A wireless cellphone battery charger is a device that charges a compatible cellphone or mobile phone placed close to it, through high frequency wireless current transfer, without any physical contact.

In this post I have explained how to build a wireless cellphone battery charger circuit for facilitating a cordless cellphone charging without employing a conventional charger.

The Objective

Here the cellphone is required to be installed with a receiver circuit module internally and connected to the charging socket pins, for implementing the wireless charging process.Once this is done, the cellphone simply needs to be kept over the wireless charger unit for initiating the proposed wireless charging.

In one of our earlier posts I have explained a similar concept which explained the charging of a Li-ion battery through a wireless mode, here too we employ a similar technique but try to implement the same without removing the battery from the cellphone.

Also, in our previous post I will comprehensively explained the basics of wireless charging, we'll take the help of the instructions presented there and try to design the proposed wireless cellphone charger circuit.

We'll begin with the power transmitter circuit which is the base unit and is supposed to be attached with the mains supply and for radiating the power to the cellphone module.

The Transmitter (Tx) Coil Specifications:

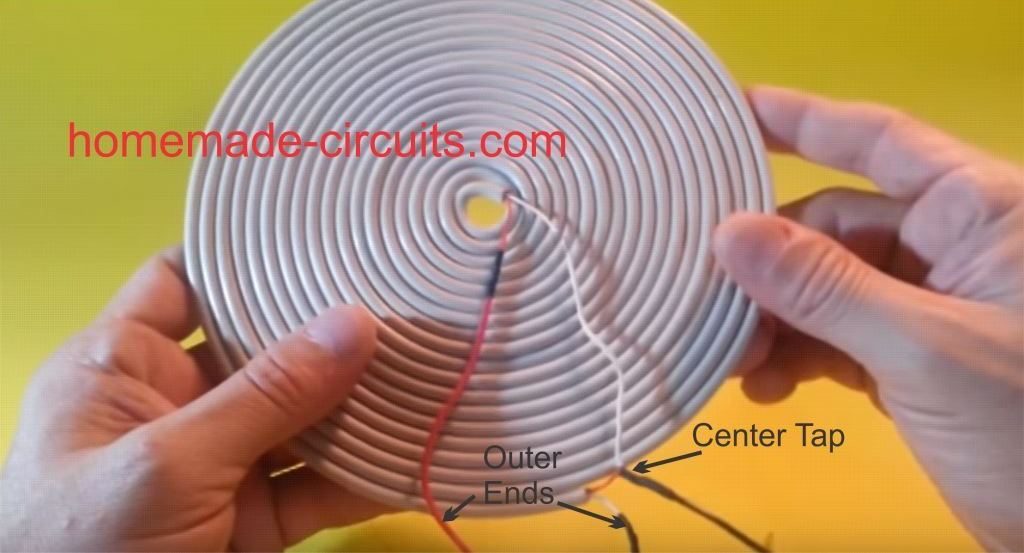

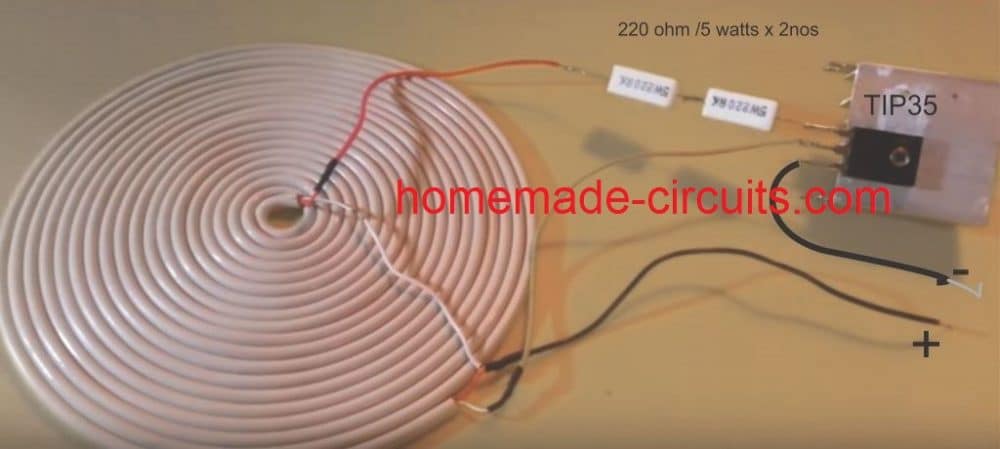

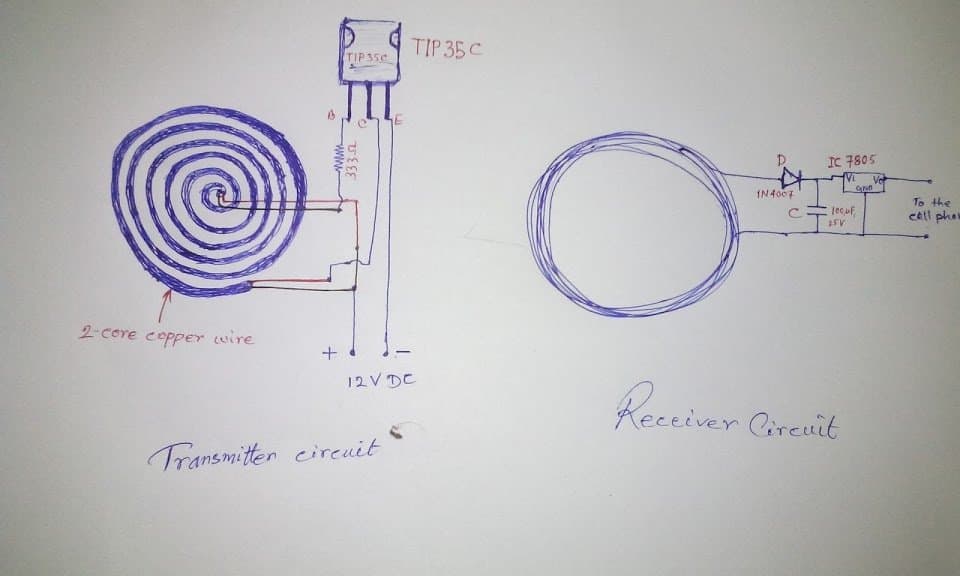

The transmitter circuit for this wireless cellphone battery charger is the crucial stage and must be built accurately, and it must be structured as per the popular Tesla's pancake coil arrangement as shown below:

