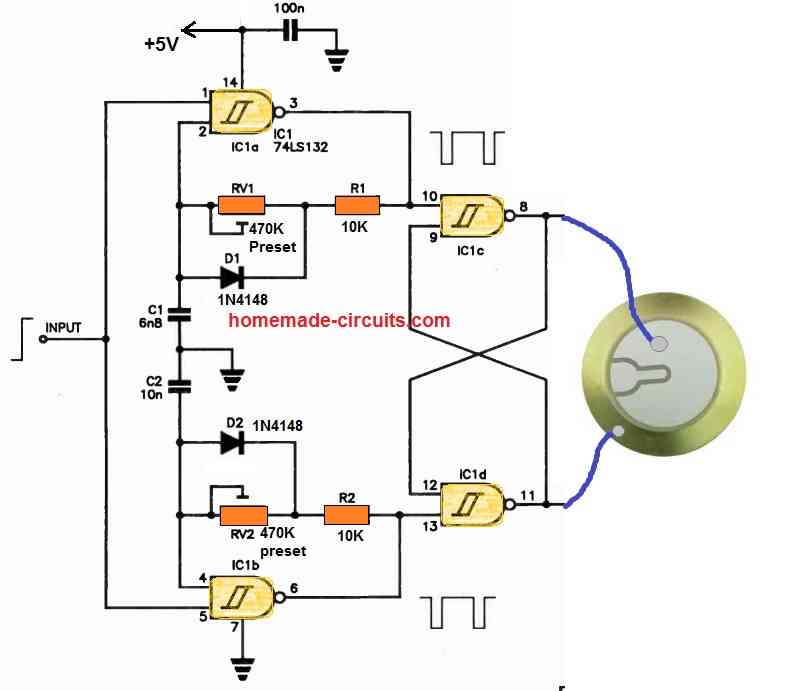

In the following piezo alarm driver circuit, a sole quad two-input NAND Schmitt trigger package, denoted as [74LS132], serves as the driving force for a piezo transducer, resulting in an exceptionally powerful output characterized by a piercing, undulating tone.

Two integrated circuits, IC1a and IC1d, are interconnected as gated oscillators, offering a mark-to-space ratio of approximately 4:1 through the utilization of diodes. RV1 and RV2 are responsible for enabling frequency adjustments.

These oscillators are meticulously tuned to distinct frequencies, thus generating complete interference between their respective notes, thereby yielding a highly urgent auditory experience when finely tuned.

The outputs from these oscillators are then directed into a flip-flop circuit, comprising IC1c and IC1d.

The push-pull outputs of this flip-flop, in turn, actuate the piezo transducer, or buzzer, delivering the desired sonic output.

The oscillators can be controlled by a high signal level to activate them, while a low signal level deactivates them.

Alternatively, a high-speed CMOS device like HCT can be employed as an alternative to achieve the same functionality.

Piezo Driver with Intermittent Beep Sounds

This piezo intermittent beep sound generator, driver circuit can be utilized as a building block in a wide range of projects.

The best example can be its application as a tone-burst oscillator to operate a piezo transducer directly, and using a transistor to sound an alarm.

It may be also possible to use the above circuit modulate an FM transmitter so that it creates an intermittent beeping sound on reception. The circuit is made up of a single quad NAND gate, a couple of resistors, and a pair of capacitors.

The first 2 gates are configured as the "burst" oscillator while the third and fourth gates function like a "tone" oscillator. The burst oscillator is a lot slower compared to tone oscillator and is accustomed to pulse the tone oscillator with an intermittent on and off.

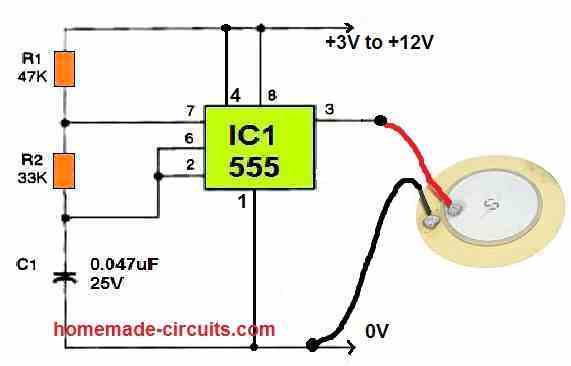

Using IC 555

A very simple yet effective piezo driver circuit could be build using a single IC 555 as shown below:

You can try adjusting the values of C1 and R1 for experimenting with the tone output of the piezo driver.

To get maximum sound output make sure to mount the piezo transducer inside a plastic enclosure with an elevated step and a 5 mm hole at the center.

Or you can simply buy a ready-made unit with the piezo fitted inside a plastic enclosure, as shown below:

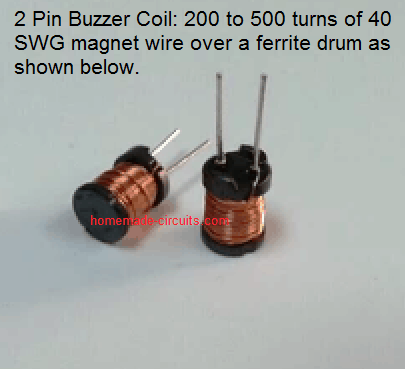

With the above assembly you may find the sound output to be quite impressive. However, if you want the sound to be extremely high and ear piercing, you may consider using a buzzer coil as indicated below:

These can be easily procured ready-made from any electronic spare part retailer.

To connect this, simply attach the coil leads across the piezo buzzer wires, or parallel to the piezo buzzer wires. Once done, you may find the piezo driver sound output increasing drastically to an extremely high level.