In this article I have explained the pinout functions of the IC SG3525 which is a regulating pulse width modulator IC. So I have explained in details:

Main Technical Features

The main features of the IC SG3525 may be understood with the following points:

- Operating voltage = 8 to 35V

- Error amp reference voltage internally regulated to 5.1V

- Oscillator frequency is variable through an external resistor within the range of 100Hz to 500 kHz.

- Facilitates a separate oscillator sync pinout.

- Dead time control is also variable as per intended specs.

- Has an internal soft start feature

- Shut down facility features a pulse by pulse shutdown enhancement.

- Input under voltage shut down feature also is included.

- PWM pulses are controlled through latching for inhibiting multiple pulse outputs or generation.

- Output supports a dual totem pole driver configuration.

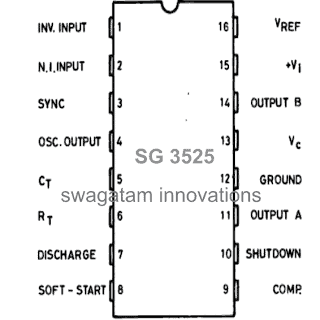

Pinout Diagram of the IC

SG3525 PinOut Description

A practical implementation of the following pinout data may be understood through this inverter circuit

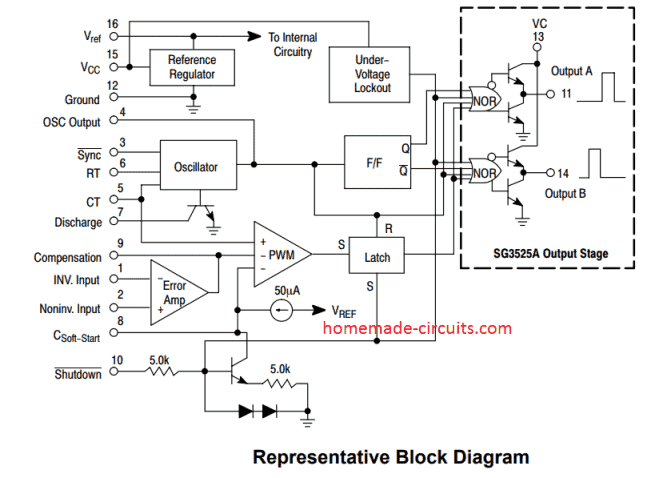

The IC SG3525 is a single package multi function PWM generator IC, the main operations of the respective pin outs are explained with the following points:

Pin#1 and #2 (EA inputs): These are inputs of the built-in error amplifier of the IC. Pin#1 is the inverting input while pin#2 is the complementary non-inverting input.

It's a simple op amp arrangement inside the IC which controls the PWM of the IC outputs at Pin#11 and Pin#14. Thus these EA pins 1 and 2 can be effectively configured for implementing an automatic the output voltage correction of a converter.

It is usually done by applying a feedback voltage from the output through a voltage divider network to the non-inverting input of the op amp (pin#1).

The feedback voltage should be adjusted to be just below the internal reference voltage value (5.1 V) when the output is normal.

Now, if the output voltage tends to increase above this set limit, the feedback voltage would also increase proportionately and at some point exceed the reference limit. This will prompt the IC to take necessary corrective measures by adjusting the output PWM, so that the voltage is restricted to the normal level.

Pin#3 (Sync): This pinout can be used for synchronizing the IC with an external oscillator frequency. This is generally done when more than a single IC is used and requires to be controlled with a common oscillator frequency.

Pin#4 (Osc. Out): It's the oscillator output of the IC, the frequency of the IC may be confirmed at this pin out.

Pin#5 and #6 (Ct, Rt): These are termed CT, RT respectively. Basically these pinouts are connected with an external resistor and a capacitor for setting up the frequency of the inbuilt oscillator stage or circuit. Ct must be attached with a calculated capacitor while the Rt pin with a resistor for optimizing the frequency of the IC.

The formula for calculating the frequency of IC SG3525 with respect to RT and CT is given below:

f = 1 / Ct(0.7RT + 3RD)

- Where, f = Frequency (in Hertz)

- CT = Timing Capacitor at pin#5 (in Farads)

- RT = Timing Resistor at pin#6 (in Ohms)

- RD = Deadtime resistor connected between pin#5 and pin#7 (in Ohms)

Pin#7 (discharge): This pinout can be used for determining the deadtime of the IC, meaning the time gap between the switching of the two outputs of the IC (A and B). A resistor connected across this pin#7 and pin#5 fixes the dead time of the IC.

Pin#8 (Soft Start): This pinout as the name suggests is used for initiating the operations of the IC softly instead of a sudden or an abrupt start. The capacitor connected across this pin and ground decides the level of soft initialization of the output of the IC.