Making a PCB version of the above Pancake coil.

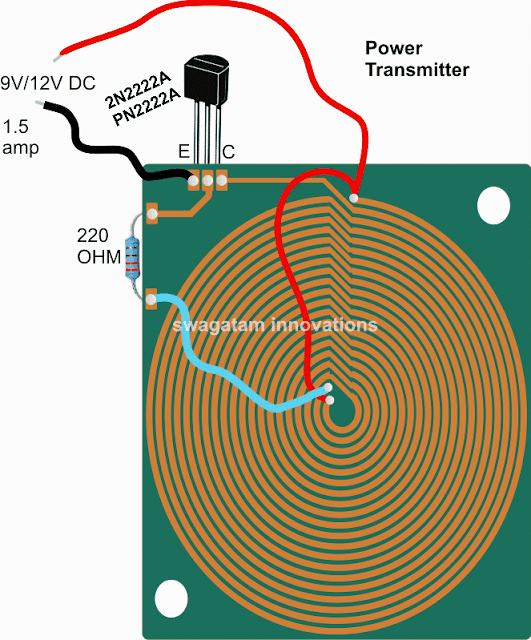

Inspired from the above theory, the smaller layout of the same coil can be etched over a PCB as shown in the following diagram, and wired as indicated:

Dimensions: 10 inches by 10 inches, bigger size might enable faster charging and better current output

The figure above shows the power emitter or radiator design, also recall the circuit diagram from our previous post, the above design utilizes exactly the same circuit layout, although here we do it through a PCB by etching the winding layout over it.

A careful observation shows that the above layout has a pair of parallel coiled copper tracks running spirally, and forming the two halves of the transmitter coil, wherein the center tap is acquired with the aid of the linked red jumper wire across the ends of the coils.

The layout allows the design to be compact and effective for the required operations.

The track layout could be in the form of a square, or oval on one side and squarish on the other in order to make the unit even sleeker.

Rest of the portion is quite straightforward and is as per our earlier diagram, where the transistor is 2N2222 included for inducing the required high frequency oscillations and propagation.

The circuit is operated from a 12V/1.5 amp source, and the number of turns (coils) may selected approximately in accordance with the supply voltage value, that is around 15 to 20 turns for each halves of the transmitter coil. Higher turns will result in lower current and boosted voltage radiations and vice versa

When switched ON, the circuit may be expected to generate a strong magnetic flux around the coiled tracked, equivalent to the input power.

