In this post I have explained the main types of batteries that are widely used in today's world for almost all important applications, ranging from cars, automobiles mobile phones, airplanes, industries, satellites to name a few.

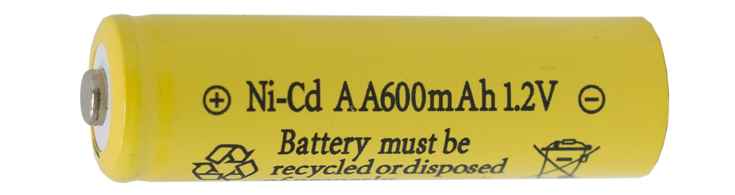

The Nickel Cadmium (NiCd) Battery

Fundamentally, the NiCd battery adopts fast charging as opposed to slow charging and employs pulse charge compared to DC charge.

Other types of electrolyte-based chargers favor a rather low discharge feature and mild load currents.

More important, the NiCd battery is robust and works silently while meeting the requirements of tough tasks.

Often, the NiCd performs best in heavily loaded conditions. Therefore, you should not let the battery sit idly on charging stations or use it only occasionally.

One of the most important practices that must be followed while discharging a NiCd battery is to allow it to complete its periodic cycle.

If you skip this step, large crystals will form on its cell plates which will cause the NiCd to lose its efficiency over time.

The NiCd is famous amongst most rechargeable batteries and these are typically used in two-way radios, emergency medical equipment, and power tools.

Now, the innovation of new batteries with higher energy density and less toxicity is slowly making NiCd less relevant compared to the more novel technologies.

Advantages of NiCd Batteries

- Quick and easy charging even when stored for a long time.

- When maintained periodically, the NiCd battery can be charged/discharged for over 1000 cycles.

- The NiCd has fantastic load performance because it permits recharging even at low temperatures.

- NiCd batteries can be stored for a prolonged time regardless of their state of charge.

- Easy storage and transportation allowing airfreight companies to take in NiCd batteries without any special arrangements.

- The NiCd battery works very well at low temperatures.

- NiCd batteries are completely sturdy and endure even the toughest application.

- Owning and maintaining a NiCd battery is inexpensive especially in terms of cost per charge cycle.

- NiCd batteries come in diverse shapes and performance ratings. Most of them are designed cylindrical.

Disadvantages

- If compared with the latest technology, the NiCd minutely lacks energy density.

- It can be prone to memory effect, if the NiCd is repeatedly recharged after only partial discharge. In such situations its maximum energy capacity will be lost.

- To avoid this, regular complete discharging and charging are important.

- NiCd is made up of toxic chemical elements which makes them environmentally unfriendly. Some nations are discontinuing or strictly regulating the use of NiCd batteries.

- NiCd can go into a self-discharge frequently. So, if you plan to use it after some time, it might require recharging first.

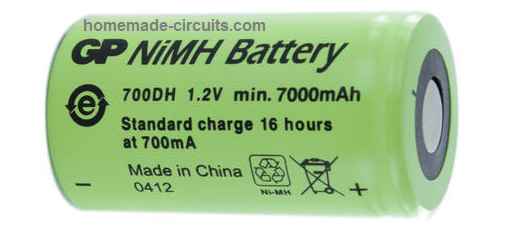

The Nickel-Metal Hydride (NiMH) Battery

The NiMH battery is fundamentally utilized for storing hydrogen in the form of a nickel-hydrogen battery.

Presently, these types of batteries of commonly found in satellite applications.

They are large and comprise pressurized steel canisters making them reasonably expensive.

During the early developmental days, the NiMH was subjected to reactive metal hydride alloys in the cell environment.

As a result, the expected performance of the battery was not met. The production of the NiMH was hampered.

Novel hydride alloys were established in the eighties and proven to be stable for use in a cell. At the end of its decade, the performance was more reliable and improved.

The reason NiMH batteries became successful can be attributed to their compact energy density and the utilization of earth-friendly metals.

In a modern NiMH battery, close to 40% higher energy density is achieved when compared to a NiCd battery. Although you can go higher with the number, it is not recommended as there are drawbacks.

The NiMH is not as robust as the NiCd. If you repeatedly use the NiMH with a heavy load or store the battery at high temperatures, the battery life is significantly reduced. The NiMH will also deplete its charge much faster than the NiCd.