Pin#9 (Compensation): This pinout is for compensating the error amplifier op amp. Mostly this pinout is connected to ground via a RC network. However, if required this pinout can be configured with an external transistor which can ground this pin during a critical situation, enabling a shutdown of the IC output.

Pin#10 (Shutdown): As the name suggest this pinout may be used for shutting down the outputs of the IC in an event of a circuit malfunction or some drastic conditions.

A logic high at this pin out will instantly narrow down te PWM pulses to the maximum possible level making the output device's current go down to minimal levels.

However if the logic high persists for longer period of time, the IC prompts the slow start capacitor to discharge, initiating a slow turn ON and release. This pinout should not be kept unconnected for avoiding stray signal pick ups.

Pin#11 and #14 (output A and output B): These are the two outputs of the IC which operate in a totem pole configuration or simply in a flip flop or push pull manner.

External devices which are intended for controlling the converter transformers are integrated with these pinouts for implementing the final operations.

Pin#12 (ground): It's the ground pin of the IV or the Vss.

Pin#13 (Vcc): The output to A and B are switched via the supply applied to pin#13. This is normally done via a resistor connected to the main DC supply. Thus this resistor decides the magnitude of trigger current to the output devices.

Pin#15 (Vi): It's the Vcc of the IC, that is the supply input pin.

Pin#16: The internal 5.1V reference is terminated through this pinout and can be used for external reference purposes. Example, you can use this 5.1V for setting up a fixed reference for a low battery cut-off op amp circuit, etc. If it's not used then this pin must be grounded with a low value capacitor.

i made a circuit using ir2153 but the fets blows as soon as i switch on power

is it possible to use sg3525 and a push pull transformer but powered by 300Dc not 1 or 48

what will be the primary/secondary voltage specs of the transformer??

Hello Mr

its nice to check the circuits & ideas on this site

i need your help making a pure sinewave inverter

as a suggestion which circuit is the final one of sg3525?

if i want to use Arduino to generate spwm chopping the output of the sg3525 is that possible?

or if i tried your Arduino example how to set the output voltage or the hertz?

thanks for help

Hello, yes that is possible. You can connect the SG3525 output to a push-pull BJT stage through 1K resistors, and configure the BJT buffer output with the power MOSFET stage. After this you can integrate SPWM with the bases of the BJT stage for the required sine wave chopping.

An example concept for the above can be witnessed in the following article:

Convert a Square Wave Inverter into a Sine Wave Inverter

thankls for reply

which sg3525 is the final one because i have noticed a different circuits on this site

different values of resistors & other parts of the circuit

You can use any SG3525 circuit from this website or from any external source….it’s just about configuring the output stage appropriately for the phase chopping

in the arduino Circuit there is 2 outputs

do i need to use the both outputs to drive the BJT’s?

or like the first circuit use 1 pin to Bases of both BJT’s?

then i need to modify the Arduino code so it can produce varying pwm on one pin

is that right ?

thanks

You will have to use only one output from the Arduino and modify the code so that it generates the varying SPWM with a total delay that corresponds to one cycle of a sine wave. And this SPWM set must keep switching again and again continuously in response to the alternate switching of the SG3525 output. Meaning, after the Arduino completes one SPWM cycle, it must be triggered from SG3525 outputs to reset the Arduino and start a new cycle again.

how to get it triggered from sg3525?

Do i have to modify the delay in Arduino Code or its enough to delete the second half of the code?

Just deleting one half of the code will not be enough. The SPWM cycles mus be synchronized with the SG3525 output switching,for this you will have to modify the code so that it accepts an external signal and resets the code to start from the beginning. In this way the SPWM sets will be delivered to the two BJT channels in a uniform manner.

thanks for your reply Mr

its easy to reset the Microcontroller to start the cycle again after using one cycle only

but do i need to Recalculate the delay periods of the code ?

But how to get this from Sg3525 ?

as i see the sync output is an oscillator output i guess

You can get a triangle wave pulse from pin#5 of SG3525, you can use this pulse to reset the Arduino. The Arduino must preferably generate a minimum 5 block SPWM which must accommodate inside the each resetting time period. So this 5 pillar SPWM must keep recycling in response to each triangle wave pulses from pin#5 of the SG3525.

The sync output can be used to sync the SG3525 through a 50 Hz or 60 Hz pulse from the Arduino, but would be more complex to code and configure.

Thanks Mr

So i have to measure the pulse period of Pin 5 & use this time in arduino to generate Atleast 5 spwm blocks or more i guess will be better smoothing the wave right?

I like to use the sg3525 features & use the arduino to generate spwm signal & some extra festures to the inverter

Yes that’s correct, but higher pwm blocks will not be good for iron core transformer.

