In this article I have explained the basics of quadcopter body assembly using aluminum pipes and bolts, in the later sections of the article we will also discuss regarding a simple drone circuit which could be use for flying a small drone assembly without depending on complex microcontrollers.

A quadcopter is perhaps the simplest flying machine requiring minimum amount of aerodynamic accuracy and complications, and therefore it's no surprise, it could gain an immense popularity among the various hobbyists who could successfully build this....a machine that they could actually fly and control at their own will.

The Quadcopter Dynamics

The fact that a quadcopter drone is the simplest in terms of technicality and dynamics is actually due to the involvement of 4 propellers and a balanced frame structure, which enable the machine to fly with relatively good equilibrium, even in difficult climatic conditions.

But simplicity also implies that the system might not be as efficient as the conventional airplane and chopper models which are intricately designed for exhibiting extreme efficiency in terms of speed and fuel consumption, and of course load bearing capability...all of these could be essentially lacking in a typical quadcopter system.

Nevertheless, as far as a hobby project is concerned, this machine becomes the ideal choice for most enthusiasts who find it very amusing and intriguing to build a flying machine of their own, at home, which ultimately "listens" and flies to whatever direction the user prefers it to move.

However, for a new player, who may be technically not so informed may find even this simple machine extremely complicated to understand, simply because most of the related info presented across the many websites fail to discuss the concept lucidly and in a "language" that might suit a layman.

This article has been specifically written for those not-so technical folks who are interested to build a magnificent flying machine but find the subject too difficult to digest.

Why Quadcopters are so Easy to Build Today

Have you ever wondered why quadcopters and drones are so easy to construct in today's world and was perhaps impossible earlier using electricity?

It is basically because of the development and enhancement of the Li-Ion Batteries. These are extremely efficient form of batteries available today which offer impressive power to weight ratio. Along with this, the invention of BLDC motors and highly refined permanent magnet motors have also contributed in making the drones easily constructable.

The Li-Ion battery is able to provide awesome amount of rotational torque on the motors which becomes sufficient enough to push the quadcopter unit to a high altitude above ground within seconds, and also allows it to remain air borne for a long duration of time making the performance very efficient and useful.

How Quadcopter Flies

Now let's jump right way and understand what are the essential things required to make a quadcopter fly successfully. Here are the basics to successfully make the machine fly smoothly:

1) Basically the machine requires a firm and strong body, but extremely light in weight. This could be fabricated or assembled using hollow square aluminum extrusion pipes, by suitably drilling holes and fixing the frame with nuts and bolts.