In wireless communication and mobile computing industries, the NiMH is more preferred compared to the NiCd.

Commonly, a buyer is recommended the NiMH battery over NiCd due to its environmental issues including poor disposal procedures.

Industry professionals have a collective say about the NiMH battery’s colossal improvement over the years.

However, it is still subjected to certain disadvantages which are typical of nickel-based technology, including the NiCd battery.

Moreover, it is agreed that the NiMH is a temporary solution to a more ideal lithium battery technology.

Advantages of NiMH batteries

- They have 30-40% more capacity than a default NiCd. Moreover, you can make the cell even more compact with a higher density if needed.

- The NiMH is less susceptible to “memory” effect compared to NiCd. As a result, intermittent incomplete charge cycles are not always recommended.

- Storing and transporting the NiMH is easy as the transportation requirements are flexible.

- In terms of environmental consciousness, the NiMH fits the bill as it houses only weak toxins, therefore, encouraging recycling.

Limitations of NiMH batteries

- The battery has a short service life. So, when consistently deep cycled at great load currents, its performance will drop after 200 or 300 cycles.

- In this case, shallow discharge cycles are more suitable rather than deep ones.

- The NiMH has a restricted discharge current as discharging with high load currents diminishes its battery life, although it is possible to do so.

- The most optimum results are obtained with load currents around 0.2C to 0.5C (20% to 50% of the rated capacity).

- The NiMH demands a more complex charge algorithm because it produces more heat when charging. Also, the NiMH necessitates a longer charging duration compared to the NiCd.

- In NiMH batteries, trickle charging is crucial and must be regulated methodically.

- The NiMH possesses high self-discharge.

- This means the battery occupies about 50% more self-discharge properties compared to the NiCd.

- It is possible to reduce the self-discharge using chemical additives, but this affects the energy density adversely.

- When stored at elevated temperatures, the NiMH battery’s performance is slowed down.

- Therefore, it is vital to store the NiMH battery in a cool place and with around 40% battery charge remaining in the cells.

- The NiMH is quite expensive to maintain as it needs routine full discharge to avoid the formation of crystals.

- Presently, the NiMH is 20% costlier to own than the NiCd. This is because the former is developed for a high current draw which uses more expensive electronic components than the usual model.

The Lead Acid Battery

The lead-acid battery was the first rechargeable battery created by Gaston Planté in 1859 for commercial applications.

Presently, the use of lead-acid batteries is spread across various machinery including automobiles, forklifts, and huge uninterruptible power supply systems.

In the seventies, many scientists attempted to design a maintenance-free lead-acid battery and that could work in any position.

The design includes liquid electrolyte which is converted into soaked separators while being in a sealed enclosure.

Then, to permit gas ventilation during charge and discharge, safety valves were incorporated.

Two battery types were developed due to diverse applications. The first one is a small-sealed lead-acid (SLA) battery or widely known under the brand Gel cell. The second type is the large valve-regulated lead-acid (VRLA) battery.

In terms of technicalities, they are the same.

However, some engineers may debate that the term ‘sealed lead acid’ is misdirection because theoretically, no lead-acid battery is completely sealable. But since our focus is on portable batteries, we will concentrate only on the SLA.

SLA Battery

Dissimilar to the flooded lead-acid battery, both SLA and VRLA are developed with faint over-voltage potential to deter the battery from achieving its gas-penetration potential when charging.

Overcharging the battery will result in gassing and water depletion. So, it is crucial to remember not to charge these batteries to the brim.

Furthermore, the issue of memory is not present with the lead-acid battery. If you leave the battery on float charge for a long duration, it will not be damaged.

The battery’s charge holding is one of the best if compared with other rechargeable batteries.

Meanwhile, the NiCd battery self-discharges about 40% of its accumulated energy in just 90 days whereas the SLA self-discharge the same in approximately a year.

Given that the SLA is a cheaper option compared to the NiCd, its functional costs can skyrocket than the latter if full cycles are needed repeatedly.

The SLA prefers slow charging and usually takes around 8 to 16 hours. Also, it is crucial that the SLA is fully charged when storing.