Now the radiated power needs to be absorbed using an identical circuit for executing the wireless power transfer and the intended cell phone charging.

For this we need a power collector or receiver circuit for collecting the radiated power, this may be devised as explained in the following section:

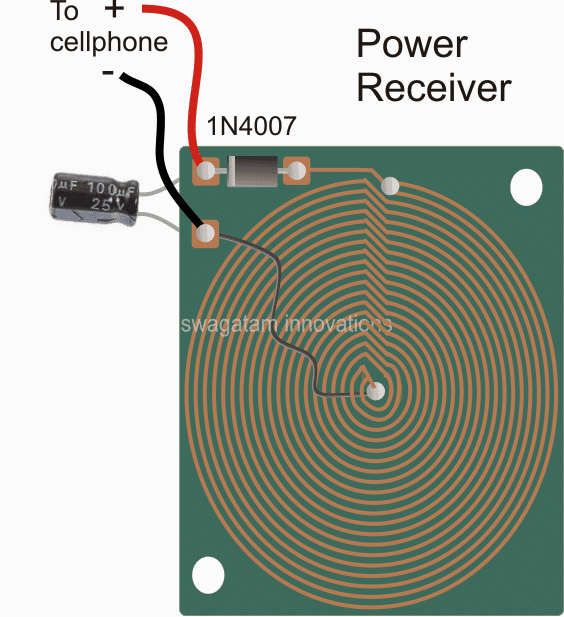

Dimension: 3 inches by 3 inches or as per the accommodation space available inside your cellphone

As may be witnessed in the above receiver design, an identical layout of the coil may seen, except that here the two concentric spirals are connected in parallel to add current in contrast to the transmitter layout which incorporated a series connection owing to the center tap restriction for the design.

The design is supposed to be small enough to fit inside a standard cellphone, just below the hind cover, and the output which is terminated through a diode may be connected either with the battery directly or across the charging socket pins (internally).

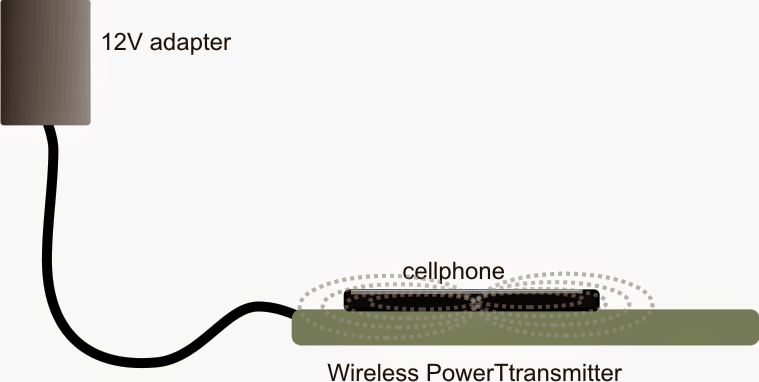

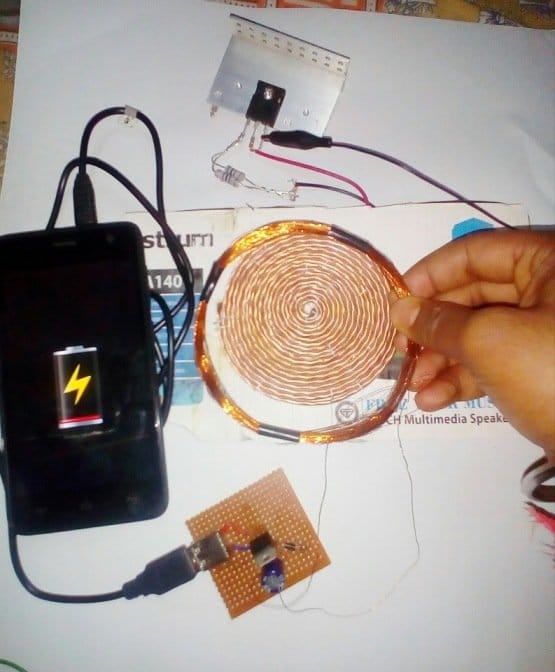

Once the above mobile battery charger circuits are built, the transmitter circuit may be connected with the indicated DC input, and the receiver module placed right over the transmitter board, at the center.