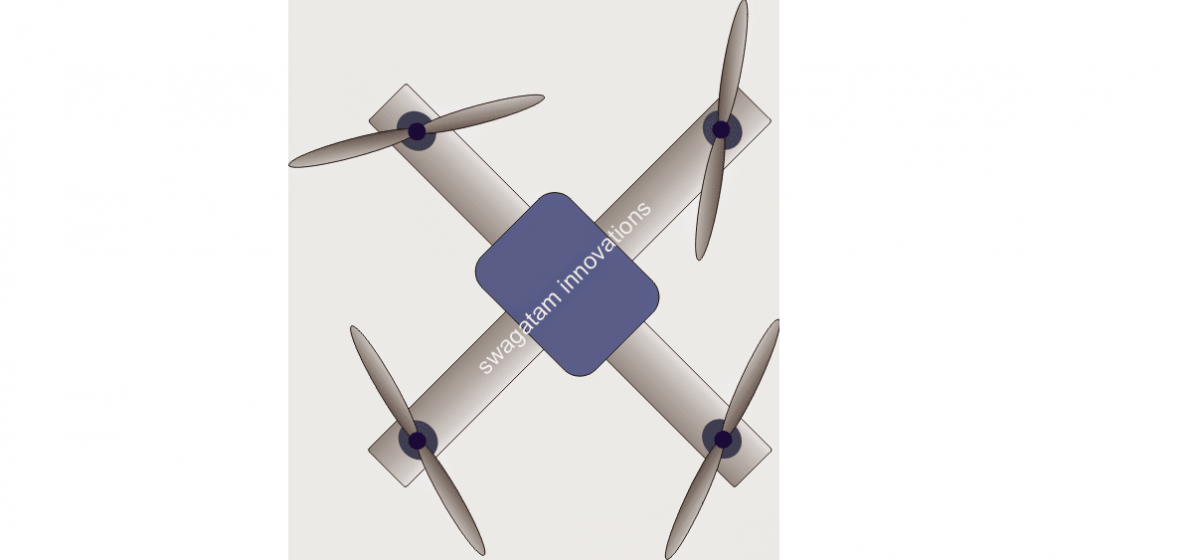

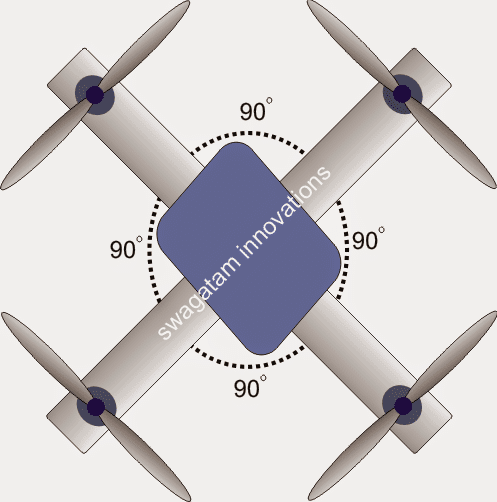

2) The structure should be in the form of a perfect "+" or a perfect "x", it doesn't make a difference as long as the angle between the "crossing" pipes are at 90 degrees each.

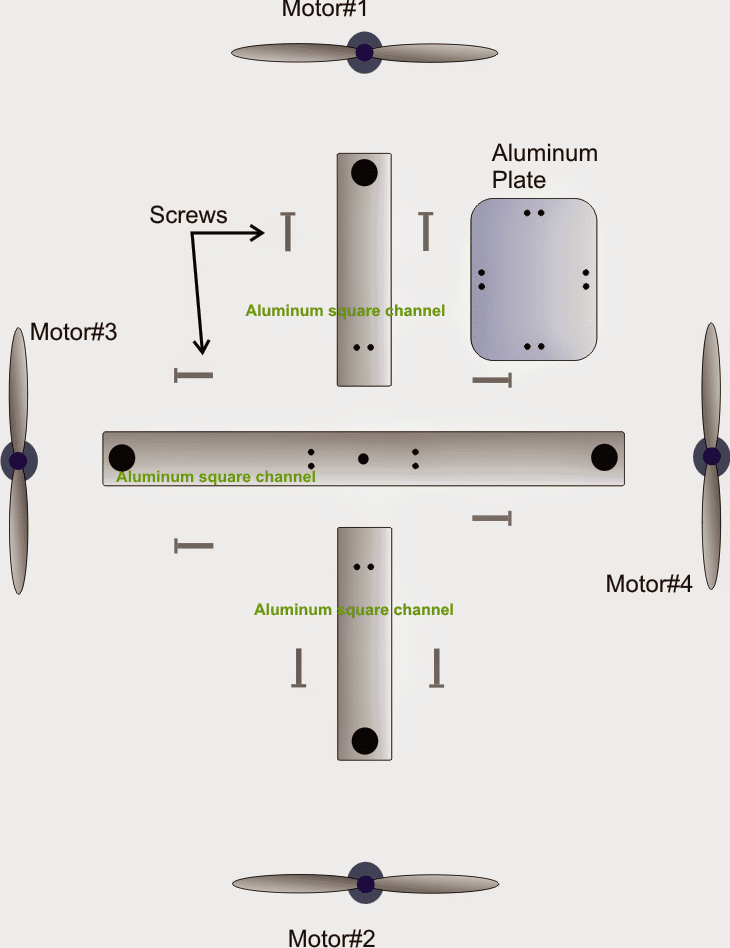

Basic elements needed for constructing a quadcopter can be seen in the following image:

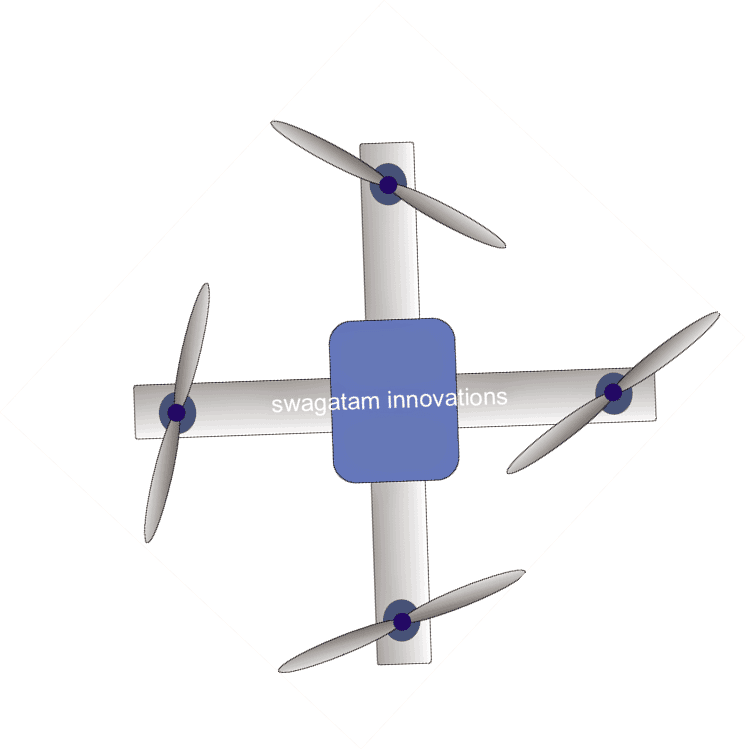

Part Assembly Simulation

The rough animated simulation below shows regarding how to assemble the above shown elements together:

How to Construct Quadcopter Framework

The aluminum for the "+" frame can be acquired by appropriately cutting and sizing ready made aluminum extrusion tubing, as shown below:

The size of the frame is relative and therefore is not crucial, you can build a wide frame with the motors fitted wide apart or build a rather compact frame structure where the motors are not too wide apart...although it must be ensured that the propellers are well aloof from each other for enabling better equilibrium and balance.

3) The "+" frame structure must be fitted with a square platform at the central section where the frame arms meet and cross each other. It could be simply a well polished aluminum plate appropriately dimensioned for comfortably accommodating all the necessary electronics and wiring.

Thus this central plate or the platform is basically required for installing and housing the electronics of the system which would ultimately be responsible for controlling your quadcopter.

4) Once the above framework is completed, the motors are required to fixed across the ends of the cross bars, as shown in the above figures.

5) It's needless to say that all the fitting work needs to be done with utmost accuracy, and perfect alignment, this might require the association of an experienced fabricator for the job.

Since everything in the design is in pairs, aligning the elements accurately won't be actually too difficult, it's just about sizing and fitting the pairs with as much similarity as possible, which will in turn ensure a maximum level of balance, equilibrium and sync for the system.

Once the framework is built, it's time to integrate the electronic circuits with the relevant motors. This will need to be done as per the instructions provided in the given circuit manual.

The circuit boards could be fitted on the bottom side of the central plate with appropriately housing or over the plate, again with an appropriate cabinet for enclosing it tightly.

