One of the best substitutes for traditional light transformer for halogen bulbs is the electronic halogen transformer. It can also be used with non-halogen bulbs and any other form of resistive loads that does not run on RF current.

Written and Submitted By: Dhrubajyoti Biswas

Halogen Lamp Working Principle

The electronic halogen lamp transformer works on the principle of switching power supply. It does not run on secondary rectifier like the switching power supply, for which DC voltage is not needed to run the same.

Moreover, it doesn’t have the option of smoothing after network bridge and it is simply due to the absence of electrolyte the application of thermistor does not come in application.

Eliminating Power Factor Issue

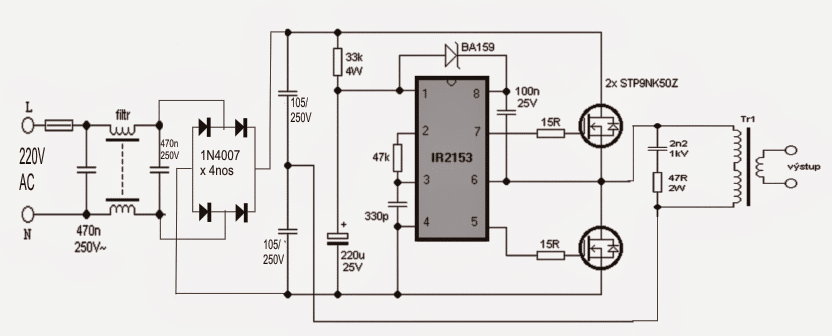

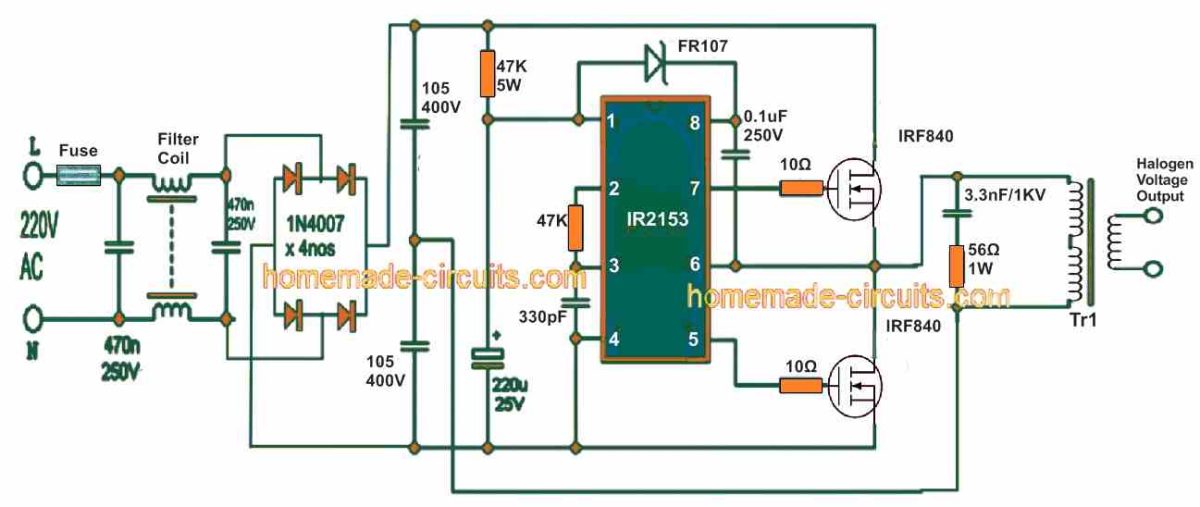

The design of the electronic halogen transformer also eliminates the issue with power factor. Designed with MOSFET as a half-bridge and IR2153 driving circuit, the circuit is equipped with upper MOSFET driver and also has its own RC oscillator.

The transformer circuit runs on a frequency of 50 kHz and the voltage is around 107V at the primary pulse transformer, which is measured as per the following calculation mentioned below:

Uef = (Uvst-2) . 0,5 . √(t-2.deadtime)/t

[Here Uvst is the input line voltage and the resulting dead-time in IR2153 is set to 1. The value 2us and t is stated as the period and especially in regard to 50 kHz.].

However, upon substituting the value with the formula: U = (230-2) . 0,5 . √(20-2.1,2)/20 = 106,9V, the voltage gets reduced by 2V at the diode bridge. It is further subdivided by 2 at the capacitive divider, which is made of 1u/250V capacitors, thus reducing the effective value at dead-time.

Designing the Ferrite Transformer

The Tr1 transformer on the other hand is a pulse transformer placed on ferrite core of either EE or E1 can be lent from SMPS [AT or ATX].

While designing the circuit, it is important to bear in mind that the core should maintain a cross section of 90 – 140mm2 (approx.). Furthermore, the number of turns also has to be adjusted with based upon the state of the bulb. When we try to determine the calculation of transformer rate, we usually take it for consideration that the primary rate is the effective voltage of 107V in case of 230V output line.

The transformer derived from AT or ATX generally gives 40 turns on primary and is further sub-divided into two parts having 20 turns on each primary – one that lies under the secondary while the other above the same. In case if you are using 12V, I would recommend using 4 turns and the voltage should be 11.5V.

For your note, the transformation ratio is calculated with a simple division method: 107V / 11.5 V = 9.304. Also in the secondary section, the value is 4t, so the primary value should be: 9.304 . 4t = 37t. However, since the bottom half of the primary remains in 20z, the best option would be wind the top layer by 37t - 20t = 17t.

And if you can trace out the original number of turns in secondary, things will be far easier for you. If the secondary is set to 4 turns just unwind 3 turns from the top of the primary to derive the result. One of the simplest procedures for this experiment is using 24V bulb, albeit the secondary to choose should be 8-10 turns.

The IRF840 or STP9NK50Z MOSFET without the absence of heat sink can be applied to derive the output of 80 – 100V (approx.).

The other option would be use STP9NC60FP, STP11NK50Z or STP10NK60Z MOSFET model. In case if you are looking to add more power, do use heat sink or MOSFET with higher power, such as 2SK2837, STB25NM50N-1, STP25NM50N, STW20NK50Z, STP15NK50ZFP, IRFP460LC or IRFP460. Be sure to consider that the voltage should be Uds 500 – 600V.

Care should also be taken, not to have a long lead to the bulb. The main reason is, in case of high voltage it may result to drop of voltage and cause interference mainly due to inductance. One last point to consider you can’t measure the voltage with the help of multimeter.