Welding inverter modified to charge and desulfator battery,why did adjusted output voltage by connected VR10k at pin9 to GND

Just use a D-flip/flop, it divides by 2 by itself ;-?

How I can decrease the output frequency to be 50 hirtz

Hi Swag can i send you the circuit diagram to get your opinion on this subject?

thank you!

Hi Matt, sorry, it can be difficult to diagnose the fault by seeing a diagram. You must first test the standard 3525 configuration and confirm the output oscillations, if it is working then your IC is OK and then you can proceed with the external frequency connection on the specified pinout.

Hi Swag ok for pin 3 but exactly the same result! maybe de ic is over?

Yes that may be possible, is the IC oscillating with the normal set up using Rt Ct, if yes then it is not over yet!

Hi Swag i have tried to connect the ground with the other circuit (common gnd) (the pwm capacitors and resistor mode on pin 5 and 6 is ok 1% to 49.9%) but, when trying to disconnect pin 5 and 6 and connect an external frequency (pin4) i have no pwm! (4,2%)

thank you for your help!

Hi Matt, the synchronizing external clock must be applied to pin#3, not pin#4.

hello swag im trying to connect the 3525 pwm on pin 2 with external signal 0 to 5v! and an external frequency of 50KHZ on pin 4! on pin 11 and 14 i have 50KHZ but no pwm!

Matt, did you connect the ground of the external signal with the ground of the 3525? If you do this then the PWM should definitely work

Hello Swagg on my sg3525 i have connected an output 50KHZ frequency on pin 4 and its ok , and connected a variable 5v on pin 2 for a pwm but theres no results! ive disconnected pin 7 and 6!

have you any idea?

thank you!

Sorry matt, I am unable to understand the configuration, and the reason behind it….

can i send you the schematic by email?

thank you

Please explain the purpose of those connections, so that I can understand your exact requirement.

Hi I have a problem with my welding inverter, it uses the compasetion pin #9 for feedback pin #1 GND,#2 is tied to Vref

Greetings,

Clear-cut explanations about the component. Extremely useful for beginners. Welldone

After replacing this IC I did quick continuity test to ensure that everything is ok. Seems like there is 0 resistance between pins 1 and 12 and between pins 3 and 12 (this also means that pins 1 and 3 have 0 resistance between each other as both have same ground). Is this ok as pin 12 is ground or does it mean that something else is still broken?

Sorry, ICs cannot be checked by measuring resistances across their pins, you must configure them as per their standard design and then check whether it

is providing the expected results ro not.

Swagatam Ji ,

Namskar,????

I have a inverter welding machine.

SG 3525 ic is used to control mosfet.

I can get 20 to 200 amp from this system for welding. There is a potentiometer to adjust amperes from 20 to 200.

But output voltage remains 40 to 50 volt .

I want to modify this Machine so that I can get variable voltage also at output.

Can you please advise me how I should connect another potentiometer and resistance to get variable voltage.

Namaskar Devendra ji, without seeing the circuit diagram it can be difficult for me to give a proper suggestion.

Example/test circuit shows capacitor for pin 9 with value of 0.01 but with no unit. Is this μF, nF, or pF? I managed to physically break this capacitor in my SMPS when I was replacing the IC so I am not able to measure it. and what would happen if replacement capacitor is either 1000 times less or 1000 times more capacitance?

I cannot find any example/test circuit in the above article, please indicate its exact location.

I meant this manual, page 5:

https://www.onsemi.com/pub/Collateral/SG3525A-D.PDF

Also I just now noticed that this article is about SG3525, but this manual is about SG3525A. Are they same or different things?

The 0.01 refers to 0.01uF capacitor. SG3525 and SG3525A are one and the same.

Thank you!

Could you also share how you reached to that conclusion? Is it default to assume that capacitors in IC circuits are in uF? Since I dont have much experience, I would just like to know if you got some hints form somewhere or is it default assumption that if unit is not marked it is uF?

A pF and nF value will always have these units marked clearly, if there’s no designation indicated then yes, it is uF by default.

Hello Sir

I have learnt a lot from your replies.But i would like to know if SG3525 has internal feedback system,and would like to know the formula for calculating then oscillation frequency of the IC ,say 50hz.Results from sites does’t satisfy me.Thanks so much.

Hello Patrick, I have updated the formula for calculating the frequency of the IC output. Please check the RT/CT pinout details above for the details.

The feedback can be added at pin#1 of the IC as indicated in the diagrams in this article:

https://www.homemade-circuits.com/sg3525-pure-sinewave-inverter-circuit/

Hello Mr Swagatam, I used the sg3525 to drive my half bridge mosfet in my half bridge SMP but, I noticed that the low side mosfet gets hot and high side mosfet remains cool or warm. If I leave the circuit running for longer time, the low side mosfet gets hotter. This happens only when a load is connected at the output of the ferrite transformer.