Nominally, the loss of charge over time also depends on battery chemistries in different conditions.

To avoid SLA batteries from being stressed through tedious discharge, bigger models are preferred.

The SLA can deliver up to 200 – 300 discharge/charge cycles depending on the working temperature and discharge depth.

The short life cycle of the SLA is attributed mainly to grid corrosion of the positive electrode, reduction of the active material, and sulphation of the positive plates.

These alterations are more prominent at heightened operating temperatures. So, cycling does not deter or undo the trend.

The nominal operating temperature for the SLA and VRLA batteries is 25°C or 77°F.

The ultimate rule is that for every 8°C (15°F) elevation in the temperature, the battery life is halved.

That means a VRLA battery that is intended to last for 10 years at 25°C will only work properly for 5 years if you work the battery at 33°C (95°F).

If you elevate the temperature further, say at 42°C or 107°F, the same battery will only last a little longer than a year.

Energy Density

The lead-acid battery occupies the lowest energy density amongst current rechargeable batteries.

As a result, this makes it unsuitable for mobile or handheld devices that necessitate compact size.

Furthermore, its performance at low temperatures is relatively inferior.

The SLA’s rating for discharge is 5 hours or 0.2C. You may also find batteries that are rated at even a slower discharge rate (at around 20 hours).

It is also known that longer discharge times generate higher capacity readings.

Furthermore, the SLA performs better on high pulse currents.

The discharge rates can be implemented at more than 1C during these pulses.

The SLA is less toxic than the NiCd battery in terms of disposal. However, the high lead content makes the SLA harmful to the environment.

Advantages of Lead Acid Batteries

- The SLA is one of the cheapest options because it is less costly and easy to produce in terms of cost per watt-hours.

- The SLA is robust and offers decent service when used correctly.

- It is a mature, dependable, and completely comprehensible technology.

- The SLA has low self-discharge and it is among the lowest in rechargeable battery systems.

- With extremely low maintenance requirements, the SLA has no memory issues, no electrolyte to fill, and is capable of high discharge rates.

Disadvantages of Lead Acid Batteries

- The SLA cannot be stored in a discharged condition.

- SLA battery has a low energy density. This means poor weight-to-energy density that restricts application for steady and wheeled usages.

- The SLA will permit a restricted number of full discharge cycles and it is suitable for standby applications that need only infrequent deep discharges.

- The electrolyte and lead content in the SLA battery is harmful to the environment.

- Transporting the SLA battery is quite risky because a spillage from a flooded lead-acid is detrimental to the environment.

- SLA batteries can suffer from thermal runway if improperly charged.

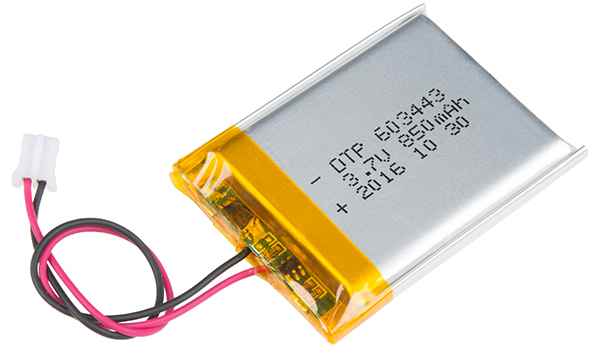

The Lithium-Ion Battery

The development of the lithium battery commenced in 1912 under the research of G.N. Lewis.

However, until the late seventies, the application of the first non-rechargeable lithium batteries was not practiced.

Since lithium is the lightest metal available, it possesses the best electromechanical potential which eventually contributed to the greatest energy density per weight.

Because of safety concerns, further research into rechargeable lithium batteries was stalled in the 1980s.

Scientists were alarmed due to the volatility of lithium metal when charging and so they channeled all research efforts to non-metallic lithium battery which comprise lithium ions instead of the active metal.

Energy Density

With a tad low in terms of energy density, the Li-on battery is considerably safer than lithium metal, given specific prerequisites are met during the discharge and charge phases.

Sony Corporation deployed the first commercial application of Li-ion battery in 1991.

Presently, it dominates the battery industry thanks to its incredibly favorable battery chemistry.

The Li-ion battery houses twice the energy density of a standard NiCd.