An LED with a 1k resistor could be included at the output of the receiver circuit in order to get a instant indication of the wireless power conduction process.

After the operation is confirmed, the output from the receiver may be connected to the socket of the cell phone for checking the response of the wireless charging effect.

However before this you may want to confirm the output to the cellphone from the wireless receiver module...it should be around 5 to 6V, if it's more, the black wire could be simply shifted and soldered a few coils towards the top until the right voltage is achieved.

Once all the confirmation are complete the module could be accommodated inside a cellphone and the connections done appropriately.

Finally, hopefully if everything is done correctly the assembly might allow you to keep the cellphone directly over the transmitter set up and enable the proposed wireless cellphone charging to happen successfully.

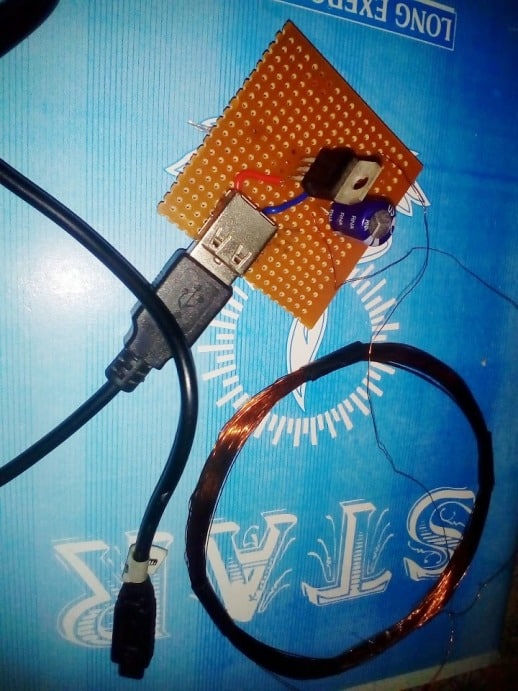

Making a Practical Prototype

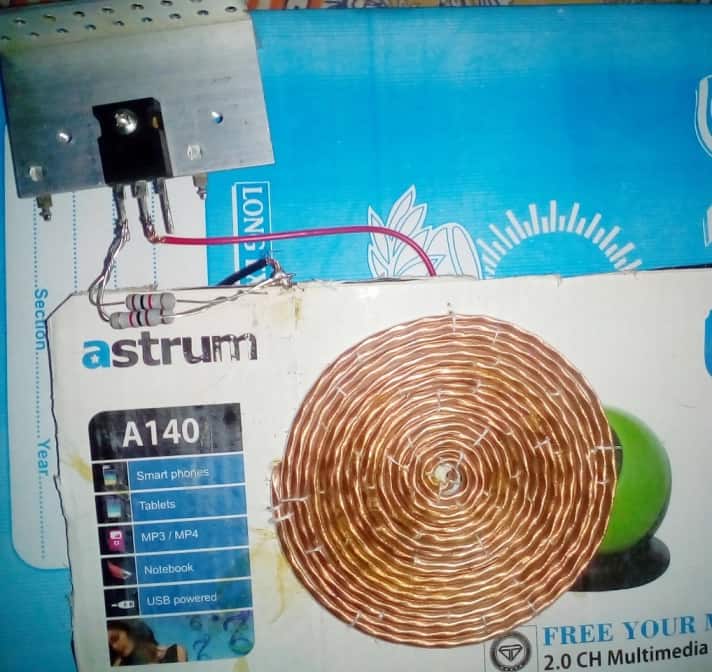

The above wireless power transfer concept was successfully tried and tested with some modifications, by Mr. Narottam Gupta who is an an avid follower of this blog.

The modified wireless cellphone charger circuit and the prototype images can be witnessed below:

Sir,

How to increase efficency of this charger?and is it works for all cell phones?

shivam, you can go through the following article for all the detail

https://www.homemade-circuits.com/2016/09/designing-induction-heater-circuit.html

yes it's for all mobiles

Sir, what type of wire did you use in your receiver?

it was 2-core flexible wire in bifilar mode.

Hi sir just to check if it can be done using normal copper wire instead of the 2 core type.

Best Regards

Normally copper wire will work but you will have to configure it in the bifilar mode, exactly as the dual core wire is done…

Thank you for answering Sir. You are a great help. Have a good day

you are welcome!

Sir, thank you for answering. i now have a clearer concept. i will tighten wind the turns later.