Turns ratio of this main ferrite transformer is 1:2 stepdown configuration. The load on the output consumes as high as 1Amp. I have used an RC snubber connected at the drain to source of the low side mosfet, though the temp. rise decreased and it wasn’t as high as when there was no snubber, but I really need to get rid of this fault.

Please I need your idea on how to stop this problem. I don’t know if this is a problem or just nothing to worry about.

Hello Victory, it can be difficult to judge the fault without checking the functioning in detail. A waveform analysis across the various points can perhaps help to the diagnose the fault better. Alternatively you can modify the MOSFET configuration as per the concept explained in the following article;

SMPS 2 x 50V 350W Circuit for Audio Power Amplifiers

I’m really appreciate your helpful explain of SG3525. So if i’d like to make a lag time between Pin 11 and Pin 14 but the freq and the duty cycle is the same , is it possible ?

My english is not good, hope you understand what i means .

Thank you so much .

Thank you, Yes it is possible to alter the deadtime without effecting the frequency, but the duty cycle will be effected

I put the double 555 circuit together as shown in the diagram that you had sent. Very nice looking waveform up to about 75% duty cycle but then goes unstable when I raise the control voltage further in an effort to go to a higher duty cycle. By the way, my power voltage is about 12.8 volts. Any suggestions for reaching a higher duty cycle? I would like to reach 95% if possible. Also, the operating frequency is about 75 Hz. I would like to operate somewhere in the range of 200 to 400 Hz. Thanks very much for any further help!

To confirm the maximum possible PWM from the IC, you can try connecting pin#5 of IC2 with the positive line of the circuit. This will provide an accurate idea regarding the maximum PWM capacity of the circuit. Beyond this level it may not be possible to increase the PWM%

The resistor R1 and the capacitor C1 together decide the output frequency or the the number of pillars per second of the PWM, so you can try manipulating the values of these 2 components to adjust the output frequency as desired. Hope this helps!

Thanks very much for your prompt reply. Will try your suggestion. Do you have any preferences/recommendations as to types of capacitors (e.g., ceramic, etc.) and resistors to use? I also see that there is an LM555 timer circuit available – would there be any difference from the NE555P IC that I have been using?

The 1uF can be an electrolytic, while remaining can be ceramic types.

Any IC 555 will work, as long as the the working supply voltage is above 5 V, the initial prefix will not make any difference.

I am designing a circuit for a solar PV-thermal system which will use a solid state relay to provide a pulsed current flow (PWM) from a PV array to an electric resistance heating element, in order to hold PV panel voltage at about 30v each, plus to ensure regular zero voltage at heating controls to prevent DC arcing. I have tried using 555 and 3525A integrated circuits, with control voltages derived from PV system voltages, but have experienced poor performance/stability at low duty cycles, which will be important for functionality under low solar insolation conditions. Could you suggest either a 555 or 3525 circuit which would actually work? Or any other approach to go from a 0-10 vdc or 0-30 vdc input to a PWM output? I need to keep the PWM frequency under 500 Hz based on the needs of the solid state relay. Thanks for any help.

you can try the following concept. You can eliminate all the stages which is linked after the pin3 of IC2, and use a MOSFET stage directly with pin3 for integrating the heating system.

Please I need your help Mr Swagatam, I just tested my sg3525, checked everything and found them to be alright, but, my sg3525 warms up quickly even when it’s totem pole drivers have not been used as a driver circuit to drive any mosfet.

Please I want to know if it’s normal with the IC or if I am not doing something right. If it’s normal, can you explain how to manage this thermal issue. Thanks

Victory, what safety measures did you apply at the Vcc pin of the IC? Please follow the following diagram and replicate them for your IC also.

https://www.homemade-circuits.com/wp-content/uploads/2017/03/sg3525-4.png

if inductor is not there with you, use a 100 ohm 1 watt resistor

By the way if it is warming up without a transformer/MOSFeT connected, and with 12V DC then definitely your IC is faulty or there’s some fault in your connections.

Pls Mr Swagatam can you help me understand the use of circular mils per amp. This parameter is required when calculations are being made for the wire size needed for transformer design in SMPS. It is used in many textbooks on SMPS that I have come across, but I don’t still understand it’s use as regards current carrying capacity of a conductor. Pls, I need your help. Thanks.

Victory, According to my understanding it is the cross sectional area of the wire which can handle 1 amp current comfortably. It is equal to the square of the cross sectional diameter of the wire and denoted by the formula:

A = d^2

Ok Mr. Swagatam, thanks for the reply.

I don’t have an oscilloscope to see the PWM signals, but isn’t there any table that shows the deadtime length per Rd value? I can’t find any such table from the datasheet.

