In this article I will try to explain how scalar control algorithm is implemented for controlling induction motor speed with relatively straightforward calculations, and yet achieve a reasonably good linearly variable speed control of the motor.

Reports from many top market analysis reveal that induction motors are the most popular when it comes to handling heavy industrial motor related applications and jobs. The main reasons behind the popularity of induction motors are basically due to its high degree of robustness, greater reliability in terms of wear and tear issues, and comparatively high functional efficiency.

That said, induction motors have one typical downside, as these are not easy to control with ordinary conventional methods. Controlling induction motors is relatively demanding owing to its rather complex mathematical configuration, which primarily includes:

- Non-linear response at core saturation

- Instability in the form oscillations due to varying temperature of the winding.

Due to these critical aspects implementing induction motor control optimally demands a thoroughly calculated algorithm with high reliability, for example using a “vector control” method, and additionally using a microcontroller based processing system.

Understanding Scalar Control Implementation

However there exists another method that can be applied for implementing induction motor control using a much easier configuration, it is the scalar control incorporating non-vector drive techniques.

It is actually possible to enable an AC induction motor into a steady state by operating it with a straightforward voltage feedback and current controlled systems.

In this scalar method, the scalar variable may be tweaked once its right value is achieved either by experimenting practically or through suitable formulas and calculations.

Next, this measurement can be used for implementing motor control via an open loop circuit or through a closed feedback loop topology.

Even though the scalar method of control promises a reasonably good steady-state results on the motor, its transient response may not be up to the mark.

How Induction Motors Work

The word "induction" in induction motors refers to the unique way of its operation in which magnetizing the rotor by the stator winding becomes a crucial aspect of the operation.

When AC is applied across the stator winding, the oscillating magnetic field from the stator winding interacts with the rotor armature creating a new magnetic field on the rotor, which in turn reacts with the stator magnetic field inducing a high amount of rotational torque on the rotor. This rotational torque renders the required effective mechanical output to the machine.

What is 3-Phase Squirrel Cage Induction Motor

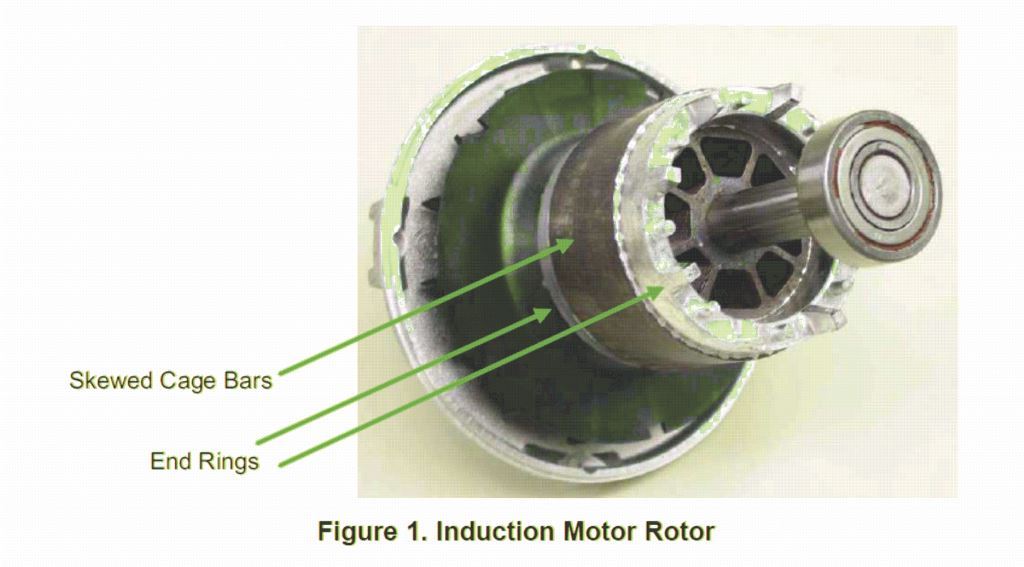

It is the most popular variant of induction motors and is extensively used in industrial applications. In a squirrel cage induction motor, the rotor carries a series of bar like conductors surrounding the axis of the rotor presenting a unique cage like structure and hence the name “squirrel cage”.

These bars which are skewed in shape and running all around rotor axis are attached with thick and sturdy metal rings at the ends of the bars. These metal rings not only help to secure the bars strongly in place but also enforce an essential electrical short circuiting across the bars.

When the stator winding is applied with a sequencing 3-phase sinusoidal alternating current, the resulting magnetic field also begins moving with the same speed as the 3 phase stator sine frequency (ωs ).