I am currently using TIP35C. I am using 470 ohm resistor and have 18 turns. Will that be enough for the circuit to work? Thank you so much. have a great day.

Best regards.

Thanks Allen, you will have to confirm it by practically testing the setup or by solving formulas, it cannot be judged by guessing..

Sir, I was able to light a LED using the modified circuit however, the TIP35C gets really hot. Can you share substitutes for the TIP35C that can bear the electrical flow? by the way, my aim is still to charge the phone. I hope you can give me answers and it will be much appreciated.

Best regards.

Allen, TIP35 is not the problem, in-fact TIP35 is an overkill, your circuit should work even with a TIP31 transistor.

make sure the coil turns are tightly wound without gaps within the turns, and try increasing the number of turns with respect to the center tap, and see if that cools the transistor.

sir iam using 30swg for transmitter and receiver for tx 18 turns two core flat spiral coil and for rx nearly 60 turns like wound coil is there any method to reduce the adopter heating by changing the windng turns or other

Sampath, you can use a 555 IC oscillator and tune the frequency and the inductance of the coil to generate optimal resonance, this will allow max efficiency for the circuit and minimum heat from the adapter.

you can use this software for calculating the resonance frequency

https://www.homemade-circuits.com/p/resonant-frequency-calculator.html

for a 555 IC a center tap coil cannot be used….a two wire coil will be required

sir is there any alternative without using other adopter is there any other reason for adopter heating sir give me formulas and theoretical derivation sir in pdf any link

Hello again sir, what is the size of the 2 core copper wire that you used? I'll be waiting sir. Thank you☺

Allen, from the image you can approximately judge the dimension of the coils with regards to the other materials lying around

Sir, i appreciated you noticing my question. Another question sir, in your 1N4007 rectifier diode, what is the specific voltage of that rectifier? Your answer is very much appreciated. Have a good day ☺

thank you Allen, A 1N4007 is rated to handle around 1000V and 1 amp current

Thank you for the answer, Sir ? . I like your set up?

sir im getting output at a distance of 2 inches i used 12v 1.5A adopter and tip 35c transistor and coil which is shown on the video u posted above but when i connect mobile phone its just chrgng for 2min then after adopter getting hot and stops working i think supply will be less can i use 12v 4A for tip35c transistor

yes you can try a 4 amp adapter and check the response.

Hi Allen, the leads are obviously connected with the (+)(-) terminals of the coil output (after the diode), it is not visible because it's shown as being inserted from the other side of the board.

For details please refer to the images which are posted at the end of the post, the one which is drawn with pen.

what should be the number of turns in the transmitter coil as well as the receiver coil? and what is the SWG of both the coils? Please, sir tell me as soon as possible. I making this project in college. Help me.

24 SWG can be tried initially

Sir,

is it possible to use CAT 5 wire to fabricate the coils, I have tons of it…

Vixr, if the strands are configured correctly as per the layout of the shown bifilar coil, then it will work

Hello Sir,

Thank you very much for all the useful information you spend time and knowledge to spread on your website !

I'd like to get out of the "trial and error" area, as I need to design a reliable circuit that could receive 9V at 400mA (minimum values) from a 12v power source on the emitter side. Coils diameter must be <40mm and the two coils will be distant of 1 millimeter.

I assume that there are laws and equations behind the transmitting efficiency, voltage levels, and efficient commutation frequency for the transistor, but couldn't find it yet… If you know them and don't mind sharing, it would be greatly appreciated 🙂

Best regards, Julien

Hello Julien,

The most efficient response can be detected and found only through a practical trial and error method….because formulas can have issues due to incorrect selection of the parameters, but a practical approach will always be precise.

The efficiency will hit the max when the two coils oscillate at their resonant frequency…the resonant point must lock across the coils, that's the critical thing we have too consider while optimizing the two.

Instead of the transistor/inductor "blocking" type of oscillator you can try other forms of oscillators using IC 555, IC 4060, or through half-bridge driver ICs which will allow you to investigate wider ranges….

Hello Swagatam,

Thank you again for your detailed answer. I perfectly understand that real tests are the most efficient way to get reliable results, but I would have liked to save time, by approaching the optimized config with calculations…

Thank you for pointing out other methods, I'll have a look further if I can't make it with the blocking oscillator principle…

I may come back to you soon if I find something interesting 🙂

Have a good day,

Best regards, Julien

You are welcome Julien!

sir thanks for your quick response, i have another question. What transistor can i use instead of tip35c? i want a transistor which can hold more heat. im using a 12v 2amp adapter. I had an output of 5V and 1 amp and a coil distance of almost 1 1/2 inch.

