In this article I will comprehensively explain everything regarding how to read and understand capacitor codes and markings through various diagrams and charts. The information can be used for identifying and selecting capacitors correctly for a given circuit application.

By Surbhi Prakash

Capacitor Codes and associated Markings

The various parameters of the capacitors such as their voltage and tolerance along with their values is represented by different types of markings and codes.

Some of these markings and codes include capacitor polarity marking; capacity colour code; and ceramic capacitor code respectively.

There are various different ways in which the marking is done on the capacitors. The markings’ format is dependent upon what type of capacitor is given.

The type of component acts as a deciding factor of the types of the codes used.

The component deciding the coding can be surface mount, technology, traditional lead, or capacitor dielectric component. Another factor which plays a role in deciding the marking is the size of the capacitor as it impacts the space which is available for capacitor’s marking.

The EIA (Electronic Industry Alliance) has also been playing a crucial role in providing standardized systems of marking the capacitors which can be followed as a standard in the industry.

Basics of Capacitor Markings

As discussed above, there are various factors and standards which are followed while marking the capacitors.

The various manufacturers manufacturing specific types of capacitors follow both basic or standard marking systems depending on the type of capacitor being manufactured and what is the best fit for it.

The marking “µF” is denoted by an abbreviation namely “MFD” on many occasions.

MFD is not used for denoting “MegaFarad” as is the general conception.

One can easily decode the markings and codes present on the capacitors if the person has a general knowledge of the marking and coding systems used for the capacitors.

The two types of general marking systems followed for marking the capacitors are:

Markings which are non-coded: one of the most common processes adopted to mark the parameters of a capacitor is to create a marking on the case of the capacitor or encapsulating them in some manner.

This is more feasible and suitable for capacitors of large size as it enables to provide enough space for creating the marks.

Capacitor markings which are abbreviated:

The capacitors which are small in size does not provide space required for clear markings and only few figures can be accommodated in the given space in order to mark it and provide a code for their various parameters.

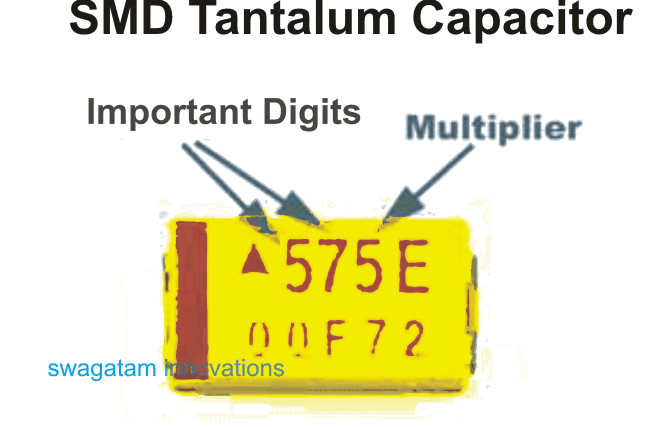

Thus, abbreviated markings are used in such cases wherein three characters are used to mark the code of the capacitor.

There is a similarity between this marking system and the resistor’s color codes system which can be observed here, except for the “color” which is used in the coding system. Out of the three characters used in this marking system, the first two characters represent figures which are significant and the third character is representative of a multiplier.

In case the capacitors are tantalum, ceramic, or film capacitors, “Picofarads’ is used to denote the capacitor’s value; while in case the capacitor is of aluminium electrolytes, “Microfarads” is used to denote the capacitor’s value.

In case, small values with decimal points needs to be represented, then the alphabetical letter “R” is used such as 0.5 is represented as 0R5, 1.0 as 1R0, and 2.2 as 2R2 respectively.

This type of marking can be observed to be used more commonly in the surface mount capacitors where there is very limited space available. The different types of coding system used for the capacitors are:

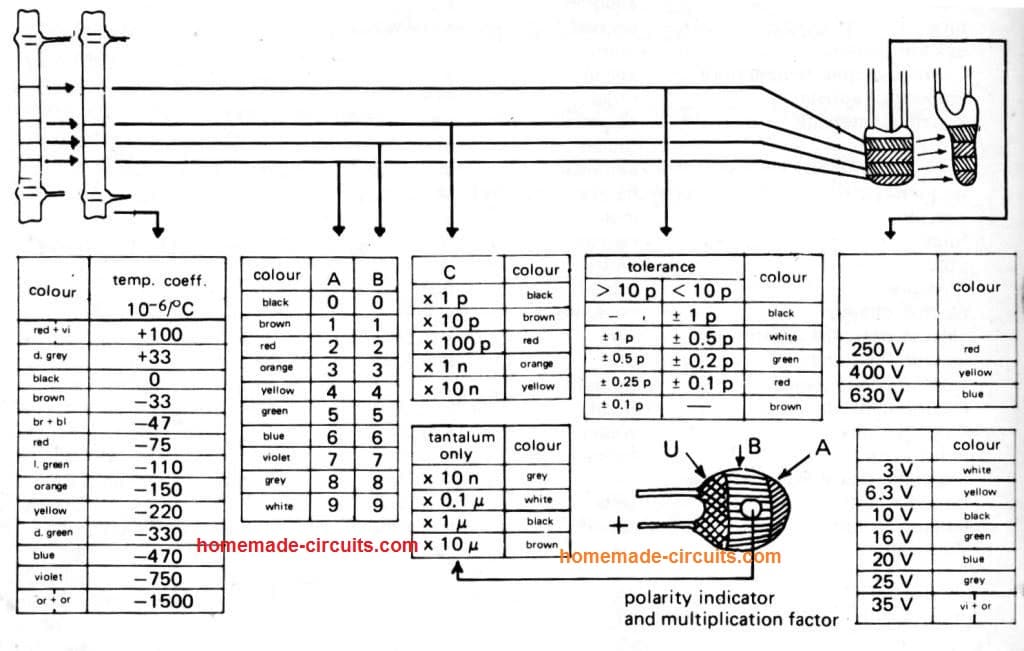

Colour Code: A “colour code” is used in capacitors which are old. In the present times, industry rarely use colour code system except seldom on some of the components.

Tolerance Codes: The tolerance code is used in some of the capacitors. The tolerance codes used in the capacitors are similar to the codes used in the resistors.

Working Voltage Code of Capacitors:

The working voltage of a capacitor is one of its key parameter. This coding is used widely in various types of capacitors, especially for the capacitors which have enough space to write alphanumeric codes.

In other cases where the capacitors are small with no space available for alphanumeric coding, there is absence of voltage coding and thus any person handling such capacitors must take extra care when he/she observes that any kind of marking is absent on the storage container or the reel.

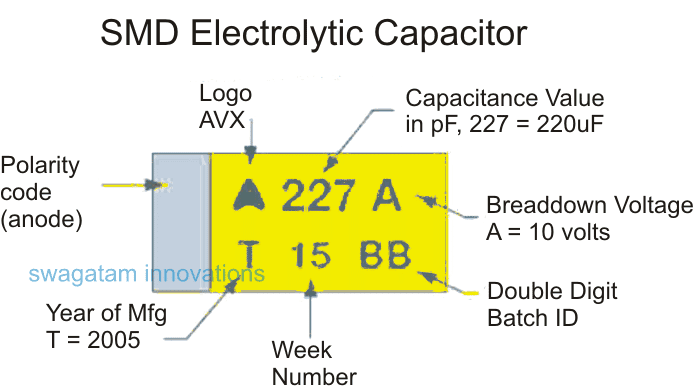

Some of the capacitors such as the tantalum capacitor and SMD electrolytic capacitor use a code consisting of one single character. This coding system is similar to that of the standard system followed by EIA and also requires very small amount of space.

Temperature Coefficient Codes: the capacitors required to be marked or coded in a manner which denotes the capacitor’s temperature coefficient. The temperature coefficient codes which are used for a capacitor are in most of the cases the standard codes given by the EIA. But there are other temperature coefficient codes which are used in the industry by different manufacturers, especially for capacitors including film and ceramic type of capacitors. The code used to quote the temperature coefficient is “PPM/ºC (parts per million per degree C).

Polarity Markings of a capacitor

The polarized capacitors require having markings denoting their polarity. In case the polarity markings are not provided to the capacitors, it may result in severe damage being caused to the component along with the entire circuit board.

Thus, utmost care needs to be taken to ensure that there are polarity markings on the capacitors when the latter is inserted into the circuits.

