This LED light bar with dimmable feature will allow the user to adjust the brightness of the lamp in 4 steps, with100%, 50%, 10% and 0% illumination control at each subsequent steps.

The idea was requested by one of the avid readers of this blog. Here's the required working concept.

Hi Swag !

I stumbled across your web page whilst searching for a solution to make an effective touch led lamp.

Actually the one my dad uses at night has gone kaput. So I thought why not make him one - being an engineer in the past.

NTE’s touch dimmable led light bar. I love how it’s built and I’d like to use this as a ref to make a night lamp for my dad whose old and needs it at night….

I intend to may be use a dimmable Led bulb or a led strip to make the lamp.

If you can help me with the circuit and maybe a tutorial sort as I’ve been out of this for a long time, it would really mean a lot.

Monish

The Design

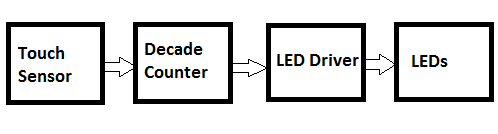

The basic design of the proposed touch dimmable LED light bar circuit can be seen in the block diagram below:

The touch sensor converts the tiny finger touch signal into amplified electrical pulses. The next decade counter stage converts these pulses into shifting logic levels across its outputs.

These shifting logic pulses are fed to the corresponding LED drivers which convert these signals into a sequentially varying voltages for the LED stage.

The varying voltages from the transistor stage which are set at specified levels cause the LEDs to illuminate with different light levels or brightness., accomplishing the dimmable effect on the LEDs.

How the Circuit Works

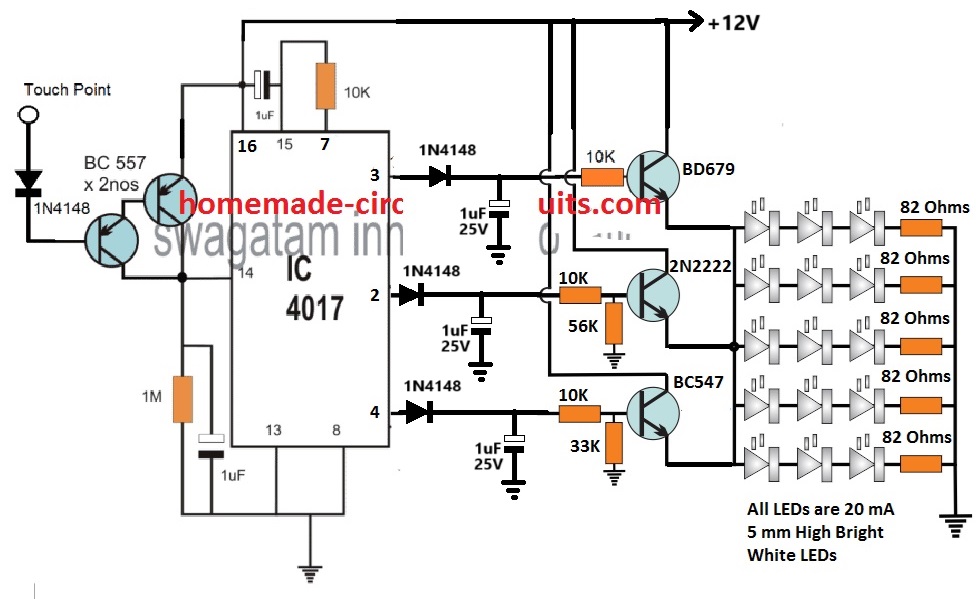

Referring to the circuit diagram above, the basic circuit functioning could be understood with the help of the following points:

The two BC557 transistors at the left side of the diagram form the touch sensor stage.

Tiny electrical pulses from the finger are amplified to the supply level and applied to the clock input of the IC 4017.

The IC 4017 is a 10 stage divide by 10 Johnson decade counter, which responds to these input signals and converts them into a shifting HIGH logic across its output pins from 3 to 4.

Initially when the circuit is powered, the 1uF at pin15 of the IC resets the IC so that the HIGH logic is set at its first pin out #3.

Due to this the corresponding BD670 transistor stage conducts and illuminates the LED array brightly. The BD670 being a Darlington device illuminates the LEDs with high brightness.

At this stage the brightness of the LEDs is maximum also because the BD670 has no potential divider at its base configuration.

This allows it to deliver an optimum 11 V from the 12 V supply to the LEDs at full current, illuminating the array with full brightness.

When the touch sensor is touched, the decade counter responds and causes its output logic to shift from pin#3 to pin#2.

This shuts off the BD670 stage and powers the pin2 transistor stage which is also wired like an emitter follower.

Therefore, now the 2N2222 transistor becomes responsible for illuminating the LED array.

However, since the base of the 2N2222 emitter follower is rigged with a potential divider that creates around 10 V at its base, causes the emitter of the 2N2222 to have a decreased emitter voltage, at around 10 V.

The 1 V reduction of the supply to the LEDs, decreases the illumination and dims the LED brightness to 50% less than the original level.

Next, when the touch sensor is touched again, shifts the HIGH logic from pin#2 to pin#4 of the IC. Likewise, now the BC547 driver stage activates and takes over the job of illuminating the LEDs.