You can use TIP3055 or 2N3055 instead.

i would like to know how can i parallel my transmitter coil? i want to add more turns so instead of making another one from scratch i want to create a coil and then add it to the one im using. thank you very much. 🙂

No that will not work…you will have to use a single coil for the intended performance

Sir I made the revised one with the TIP35C and we got an ouput of 5.4 V and 1.4 amp in the receiver end and the phone is charging but the problem is the transitor is getting very hot to the point that it emits smoke. We tried heat sink and it failed. Our source is 12V 2 amp. Thank you !

Carmelita, the transistor will become hot if the inductor and the transistor does not oscillate at an efficient rate, which might lead to the consumption of excess current by the transistor.

Try increasing the number of turns of the transmitter coil or try reducing the voltage until the transistor operates at a cooler temperature

Thank you sir. I will update if it works.

Its me again sir, does the amount of input voltage affect the temperature of the transistor?

Tried 3V 2amp source transistor is still very hot

try the configuration as explained in the following article:

https://www.homemade-circuits.com/2016/02/illuminating-led-using-wireless-power.html

My 2n2222a keeps burning out, and I have to replace it every time .

What do I do about that, if I'm to reduce the power or voltage, how do I do it .

PS, my power source is usually my laptops USB port

pancake configuration is not compulsory, it just needs to be in the form of a coil….

if it's configured as shown in the diagram then it will work

Hello sir. Is it okey we use #18 wire for transmitter and #26 wire in receiver? How about the ideal number of turns for the coil? Do we need to compute?

hello domnic, there's no ideal number,because the coil dimension is strictly related to volatge frequency, and current…so all these needs to be perfectly optimized through some trial and error to get the maximum efficiency.

technically wire gauge must be thinner for the transmitter and thicker for the receiver

Sir,i tried to made it…evertime my transistor is burning out…sir hlp me to solve it out..contact me to sagarneel.bosu@gmail.com

Sagarneel, please go through all the comments, I am sure it will help you understand the issue and find a solution…or you can try with a lower supply voltage and try increasing it only upto the point where your transistor is not heating up.

I did everything right…but I am not at all getting any output at the reciever end..please help

If you did everything right, then it should have worked.

I have referred a video link in one of the above comments, please watch that video, it might help you troubleshoot your design.

Pardon me sir. With all due respect, how can this be a wireless charger if usb cable is still needed to be connected to the receiver?

Thanks btw for your informative thread. We need more people like you sir. Salute!

Good observation Mharlee, thanks! The shown experiment using USB wire is just a prototype which confirms two things: the wireless power transfer concept and the successful charging of a cell phone using this concept….the USB wire can be ultimately eliminated once the receiver circuit is somehow accommodated inside the cellphone back cover…once this is done, the cellphone will not require any form of wire and could be charged just by placing it over the transmitter unit.

Sir I'm a novice at this, I did everything exactly as I saw it except my coil doesn't have up to 15 turns, when I power it my 2n222a gets very hot and burns, is it because of the coil or is there anything else I can do about it ?

Michael, yes it could be because you reduced the number of turns…in that case you can try reducing the supply voltage to a lower value and check the response

Hi sir. I wanna make a wireless charging which is like yours, but I uses Galaxy S6 from Samsung and it has a NFC to it which also can be use for wireless charging. So did I still need a receiver module or I can directly put my phone on top of it? If you got the answer please send it to my email on letsmake0470@gmail.com

sorry, I do not have much idea about it!

How is NFC related to wireless charging??

most of the appliances in your house has a 2-core wire as the mains cord

Sir I made that transmitter from your above diagram of transmitter

But it is not working

Sir,

In transmitter circuit how can produced high frequency power ?

By using transistor, but for transistor switching needs a continuous pulse,here the transistor from where get that type of pulse ?

Please explain…

(Actually my teacher asked me that type of question but I can't explain properly.)

Narottam,

the working of the above design resembles to a "blocking oscillator" functioning, where the transistor is switching is blocked and released at a rapid rate resulting the generation of pulses. This happens due to the coil feedback tap.

https://en.wikipedia.org/wiki/Blocking_oscillator

Ok…thank you…#Sir…

Hi sir I have a new idea regarding this project . why we not use this circuit as a hand gulf . how future stoic it look .