Hi Victory, I don’t have any info regarding that, but you can physically check the output DC to know the level of duty cycle the resistors are able to vary. Lower dC will mean lower duty cycle and larger dead time and vice versa.

Hello sir

Am beginner, I want to construct 500w inverter using sg3525.

But I need to know, did sg3525 need regulator if it will power by 12v 75AH?

Hi, you can try the 3rd circuit from this article:

https://www.homemade-circuits.com/sg3525-pure-sinewave-inverter-circuit/

Hello Mr. Swagatam, you said that deadtime can be set be placing a resistor between pin 7 and ground, but I read, from some other article on the web, that the deadtime is also set by placing a resistor between pins 5 and 7. Don’t know which to follow as this is confusing. Please, which do I follow?

Also, is there any formula for calculating deadtime length? because I couldn’t find any such formula on the net or even from the sg3525’s datasheet.

Hello Victory, yes there was a mistake in the above article, I have corrected it now. The deadtime is fixed with a resistor between pin5 and pin7. It seems this resistor decides how fast the Ct can be discharged and how thin or wide the output pulse width can be. Thinner PWM would mean higher deadtime and vice versa. So the formula has to be related to RC time constant.

Hi,I’m designing a 5KVA pure sine inverter. I’m using this sg3525 for the pre-stage push pull converter to convert the battery level to 400v. but the feedback op amp is not so accurate. So is it possible to just ignore the IC internal opamp and connect the output of an external control circuit to the compensation pin of sg3525(pin9)?

and what is the maximum voltage that can be applied to pin 9(comp pin)?

and is it logical to share the grounds from both sides of the transformer just to have a feedback for sg3525?since the whole point of a push pull converter is the grounds isolation

Hi, SG3525 feedback system is very accurate if wired correctly, still you can use an external op amp for this. However, it is pin1 or pin10 which is normally used for feedback output control, I am notsure how pin9 can be used for this.

you can check the 3rd diagram from the following article for more info:

https://www.homemade-circuits.com/sg3525-pure-sinewave-inverter-circuit/

Thanks for answering swagatam

I studied the datasheet and tested the IC.I found out that pin 9 is connected to the output of error opamp and the input of pwm generator unit.the voltage on pin 9 varies from 0.2 to about 5.6 volts by changing the feedback and reference voltages. Therefore I applied an external voltage source on pin9 and was able to control the duty cycle accordingly.

For the SPWM part,I’m using EGS002 module, since its super easy to use

OK Alireza, in that case you can apply the external PWM to pin9, the peak voltage should not be more than the supply voltage used for the Vcc of the SG3525 IC

Hello Swag

is it possible to use the voltage correction of sg3525 as variable output for exemple 0-220vdc

by adjusting the error amp input of the ic ?

Hello yassi, yes that’s possible, but with a transformer at the output.

Hi Swag so for pin 10 a should have a pwm frequency! what frequency do i need for pwm input? 50HZ 200HZ?

sorry!

thank you!

Mathieu, If you ae trying to achieve a constant voltage output then PWM is not recommended, instead you can use a resistive divider network at pin#1, as done in the following design

Hello Swag: sorry but isn t a dc voltage on that pin?

Hello Mathieu, a DC at pin10 will permanently shut off the iC, do you wish to have a permanent shut off?

Hi Swag ive finished my voltage follower! can i fix it on the pin 10 of the SG3525 for a pwm?

thanks reguards

Hi Mathieu, if you have confirmed the response with a scope then you can try it with pin 10 of the of SG

Hi Swag for a pwm on pin 10 what maximum voltage does this pin can support? can this pin work for a better pwm?

thanks!

Hi Mathieu, it can support upto the supply level of the IC

Hi Swag for pin 10 you told me that pin 3 of the second 555 will be connected on pin 10 of the SG3525 sorry but its a PWM is that?

yes PWM is not an AC, and frequency is not relevant to pin10, because it responds to only for high or low signals. Wider PwM will make the shut down to last longer, and vice versa, thus controlling the output average voltage. You can also use the 555 PWM with the dead time control pin7 of the IC with similar results.

(connect it with pin10 of the IC)! so pin 10 is a dc voltage but on the (output voltage correction of a converter).post you insert the 555 pin 3 pwm! i dont undersand so well

thank you sorry !

Hi Swag what is the maximum frequency for pwm i can fixed on pin 10?

what is the ideal frequency for it?

thank you

Hi Mathieu, pin10 should be supplied with a constant DC for shutdown, not frequency.

Thanks for response

Before now I have interchange the mosfet position.. I noticed that any of the either mosfet I connect to pin 11 get hot quickly while the one connected to 14 is normal.. After interchanging positions it’s still same.. D ferrite Trafo I used was removed from a scrap inverter I didn’t temper on the anything.. Am getting abt 13 to 14vac from pin 11 and 14…is that normal.. Am thinking its too hi on the mosfets

Actually it’s mostly the transformer that could be causing the issue, not the IC outputs. Inter-changing the transformer taps at the MOSFET drains will provide us a clear idea regarding the truth. For checking the voltages at pin 11 and 14, you can check them by keeping the meter at DC range, this will give the average DC voltages at the relevant outputs, which must be almost equal.