Since the squirrel cage rotor assembly is held within the stator winding, the above alternating 3 phase magnetic field from the stator winding reacts with the rotor assembly inducing an equivalent magnetic field on the bar conductors of the cage assembly.

This forces a secondary magnetic field to build up around the rotor bars, and consequently this new magnetic field is forced to interact with the stator field, enforcing a rotational torque on the rotor which tries to follow the direction of the stator magnetic field.

In the process the rotor speed tries to attain the stator’s frequency speed, and as it approaches the stator synchronous magnetic field speed, the relative speed difference e between the stator frequency speed and the rotor rotational speed begins decreasing, which causes a decrease in the magnetic interaction of the rotor's magnetic field over the stator's magnetic field, eventually decreasing the torque on the rotor, and the equivalent power output of the rotor.

This leads to a minimum power on the rotor and at this speed the rotor is said to have acquired a steady-state, where the load on the rotor is equivalent and matching the torque on the rotor.

The working of an induction motor in response to a load may be summarized as I have explained below:

Since it becomes mandatory to maintain a fine difference between the rotor (shaft) speed and the inner stator frequency speed, the rotor speed which actually handles the load, rotates at a slightly reduced speed than the stator frequency speed. Conversely, if we suppose the stator is applied with 50Hz 3 phase supply, then the angular speed of the this 50Hz frequency across the stator winding will be always slightly higher than the response in the rotor’s rotational speed, this is inherently maintained to ensure an optimal power on the rotor.

What is Slip in Induction Motor

The relative difference between the stator’s angular speed of frequency and the rotor’s responsive rotational speed is termed as the “slip”. The slip needs to be present even in situations where the motor is operated with a field-oriented strategy.

Since the rotor shaft in induction motors does not depend on any external excitation for its rotation, it can work without conventional slip rings or brushes ensuring virtually zero wear and tear, high efficiency and yet inexpensive with its maintenance.

The torque factor in these motors is determined by the angle established between the magnetic fluxes of stator and the rotor.

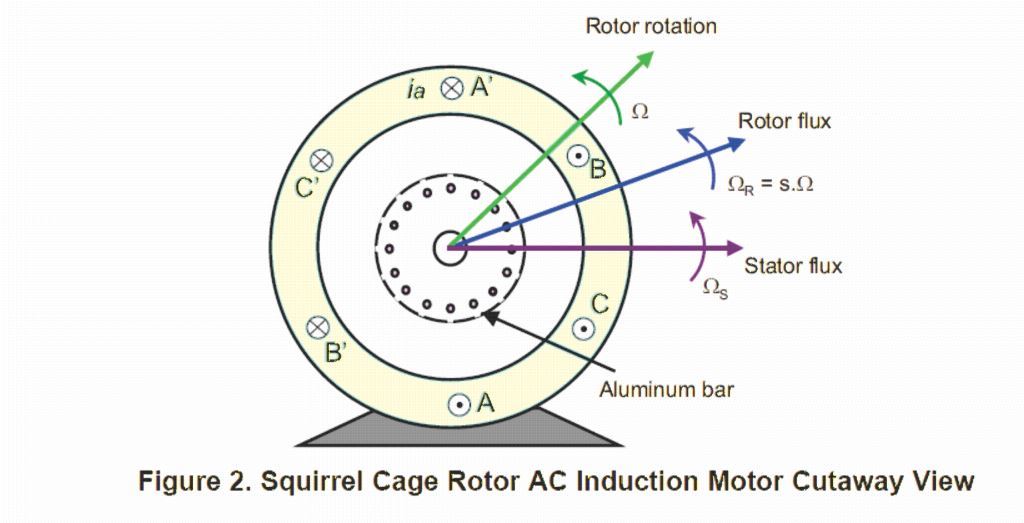

Looking at the diagram below, we can see that the speed of rotor is assigned as Ω, and the frequencies across stator and the rotor are determined by the parameter “s” or the slip, presented with the formula:

s = (ωs - ωr) / ωs

In the above expression, s is the “slip” which exhibits the difference between the stator’s synchronous frequency speed and the actual motor speed developed on the rotor shaft.

Understanding the Scalar Speed Control Theory

In induction motor control concepts where V/Hz technique is employed, the speed control is implemented by adjusting the stator voltage with respect to frequency such that the air gap flux is never able to deviate beyond the expected range of the steady-state, in other words it is maintained within this estimated steady-state value, and hence it is also called the scalar control method since the technique heavily depends on the steady-state dynamics for controlling the motor speed.