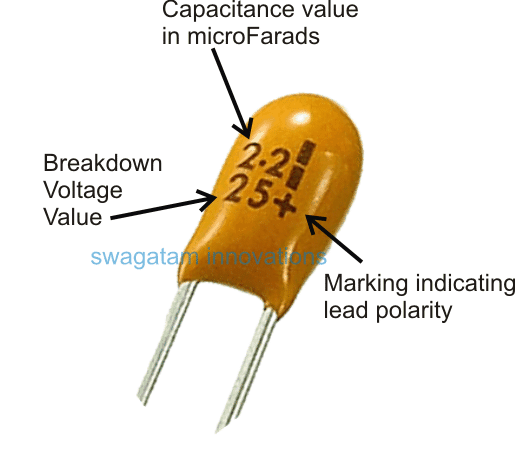

The polarized capacitors are in other words capacitors which are made of tantalum and aluminium electrolytes. A capacitor’s polarity can be easily determined if they are marked with signs such as “+” and “-“. Most of the capacitors which are circulating in the industry recently possess such markings. Another marking format which can be used for the polarized capacitors, especially electrolytic capacitor is the by marking the components with stripes.

A stripe marking denotes a “negative lead” in an electrolytic capacitor.

The stripe marking on a capacitor can also be accompanied by the symbol of an arrow pointing towards the negative side of the lead.

This is done when axial version capacitor is present where both ends of the capacitor consist of lead. The positive lead of a leaded titanium capacitor is denoted by the polarity markings on the capacitor.

The polarity marking is marked near the positive lead with a “+” sign indicating the marking. In case of a new capacitor, an additional polarity marking is placed on the capacitor to denote that the negative lead is shorter than the positive lead.

Different types of capacitors and their markings

The markings on the capacitors can also be done by printing it on the capacitor. This is true for capacitors which provide enough space for marking to be printed and include film capacitors, disc ceramics, and electrolytic capacitors.

These large capacitors provide sufficient space to print markings which shows the tolerance, ripple voltage, value, working voltage, and any other parameter associated with the capacitor.

The differences between the markings and codes of the various types of lead capacitors are very minimal or marginal; but nevertheless these differences are many in number.

Markings on Electrolytic Capacitor: The lead type capacitors are manufactured in both large and small sizes. But the large leaded capacitors are more abundant.

Thus, for these large capacitors, the parameters such as value and others can be provided in detail instead of giving in abbreviated form.

On the other hand, for the smaller capacitors due to lack of sufficient space the parameters are provided in the form of abbreviated codes.

An example of the marking which can be typically observed in a capacitor is “22µF 50V”. Here, 22µF is the value of the capacitor while 50V denotes the working voltage. The marking of a bar is used to denote the polarity of the capacitor indicating the negative terminal.

Markings of leaded tantalum capacitor: The unit, “Microfarad (µF)” is used to mark the values in the leaded tantalum capacitors. An example of a typical marking observed on a capacitor is “22 and 6V”. These figures indicate that the capacitor is of 22µF and 6V is its maximum voltage.

Markings of Ceramic Capacitor: The markings on a ceramic capacitor are more concise in nature since it is smaller in size as compared to electrolytic capacitors.

Thus, for such concise markings many different types of schemes or solutions are adopted. The value of the capacitor is indicated in “Picofarads”. Some of the marking figures which can be observed are 10n which denotes that the capacitor is of 10nF. In a similar way, 0.51nF is indicated by the marking n51.

Codes of SMD Ceramic Capacitor: The capacitors such as surface mount capacitor do not have sufficient space available for markings due to their small size.

The manufacturing of these capacitors are done in such a manner that any type of marking is not required. These capacitors are loaded in a machine called pick and place which eliminates any marking need.

Markings of SMD tantalum capacitor: Similar to the ceramic capacitors, there is absence of markings which are observed in some of the tantalum capacitors.

The tantalum capacitors only consist of the polarity markings. This is present in order to ensure the correct insertion of the capacitor in the circuit board.

The marking format consist of three figures is generally used for the capacitors which has sufficient space available such as is evident in the ceramic capacitors.

The marking of a bar can be observed in some of the capacitors across their one end denoting the capacitor’s polarity.

The marking for polarity is important in order to identify and check the capacitor’s polarity since the destruction of the capacitor can occur if the polarity is not known and a person places it in reverse biasing, especially in the case of tantalum capacitors.

It is utmost important that one can identify, read, and check a capacitor’s value.

Since there are a range of capacitors available and their different coding and marking systems, it is quintessential that a basic understanding of these marking and coding is there to an individual in order to apply it appropriately to respective capacitors.

An individual can determine the capacitor’s value with practice and experience and just going through few examples mentioned here would not suffice.

Capacitor Color Code Chart