But again, due to a potential divider at its base set to generate approximately 9 V output at the emitter, causes the LEDs to further dim at the lowest 10% of its original full level.

After this when the touch pad is touched, the clock signal at pin#14 of the IC shifts the HIGH logic from pin#4 to the next subsequent pin which is the pin#7.

However, since the pin#7 is attached with the reset pin#15, cause the IC output reset back to pin#3. This enables the LEDs to illuminate again with full brightness.

Thus means the dimmable tube light bar does not have a switch OFF step across the touch sensitive range.

If you wish to have the switch OFF function at the last stage, after the pin#4 step, you can achieve this simply by replacing the pin#7 with pin#10.

Meaning, pin#15 now connects with pin#10 via the 10K resistor. This will allow the 3rd touch action to switch OFF the entire LED bar, and the next subsequent touch will yet again restore the LEDs to its full brightness level.

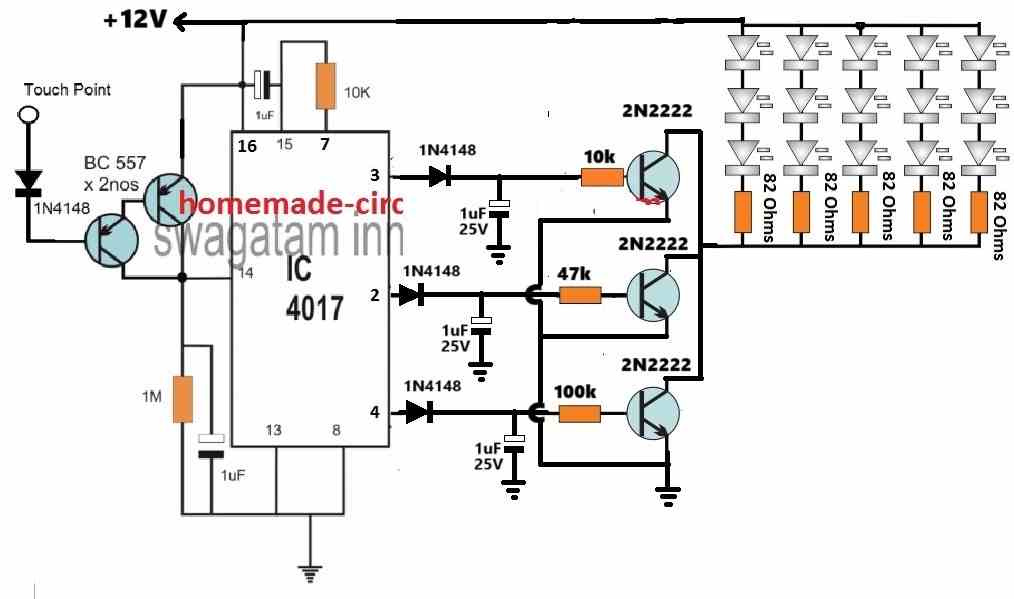

Using Current Control for Dimming

In the above concept, the LED driver section dependent on a voltage controlled dimming on the LEDs.

In this concept the transistors are configured as emitter followers and their base voltages are controlled using potential dividers.

This allows their emitters to follow the base voltage and produce an equivalent controlled voltage for the LEDs.

This controlled voltage is appropriately calculated to generate the sequential dimming effect on the LEDs.

However, calculating and adjusting the base potential divider networks can be time consuming.

Therefore to make things easier we can simply convert the above voltage controlled dimming effect into a current controlled dimming effect, as depicted in the following diagram.

In the above configuration, the LEDs are shifted on the collector side of the transistors, and the base resistors are replaced with single resistors.

Here, the base resistors govern the collector current to the LEDs, which can be appropriately calculated for generating the desired sequential brightness control on the LEDs.

The following formula can be used for manipulating the base current for each of the transistors to illuminate the LEDs with a varied sequential brightness.

R = (Supply Voltage - Base/Emitter drop) x hFE / LED Current

Practical Example

In the above formula, the "R" represents the base resistors of the transistors.

Let the supply voltage be = 12V.

The base/emitter drop for a BJT is normally around 0.7V

The hFE of 2N2222 can be taken as 100.

Let's consider each LED to be rated at 20 ma, so each LED string with 3 series LEDs will also consume 20 ma. Since 5 LED strings are used, the LED current for generating maximum brightness on the LEDs will be 20 mA x 5 = 100 mA.

Therefore substituting the above values in our formula we get:

R = (Supply Voltage - Base/Emitter drop) x hFE / LED Current

= (12 - 0.7) x 100 / 0.1 = 11300 ohms

Thus a 11.3k resistor will cause all the LEDs to illuminate with maximum brightness.

Now, suppose we want the LEDs to illuminate with 50% less brightness on the second step. For this we have to reduce the LED current to 100/2 = 50 ma.

R = (Supply Voltage - Base/Emitter drop) x hFE / LED Current

= (12 - 0.7) x 100 / 0.05

= 22600

Therefore to illuminate the LEDs with 50% less brightness we have to select the base resistor of the second transistor as 22.6k

And so on, in this way we can generate the desired sequentially varying brightness on the LEDs, simply by changing the base resistor values of the transistors.