Understanding the Rotational Direction of the Propellers

Analyzing the direction of Rotation of the Motor propellers for a Balanced Lift-of:

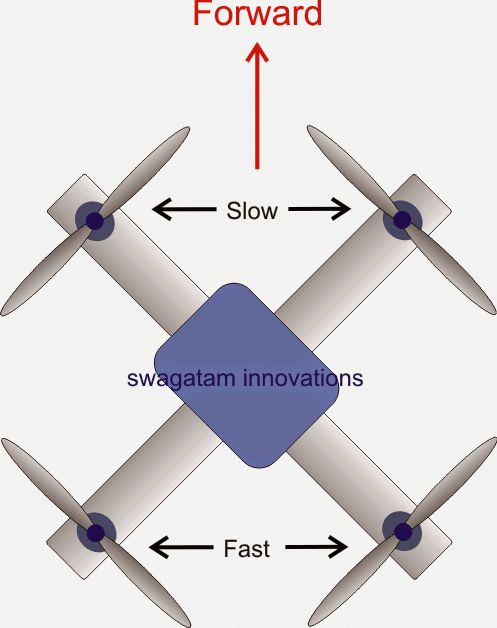

Referring to the above animated simulation, the direction of rotation of the motor propellers should be aligned in the following manner:

It simply needs to be such that the motors at the ends of one rod should be identical but different to the other rod motor direction, meaning if one rod has the motors spinning in the clockwise direction, then the motors at the ends of the other complementing rod must be tuned to spin in the anti-clockwise. direction.

Please refer to the simulation above to correctly understand the counter-acting movement of the motors that may be needed to be assigned to the motors for ensuring a balanced take of

