The proposed solar water heater with battery charger controller circuit explains a simple method of utilizing the excess solar energy from a solar panel for heating water in water tanks or swimming pools or poultry egg chambers. Normally the circuit also functions like an automatic solar battery charger, and simultaneously powers domestic electrical appliances.

Understanding Solar Charging

Solar energy is abundantly available across the globe and it's free to use. It's all about laying down a solar energy collector or simply a solar PV panel, and harness the available resource.

In this blog and in many other sites you might have come across various efficient solar battery charger circuits. However these circuits generally speak about using the solar panel for acquiring electrical energy.

While functioning, the involved regulators/chargers stabilize the solar voltage such that the output voltage becomes suitable for the connected battery which is normally a 12V lead acid battery.

Since normally a solar panel is designed for generating voltages in excess of 12V, that is around 20 to 30 volts, the process of stabilization completely neglects the excess voltage which is either shunted to ground or cancelled out through electronic circuitry.

In the present article I have explained a simple method of converting excess solar energy to heat even while charging a battery, and operating household appliances safely together.

The circuit functioning may be understood with the following points:

Using Excess Unused Solar Power for Heating Water

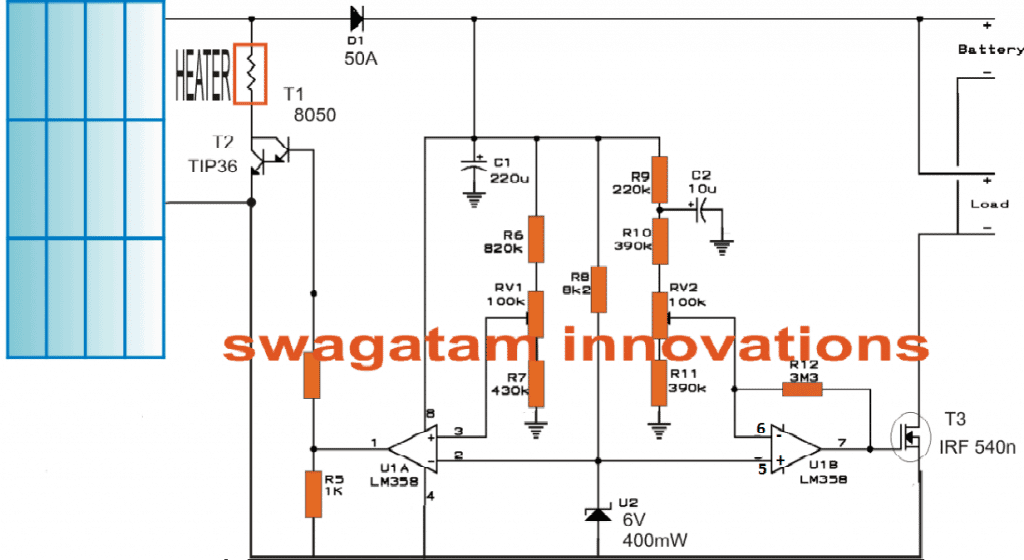

In the given solar water heater with battery charger controller circuit diagram, let's assume at peak sunshine the attached solar panel is capable of generating around 24V.

In the diagram we can see a couple of opamps positioned in between the solar input and the battery charging outlet.

The opamp at the left is basically set for allowing the specified charging voltage to its right hand side stages.

For a 12V battery this voltage would be around 14.4V.

RV1 is therefore adjusted such that the output of the opamp becomes high in case the input voltage exceeds the 14.4V mark.

The opamp at the right is designated as the over charge cut off stage which is responsible for monitoring the charging voltage of the battery, and cut it off when the upper threshold is reached.

This happens when the non inverting input of U1B senses the higher threshold and shuts off the positive bias to the mosfet which in turn cuts off power to the connected battery.

However the load which is essentially an inverter stays operative, as now it starts deriving the power from the charged battery.

In the course, if the voltage drops even by a few voltages, U1B reverts its output to logic high and the battery once again begins getting charged while simultaneously allowing the connected appliances to remain operative via the common panel voltage.