If you enhance the active materials in the electrode of the Li-ion battery, there are high chances that the energy density to have three times the amount present in NiCd batteries.

On top of achieving high capacity, the Li-ion battery equips decent load characteristics and exhibits the NiCd’s discharge properties, where the discharge profile graph is identical but with different a voltage ranges.

As a result, the flat discharge curve facilitates the successful consumption of the stored power in the specified voltage range.

Battery packs with just one cell are possible thanks to the high cell voltage.

The single Li-Ion cell application is common on present-day mobile phones.

Elevated currents are stimulated to sustain the required amount of power.

Typically, in these types of applications, a low cell resistance is crucial to permit undisruptive current flow during load pulses.

One of the best advantages of using the Li-ion battery is its low maintenance feature.

There is no memory issue, and it does not require scheduled cycling to preserve its battery life.

Furthermore, the self-discharge is very minimal (less than half) compared to NiCd allowing the Li-ion exceptionally apt for modern fuel gauge products.

On top of that, Li-ion batteries have minimal environmental hazards when disposed of.

Given all its perks, the Li-ion battery still has some downsides.

It is delicate and therefore demands a protection circuit to guarantee safe operation.

The protection circuit which is constructed into each pack restricts the peak voltage of each cell during charge.

Furthermore, it stops the cell voltage from dipping too low during the discharge phase.

Moreover, the cell temperature is also tracked by the circuit to avoid excessive temperatures.

Nominally, the discharge current and the maximum charge are locked between 1C to 2C.

With the above safety precautions are implemented, the possibility of metallic lithium plating happening internally, because of overcharging is practically eradicated.

One of the overlooked issues for Li-ion batteries is aging and manufacturers often conveniently forget about it.

Usually, after a year, capacity deterioration is noticeable regardless of the usage of the battery.

In 2 to 3 years, the battery typically fails.

It is important to know that other chemistries also experience age-related worsening effects.

This is undeniably true if the Li-Ion is subjected to high ambient temperature.

Keeping the battery in a cool place delays the aging process of the Li-ion (and other chemistries).

It is widely accepted that storage temperatures of 15°C (59°F) are used. Moreover, the battery must be moderately charged during storage.

Battery producers are always upgrading the chemistry of the Li-ion battery. Novel and improved chemical mixtures are launched almost bi-yearly.

Cost-to-energy ratio

Given the speedy headway, it becomes tough to evaluate the aging process of the enhanced battery.

The most cost-friendly Li-ion battery under the cost-to-energy ratio is the cylindrical 18650 cell.

This one is utilized in almost all mobile computing devices and some other applications that do not necessitate super-thin geometry.

Should a thinner pack be needed (less than 18 mm), you can go with the prismatic Li-ion cell.

Although there might not be gains in the energy density of the 18650 cell, to get the same energy maybe two times costlier.

In the case of extremely slim geometry (below 4 mm), Li-ion polymer is the last resort.

Unsurprisingly, this is the costliest system in terms of cost-to-energy ratio. There are no gains in energy density.

Furthermore, it is less robust compared to the sturdy 18650 cells.

Benefits of Li-ion Batteries

- Its high energy density makes it perfect for greater capacities.

- The Li-ion possesses comparatively low self-discharge (about less than half) compared to NiCd and NiMH.

- Li-Ion is easier to maintain because no regular discharge is required and has no memory.

Drawbacks of Li-ion Batteries

- Li-ion batteries demand a protection circuit that restricts voltage and current. So, the battery is safe if not triggered.

- Even while the battery is not in use, it is subject to aging. Placing the Li-ion battery in a cool place with a 40% charge remaining may lower the aging effect.

- It might exhibit a mild discharge current.

- Transporting the Li-ion in large quantities may be subjected to regulatory control but this law does not affect personal carry-on batteries.

- The cost of producing a Li-ion battery is 40% more than that of NiCd.

- The introduction of new manufacturing processes and the incorporation of alternative metals with lesser cost options may bring down the price.

- Li-ion batteries are not matured, as alterations in metal and chemical mixtures affect battery test results particularly with quick test techniques.