Hi Swag for pin 1 and 2 of the pwm, what zener diode voltage i can put for under voltage with a 4N35? ( reference is 30VDC!) and what will be the maximum voltage when the pwm will stop?

thank you

Hi Mathieu, external zener is not required, you can get a 5.1V reference from pin16. I am not sure what you meant 30V reference.

You can either get an over volt control, or an under volt control, but not both. If you wish to control the output between two thresholds you will need an external op amp along with the IC pin1/2

hi mr.Swagatam

i just bought a 12v dc to 220v and 380v ac inverter with SG3525 as PWM controller,mosfet is 4x irf3205

its advertised as 500w and frequency about 20KHz,

https://drive.google.com/open?id=1ANyyQYAXhzQEMf-UnOj9Y-XpFk50maPV

https://drive.google.com/open?id=1-c34g2RU8SFaHDQcCx98QnLUeLlbAX39

i tried to convert my old bike ac cdi to dc with this and tried to power it from the inverter, its working but the problem is when the capacitor dump the voltage to ignition coil the mosfet from inverter is getting too hot

my question is can we pause SG3525 oscillation if capacitor at full charge, or when the pickup coil send a signal to discharge the capacitor ?

Hi John, I’ll have to see the schematic to understand the issue, because the CDI which I created using IC 555 and a cDI coil, the MOSFET did not have any issues.

here’s the schematic https://drive.google.com/open?id=11jelHZz-pTGnbx4xueMv2DDqtpkcpPrF

I think you should try connecting diodes across the transformer primary halves to minimize the back EMF to the MOSFETs, additionally reduce the gate/ground 10K to 1K…and check the response.

should i use fast diode or can i use 1N4007 instead ?

Yes, for 20kHz they should be fast recovery type.

use 1n5820

https://www.vishay.com/docs/88526/1n5820.pdf

much better now, thanks for your input 😀

following you recommendation, i replace 10K to 1K, frequency increased from 20 kHz to 42 kHz

added UF4007 on transformer primary side (its all i got ATM, will replace it later with 1n5820), mosfet is cool even without heatsink

is it possible to pause the oscillation if i connect trigger pickup from the stator to IC pin 10 ? i measure the voltage is about 5v from pickup

Glad to know about the improvements, however the frequency shouldn’t have increased?

Yes, a 5V DC at pin10 should instantly shut down the MOSFETs and the entire system.

oops, my bad… i measure the frequency from pin 4, pin 11 and 14 is 20 Khz

OK, no problem…

hi Swag, for an external clock,do i need to put rt ans ct to ground?

Hi Matheiu, I am not quite sure about it, you can try connecting them to ground through 1M resistors, and see what happens.

Sorry Swag its about pin 3 what is the max voltage necessery on this pin input?

Any voltage frequency will do that is below the Vcc of the IC

Hello Swag! what is the maximum voltage that i can insert on pin 4?

thank you

Hello Mathieu, it’s 500 kHz. pin4 will produce this frequency as an output for any external…

hello Swag! does pin4 can work with a 4.4v signal?

it says: (A clock pulse of approximately 3 V can be applied directly to the oscillator!)

thank you!

Hi mathieu, yes it can work with 4.4V

Hello swag.. I made Ferrite core inverter using sg3524 it’s working fine.. But one side of d mosfet get hot fast even without load.. And d voltage without load is 320v but Wen Connected 26watt Low energy bulb d voltage drops to 150v..please what do I need to adjust.. Rt =22k Ct =102..

Hello Adam,

Try flipping the MOSFET drain side connections and check now whether the other MOSFeTs becomes hotter or not? If the other mosfet gets hotter will prove that the problem is with the transformer winding and not the MOSFET. Also, connect rectifier diodes across the drain/collector of each mosfet, and a 1K resistor across their gate/source.

For more tips you can refer to the following article:

https://www.homemade-circuits.com/mosfet-protection-basics-explained-is/

The voltage drop may be due to low current rating of the transformer winding along with low battrey Ah rating.