Meanwhile as discussed in the previous lines, U1A monitors the panel voltage and just like U1B when it instantaneously senses the panel voltage exceeding the 14.4 mark, it switches its output to logic high so that the connected transistors are instantly switched ON.

A DC heater coil can be seen attached across the collector and positive of the transistor.

When the transistor conducts, the coil is shunted across the direct panel voltage, and therefore it instantly begins getting hot.

The low resistance of the coil pulls lot of current from the panel which forces the voltage to drop below the set 14.4 level for U1A.

The moment this tends to happen, U1A reverts the situation and cuts off the supply to the transistors and the process rapidly fluctuates, such that the voltage fed to the battery stays within the 14.4V mark and in the process the heater coil manages to stay active so that its heat becomes applicable for any preferred purpose.

Diagram for the solar water heater with battery charger controller circuit

Solar Panel Excess Power Dump Load Circuit

Requirement: Hello there, I'd want to build a device to restrict power output to the grid from an already present 5kW solar system that I'd like to expand.

The issue I'm having is that in the winter we require additional solar panels, yet during the summer we produce excessively high amounts of power.

We are constrained to 5kW of electricity production, and therefore require around 10kW of solar panels in order to attain power self sufficiency during winters.

I was thinking of utilizing a current coil to sense the quantity of energy being transferred and thereafter incrementally switching in resistive loads of perhaps 750W a piece to absorb surplus power, with the goal of limiting power exporting to perhaps 4kW?

The existing system can employ frequency control to restrict panel output, but the overall power output would be too high in the summer. We have a power source that runs at 240V, 50Hz.

I was thinking about load detecting the export and switching in resistive loads with a brief duration on time periods.

Do you have any suggestions for a realistic and, hopefully, straightforward way to accomplish this?

The Design

The above requirement could be accomplished using the following simple concept:

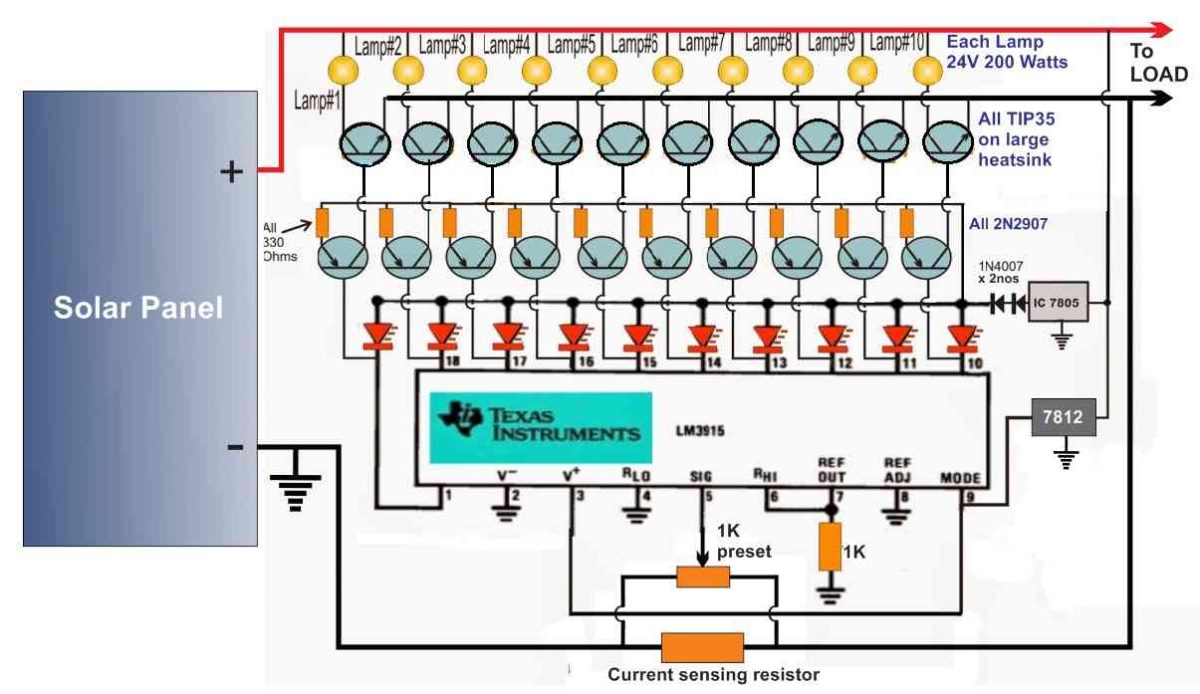

As we know, the output pins of the IC LM3915 exhibit a sequentially shifting low logic across its 10 output pins in an incrementing manner, in response to an increasing potential at its pin#5, ranging between 0 to 200 mV.

The above solar panel power load dump circuit exploits the above feature of the IC to accomplish the requested design.

Instead of a current transformer, we utilize a current sensing resistor Rx here. The value of this resistor could be calculated using the following formula:

Rx = 0.1 / Max current limit

The preset across the Rx can be used to set the maximum current limit for switching the connected dump loads.

As the current export exceeds the set limit, the voltage across Rx begins increasing above the 0.1 V mark which causes the outputs of the IC to become low sequentially and proportionately, depending on the excess current exporting from the panel.

As this happens the dump load lamps begin illuminating and thereby shunting the excess wattage to ground, which in turn helps to decrease the output load current to the desired maximum limits.

The illuminated lamps could be immersed in water to heat water if required, so that the excess wattage from the panels can be used for heating water, or any other similar application.

Good day Swag, please how can I make dummy load with copper coil, or what can I use

Adeyemi, you can use heater coil or car headlight bulbs as the dummy load

Ok I have now got it, thanks.

Why not simply the circuit to use LM358 to trigger a mosfet to the heater when the voltage reaches a certain hight to be varied by a potentiometer. Or there is a repercussion?

the heat produced in the above circuit is a by-product and is achieved while controlling the panel voltage for charging the battery…..

Hi Swagatam,

Please I await for your reply with keen interst, I mean the determination of the exact power rating of the dc heater coil, do you use the current rating and voltage rating of the solar panels or those of batteries.

Thanks

Bernard Tendengu

Hi Bernard,

The heater coil value is related with the solar panel, and also to the battery specs.

You'll have to find the optimal resistance value by some experimentation.

Do this without connecting any battery.

A correctly selected heater dump coil should produce about 16V across the cathode of D1 and ground.

Yes sir , done first opamp Section i am able to control voltage, if I changed input voltage .

But no voltage getting on T3 irf 540 (currently i am using 840)

Irf -ve to supply , pls tell me second step .

OK good! but remember the input supply current must be lower than what T1 may be rated to handle otherwise your T1 will blow off and then the IC will blow off.

once you fix 14V across the opamp side….connect an LED with a 1K resistor from the output of the right side opamp to ground.

now adjust the RV2 reverse/forward and force the LED to flicker ON/OFF, this will confirm that the opamp is responding to the preset adjustment.

finally, adjust the preset such that the LED just shuts off with existing 14V.

this will ensure that as soon as the battery voltage reaches 14V , the opamp will switch OFF the mosfet and the charging of the battery.

do not connect the load while charging the battery…

Hello Sir, sorry for long delay, I was busy. whatever I will explained before I did and had check after rotating vR2 led get turned off and at other side it turned on, op_amp is functioning, but I observ that, if I set preset on where led goes off position & if I turned input voltage off and on that time led not come to on position so I choose on set preset on ON position now led glowing automatically, but taking 6_8sec glow, how we will know battery not getting overcharge? Is there anything we can able to check.

Also I had changed R11 as 500k present because I am not able to get Led on.

I note that the both of voltage difference is 0.8v to 1.0v volt please replay

Hello Mahesh,

you can remove R6,7,8,9,10,11, and C2, and keep only the presets…this will enable you to set the circuit without having to take care of unnecessary parameters..

please do this and check the response

Hi Sir, thanks for reply, I removed above component what ever I will explained before conversation. it help to swhching led fast but overcharging not done. And Led not glowing once power get on off.