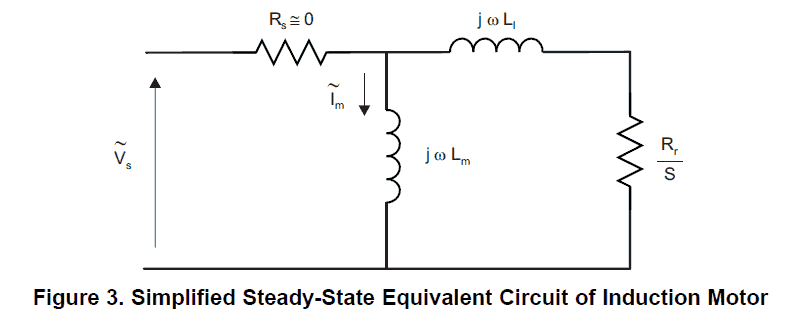

We can understand the working of this concept by referring to the following figure, which shows the simplified scheme of a scalar control technique. In the set up it is assumed that stator resistance (Rs) is zero, while the stator leakage Inductance (LIs) impressed upon the rotor leakage and magnetizing inductance (LIr). The (LIr) which actually depicts the magnitude of the air gap flux can be seen to have been pushed prior to the total leakage inductance (Ll = Lls + Llr).

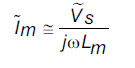

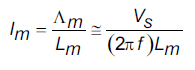

Due to this, the air gap flux created by the magnetizing current gets an approximate value close to the stator’s frequency ratio. Thus the phasor expression for a steady-state assessment can be written as follows:

For Induction motors which may be running at their linear magnetic regions, the Lm will not change and remain constant, in such cases the above equation may be expressed as:

Where V and Λ are the stator voltage values and stator flux respectively, whereas Ṽ represents the phasor parameter in the design.

The last expression above clearly explains that as long as the V/f ratio is held constant regardless of any change in the input frequency (f), then the flux also remains constant, which enables the toque to operate without depending on the supply voltage frequency. That implies if ΛM is maintained at a constant level, the Vs / ƒ ratio would also be rendered at a constant relevant speed. Therefore whenever the speed of the motor is increased, the voltage across the stator winding will also need to be proportionately increased, so that a constant Vs/f could be maintained.

However here the slip being the function of the load attached to the motor, the synchronous frequency speed does not depict the real speed of the motor.

In an absence of a load torque on the rotor, the resultant slip may be negligibly small, allowing the motor to attain close to synchronous speeds.

That is why a basic Vs/f or a V/Hz configuration usually may not have the capability of implementing accurate speed control of an induction motor when the motor is attached with a load torque. However a slip compensation may be quite easily be introduced in the system along with speed measurement.

The below indicated graphical representation clearly depicts a speed sensor within a closed loop V/Hz system.

In practical implementations, typically the ratio of stator voltage and frequency may be dependent on the rating of these parameters itself.

Analyzing V/Hz Speed Control

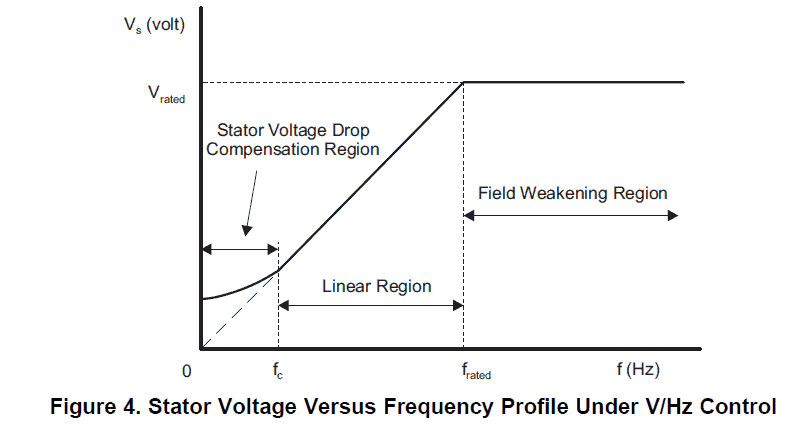

A standard V/Hz analysis can be witnessed in the following figure.

Fundamentally you will find 3 speed selection ranges within a V/Hz profile, which may be understood from the following points:

- Referring to figure 4 when cut off frequency is at the region 0-fc, a voltage input becomes essential, which develops a potential drop across the stator winding, and this voltage drop cannot be ignored and requires to be compensated by increasing the supply voltage Vs. This indicates that in this region the V/Hz ratio profile is not a linear function. We can analytically evaluate the cut off frequency fc for appropriate stator voltages witg the help of the steady state equivalent circuit having Rs ≠ 0.

- In region fc-r(rated) Hz, it is able to execute a constant Vs/Hz relationship, in this case the slope of the relationship signifies the amount of the air gap flux.