Please make some comments on this idea

Hi Kuldeep,

sorry I did not understand your point…how can it be used with hand gloves?

Hello sir..

Can give me all components that's use for this project… And give the value

Sir, I would like to give you a lot of thanks for showing my projects design in your blog.

The pleasure is all mine, Narottam…

Good day sir Narottam. What 2 core copper wire did you use? And what awg of receiver did you use and how many turns did you apply? Sorry for the questions but I am currently needing your answer. Thank you and have a great day.

sir me Kuldeep Tripathi i make this circuit but i have a question related this circuit . When I supply 3 volt and 1000 milli amp so the reciving volt is 6 v please help me i want to charge my mobile of 1800 milli amp

Vaibhav, do you mean to say you are getting 6V at the receiver end? If it so then you can still use it for charging your cell phone by adding a 5 ohm resistor in series with the output.

Sir How much capacity of capacitor u have used in receiving coil.

Sir,

I made it but one problem,

I get sufficient voltage in receiver but current is not sufficient. So showing the mobile is charging but mainly it's not charging or charging too slowly.

So,plz tell me how can I increase the receiver end current ?

I used 12V, 1Amp transformer for power supply.

Narottam, try adding more number of coils parallel with your existing receiver coils, this will help to induce or absorb more current from the transmitter…also make sure the Tx transmitter is supplied with sufficient current from the power supply.

I am afraid 12v 1amp will not do….use a 15V 3amp or 5amp..

I would be interested to see the pics of your design with full details…it would help the many readers to understand the concept better,

Hello sir i made this circuit it is working good but I use 2N3904 and it get hot on few minute so please give name of a better Transistor .I also use BD139 but it not work

That's great Kuldeep, however BD139 should also work may be it's faulty or not connected correctly.

you can try the other alternatives as suggested in the previous comment…a TIP122 can also be tried

8050 can also be a good candidate.

Please suggest me any other transistor . please reply me soon . please give me many choice please.

you can use a BD139, D1351, D880, D313, SL100, TIP31 or any similar

Please can i use ceramic capacitor for the reciever circuit

And how many capacitor will I use for the reciever circuit

Ceramic capacitor will be fine but the value should be 100uF. You can use any value higher than 100uF

Can I use BC547 IN PLACE 2n2222

NO, you can use other higher rated BJTs than 2N2222, but nothing lower than this.

Hello sir I have many question regarding this post .Are you tested this circuit. I have not more knowledge but I think than induce current is only for AC current . Sir you use 12 volt 1.5 amps. Can I use an invertor battery of 12v/180amps .

Please clear me what is SWG Number of copper wire and number of turns .

Please reply soon .

Thanks in advances

Hello Kuldeep, please go through the comments, and you'll also find video link which you can refer for more info.

if you are new then I would recommend NOT to try this circuit because it can be very difficult for anybody who does not have a thorough practical and theoretical knowledge of electronics.

Pls sir I used 2N2012 it worked fine ,had a voltage of 5v at the receiver but wasn't able to charge my phone .why?

An sir pls can the distance be increased? How so?..thanks. Please reply soon

I am glad you could succeed with the project, the cell phone might not be charging because of low current, try increasing the input current and check the response….or you can also try decreasing the distance between the Rx and the Tx

sorry the distance range cannot be increased by much, that will strictly affect the performance of the output

Sir please how can i make mine to charge fast

To make the charger faster you may have to use higher amount input current through the transmitter

I've taken the time to design this on a 4×4 inch PCB in Eagle CAD if anyone's interested. Willing to share as long as the files are not altered in any way. DRC rules pass for production @ OSH Park.

Relic 1974 – I AM interested in the PCB pattern IF you can please send me a .png or .gif or .jpg graphic of it ?? theiceprince597@gmail.com – Thank you in advance Relic1974 – Huggs ! <3

Could the transmitting coil be made on transparent printer film (like the film used to transfer toner to PCB when making your own boards) and conductive ink? I was thinking of the cost of copper clad or having a 10×10 inch PCB made which would cost a lot. My idea is to use 2 sheets (legal paper size) of the transparent film and use conductive ink to draw the coil design on one sheet. Then insulate by placing another sheet over it. Use solar panel tabbing/wire to make connections with conductive glue or tape. This would also be a very thin design. Question is … could it handle the current? I'd probably have to draw the traces pretty thick and wide. Ideas ???