So I did some modifications I changed output at below irf T3 to ground, and connect preset supply point to posive of drain point. also swapped pin5 and pin6 because function are getting reversed. to check over charging function. I used weak battery and halogen lamp to get battery voltage drain and check led function, and overcharging function, it's working fine now. Sir if possible please send me your fb I'd thank you so much for your support.

Hi Swagatam,

Instead of Heater can we replace it with Dummy load Register,

If Yes then what is Value of Dummy Load Register.

Thanks

Nilesh Patil

Hi Nilesh,

the heater coil is also a dummy load, and can pass greater amount of current without burning.

anyway you can use any 30 ohm 100 watt dummy load for trial

What is Exact Number of Opamps to use.

LM358N

LM358AN

LM358P

LM358M.

LM358N/NOPB

LM358M/NOPB

LM358ADT

LM358AP

LM358AM

LM358D

LM358AN/NOPB

LM358AM/NOPB

LM358DR

LM358DR2G

LM358DG

Thanks,

Nilesh Patil

anyone will do, just "LM358" is what needs to be confirmed

Thanks Swagatam,

Considering earlier comment for T1and T2

I have replace both Transistor with N Channel : IRF840 MOSET,

Right ? Please suggest if any additional Changes with Respect to Motor Specification,

Thanks

Nilesh Patil

Nilesh, do not use two mosfets, T2 is not required for mosfets, it's for a BJT application only.

use a single IRF540 for T1/T2

Hi Swagatam,

I m back again. 🙂

for T2 TIP 36 NPN Transistor ..

However i found list of PNP only for T2 TIP

Name Mat Struct Pc Ucb Uce Ueb Ic Tj Ft Hfe Caps

TIP36 Si PNP 90 80 40 5 25 150 3 20 TO218

TIP36A Si PNP 90 100 60 5 25 150 3 20 TO218

TIP36B Si PNP 90 120 80 5 25 150 3 20 TO218

TIP36C Si PNP 90 140 100 5 25 150 3 20 TO218

TIP36D Si PNP 90 160 120 5 25 150 3 20 TO218

TIP36E Si PNP 90 180 140 5 25 150 3 20 TO218

TIP36F Si PNP 90 200 160 5 25 150 3 20 TO218

1. Which Transistor to use (PNP/NPN) ? Please advice.

2. for C1 and C2 do we have voltage cutoff range / or any i can use ?.

3. D1 – Number please will help me easy to get it from market.

Thanks,

Nilesh Patil

Hi Nilesh, actually it should be TIP135, i'll correct the diagram soon.

however since your motor could generate upto 220V, you must use a 500V rated device, for example a TIP151 or a mosfet IRF840…..TIP35 will not work for you.

C1/C2 could be 25V rated

for D1 you can use 2nos of 6A4 diodes in parallel

Hi Swagatam,

It is possible to you courier the all the exact value part.. .. We are not getting all part in shop.

Thanks,

Nilesh Patil

sorry Nilesh, that wouldn't be possible.

Thanks Swagatam,

can you please provide input for below points.

1. Can i use Resistance value 5K (near to R5) ?

2. All Registes are in quarter watt range ?

3. for R8 only – 8K2 – means 8K 2 watt ?

4. for R12 only – 3M3 – means 3M 3 Watt ?

5. Heater watts ? – so that I can avoid voltage/current loss if any ?

6. For 12 volt Battery charging – Required to adjust Rv1 so that voltage across pin#1 & gnd = 14.4v (of U1A) if my understanding in correct

then what is voltage required to adjust Rv2 across pin#7 & gnd ? (of U1B)

Thanks

Nilesh Patil

Nilesh,

1) yes 5K will work for the transistor base.

2)all are 1/4watt

3)8k2 means 8.2k, use can use 10k

4) 3m3 = 3.3M

5)procure a iron coil from market and use it's 50% length for the heater or experiment with other lengths.

6)RV1 is for getting 15 to 20V aross the cathode of D1, RV2 is for getting 14.4V across the batt terminals

since its 220V from the generator, replace T1 with mosfet IRF840 or STB9NK60Z