- At the region beyond f(rated), running at higher frequencies, it becomes impossible to carry out the Vs/f ratio at constant rate, since in this position the stator voltage tends to get restricted at the f(rated) value. This happens to make sure that the stator winding is not subjected to an insulation breakdown. Due to this situation, the resulting air gap flux tends to get compromised and reduced, leading to an correspondingly decreasing rotor torque. This operational phase in induction motors is termed as the “fieldweakening region”. To prevent this kind of situation, usually a constant V/Hz rule is not obeyed in these frequency ranges.

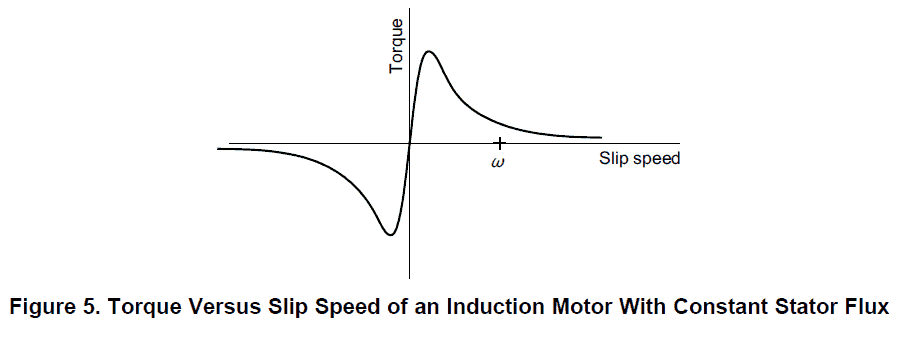

Due to the presence of a constant stator magnetic flux irrespective of the frequency change in the staor winding, the toque on the rotor now only has to rely on the slip speed, this effect can be seen in the figure 5 above

With appropriate slip speed regulation, the speed of an induction motor could be effectively controlled along with the torque on the rotor load by employing a constant V/Hz principle.

Therefore whether it is an open or a closed-loop mode of speed control, both could be implemented using the constant V/Hz rule.

An Open loop mode of control could be employed in applications where accuracy of speed control may not be an important factor, such as in HVAC units, or fan and blower like appliances. In such cases frequency to the load is found by referring to the required speed level of the motor, and the rotor speed is expected to approximately follow the instantaneous synchronous speed. Any form of discrepancy in the speed arising from the slip of the motor is generally ignored and accepted in such applications.

Reference: http://www.ti.com/lit/an/sprabq8/sprabq8.pdf

Hello. I tried to get in touch with you for product consultancy/development for VFD’s. Your live.com e-mail ID bounced back. Please get in touch with me at my mail ID.

Hello, you can discuss your problem through comments here. However, I won’t be able to provide practical verifications or prototypes.

Thank you for the response. We’re looking for someone to design/develop a VFD designed to our specific needs (0.25KW, 3 phase) that we need in quantity. We’ll bear all costs (prototyping etc.), apart from any applicable consultancy charges. If you, or any one else you may know, would be interested, please get in touch. FYI, we are based out of Mumbai.

I appreciate your proposal, however a commercial 3 phase VFD can be a complex circuit to create, which may be beyond the level of my expertise. If I find someone capable I will surely let you know.

I can design & Develop VFD as per your specific needs (0.25W – 2.0 Kw) , 3 phase a very good design with very competitive pricing. I have already designing & Developing low cost 3 Phase VFD drive (Single Phase 230 V ac , 0.25W – 2.0 Kw) for Indian market as general purpose speed variation in small industrial machines , control panel , blower etc. I am in final stages of of testing prototype. I was developing this drive for supplying to OEM in bulk quantities. If your interested then Please share your requirement. I will take very small one time charge for development but charge a reasonable amount per drive basis in bulk quantity , Even after that drive will be very cost competitive by good amount as compared to drive available in Indian market

Thank you for the proposal. I will keep your comment posted so that needy people can contact you for further details

Thank you for your reply.

Shortly after my comment above, we have taken a policy decision to migrate from Ac to DC for the lower power (<500W) applications. So for lower power drives, we would be interested in drive design for sensored BLDC drives. Please let me know if that would be in your interest/skill set.

Presently I do not have any requirement for this circuit, if some other visitors is interested you will be surely notified about it.

Yes I can also design sensored BLDC drives. Please share your specs. Sensors means hall sensors , 1 shunt/2 shunt design etc & Max voltages

Thank you for your response. Perhaps it’s better to take the chat off the board? You can contact me at apatel365@gmail.com

Hello sir.

I am interested to vfd that can control up to 15kw

Dear Sir,

Have you written any article for Arduino based 3 phase induction motor controller circuit? please

Dear GD, At present I do not have any article related to this topic.

OK. If you can, Thank you in advance.