Noble SWAGATAM,

I come here, Ask you for a Help, because I am trying to build a 60Hz DC / AC INVERTER Pure Wave, but I have seen several models here on your Home Site, but I did not understand why I could not do any of them, I would first like to ask you, to make an ORDER 24DB FILTER 3 OR ABOVE, WITH LM741 OR LF356 OPERATIONAL AMPLIFIER, To do the following: to take the SG3525 pwm output wave and transform it into a SQUARE WAVE FILTERING IT – I will mount a filter on each side of the two outputs of the SG3525 ……. So I will have on the filter output two sine turns made 180º to be delivered to the mosfet´s or an amplifier step …… .. WHAT TB WOULD LIKE FRIEND TO GIVE ME (step by step if possible) HOW ARE YOU ALSO DOING THE AMPLIFIER STAGE THAT WILL COME AFTER THE 24DB FILTERS ORDER …. (detail! I don’t understand much of filters, so please tell me what is best for this kind of pr what I’m trying to develop is ok)? , I will wait for your contact because I need a lot to develop this project, because where I live my parents do not have the energy very good, and I need it to use very sensitive devices ……. Hospital, pharmacy things like this: you can you help me please friend SWAGATAM?

Signed: ENDEL NEIVA – FROM AFGHANISTAN

Hello Endel, all the inverters presented in this website are well explained and tested designs. I think you may have to learn more about inverters and then surely you will be able to build one of them correctly.

MOSFETs in inverters are not supposed to work with sine waveforms, they are designed to work only with rectangular PWMs, so your idea about feeding sine waves to MOSFET gates won’t work and is not recommended. Filter can be applied at the output side of the inverter, not at the input side.

Let me know if you have anymore doubts!

Good day sir please sir I it possible to use only one of the output of sg3525 if yes how will other be connected should I ground it

Faith, No need to connect the other output to ground..you can just leave it unconnected

The issue is a power supply with an sg3525 is not generating output on pins 11 and 14. Pin 9 is connected through a diode and a resistor network to pin 1. Pin 9 is 5V and pin 1 is about 3 V DC. Pin 2 is connected to a voltage divider network to Pin 16, Pin 2 is about 3V DC. Pin 4 is connected to a timing circuit of 5% duty cycle 250KC pulses. Pin 5 and 7 are connected to a 250KC .75 to 3.7 sawtooth . Pin 6 is 3.7V DC. Pin 8 is 5.4 V DC. Pin 10 .3 V DC. Pin 12 GND. Pins 13 and 15 are 8.8 V DC. Pin 16 is 5.1 V DC. Pin 3 is open. Does anyone see something obvious as to why there no output on 11/14 ?

You can try other slightly different configurations available across other websites, if still the output does not appear for all those attempts, then your IC may be faulty.

Thank you for that lead. As an operations question, a 3525 block diagram shows 3 inputs to the PWM. The input on the PWM diagram shows pin 5 as plus and pins 9 and 8 as negative. As noted above pin 5 is ramp between about .75 VDC and 3.7 VDC, while pin 9 is about 5V and pin 8 is about 5 V. The designations on the block diagram represent pin 5 as positive input on the PWM while pins 9 and 8 being negative . This is the reverse of the measured values. Does this imply the PWM is locked out? Does this imply that could be the error? Will the PWM operate with pin 8 higher than pin 5? Will the PWM operate with pin 9 higher than pin 5? Is there a description of the requirements for the PWM to operate? Is it sufficient for pin 5 to higher than either of pins 9 or 8? Or must pin 5 be higher than both pins 8 and 9 for the PWM to operate?

sorry I am finding it difficult to interpret the opamp configurations since they are complexly interconnected with each other.

and also I am not sure regarding pin#9 which is the compensation pinout of the IC, how this pin is supposed to be configured?

You can refer to the following standard design in which it shows pin#9 attached with pin#1.

https://www.homemade-circuits.com/modified-sine-wave-inverter-circuit/

In this the PWM could be effectively adjusted simply by adjusting the voltage at pin#2

Thank you, I realize this is hard. In that circuit can you provide a description if the voltages on pin 9, pin 8, and pin 5 when the circuit is operating?

I have ordered some IC to test in a breadboard. That will help clear up a simple operation.

Thank you for you help.

sorry no, I do not have any information regarding those values, as you are about to buy new ICs so I think you will be able to learn about them easily through practical measurements.

I made simple inverter circuit using sg3525 but emitter output pin of ic have different voltage about 1 volt difference.

Is my ic faulty

please provide the voltage details and the frequency details if you have measured it….I’ll try to assess

The voltage is 12 volt frequency is 50 hz according to the calculated value (470 ohm for rd. 157k ohm for rt and. 1uf cap)

you must confirm the frequency with a frequency meter, and voltage with a voltmeter, if V is around 6V at 50Hz then the 1V difference can be ignored

So, i check output directly from transformer secondary without cap?

I'm designing a dc-dc converter using sg3525 by push-push. So I'm using 2 mosfets with a HF center-tapped transformer that i coiled myself. Then i have a bridge rect and a output capacitor at the secondary side to get my DC output.

I'm trying to power up the laptop charger using DC instead of AC. The laptop charger is assumed to be smps-based so first stage is usually rectification?