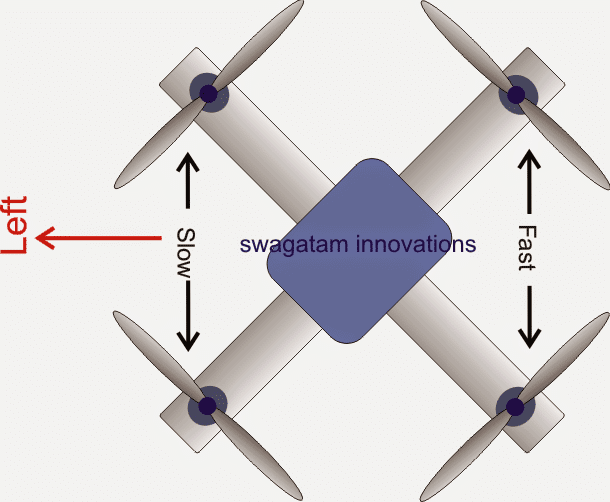

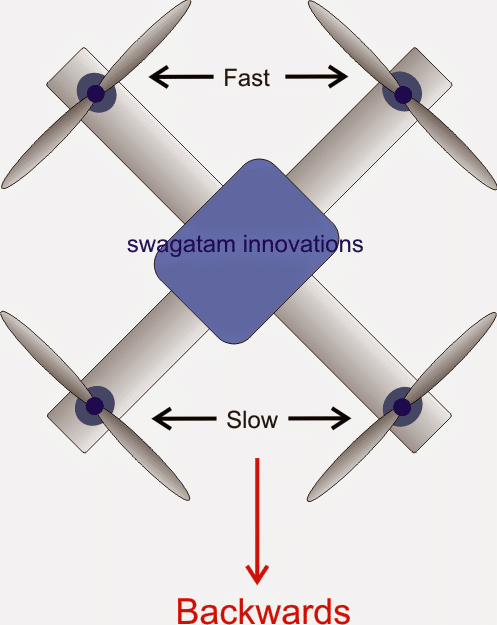

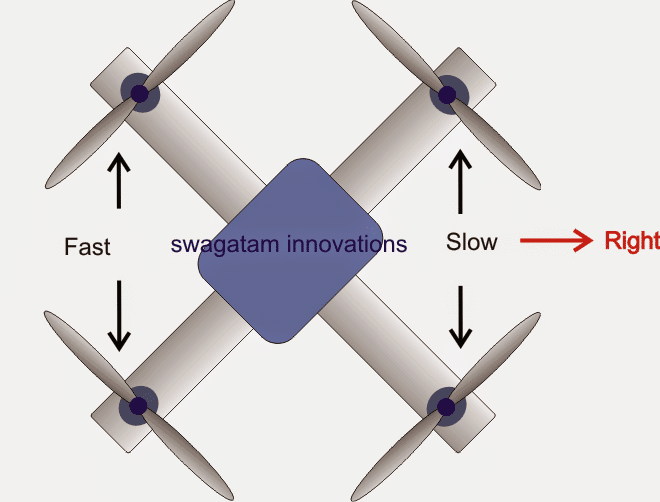

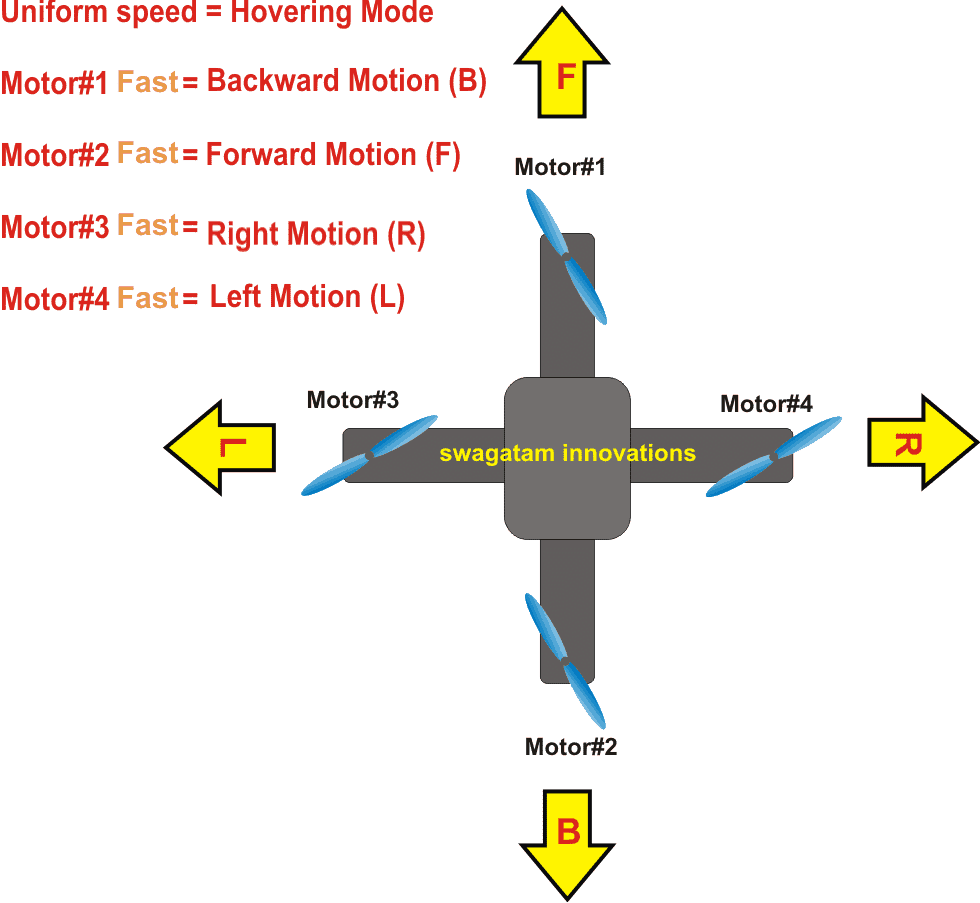

How to Control the direction of the quadcopter by controlling the speed of the motors.

Yes, the flying direction of the quadcopter can be tweaked and controlled as per your own wish and will by simply applying different speeds (RPMs) to the concerned motors.