That's possible if sufficiently thick and wide tracks are created with the ink, because the track thickness and width will determine how much current it can handle and can be manipulated by the designer….or alternatively the receiver section can be simply implemented using a pancake kind wire assembly, as shown in the video, because the compactness of the receiver may be not so important.

hello sir, why its not work in my project. i was trust your tutor but not work. i make coil 18 turns in transmiter n power adapter 12v/1,5amp, in receiver i make coil 24 turns. but its not work 100% . pls help 'me.

I have checked it myself and it worked for me, see the video above for more info, if still you cannot make then sorry i can't help.

Please can i use a 5v 2amp charger in the input of the tx

You can try it, but if the response is not good then you may have to increase it to 9V or 12V.

Hello watched that video

Done editing but still there is no output in my secondary coil .

BTW i m using a old samsung mobile adapter as power source whose output is 5.13vdc.plzz help

Hello sir

Was trying the same on a pcb with 24 gauge copper wire ..

But transistor burnt …

Plzz help with solution

see this video:

https://www.youtube.com/watch?v=4UmVLfFNx7U

Back EMF occurs in between transistor switching, when the magnetic field of the coil collapses (which is what makes it self-oscillate). This back EMF can be a spike of high voltage depending on the coil design. I suspect this is what is burning out your transistor. Try placing a 1N4001 or 1N4007 diode between the collector and power supply. This blocks the back EMF current from re-entering the collector. You may also want to protect the emitter/base junction with a 1N4001 by wiring the striped side of the diode to the base and other side to the emitter. For an example, just look on google for any "Bedini SSG" circuit which protects the transistor in the same manner.

I don't think back EMF could be the problem, because it's a self oscillating circuit and not induced by an external agent, I have never seen a diode being used in self oscillating circuits for back EMF protection….may be because the coil turns are significantly less and the frequency is high.

the problem could be due to a wrong wiring, or wrongly connected coil, or a mismatch between number of turns and input voltage.

It's the same magnet kicker principle!

Hello again sir. I tried to constuct the circuit on breadboard but it is not working. I think theres a problem with the coil. is the number of coil turns on the transmitter the same also with that of the receiver. Sir please help me out. Thank you.

Hello chara,

you made the coils on breadboard?? please explain your prototype so that I can locate the fault.

you need to do exactly as shown in the above article, if you are not able to make the PCB layout coils, then replicate it with wire coils which should be exactly identical to the PCB configuration.

the receiver coil numbers is not crucial, more number of turns will more voltage and vice versa.

Thank ypu for the answer sir. i want to ask again if what type of copper wire(coil) was used?

you can use any super enameled copper wire or pvc flexible wire…

what swg wire is required to make coils?

any gauge wire do initially, it's related to current so won't affect the transfer operation in any manner.

Sir i want to know if this circuit is working i wAnt to make it for my project

Chara, I have tested it using flexible wire coils, but not with PCB yet, but I am sure it will work in this mode too, if optimized correctly.

sir i tried it by making different four coils every two coils joining required points but not placed like you showed but when i connect 6volts source transistor burnt.i connected all elements as you showed in picture.What can i do to perform surely?please help me.

Mohammad, I am not sure exactly how you might have connected the elements, but you can try correcting or troubleshooting the circuit by first using a 3V supply and by checking the response of the Rx at touching level..if it works then you could increase the voltage gradually until the transistor is felt warm…then you could increase the turns for reducing the warmth on the transistor and proceed so on..

hello sir, avid reader, first attempt at one of your many informative circuits. Just to clarify the main power source for the transmitter reads 12.5 volt 11.5 amp in description but in the picture it shows only 1.5 amp since the 11.5 might have an extra accidental one only because I've never heard of such a high amp DC power source sorry to bother and please never stop teaching, your ability to clarify electronic circuitry has been second to none a long overdue thank you is owed , sincerely Michael Shoop

Thanks Michael, It looks like a typo in the article, it should be 1 amp actually, or may be 2 amps….not more than that.

I'll correct the mistake soon.

Sir how much distance between transfer coil or receiver coil

not more than 1 inch

can i remove the capacitor in the power receiver?

then the output will be accompanied with ripples, it won’t be constant

TY sir. What is the short explanation in your wireless cellphone charger circuit?

jomar, all the explanation is already discussed in the content, you can select whichever portion suits your requirement

Sir what the copper coil used in transmitter and receiver