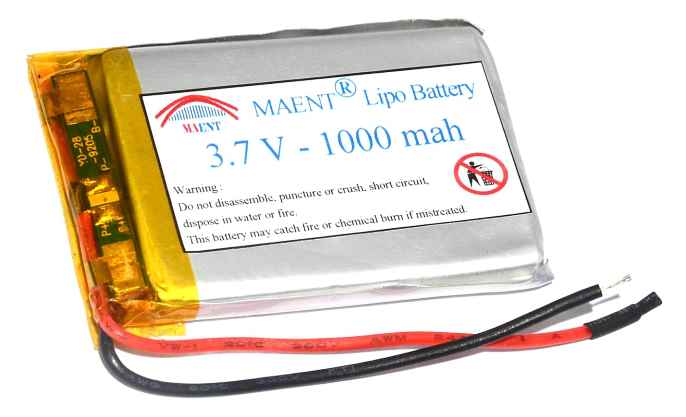

The Lithium Polymer (Lipo) Battery

The Lithium polymer battery or the Lipo battery is different from other battery models in terms of the type of electrolyte.

The first design which was developed in the 1970s employed the use of dry solid polymer electrolyte.

This chemical compound looks like a plastic film that acts as an insulator but permits the transaction of ions (electrically charged atoms).

The polymer electrolyte substitutes the standard porous separator, which is drenched in the electrolyte.

The dry polymer build presents a simpler construction in terms of manufacturing, durability, safety, and slim geometry.

Moreover, the fire hazard is eliminated due to the absence of liquid or gelled electrolyte.

The designers are free to build the battery as creatively as possible with various forms, shapes, and sizes thanks to the ultra-slim cell thickness which measures only 1 mm.

However, the dry Li-polymer is not a good conductor.

Its internal resistance is too large and unable to channel the current surges which are necessary for modern communications machines and powering hard drives of mobile computing devices.

You can ramp the conductivity by heating the cell to 60°C (140°F), but it is impractical for portable purposes.

The gelled electrolyte was added to ensure a small Li-polymer battery becomes conductive.

A wide collection of Li-polymer batteries used today for handphones are a hybrid type and comprise gelled electrolytes.

The right term for this design is Lithium-Ion Polymer. For marketing purposes, most battery producers mark their batteries as Li-polymer.

We will only pay attention to the hybrid lithium polymer because it is the only functioning polymer chemistry for portable batteries presently.

Difference Between Li-Ion and Li-Polymer

- One may ask what are the differences between typical Li-ion and Li-ion polymer when the gelled electrolyte is added?

- The answer is simple; the Li-ion polymer is special, wherein the solid electrolyte supplants the porous separator, although the attributes and performance of the two types are identical.

- Moreover, a gelled electrolyte is included to enrich ion conductivity.

- Technical limitations and delays in volume production have hampered the deployment of the Li-ion polymer battery.

- Furthermore, the supremacy of the Li-ion polymer has not yet been recognized.

- So, zero upgrades in capacity gains have been reached to date. Furthermore, the capacity Li-Polymer is marginally less than that of the typical Li-ion battery.

- At present, there is no cost-benefit. The main reason for considering the Li-ion polymer is the form factor.

- Ultra-thin wafer geometries are possible with Li-Polymer, and this is a trend that is currently in demand in the highly competitive mobile phone industry.

Advantages of Li-ion Polymer Batteries

- The Li-ion polymer batteries have the smallest profiles (comparable to a credit card) and are viable with their specifications.

- Due to their flexible form factor, producers of Li-ion polymer batteries are not restricted to standard cell structures.

- Any high volume and acceptable size can be produced at reasonable costs.

- Using gelled compared to liquid electrolytes makes the Li-ion polymer lightweight which permits easy packaging wherein some instances, no metal shells are needed.

- Enhanced safety is ensured with Li-ion polymer batteries as they are more resistant to overcharge. This means the chances for electrolyte leakage are minimal.

Drawbacks of Li-ion Polymer Batteries

- The Li-ion polymer batteries exhibit lower energy density and reduced charge/discharge cycle count compared to Li-ion batteries. The good news is that there is scope for improvements in the future.

- They are costly to produce.

- However, once Li-ion polymer batteries are manufactured, they become very cost-effective for the end user.

- Thanks to relatively smaller control circuits which compensate for elevated production costs.