The following images show how the basic speed transmission may be applied to the relevant motors in order to achieve and execute any desired flying direction to the machine:

As indicated in the above diagrams, by appropriately decreasing the speed of a set of motors, or increasing the speed of the opposite set of motors, or tweaking the speeds as per ones own preference the quadcopter can be made to travel in the air in any desired specific direction.

The above images indicate the basic directions, such as forward, reverse, right, left etc...however any other odd direction can also be efficiently implemented by suitably adjusting the speeds of the relevant motors or may be just a single motor.

For example in order to force the machine to fly towards the N/W direction, the speed of only the S/E motor may be increased, and for enabling the machine to fly at the N/E direction, the speed of the S/W motor may be increased...and so on. It just needs to be practiced until the full control of the quadcopter becomes achievable and mastered by the user.

Designing a Practical Quadcopter

So far I have explained about the basic construction of the drone body and hardware, now I have explained how to make a quadcopter or a drone circuit quickly and cheaply using very ordinary components. In one of my earlier posts I have explained how to make a relatively complex and therefore efficient quadcopter flying machine without using microcontroller, for more info you would want to go through the following posts:

Remote Control Circuit without MCU | Electronic Circuit

In the present article we try to make the above design much simpler by eliminating the brushless motors and replacing it with brushed motors, and consequently making it possible to get rid of the complex BLDC driver circuit module.

Since the mechanical construction details of the quadcopter is already discussed above comprehensively, we will only deal with the circuit design section and learn how it may be built for flying the proposed simplest drone circuit.

As mentioned earlier this simple quadcopter requires only the basic RF remote control modules as shown in the below example image:

You will need to buy these RF modules from any online store or from your local electronic spare dealer:

Apart from the above mentioned RF remotes modules 4 permanent magnet brushed motors will be also required which actually forms the heart of the drone machine. It could be as specified in the following image with the given descriptions, or any other similar as per the required user specifications:

Electrical Specifications of the Motor:

- 6V = operating voltage (peak 12V)

- 200mA = operating current

- 10,000 = RPM

Parts List

- 1K, 10K 1/4 watt = 1 each

- 1uF/25V Capacitor = 1no

- Preset 10K or 5K = 1no

- Rx = 5 watt wirewound resistor, value to be confirmed with experimentation.

- IC 555 = 1no

- 1N4148 Diodes = 2nos

- IRF9540 Mosfet = 1no

- 6V Motor Brushed Type = 4nos

- Flexible wires, solder, flux etc.

- General purpose PCB for assembling the above parts

- 4 Channel RF Remote Control Module, as shown in the relevant images.

- Aluminum Channels, screws, nuts, plates etc as explained in the article.

- Battery as shown below:

How to Configure the Remote Control Receiver with the Motors

Before understanding how to configure the remote control receiver with the quadcopter motors, it would be important to learn how the motor speeds are supposed to be adjusted or aligned for generating the required left, right, forward, backward motions.

Primarily there are two ways a quadcopter can be enabled to move, which are in the "+" and the "x"modes. In our design we employ the basic "+" mode of motion for our drone, as indicated in the following diagram:

Referring to the above diagram we realize that we simply need to appropriately increase the speeds of the relevant motors for executing the desired directional maneuvers on the drone.