So, feeding DC or AC doesn't really make a huge diff in smps-charger since it will be processed to a lower DC volt.

But my issue is that my charger seems to on and off repeatedly. I'm thinking the mosfet issues. So I'm wondering what could be the issue or does it not work? But I've seen ppl testing this concept and working successfully.

OK got it, I think the charger is switching ON/OFF due to lack of current and your 12V power supply could be responsible for this, try with a higher current 12V supply and check the effect.

However, an easier approach would be to use a 12V to 24V boost converter and directly connect your laptop with it…the 220V SMPS charger may not be required

I suspect it's my 12V power supply as well. Im using the typical DC power supply used in the labs and i think the maximum current they can supply is only about 3A. The power supply seems to flicker from CC to CV mode as well when the charger on and off.

However, i dont have access to 12V batteries to test out the different effects or if it's really my power supply that is causing this issue due to the lack of current.

I've thought of that but using the charger to test is one of the requirements of my testing.

Thanks for your help. I'll try to verify my power supply first.

OK fine, but if the input is really 3Amp then that should be quite sufficient…??

I would suggest a single 12V to 19V converter and use it directly for charging the laptop battery, this looks technically more correct….

I'm still having issues with my output from the sg3525. If i just connect my scope to pin 11 and 14 without connecting the mosfets and transformer yet, i get almost perfect square with a reasonable capacitor on the supply. The +ve duty cycle is about 45%.

I tried changing my mosfets for pushpull and it seems to get rectangular outputs now. However, when i connect the entire circuit, including the transformer and stuff, the duty circuit shrink to 13% and the frequency seems to shoot up to a much larger value. My circuit was made to be 100khz sw frequency.

Is this normal? I think i should fix this first if this is an issue before even moving on to other stuff.

may be you can try changing the mosfets, the mosfets seem to be the culprits, alternatively you can try replacing the mosfets with TIP142 BJTs and see if that solves the issue

Hi,

Thanks for the reply. I did include the capacitor on the supply and output when I tested it. But the square wave is not simply distorted with spikes, it changes completely to a triangular wave and the duty cycle seems to be off because it became slimmer, that's ok too? Only happens when i connect it to the moafets. Output seems right though.

Also, dont mind if I ask one more qns. I'm trying to test this DC output to try and power up a smps laptop charger. In smps, first stage is bridge rect, so feeding ac and dc doesnt matter much right? Excluding some losses if using DC due to diode. I tried connecting the dc output to the live and neutral pins of my 3pin plug, leaving the earth pin unconnected. It seems to be able to charge up but the charger seems to be on and off constantly instead of charging constantly. For this testing, I'm using a dc power supply to provide 12V for my circuit, it seems to keep flicker as well from CC to CV. Is it because of the limitations of the dc supply and i should use a 12V battery instead?

Thanks.

No that's not OK, the waveform should be like rectangular wave, not triangle wave, try removing the output capacitor and check again? by the way are you using a transformer with the mosfets? because you mentioned that the output is DC? I am not able to get what exactly are you making? is it an inverter or a DC to DC converter?

Hi,

I used the Sg3525 to build a DC-DC converter running at 180V DC. I managed to get about 178.6V which is pretty close to my design so I guess should be fine. Before I connect it to my 2 mosfets in push-pull, pin 11 and 14 shows quite a perfect square waves on my oscilloscope. But when I connect it to my mosfets and transformer, the square wave seems to be distorted into a slim triangular sharp edge, but I still get the the output I need. Is there anything wrong?

Thanks.

Hi, there's nothing to worry, that usually happens due to the small spikes and other form of diturbances generated by the transformer induction switching.

You can improve it by connecting a high value capacitor across the battery terminals and also an appropriately selected high value capacitor across the trafo output winding.

Thank you sir.

I am going to read it carefully to achieve my goal.

Hello Sir.!

Hope you are good. I learn many basic knowledge for you blogs. i have question.?

how to control pulse width through sg3525. when i increase the feedback voltage at inverting terminal compared to reference voltage at non-inverting terminal i-e 5.1v, and connect the prob of oscilloscope at the output stage, so the wave form abruptly goes to zero. and when voltage at non-inverting terminal is slightly high than inverting i get maximum duty cycly i.e 49%. so suggest me how can i decrease the pulse width.?

Hello Adrees, I am glad you are learning from my blog…

the feedback should be automatic and should be connected with the mains AC, then it will not behave abruptly….

instead of a feedback you can use an external chopper circuit and integate with your inverter circuit, this will enable you to precisely adjust the PWM and also get a sine wave output for your SG3525 cirucit, you can refer to this post for more help

https://www.homemade-circuits.com/2016/08/sg3525-pure-sinewave-inverter-circuit.html