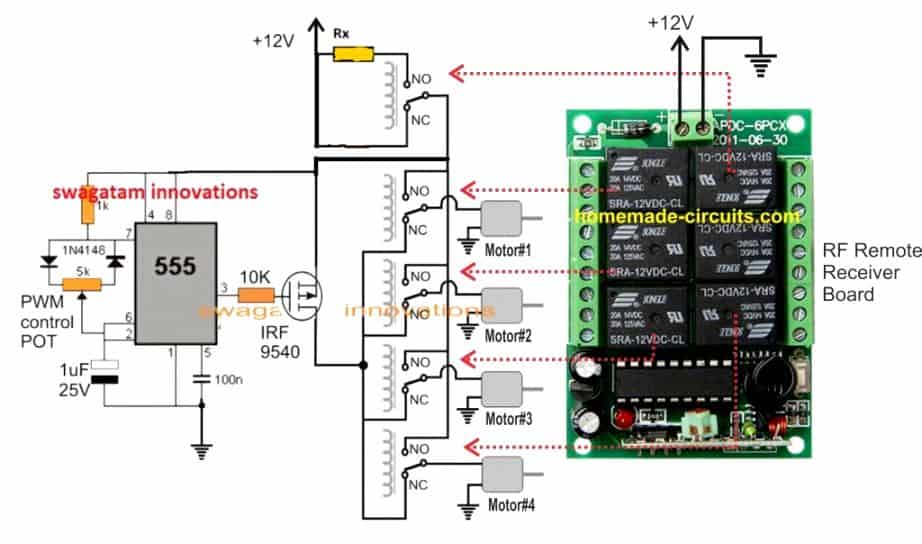

This increase of speeds can be enforced by configuring the remote control relays as per the following wiring diagram. In the diagram below we can see an IC 555 PWM circuit wired with the 4 relays of the remote control receiver module of the 6 relays (1 relay being unused and could be simply removed to educe space and weight).

Adjusting the PWM

As may be witnessed in the diagram, the PWM feed is connected with all the N/C contacts of the relays, which implies that normally the quadcopter would be hovering through this uniform and equal PWM feed, whose duty cycle may be initially adjusted such that the quadcopter is able to attain a correct specified amount of thrust, and altitude.

This may be experimented by appropriately adjusting the shown PWM pot.

How to Configure the Relay Contacts

The N/O contacts of the relays can be seen wired directly with the positive supply, so whenever a relevant button is pressed on the remote transmitter handset, the corresponding relay is activated in the receiver module, which in turn enables the relevant motor to get the full 12V supply from the battery.

The above operation allows the activated motor to gain more speed than the rest of the motors which allows the quadcopter to move towards the stipulated direction.

As soon as the remote button is released, the drone stops instantly and continues to hover in the constant mode.

Identically, other directional motions can be simply achieved by pressing the other assigned buttons, on the remote handset.

The topmost relay is for ensuring a safe landing of the machine, this is done by adding a current dropping resistor in series with the N/O contact of the shown relay.

This resistor value must be calculated with some experimentation such that the quadcopter hovers around a couple of feet above the ground whenever this resistor is toggled through the attached relay.

Circuit Diagram

The shown relays are the part of the RF module receiver, whose contacts are initially unconnected (blank by default) and needs to be wired as indicated in the above diagram.

The RF remote receiver is supposed to be installed inside the quadcopter and its relays wired with the relevant motors and battery as per the above shown layout.

You can see a few connectors (green colored) which can unnecessarily add weight on the drone. You can remove them all to reduce weight, and connect the relevant wires directly to the PCB by soldering.

How the Drone Moves:

As explained in the above discussion, when a particular remote button is pressed, it actuates the corresponding relay of the quadcopter module causing the relevant motor to move faster.

This operation in turn forces the machine to move in the direction opposite to the motor which is being switched to rotate at the faster RPM.

Thus for example, increasing the speed of the south motor causes the machine to move towards north, increasing the north motor causes it to move south, similarly increasing east motor speed causes it to move west and vice versa.

Interestingly, increasing the south/east motors enables the quadcopter to move towards the opposite north/west that is in the diagonal mode....and so on.

Pros and Cons of the above explained Simple Qaudcopter remote control circuit.

Pros

- Cheap, and easy to build even by a relatively new hobbyist.

- Does not require complex joystick operations.

- Can be controlled using a single 6 channel remote control module

Cons

- Less efficient in terms of battery back up due to the involvement of brushed motors

- Directional speed is constant and cannot be varied through the remote control handset

- Maneuvering may not be smooth rather a bit jerky while switching the buttons.